Beruflich Dokumente

Kultur Dokumente

Digital Energy Meter

Hochgeladen von

Chintan PatelCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Digital Energy Meter

Hochgeladen von

Chintan PatelCopyright:

Verfügbare Formate

Scientific Journal of Impact Factor(SJIF): 3.

134

e-ISSN(O): 2348-4470

p-ISSN(P): 2348-6406

International Journal of Advance Engineering and Research

Development

Volume 2,Issue 5, May -2015

Implementation of Smart Grid System using Digital Energy Meter

Viren Patel1 , Prof. M ithila S. Zodape 2

1

PG Student, G. H. Patel College of Engineering & Technology

Professer, G. H. Patel College of Engineering & Technology

ABSTRACT: After enactment of Electricity Act 2003 in India, a comprehensive change is occurring in Indian power

sector, and power distribution utilities are going through a reformation pro cess to cope up with the regulatory change

for reduction in Aggregated Technical and Commercial Loss, improvement in Power Quality, Reliability of Power

Supply, Improvement in Customer Satisfaction and rationalization of electricity tariff. Apart from rest ructuring and

unbundling of the power sector there is a need for introduction of `smart grid' technology to increase the operational as

well technological efficiency of the power distribution network to meet the growing energy demand of India. One subset

of smart grids is smart metering.

This research work focuses on a Smart Metering technology for distributing electricity smartly and efficiently to the

consumers. The main drawback of previously used traditional meters was that no information was provided t o the

consumers, which is accomplished with the help of Smart Meter. A Smart Meter helps consumer to know the consumption

of electricity for appliances in their respective houses. The aim of this research work is to measure and analyze power

consumption using Smart Meter.

One way to make the smart metering feasible is to have real time Digital Energy Meter. Digital Energy Meter offers high

reliability and a longer operating life. Coming to Apparent energy metering, a shift from the existing kWh system to the

kVAh system will have a major impact on loss reduction and power quality, due to the exponential relationship between

line losses and current. The current electrical tariff system is awed, unfair, and inefficient. World over, kilo -Watt-hour,

or kWh, is used as the unit of electrical energy for measurement and tariff which represents only the useful component of

Electrical Energy. However, current drawn from a utility not only delivers active energy component to the load, but also

the inefficient lossy energy components such as the Inductive and Harmonic components.

By using smart meter, meter to hub communication are possible so consumers are more aware about their energy use in

real time.

Keywords: Smart Gri d, S mart Meter, MSP430, Digital Energy Meter

I.

INTRODUCTION

Current grids have one way communication and are typically not real time system. The smart grid has two way

communicat ions and is real time system. Being a real t ime system they can interact extensively with the consumer. Smart

grid provides digital metering which is pro-active, provides real time protection. For digitally metering smart meter is

used. Energy expenditures will be lowered by increasing the possibility of reduced consumption using analyzed Smart

Meter data motivated to perform this research work. During the usage of traditional meters, there is involvement of

wastage of much energy to man power. As the electricity consumption of the household is known on monthly basis by

conventional meters, there is an overall demand for the electricity utilities to explore a new develop ment for benefit of

the consumers as well as themselves. However, the study determines to make attempts to replace electricity meter in

respective households by minimizing the drawbacks occurred by consumer. The d aily electrical usages change with

respect to habits and it is mostly dependent on behaviour of consumers. By using tradit ional meters, usages are not

flattened as consumers are not aware of the knowledge about how much consumption has been made in an hour or any

particular interval of time in a day. The uncertain perception of the consumers can also be falsified as most of the

consumers have very low knowledge regarding the Smart Meter and its installation. Lastly, to enable change and read

concerns in the market also motivated to perform this study.[2]

At current grid consumer are not aware about real time power consumption and due to that lots of energy is wasted.

And also consumer less interact with the grid. By using the smart grid consumer are aware about real time power

consumption and customers will have greater control over their electricity use when coupled with time based tariff. It

provides sufficient information to the grid in order for the grid to communicate back. Smart Meters are the first s tep

toward creating a Smart Grid through which variable tariff can be ach ieved which will save electrical energy and also the

consumer will benefit economically. Through smart meters the problem of electrical energy theft can be co mpletely

nullified.[3]

II.

