Beruflich Dokumente

Kultur Dokumente

C2000PE Dragon 06 14

Hochgeladen von

Angelica DragulescuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

C2000PE Dragon 06 14

Hochgeladen von

Angelica DragulescuCopyright:

Verfügbare Formate

DRAGON

Automatic Lubrication System

GB

USA

DRAGON

Motor driven gear pump

for automatic lubrication

systems

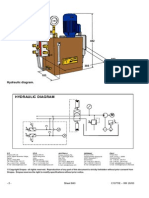

MOTOR DRIVEN PUMP for lubrication systems using

mineral oil or fluid grease NLGI 000

Due to their compactness and flexibility, the Dragon series are particularly suitable for feeding lubrication

systems in presses, machine tools, reduction units, guides, chains, and more.

The pump unit is a gear pump and there are there are two available sizes: the first has a flow rate of 350

cm/min (21.3 cu.in./min), the second has a flow rate of 500 cm/min (30.5 cu.in./min), and both operate at

1,500 rpm.

Thanks to a wide range of electric motors and reservoirs, the Dragon series can be adjusted according to

the customers requirements.

There are three basic versions available:

For lubrication systems with restrictors and for circulation systems with operating pressure < 20 bar

(290 psi) system 01

With a built-in release valve and for lubrication systems equipped with direct response feeding

devices with operating pressure < 50 bar (735 psi) system 33V

For progressive lubrication systems and for circulation systems controlled by progressive feeding

devices with operating pressure < 70 bar (1029 psi) system 26

Maximum pressure:

70 bar (1029 psi) with intermittent running and a three-phase motor; 40 bar (588 psi) with a singlephase motor; working temperature +5 C +40 C (+41 F +104 F) ; working time max 5 min.,

with 1:1 pause time ratio.

30 bar (441 psi) with continuous running both with single-phase or three-phase motor; operating

temperature + 5 C + 40 C(+41 F +104 F).

Pressure depends on lubricant, voltage and type of motor.

The system may only be used with mineral lubricating oil with a viscosity of between 15

4628 SUS) or also with NLGI 000 grease by using a level indicator sensor.

1000 cSt (77.31

Dragon pumps can be used with either an Integrated Electronic Controller (VIP Controller, with the

possibility to transmit data via infra-red), or connected to separate electronic equipment.

ORDERING INFORMATION

Part

Number

3901xxx

3902xxx

3903xxx

3904xxx

3291022

3042098

20564

20566

3085230

1639076

1639077

TECHNICAL CHARACTERISTICS

Description

Pump for single-line (low pressure)

Pump for 33V line (with discharge)

Pump for Serial 26 Progressive System

Pump for 33V line (accessories included)

ACCESSORIES

Adjustable pressure switch 20 50 bar (294 735 psi) (*)

Pressure switch nipple

Manometer, pressure scale 0 100 bar (0 1470 psi)

Manometer, pressure scale 0 16 bar (0 235.2 psi)

T fitting

VIP controller equipment (24 V AC/DC)

VIP controller equipment (110/220 V AC)

(*) Factory calibration: 30 bar (441 psi)

Reservoir Capacity

Compatible

lubricants

Storage temperature

Electrical power

Absorbed

consumption

Outlet signals

Working temperature

Web site:

http://www.dropsa.com

E-mail:

sales@dropsa.com

WK 06/14

C2000PE

3 lt (0.66 galls) in oil-proof

transparent plastic

3 lt (0.66 galls) in aluminium

with visual level indicator

6 lt (1.32 galls) in oil-proof

transparent plastic

6 lt (1.32 galls) in varnished

plate with visual level indicator

Mineral oil 15-1000 cSt

(77.31 4628 SUS)

Fluid grease NLGI 000

-20 C +65 C

(-4 F +149 F)

110 / 220 V AC 50 Hz mono

phase

220 440 V AC 50 / 60 Hz 3phase

90 W

Minimum level contact max

220 V 3 A NO / NC

+ 5 C + 60 C

(+41 F +140 F)

Working humidity

90% max relative humidity

Protection

IP 55

Pressure sound

continuous level

< 70 dB (A)

ITALY

Dropsa SpA

t.(+39) 02-250791

f.(+39) 02-25079767

U.S.A.

