Beruflich Dokumente

Kultur Dokumente

Iopf Paper Qualification Testing 04 Final1

Hochgeladen von

chau nguyenCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Iopf Paper Qualification Testing 04 Final1

Hochgeladen von

chau nguyenCopyright:

Verfügbare Formate

Proceedings of the 3rd International Offshore Pipeline Forum

IOPF 2008

October 29-30, 2008, Houston, Texas, USA

IOPF2008-922

DEEPWATER PIPE-IN-PIPE (PIP) QUALIFICATION TESTING FOR 350F SERVICE

Paul Jukes, PhD CEng.

J P Kenny, Inc.

Houston, Texas, USA.

Francois Delille

J P Kenny, Inc.

Houston, Texas, USA.

Gary Harrison

BP America, Inc.

Houston, Texas, USA.

ABSTRACT

Development of future deep water oil reservoirs in the Gulf of

Mexico (GoM), where the flowline product temperatures are

approaching 350F (177C), water depths approaching 10,000ft

(3050m), and tie-backs in the order of 40 miles (64.4km), requires the

appropriate material selection for key pipe-in-pipe (PIP) components.

These extreme flowline temperatures, water depths and distances,

restrict the choices in PIP component materials, and present real

challenges to the design of centralizers, waterstops seals, thermal

insulation and loadshares. These challenging conditions warrant

qualification testing to be undertaken on PIP components to ensure

structural integrity and long-term thermal and structural performance.

This paper describes a qualification testing programme for the

testing of PIP components for 350F (177C) service, and includes the

testing of centralizers, waterstop seals, thermal insulation and

loadshares. The following qualification tests are proposed: (i)

Centralizers tests: Slippage tests, creep tests, abrasion tests, bolt

relaxation and aging tests are undertaken. Structural integrity testing

under installation loads and in-service conditions is undertaken to

ensure no long-term creep or degradation of the material due to

temperature. (ii) Waterstop seal tests: Load test, hydrostatic pressure

test, elevated temperature tests and material aging tests are

undertaken. The material selection for the waterstop seals are

undertaken to examine the integrity of the seal at temperature. (iii)

Thermal insulations tests: A number of tests undertaken on aerogel

materials to evaluate the effect of prolonged exposure to temperature

on thermal conductivity and mechanical integrity. Tests include

checking thermal conductivity, compressive strain recovery, long-term

exposure to high-temperature and aging effects on thermal

conductivity and mechanical integrity. (iv) Load-share tests: A

mechanical radial clamp load-share is tested to ensure performance

under sustained installation loads.

Each test planned and performed, testing rationale and results are

presented within the paper. Conclusions are drawn on the suitability

of these qualification tests for high-temperature applications. The

successful qualification testing of the components extends the

boundaries of what is possible with PIP designs and opens up the

possibility of XHPHT field developments in the GOM.

KEY WORDS

Aerogel, Annulus, Centralizer, Deep Water, Extra High-Pressure

High-Temperature (XHPHT), Flowlines, Load-share, Nanogel,

Overall Heat Transfer Coefficient (OHTC), Pipe-in-Pipe (PIP),

Pipelines, Spacers, Thermal Insulation, Waterstop.

INTRODUCTION

Pipe-in-pipe (PIP) is increasingly being used for the transportation of

hydrocarbons. Pipe-in-pipe flowline systems are frequently used in

the GoM for subsea tie-backs where there is a requirement for high

thermal performance. A PIP system consists of the inner pipe carrying

the fluid encased within a larger diameter outer pipe. Figure 1 shows

a typical PIP system configuration.

Fig. 1: A typical PipeinPipe configuration

The outer pipe seals the annulus between the two pipes and the

annulus can be filled with a wide range of thermal insulating materials

incompatible with water exposure and hydrostatic pressure. A PIP

flowline has the advantage over traditional wet insulated pipelines of

Copyright 2008 by ASME

allowing a lower overall heat-transfer coefficient (OHTC) or U value

for the system. PIP is a common method of achieving low U values of

0.176 BTU/hr.ft2.F (1.0 W/m2K) or less, and has been used on a

number of projects in both the North Sea and in the GoM. For longer

subsea tie-backs, a lower OHTC allows the production temperatures of

the internal contents to remain above the wax allowable temperature

(WAT) and hydrate formation temperature. Low OHTC facilitates

longer cool-down times during a shut-down, to prevent hydrate

conditions. A shut-down time of at least 8 to 10 hours is considered to

be the minimum requirement, which can be a large challenge for long

tie-back distances.