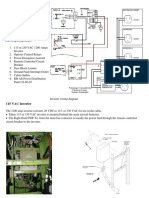

Basic Block Diagram of Digital Energ y Meter

The basic block d iagram of the embedded system is as shown in the figure 1

@IJAERD-2015, All rights Reserved

1533

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 2,Issue 5, May -2015, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

Figure 1 B asic Block Diagram of Digital Energy Meter

The power line voltage is the one which is measured. The resistive divider attenuates the line voltage to an acceptable

input voltage for the energy measurement IC. As this voltage is analog, it has to be converted into digital value for

further processing and to serve the purpose we require an Analog to Dig ital Convertor (ADC) functional block. The

outputs from ADC are fed to the controllers which are then processed to give actual outputs on the Liquid Crystal

Display (LCD). We also have the LED for pulse output with the pulse count generally being 3200 or 6 400 pulses per

kWh. Real Time Clock (RTC), EEPROM or other peripherals may be connected as per requirements. These days there

are mixed signal p rocessors that feature an inbuilt ADC unit as well as LCD driver.

Algorith ms require clear representation of both actual power consumption and actual demand. Th is necessitates high

accuracy and mult iple metrology functions, including: distortion; active, reactive, and apparent power; energy; RMS

voltage and current; and frequency. Fro m figure 2.1 one can make out th at the micro-controller unit (M CU) is at the heart

of the metering design with essential peripherals connected to it. The various functional blocks include ADC, RTC, LED,

LCD display and EEPROM. AM R can be included for added functionalities. Individual b lo cks are exp lained as follows:

MCU: Measurement accuracy is determined by resolution, precision, and dynamic range. Many general-purpose MCUs

are limited in their accuracy and dynamic range. Hence we have ASIC c h ips that are designed for a single application.

The micro-controller unit is the first and foremost requirement to build up a meter. The choice of the controller decides

the choice of peripherals to be connected to it.

ADC: Analog to digital conversion is almost used in every field for dig ital outpu t. A number of ADC ICs are availab le.

As the signal to be measured is AC and requires dig ital p rocessing before it is in the form o f final output, the ADC unit is

essential. It converts the AC voltage into dc value. Separate ICs can be used for ADC functio nal block. Successive

approximation or Sig ma delta conversion may be the method followed for ADC conversion. Once the ADC outputs a

digital value, it is fed to the MCU for further processing. ADC ICs are available with 8 -,10-,12-,14- bit sampling. A few

examples are A DC1002, AD7440BRTZ, AD7921, and MAX182BCPI.

RTC: In this world of digit ization we are working with real t ime systems. RTC stands for real time clock. RTC ICs

operate as the clock in various devices. This clock function operates even when the p ower is turned off. In portable

devices, it is important to reduce the current consumption of the real -time clock IC to extend the battery life. For eg. SII's

real-t ime clock ICs have a time-keeping current consumption of 0.25 A and a time-keeping operating voltage of 1.1 V,

which enables a much longer battery life. It also offers various total-system solutions, such as high-accuracy clock

correction, constant output of 32 kHz, wakeup signals, expanded alarms and 24-bit binary up-counters. SII's real-t ime

clock ICs are world's smallest due to the employment of small W LP and SNT packages, enabling users to streamline

their devices.

EEPROM: It means Electrical Erasable Programmable Read On ly Memory. An EEPROM can be both erased and

programmed with electrical pulses fro m a programmer kit, burner or the equip ment itself. Since it can be both electrically

written into and electrically erased, the EEPROM ic can be quickly programmed and erased in circuit for reprogramming

without taking them out from the main board. EEPROM is also called a non-volatile memo ry because when the power is

switched off, the stored data (informat ion) in the EEPROM ic will not be erased or corrupt and the data is still intact.