Dropsa Corporation

t.(+1) 586-566-1540

f.(+1) 586-566-1541

BRAZIL

Dropsa

t.(+55) 011-5631-0007

f.(+55) 011-5631-9408

AUSTRALIA

Dropsa Australia Ltd.

t.(+61) 299-386-644

f.(+61) 299-386-611

China

Dropsa Lubrication Systems

Tel: +86 (021) 67740275

Fax: +86 (021) 67740205

U.K.

Dropsa (UK) Ltd

t.(+44) 01784-431177

f.(+44) 01784-438598

GERMANY

Dropsa Gmbh

t.(+49) 0211-394-011

f.(+49) 0211-394-013

FRANCE

Dropsa France

t.(+33) 01-3993-0033

f.(+33) 01-3986-2636

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Embroidery BooksDokument19 SeitenEmbroidery BooksAngelica Dragulescu100% (1)

- Grid Connection - NIEDokument45 SeitenGrid Connection - NIESeán Mc Cann100% (1)

- Cac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)Dokument120 SeitenCac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)EngineeringNoch keine Bewertungen

- CIG14 Benchmarking 575-1Dokument119 SeitenCIG14 Benchmarking 575-1Rémi100% (1)

- Burda Primavara 2015Dokument196 SeitenBurda Primavara 2015Angelica Dragulescu94% (36)

- Pompa Pneumatica de Transvazare Si UmplereDokument2 SeitenPompa Pneumatica de Transvazare Si UmplereAngelica DragulescuNoch keine Bewertungen

- C1079PE Heavy Duty Pneumatic Pumps Series 400200Dokument2 SeitenC1079PE Heavy Duty Pneumatic Pumps Series 400200Angelica Dragulescu100% (1)

- C2201IE HYDCannonpumpDokument13 SeitenC2201IE HYDCannonpumpAngelica DragulescuNoch keine Bewertungen

- C2187PE Ultrasensor DMGDokument2 SeitenC2187PE Ultrasensor DMGAngelica DragulescuNoch keine Bewertungen

- Pompa Pneumatica LOCOPUMPDokument10 SeitenPompa Pneumatica LOCOPUMPAngelica DragulescuNoch keine Bewertungen

- C2186PE Ultrasensor DMMDokument2 SeitenC2186PE Ultrasensor DMMAngelica DragulescuNoch keine Bewertungen

- Grease Guns: K000437: TWIN-LOCK Grease Gun With High Grade Steel Silver FinishDokument3 SeitenGrease Guns: K000437: TWIN-LOCK Grease Gun With High Grade Steel Silver FinishAngelica DragulescuNoch keine Bewertungen

- C2017ie-Pompe PN Seria 233000 .Si 234000Dokument9 SeitenC2017ie-Pompe PN Seria 233000 .Si 234000Angelica DragulescuNoch keine Bewertungen

- LOCOPUMP S2 User ManualDokument9 SeitenLOCOPUMP S2 User ManualAngelica DragulescuNoch keine Bewertungen

- Pompa 3413001Dokument4 SeitenPompa 3413001Angelica DragulescuNoch keine Bewertungen

- C1020CE - 47 Pompa Pneumatica Seria 3413000Dokument1 SeiteC1020CE - 47 Pompa Pneumatica Seria 3413000Angelica DragulescuNoch keine Bewertungen

- C1079PE Heavy Duty Pneumatic Pumps Series 400200Dokument2 SeitenC1079PE Heavy Duty Pneumatic Pumps Series 400200Angelica Dragulescu100% (1)

- C2023ie 234700 01 12Dokument13 SeitenC2023ie 234700 01 12Angelica DragulescuNoch keine Bewertungen

- AutoungatoareDokument1 SeiteAutoungatoareAngelica DragulescuNoch keine Bewertungen

- Elpompa 1222000Dokument2 SeitenElpompa 1222000Angelica DragulescuNoch keine Bewertungen