Today, it is not uncommon for PIP designs to be considered in

water depths up to 10,000ft (3,050 meters) and flowline temperatures

up to 350F (177C) (1).

This paper is part of significant analysis works related to extra

high-pressure and high-temperature PIP designs sponsored by a major

operator (2, 3). The study targets the Gulf of Mexico (GoM), where

subsea production wells may be drilled at water depths (WD) to

10,000 feet (3,050m), with a flowing product temperature to 350F

(177C), and system shut-in pressure of 65ksi (64.8MPa). These

temperatures can present real challenges in the design, and failure

modes have to be addressed (4). Also high axial loads can lead to

lateral buckling, and mitigation methods are necessary, such as

thermal expansion management with the use of sleepers, which is

integrated into the design philosophy (5, 6).

As a result of the relatively high temperatures, it is important to

determine the effect of these temperatures on the components that

make up the PIP system. A PIP system consists of a number of

additional components, such as centralizers, waterstop seals and

loadshares. It is important to gain an understanding of the effects of

temperature on the material strength and durability, and to ensure that

there is no long-term degradation of the structural performance. These

issues are addressed within this paper.

PIP COMPONENTS

Centralizers, waterstops, thermal insulation and loadshares

make up a PIP system. The function of each component is briefly

described, and issues associated with high temperatures are addressed.

Centralizers

Depending on the thermal insulation type, centralizers are

placed between the inner and outer pipes at regular intervals. The

function of the centralizers in a PIP system are to support the inner

pipe centralized within the outer pipe, prevent possible damage to the

PIP thermal insulation between the inner and outer pipes, and to

transfer loads between the inner and outer pipes.

The distance between the spacers will depend on the loading to

which the section of the PIP will be subjected. This spacing may be

two meters for reeled pipelines, and four to six meters for S-lay and Jlay installation methods. The presence of centralizers provides heat

loss paths and can present cold spots, reducing the overall thermal

performance of the PIP system. For high-temperature flowlines, the

temperature can reduce the structural integrity of the centralizers, and

lead to deformations that could crush the thermal insulation.

Ability to undertake the functions of the centralizers

successfully at high temperatures requires the spacer material to

tolerate high temperatures without excessive deflections and maintain

structural integrity. Compression loads on centralizers are a key

aspect in their design.

Traditional lower temperature service centralizers are made of a

nylon material that exhibits good resistance to abrasive wear. Other

materials, such as injection-molded thermoplastic polypropylene, have

a temperature limitation of about 266F (130C).

The selection of an appropriate material for high-temperature

applications is difficult. Tests during this project on a proposed

centralizer material resulted in cracks in the centralizer due to the

material being too brittle. Other materials are presently being sourced.

Waterstops

The fundamental driver for waterstops is to avoid flooding the entire

annulus of a PIP due to a single defect in the outer pipe of the system.

To avoid this unlikely result, most designers have opted to include

waterstops capable of preventing flooding of the entire annulus by

isolating the breach in the outer pipe between adjacent waterstops.

The waterstops must reliably seal the annulus against the maximum

water pressure expected on the seabed.

The spacing of the waterstops can be arbitrary, but there are

some practical considerations to provide guidance. The first constraint

is the maximum tolerable temperature loss from a flooded section or

sections. It may be acceptable to tolerate one or two flooded segments

with a predicted temperature loss during steady state production of

perhaps 5-20F. Burial of the pipeline will mitigate temperature loss

over the flooded section, and may constrain waterstop spacing to the

amount of spare pipeline repair materials available. The acceptable

temperature loss is determined by a flow assurance specialist.

Waterstop spacing is also constrained by the amount of spare

materials (pipe, insulation, centralizers, etc) available for a single

repair. Assuming an accidental flooding of one segment during

construction, there should be enough spare material available for

repairs. It may be unacceptable to lose any reasonable length of

insulation, and in that case the spacing would be solely governed by

material constraint. The above waterstop spacing constraints should

be considered and evaluated in a project during the final design work

to determine final spacing. A spacing of 3,000 feet (914 m) is a

representative value.

Waterstops must be able to sustain the temperature effects from

the inner pipe for the life of the project. There is a waterstop seal on

the market that fits between the pipes and is activated by the

tightening of screws. High-temperature waterstop seals are presently

being developed and tested. The material of the seals is a highperformance plastic and has been demonstrated to tolerance

temperatures to 350F (177C), although the long-term service life

could not be guaranteed.

Thermal Insulation

The thermal insulation placed in the annulus of the PIP system

is a key component, and allows a low OHTC if the thermal

performance (k-factor) is good. There are various types of thermal

insulation on the market, such as polyurethane, rock-wool, fiberglass,

and aerogel.