Examples of EEPROM ICs are 24C128 (16k), PCF8594 (512-byte).[7]

LCD Dri ver: The display module co mprises of LCD driver and LCD d isplay. This driver drives various segments of

LCD. A number of LCD drivers are available that are compatible with different MCUs. For eg. PCF8676D is a universal

LCD driver by NXP, wh ich can drive upto 160 segments of LCD. These days some MCUs have in built LCD driver.

Various packages are also available in o rder to choose the one most suitable to your design.

LCD: LCD stands for Liquid Crystal Display. It is a thin, at electronic v isual disp lay that uses light modulating

properties of liquid crystals. They are used in a wide range of applications. They are compact, light weight, portable and

more reliable. Now a days dot matrix LCDs are available that uses 2-dimensional array of dots to represent characters.

@IJAERD-2015, All rights Reserved

1534

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 2,Issue 5, May -2015, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

LCD needs to be interfaced with the controller for being used. LCD driver drives the LCD.

AMR: The AMR system starts at the meter. AMR automates the process of measurement through digital communicat ion

techniques. Critical benefits from AMR include ability to detect tamper events and outage occurrences, remotely connect

or disconnect power supply through meter; timely data which g ives accurate load information for supply scheduling,

switching operations and planning. AMR net- work architecture consists of GSM based communication where we have

single stage communication between meter and central station through GSM Modem or Hybrid Co mmunicat ion where

we have two stages of communication. The outcome is smart automated process instead of manual work and accurate

informat ion fro m the network load to optimize maintenance and investments.

III.

RES ULTS AND DISCUSS ION

The AC voltage is brought down from 230V to 0.32Vrms through a resistor divider and fed to the controller for further

processing as discussed in the analog section. The voltage signal of value 0.32Vrms was externally provided through a

small circuitry direct ly to the port pins. The setup is shown in figure 2. Results obtained are tabulated in table 1 where P

represents active power and S apparent energy.

V(volts)

200.25

200.52

200.24

200.51

200.24

Table 1 Readings

I(A mp)

2.94

2.94

2.94

2.94

2.94

of the TI-meter

Freq(Hz)

49.87

49.67

49.53

49.98

49.79

P(Watts)

592

582

594

589

586

S(VAh)

5

11

17

23

29

Cal. VAh

5.88

11.76

17.64

23.52

29.40

There is a time lapse of 35 seconds every time the kVAh reading appears. It is well observed that the reading increases

by a constant difference of 6VAh. Hence, in 3600 seconds we will obtain 617.4VA h i.e. 0.617kVAh. Taking the first

reading,

Figure 2 Setup to provi de 0.36Vrms externally

Apparent power calculated as the product of Vrms and Irms as follows:

S = Vrms x Irms

S = 200.21 x 2.92 = 588.735 VA

Therefore for one hour, 588.735 VA x 1 hour = 0.588 kVAh.

As per the readings, we have 0.617 kVAh. Hence the theoretical and practical values match. The calcu lated v alues are

tabulated in table 1

Current consumptions: The various operating modes of the chip are software co nfigurable. In an infinite loop the

controller is made to wait in low power mode. Different low power modes are configured after which the measurement of

current consumed by the metering board is performed. The current consumption in various operating mode s of the

controller is noted in table 2.

Where, V is voltage in volts, I is current in microamperes and P is the power consumption in mill watts. Active mode,

Low power mode 0 and low power mode 4 are the various operating modes of the controller.

Op. mode

V(volts)

Active

3.3

LPM0

3.3

LPM4

3.3

Table 2 power consumption of the TI-meter

@IJAERD-2015, All rights Reserved

I(A)

4400

12.5

6.5

P=V* I(mW )

14.2

0.0418

0.0214

1535

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 2,Issue 5, May -2015, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

In electro mechanical meters the power consumption of the metering circu it was one Watt. Now it has been brought down

upto 0.014 Watts with the help of efficiently working ASICs. Power savings of 98.5% are achieved. This special feature

of low power modes makes them ideally suitable for energy metering.

Energy-meter outputs: Once the metering code is loaded into the ash, the code begins execution and shows results.

Various display parameters like Vo ltage, current, frequency, active power and apparent energy are shown in figures 3, 4,

5 and 6 respectively.