- Accesorii UngereDokument2 SeitenAccesorii UngereAngelica DragulescuNoch keine Bewertungen

- Pompa Dragon 1Dokument10 SeitenPompa Dragon 1Angelica DragulescuNoch keine Bewertungen

- C2150PE DragonXDokument2 SeitenC2150PE DragonXAngelica DragulescuNoch keine Bewertungen

- Pitco 2008 Equipment Price List L15-020 Rev10Dokument23 SeitenPitco 2008 Equipment Price List L15-020 Rev10afbintanNoch keine Bewertungen

- 1212.01 15kV GRD WYE-Padmount & Overhead Distribution TransformersDokument18 Seiten1212.01 15kV GRD WYE-Padmount & Overhead Distribution TransformerskrisNoch keine Bewertungen

- IJEAS0205034Dokument6 SeitenIJEAS0205034erpublicationNoch keine Bewertungen

- Addendum Centrifugal Fans ZAvblue 00704309 en enDokument178 SeitenAddendum Centrifugal Fans ZAvblue 00704309 en enalbsalves8645Noch keine Bewertungen

- 18 Series Hydraulic Pump: Electric-PoweredDokument25 Seiten18 Series Hydraulic Pump: Electric-PoweredpamururamuNoch keine Bewertungen

- Monitoring Relay ABBDokument18 SeitenMonitoring Relay ABBAthanasios AntonopoulosNoch keine Bewertungen

- AnyScan-S PreinstallationGuide v2Dokument23 SeitenAnyScan-S PreinstallationGuide v2Abraham Antonio HidalgoNoch keine Bewertungen

- BEDO Promotional CatalogDokument164 SeitenBEDO Promotional CatalogAidi FinawanNoch keine Bewertungen

- 867a44450286ca8a632d36651bb7eea7Dokument110 Seiten867a44450286ca8a632d36651bb7eea7Claudio TurlherNoch keine Bewertungen

- Atuador IQTDokument0 SeitenAtuador IQTcristinainoueNoch keine Bewertungen

- TECHNICAL Lowara DOMO-series enDokument8 SeitenTECHNICAL Lowara DOMO-series encarlosrei2100% (1)

- Delta AC Servo Drive and Motor Installation ManualDokument357 SeitenDelta AC Servo Drive and Motor Installation Manualimamsakroni048Noch keine Bewertungen

- Agricultural Engineering Formulas GuideDokument36 SeitenAgricultural Engineering Formulas GuideJayvee LauretaNoch keine Bewertungen

- FRENIC Eco CatalogDokument32 SeitenFRENIC Eco CatalogMuhamad Ihsan SatrionoNoch keine Bewertungen

- MV - LV Design ConstructionDokument36 SeitenMV - LV Design Constructionpedro171285Noch keine Bewertungen

- Nec 210.4Dokument16 SeitenNec 210.4HassenLNoch keine Bewertungen

- Overview of Distribution SystemDokument20 SeitenOverview of Distribution SystemKelvin OoNoch keine Bewertungen

- 0v001 19301 Catalogo Liftket EnglishDokument9 Seiten0v001 19301 Catalogo Liftket Englishf157839100% (1)

- Live BookDokument748 SeitenLive BookWendell PachecoNoch keine Bewertungen

- En Delta CatalogDokument137 SeitenEn Delta Catalogkamesh213Noch keine Bewertungen

- CFW 10 Manual EnglishDokument109 SeitenCFW 10 Manual Englishpetrelli17Noch keine Bewertungen

- Electrical Notes 1Dokument48 SeitenElectrical Notes 1Shrikant KajaleNoch keine Bewertungen

- 264869621Dokument93 Seiten264869621Dwi Cahyo Wibowo S100% (1)

- MS2203 Power Clamp Meter English ManualDokument35 SeitenMS2203 Power Clamp Meter English ManualgcninstalNoch keine Bewertungen

- 10 7ut6 IntroductionDokument25 Seiten10 7ut6 IntroductionKshitij RanjanNoch keine Bewertungen

- TB 00400001 eDokument35 SeitenTB 00400001 eRicardo Lopez100% (1)