The short-term loading during installation and the long-term

loading due to startup / shut down loading are important factors to

consider when choosing thermal insulation for the life of the project.

Also, no long-term thermal degradation of the insulation can occur

during the life of the project.

It is important that the thermal insulation demonstrate

acceptable performance for high temperatures, without degradation of

the thermal or structural performance due to aging. The k-factor for

Copyright 2008 by ASME

each proposed material should be checked, and aging of the materials

at elevated temperatures, should be investigated to ensure performance

and structural integrity.

Aerogel is a nanoporous solid, originally developed during the

1930s. This insulation is suitable for PIP applications, and is classed

as a high-tech material with excellent thermal properties compared to

PU foam.

Aerogel is a high-performance thermal insulation used in a

variety of forms and conditions, and is one of the worlds best

insulating solids. It has many advantages: it is lightweight, water

repellant, highly porous, has a unique microstructure, high surface

area, translucent or IR-opacified, and is available in a number of

grades. It achieves high levels of thermal insulation due to the

entrapped air in its micropore structure. It has extremely low thermal

conductivity, 0.008-0.013 BTU/hr.ft.F (14 - 22 mW/m.K) and is

stable from -321 to 662F (-196 to 350C). It is water resistant and

can be dried if there is water ingress.

Centralizer Tests

Centralizers are used to avoid the loading that could crush the

thermal insulation. Installation loads can be particularly large during

reeling, and the centralizers are tested in compression for the

maximum loads seen during the reeling process.

Operational conditions need to be considered, and degradation

of the material due to temperature, long-term creep, and structural

integrity are all issues related to the performance of the centralizer.

These high temperatures severely restrict the material selection

available for pipe-in-pipe centralizers. Based on the temperature, a

modified Polyphenylenesulphide (PPS) material was selected for

testing, based on its characteristics of having high thermal mechanical

strength, high hardness and rigidity, high creep strength and excellent

wear characteristics.

The type of tests undertaken when testing centralizers are as

follows:

Aerogel allows the design of pipelines with overall system 'U'

values significantly less than 0.176 BTU/hr.ft2.F (1.0 W/m2K)

without compromising the overall external dimensions of the PIP

system.

Loadshares

Load shares are necessary to redistribute gravity loads between

the inner and outer pipes of an un-bonded PIP. Without load shares,

the accumulated in-situ compression load in the inner pipe can reach

30% to 50% of yield strength (4). Upon startup, the added thermal

expansion compression can result in failure (axial collapse-rupture) of

the inner pipe due to combined axial compression and internal

pressure loads. Load shares combined with pre-tensioning of the inner

pipe prior to establishing the load share coupling redistributes the PIP

gravity loads to realize a much lower in situ axial compression load in

the inner pipe.

Slippage Tests;

Abrasion Test;

Creep Tests;

Bolt Relaxation Test;

Aging Test.

The test program that J P Kenny is presently undertaking is still

ongoing, however some of the preliminary findings are presented (9).

Slippage Tests. The aim of the slippage test is to ensure the

centralizer does not slip on the flowline under installation and inservice loads. A typical test set-up for the slippage test is shown in

Figure 2.

To be effective the pre-tension must be performed before

excessive friction between the inner and outer pipes prevent the

desired distribution of the pre-tension load. Practically, this implies

that the load share spacing should be something less than the water

depth, although it might approach or equal the water depth. Detailed

FEA is performed to validate the load re-distribution achieved for a

selected spacing by load shares and pre-tensioning (7, 8).

Mechanical loadshares seem to be the preferred method of

choice. This method employs a bi-radial clamp which mechanically

locks the inner and outer pipes together. Although these clamps are

relatively expensive, it is presently the only viable method. As these

components are steel, there are no long-term degradation issues.

Finite Element Analysis (FEA) should be undertaken to avoid a global

collapse-rupture in a PIP flowline.

TESTING OF PIP COMPONENTS

J P Kenny recently undertook a series of tests for a major

operator in the Gulf of Mexico region. The objectives of the tests

were to qualify PIP components for extra high-temperature and extra

high-pressure conditions. In the following section, the different

components tested are described, and results from the tests are

presented.

The tests were undertaken for the base case of an 8 inner pipe,

12 outer pipe, with a maximum operating temperature of 350F

(177C).

Fig. 2: Centralizer slippage test setup

Both sets of centralizers tested suffered brittle failures prior to

reaching the weld bead, which meant that the test was abandoned and

the centralizer could not pass over the weld bead. Figure 3 shows a

failed centralizer from the slippage test.

Copyright 2008 by ASME

Fig. 3: A failed specimen from slippage test

Fig. 4: Field proven waterstop seal

Abrasion Tests. The abrasion test consists of passing a centralizer

over a number of weld roots. A winch is used to pull the flowline

assembly along the length of an 80 ft (24m) trough. A total of 17 runs

were intended, equating to 119 weld beads passed. However, after

five complete passes (35 welds), the centralizer suffered brittle failure.

Pressure Tests. A further requirement of the seal is to provide leakfree sealing of the large pressures that occur in the PIP annulus if the

outer pipe is breached. The purpose of this test is to verify the

pressure and sealing capacity of the waterstop seal. The seal was

enclosed in a special pressure test rig consisting of bolted end flanges.

The seal was tested to 375bar (37.5MPa), which includes a safety

factor of 1.25. A pressure based on water-depth of 10,000ft (3050m)

was applied. The seal was examined after the test, and no permanent

seal damage was observed. Below is a picture of the pressure test

apparatus and setup.

As a result of the brittle failures, for both the slippage and

abrasion tests, the other tests were abandoned, and a search is still

continuing for an appropriate material suitable to 350F (177C) with

acceptable ductility.

Conclusions following the tests are that there is no single

thermoplastic capable of meeting the stringent demands covering both

insertion case and service conditions for a centralizer, and the solution

relies on a substrate, possibly such as a pultrusion being overlaid with

a cast polyamide material. Such configurations could offer the

temperature requirement local to the inner pipeline, and the necessary

creep and abrasion resistance to cater for insertion.

Waterstop Seal Tests

Testing of the waterstop seals is necessary to ensure the seal can

undertake the hydrostatic loads in the event of flooding. Due to the

high-temperature of the inner pipe, sealing tests at temperature are

also undertaken to ensure that material degradation of the seal does

not impact the integrity of the seal. A test is performed to examine the

integrity of the seal at temperatures of 350F (177C) and a waterdepth pressure equivalent to 4500ft. Figure 4 shows a typical

arrangement of the waterstop seal and clamp arrangement to be used

in a PIP. The following tests are undertaken for the testing of PIP

waterstop seals (10):

Load Tests

Hydrostatic Pressure Test

Elevated Temperature Test

Material Aging Test

Load Tests. Assuming a breach of the outer pipe, the hydrostatic

pressure will create an axial load on the waterstop seal and clamp. A

force based on water-depth pressure of 4500ft (1372m) was used. The

test load was 90.2Te (885kN), and this included a load factor of 1.1.

The load was applied for 5 minutes, and no slippage occurred. The

test was deemed successful.

Fig. 5: Waterstop seal pressure test in progress

Elevated Temperature Test. In the event that an outer pipe breach

occurs, the water in the annulus will be heated due to the temperature

of the inner pipe. Hence it was important to verify the temperature

resistance capacity of the waterstop seal. The seal was tested at 383F

(195C) with a test factor of 1.1. The applied pressure was 375 bar

(37.5MPa), and represents 10,000ft (3050m) water depth with a test

factor of 1.25. A range of different seal materials was investigated.

Copyright 2008 by ASME

The final seal type used a hydrogenated nitrile butadiene rubber

(HNBR) lip, and a thermoplastic body, as shown in Figure 6.

Material Aging Tests. The purpose of these tests was to investigate

the integrity of the seal due to thermal aging. The method of testing is

based on the Arrhenius principle, which artificially ages the material

by applying a temperature greater than its service condition to

accelerate the deterioration. A temperature of 554F (290C) for 6

days, which is equivalent to 30 years service at 350F (177C), was

applied.

As the inner pipe will be operating at 350F (177C) continuous

service there will be a considerable temperature drop to the outer pipe

wall at seabed ambient temperature (typically 37-41F (3-5C)) in the

actual service condition. It was assumed for test purposes that the

average temperature across the whole seal is approximately 194F

(90C) during its working life. Based on this, age testing was carried

out at and based against the actual 194F (90C) average. It was

decided that this would give a more accurate conclusion regarding the

actual material service life.

Tests undertaken at 554F (290C), and using the Arrhenius

principle, showed that the material would still be serviceable at 350F

(177C) for up to 30 years. For the test at 350F (177C) the material

was unaffected over a 42 day test period.

Fig. 6: A typical HNBR / plastic seal (10)

Hydrogenated nitrile butadiene rubber (HNBR) has an

intriguing combination of properties. Like other elastomers, the

HNBR material has high tensile strength, low permanent set, very

good abrasion resistance and high elasticity. But in HNBR, these are

complemented by good stability from thermal ageing and better

properties at low temperatures compared to other heat- and oilresistant elastomers. This combination of properties makes it

particularly suitable for a high-temperature waterstop seal.

Thermal Insulation Testing

The primary objectives of these tests are to evaluate the effect of

exposure to extreme operating temperatures of 350F (177C) and

compressive stresses (due to pipe laying and lateral buckles). The

compressive stresses are applied for prolonged periods of time to

determine the insulation performance and mechanical integrity of the

aerogel material.

Two different types of material tests were

undertaken to examine this effect.

The first test evaluates the thermal conductivity of the material

after aging at the maximum operating temperature, and the second

evaluates the mechanical integrity of the material after thermal aging

under installed conditions by unidirectional compression loading. The

compression loading deformation is limited by centralizers. Worst

case deformation is likely to occur in the pipe straightener during reellay; however this is prior to aging. Subsequent in-situ deformations

are probably less, but the material will be thermally aged.

The testing of the thermal insulation has a number of specific

objectives, as follows:

Fig. 7: Pressure / temperature versus time

Temperature and pressure was held at 375 bar (37.5MPa) and

383F (195C) respectively for 24 hours. Upon inspection of the seal

following removal from the rig, it was clear that the thermoplastic

body had tolerated the pressure and temperature combination loading.

There were no leaks past the seal during the test. The sealing lip

showed no visible signs of damage or deterioration.

To evaluate the thermal insulation of the XHPHT PIP

system;

Obtain thermal conductivity at different

compression and different mean temperatures;

Ensure no long-term degradation of the thermal properties of

the aerogel insulation, such as thermal conductivity;

Mechanical testing of the material to understand how it

behaves under compression;

Ensure that compressive loads are not detrimental to the

thermal performance;

Assess thermal aging effects on structural integrity of the

aerogel.

levels

of

The following tests were successfully undertaken on aerogel

materials:

Thermal conductivity;

Compressive strain recovery after static loading - resilience;

Hydrophobic threshold;

Copyright 2008 by ASME

Long-term exposure of high-temperature on shrinkage;

Aging effect of high-temperature on thermal conductivity

and mechanical integrity.

Nanogel Aerogel Thermal Insulation

Nanogel aerogel from Cabot Corporation is a particularly

thermally efficient insulation material. It is an extremely lightweight

and ultra-high performance insulation material that can be used in PIP

systems as a substitute for typical insulation materials, such as PUF.

Nanogel aerogel is produced by drying a gel to produce a solid

material that consists of a lattice structure of the gel material with

nanometer-sized pores dispersed throughout the material. The size of

the pores (~20-40 nm) is smaller than the mean free path of air (~60100 nm) and consequently gas phase conduction is greatly reduced as

a heat transfer mechanism. The thermal conductivity ranges from

0.008-0.013 BTU/hr.ft.F (14 - 22 mW/m.K).

The important salient features of aerogel are as follows:

Pure aerogel in granular form

Worlds best insulating solid

Lightweight

Hydrophobic (water repellant)

Highly porous

Unique microstructure (fractal)

Elastically compressible (springy)

thermal conductivity and mechanical property tests were undertaken

(11) as described in the following sections.

Thermal Conductivity Tests

The first step of the test method is aging of the opacified

aerogel. The most extreme operational thermal gradient that the

aerogel will experience in the XHPHT pipe-in-pipe system is 310F

(154C), based on 350F (177C) internal contents temperature, 40F

(4C) seawater on the outside of the carrier. The samples of aerogel

were conservatively aged at 350F (177C) in glass containers, under

0% compression, in an oven for 0, 1, 2 and 4 weeks to evaluate effects

of thermal aging.

The first set of thermal conductivity measurements was

undertaken at 0% material compression. Tests were undertaken in

accordance with ASTM C518. Conductivity measurements were

made over a range of mean sample temperatures of 14F, 55F, 100F,

145F, and 176F (-10C, 13C, 38C, 63C, and 80C) with the hot

and cold plate boundary temperatures.

The maximum mean testing temperature equipment was limited

to 176F (80C) whereas the mean temperature of the XHPHT system

is 195F (91C) (assuming seawater at 40F (4C) and product at

350F (177C)). This compromise is considered to have negligible

impact on the results.

Thermal conductivity tests were also undertaken at 15% and

30% compression, to represent the expected levels of installed

compression.

The results did show a downward trend for the tests aged for

four weeks, however the trend was not statistically significant. Figure

9 and 10 show typical set of results for thermal conductivity for 0%

and 30% compression respectively. The graphs also show the effect of

age and temperature on the thermal conductivity.

Fig. 9: Thermal Conductivity (mW/mK) for

0% Compression

The results of the thermal conductivity testing demonstrated;

Fig. 8: Lattice arrangement of Nanogel Aerogel

The lattice arrangement of Nanogel aerogel is shown in Figure 8.

The use of opacifiers, such as carbon black or titanium dioxide, are

introduced into the aerogel to minimize radiation effects. A number of

A very tight standard deviation in the test results.

Thermal conductivity increases with temperature

Thermal conductivity was not affected by aging.

Effect of compression on thermal conductivity

demonstrated some improvement in k-factor due to

pore-size reduction

Copyright 2008 by ASME

Fig. 10: Thermal Conductivity (mW/mK) for

30% Compression

Fig. 12: Aging setup for mechanical integrity test samples

Mechanical Integrity Tests

Ageing tests were undertaken at 0%, 15% and 30%

compression. Aging effects were investigated in material sample

holder with different compression levels. The material sample holder

consisted of polytetrafluoroethylene (PTFE) cylinder, 1.52 inner

diameter, and two cylindrical, aluminum plates locked in place with

machine screws. By varying the quantities of aerogel material it was

possible to produce samples with different compression levels, as

shown in Figure 11.

Fig. 13: Youngs Modulus (MPa) for 0%, 15%, 30%

compression over four weeks aging

Results of mechanical testing of aerogel material showed the

following;

Youngs Modulus increased with the level of compression;

Aerogel aged up to four weeks at 350F (177C) does not

show any statistically significant aging effects on

mechanical stiffness;

Cabots Nanogel aerogel material does not thermally age

while operating continuously at temperatures up to 350F

(177C).

Fig. 11: Sample holders for mechanical integrity testing

The aging system consisted of placing the mechanical test

specimens in the cold/hot plate system. Thermocouples were used to

measure the temperature. Figure 12 shows a typical sketch of the

aging setup for mechanical integrity test samples.

The tests were successful and it can be concluded that Cabots

Nanogel aerogel is suitable as thermal insulation for XHPHT PIP

systems.

The Youngs Modulus for the test specimens was determined

using an Instron 5500R uniaxial mechanical testing machine. The

compressive testing consisted of ten, 5% strain compression cycles.

The 5% strain level represents the level of strain experienced by the

aerogel during laying and operation. Compression cycles for various

aged samples were 0, 1, 2 and 4 weeks at 0%, 15% and 30% precompression. The results are shown in Figure 13.

Mechanical Clamp Loadshare Tests

A mechanical radial clamp will be inserted in the annulus of the

PIP. The purpose of testing of a mechanical clamp loadshare is to

ensure performance as a loadshare component in the PIP system.

Load tests were successfully performed on the loadshare.

Copyright 2008 by ASME

Centralizers. The test program was not successful. The

main challenge is finding a material suitable to 350F.

Materials tested to date have failed due to lack of ductility

(brittle behavior).

Waterstop Seals. Waterstop seals were tested for structural

loading and thermal testing, and the seal passed all aspects

of the testing.

Thermal Insulation. The Nanogel aerogel material tested

does not thermally age while operating continuously at

temperatures up to 350F (177C). The material is very well

suited for PIP insulation applications in XHPHT systems.

Loadshares. The tested design is suitable for accepting a

load of 176Te.

The qualification testing of the components presented within this

paper extends the boundaries of what is possible with PIP designs and

opens up the possibility of XHPHT field developments in the GOM.

Fig. 14: A typical arrangement of a load share clamp

Load Test. The maximum expected axial load for the loadshare was

determined using finite element analysis FEA (7, 8). For a water

depth of 4500ft (1372 m), the test load was 193.6Te (1900kN) and this

included a load factor of 1.1. The load was applied using a series of

four calibrated hydraulic pistons and a calibrated hydraulic hand

pump. The full test load was applied for one hour.

ACKNOWLEDGMENTS

The author would like to thank all that have provided input into

this work, especially BP, Cabot Corporation, TEKMAR and Devol

Engineering Ltd.

REFERENCES

[1] Jukes, P and Harrison, G. An XHPHT Pipe-in-Pipe Design for

Installation By S-lay, J-lay and Reel-lay Methods, Proceedings

of IOPF2006-16, Houston, Texas, USA, October 24-25, 2006.

[2] J P Kenny Inc., Extra High-Pressure High-Temperature Pipe-InPipe Design Study, Internal Report, Rev. 0, July 2006.

[3] J P Kenny Inc., XHPHT Pipe-In-Pipe Design Study: sensitivity

for additional water depths (7,750ft and 10,000ft), Internal

Report, Rev. 0, July 2006.

[4] Harrison, G. and McCarron, W. Potential Failure Scenario for

High-Temperature, Deepwater Pipe-in-Pipe, Proceedings of

Offshore Technology Conference, OTC# 18063, May 2006.

[5] Jukes, P., A Design Philosophy for Lateral Buckling in

Deepwater, Proceeding of ASME International Petroleum

Technology Institute, IOPF# 2006-002, Oct. 2006.

[6] Jukes, P., Wang, J., Eltaher, A., and Harrison, G. A General

Flowline Thermal Expansion Design Philosophy Employing

Buckle Initiators and Piles, Proceeding of IOPF, Houston Texas,

USA, October 23-25, 2007.

[7] J P Kenny Inc., XHPHT Component Testing & Further FEA Local Loadshare FE Study, Internal Report, Rev. B, June 2007.

Figure 15 A loadshare clamp axial load versus

clamp activation chart

The results showed no slippage of the clamp. No further movement

occurred, as shown in Figure 15. No buckling of the inner pipe

occurred, and the test was successful.

CONCLUSIONS

This paper describes a qualification testing programme for the

testing of PIP components for 350F (177C) service, and includes the

testing of centralizers, waterstop seals, thermal insulation and

loadshares. Conclusions from the testing program are;

[8] Sun, J.J., Jukes, P and Eltaher, A., Finite Element Analysis of

Loadshare for the Installation of Pipe-in-Pipe Flowline by S-lay

and J-lay Methods, Oceans 07 MTS/IEEE Conference,

Vancouver, Canada, 29th Sept-4th Oct, 2007.

[9] Devol Engineering Ltd, HPHT Pipe-in-Pipe Centralizer

Evaluation, Document No. CDT 6676 CR, Feb. 2008

[10] TEKMAR, 8/12 pipe-in-pipe waterstop seal development

programme test report, 7th Issue, 6th Oct. 2008.

[11] Cabot Corporation, Nanogel Aerogel Material Qualification

Testing Report, June 2007.

Copyright 2008 by ASME

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Weld Longitudinal Tensile Results After Heat Treatment 12 Samples MMT61179Dokument3 SeitenWeld Longitudinal Tensile Results After Heat Treatment 12 Samples MMT61179chau nguyenNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- 1 Guide For WPS PQR WPQR PDFDokument6 Seiten1 Guide For WPS PQR WPQR PDFmuhammadazhar100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Acme Thread DesignstdDokument7 SeitenAcme Thread DesignstdFilipe Martinho100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Acme Thread DesignstdDokument7 SeitenAcme Thread DesignstdFilipe Martinho100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- White Star Quatro BrochureDokument3 SeitenWhite Star Quatro Brochurechau nguyenNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- API 6X Design CalculationsDokument14 SeitenAPI 6X Design Calculationschau nguyenNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- OTC 17691 Pressure Testing BallisticsDokument9 SeitenOTC 17691 Pressure Testing Ballisticschau nguyenNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Pipe Thread Types and DesignationsDokument6 SeitenPipe Thread Types and Designationsvijayn33Noch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Merging ASME and API Design Methods For Subsea Equipment Up To 25,000 PSI Working Pressure Otc23063Dokument10 SeitenMerging ASME and API Design Methods For Subsea Equipment Up To 25,000 PSI Working Pressure Otc23063chau nguyenNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- 5 HPHT API 6x - FowlerDokument13 Seiten5 HPHT API 6x - Fowlerchau nguyenNoch keine Bewertungen

- OTC 17691 Pressure Testing BallisticsDokument9 SeitenOTC 17691 Pressure Testing Ballisticschau nguyenNoch keine Bewertungen

- Yield Strength of Common Structural SteelsDokument1 SeiteYield Strength of Common Structural Steelschau nguyenNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Ankle Rehab Exercises GuideDokument4 SeitenAnkle Rehab Exercises GuideHazel Grace LancasterNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 1 - Ring Groove Dimensional ChartDokument2 Seiten1 - Ring Groove Dimensional Chartchau nguyen67% (3)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Closed Form Seabed Interaction Models For SCRDokument20 SeitenClosed Form Seabed Interaction Models For SCRchau nguyenNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Analysis of Bolting in Flanged ConnectionsDokument38 SeitenAnalysis of Bolting in Flanged ConnectionsFanel Bucur100% (2)

- Flag EffectDokument6 SeitenFlag Effectchau nguyenNoch keine Bewertungen

- GasesDokument38 SeitenGaseshNoch keine Bewertungen

- Design and Manufacturing Guideline For Aerospace CompositesDokument11 SeitenDesign and Manufacturing Guideline For Aerospace CompositesBrice_ParmentierNoch keine Bewertungen

- Assignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsDokument61 SeitenAssignment Group 13: Sodium Hydroxide Production: CH 1060 Process Engineering FundamentalsHarshil JainNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- VL2018195000813 Ast04 PDFDokument1 SeiteVL2018195000813 Ast04 PDFYubraj JhaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Why nanocrystals get softer with decreasing grain sizeDokument8 SeitenWhy nanocrystals get softer with decreasing grain sizeSaadFarooqNoch keine Bewertungen

- U-5 - 2022 - Tecnologías de Tratamientos - BDokument39 SeitenU-5 - 2022 - Tecnologías de Tratamientos - BSimón OsésNoch keine Bewertungen

- IV Report KeltronDokument10 SeitenIV Report KeltronRijy LoranceNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- WWW Visionalloys Com Stainless Steel Fasteners HTMLDokument4 SeitenWWW Visionalloys Com Stainless Steel Fasteners HTMLNikhil JainNoch keine Bewertungen

- Astm A500Dokument5 SeitenAstm A500Pierre Papeen67% (3)

- 2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions HyderabadDokument4 Seiten2 Year Chemistry Weightage: V. Kumar Dean Sri Chaitanya Educational Institutions Hyderabadnithish0% (1)

- Chapter 10 Solution Lecture Solution Ecture NotesDokument37 SeitenChapter 10 Solution Lecture Solution Ecture NotesLiew KahJiannNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- HYDRAZINEDokument19 SeitenHYDRAZINEDamla Taykoz100% (2)

- Mechanical Design of Overhead LinesDokument26 SeitenMechanical Design of Overhead LinesAsheque Iqbal100% (1)

- Gas Safety Regulations PDFDokument55 SeitenGas Safety Regulations PDFPhil MoffatNoch keine Bewertungen

- NONWOVEN - Vinay Kumar MidhaDokument11 SeitenNONWOVEN - Vinay Kumar Midhaglobal-marketin8184Noch keine Bewertungen

- Pre-AP Unit 10 Homework PacketDokument13 SeitenPre-AP Unit 10 Homework PacketTrish lamNoch keine Bewertungen

- FIB TheoryDokument38 SeitenFIB TheorySabri TraderNoch keine Bewertungen

- Closures Technical Manual 14nov2008Dokument37 SeitenClosures Technical Manual 14nov2008jjescudero100% (1)

- Assignment 2015 1Dokument1 SeiteAssignment 2015 1manishNoch keine Bewertungen

- Determination of Alcohol Content in WineDokument5 SeitenDetermination of Alcohol Content in WineAna María Vallejo TorresNoch keine Bewertungen

- Fruit Juice ClarificationDokument26 SeitenFruit Juice ClarificationRoshan JainNoch keine Bewertungen

- White Powder GoldDokument28 SeitenWhite Powder GoldSpiredon Kayyal57% (7)

- General ChemistryDokument44 SeitenGeneral ChemistrySUSANA, NIÑA FELIZ C.100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Duct Tape and Insulation Tape GuideDokument2 SeitenDuct Tape and Insulation Tape GuideDhanish AhsenNoch keine Bewertungen

- Gas and Oil - ExploitationDokument12 SeitenGas and Oil - ExploitationAnonymous puv25NQenNoch keine Bewertungen

- Coal combustion calculationsDokument3 SeitenCoal combustion calculationsShane PatulotNoch keine Bewertungen

- Vertical Drains May Not Work Alone Due To Thick Uniform Soft ClayDokument77 SeitenVertical Drains May Not Work Alone Due To Thick Uniform Soft ClayChitharanjan VishnukripalNoch keine Bewertungen

- Hazardous Waste Management TechniquesDokument12 SeitenHazardous Waste Management TechniquesSyed YousufuddinNoch keine Bewertungen

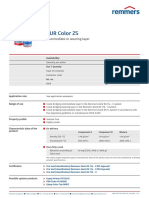

- PUR Color ZS PUR Color ZS: Intermediate or Wearing LayerDokument5 SeitenPUR Color ZS PUR Color ZS: Intermediate or Wearing LayerUrsulet SilviuNoch keine Bewertungen

- Retrofit Guidelines For Dupont Isceon 9 Series RefrigerantsDokument20 SeitenRetrofit Guidelines For Dupont Isceon 9 Series RefrigerantsaNoch keine Bewertungen