Figure 3 Vol tage reading

Figure 4 Current Readi ng

Figure 5 kW reading

Figure 6 kVAh readi ng

@IJAERD-2015, All rights Reserved

1536

International Journal of Advance Engineer ing and Research Development (IJAERD)

Volume 2,Issue 5, May -2015, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

IV.

CONCLUS ION

Fro m the analysis we can say that MSP430FE427A is ideal choices for build ing up an efficient energy meter

and a smart meter.

MSP430 is best suitable as it requires lo w supply voltage range, ultra lo w power consumption, anti-tempering

characteristics and high performance fo r precision measurement for the design of the digital smart meter.

In active operating modes the current consumption is around 4400A whereas the current consumption for

Sleep modes is around 0.1A for MSP430. Thus significant power savings up to 98.5% are achieved.

It is concluded that MSP430FE427 provide a single chip solution for efficient energy metering. They have

powerful analog front end with mu ltip le converters and enhanced peripherals for g reate r accuracy. So, they

provide accurate measurements. They are compact in design and easy to install. They are highly reliable over

conventional meters as they employ efficient real t ime modules. Tamper detection functionalities are also

inherited in it reducing the chances of theft.

The tariff: Significant power savings can be achieved with kVAh tariffs imp lemented. Apparent energy based

tariff is the only single parameter based tariff that is fair and incorporates an embedded power factor based

discount mechanism. By having a singular definition of apparent energy and simple d igital signal processing

based metering technologies we can effectively trigger an electrical revolution where the market will see rapid

sales of efficient electrical appliances. It is a Win -Win solution where the consumers can avail tariff discounts

by becoming more efficient while the electric utilit ies can increase its revenue considerably both through loss

reduction and through the collection of penal charges fro m the defaulting co nsumers

ACKNOWLEDGEMENT

I would also like to exp ress my deepest gratitude to my Dr. Vithal N. Kamat and his co mpany of Baroda Electrical Meter

for providing me support throughout work and always boosting up my spirit.

REFERENCES

[1] Kamat V.N. Dr. On the Implementation of an Appropriate Tariff System for better Energy Management in Rural and

Urban Areas , 1997.

[2] Fawzi Al-Naima and Bahaa Jalil Bu ild ing a prototype

prepaid electricity metering system based on RFID in

International Journal of Electrical Engineering,ISSN:2277-7040, volume 1, Issue 1

[3] Anmar Arif, Muhannad AI-Hussain, Nawaf AI-Mutairi, Essam AI-A mmar,Yasin Khan and Nazar Malik

Experimental Study and Design of Smart Energy Meter for the Smart Grid in IEEE-2013

[4] Potuganti Prudhvi, Dhruv Bhalodi, Manikant Manohar, Vamshi Padidela, Sudarshan Adapa A Smart Energy Meter

Architecture in Indian Context in IEEE-2012

[5] Nabil Mohammad, Ano madarshi Barua and Muhammad Abdullah Arafat, A Smart Prepaid Energy Metering System

to Control Electricity Theft 2013 International Conference on Po wer, Energy and Control

[6] B.Rajesh ku mar, G.kiruthika,RFID Based smart grid with Power Factor Maintenance in Load Side international

journal,vol.2,special issue 1,March 2014

@IJAERD-2015, All rights Reserved

1537

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Transmissionsystem 130209015254 Phpapp01Dokument23 SeitenTransmissionsystem 130209015254 Phpapp01Ahsan SattarNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Power System BasicsDokument58 SeitenPower System BasicsArun ChandNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 2150908Dokument16 Seiten2150908Chintan PatelNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- G H Patel College of Engineering & Technology: Electrical Power System-1 (2150908)Dokument21 SeitenG H Patel College of Engineering & Technology: Electrical Power System-1 (2150908)Chintan PatelNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 2150908Dokument1 Seite2150908Chintan PatelNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Gujarat Technological UniversityDokument1 SeiteGujarat Technological UniversityChintan PatelNoch keine Bewertungen

- EEE - 13-14 (Compatibility Mode)Dokument11 SeitenEEE - 13-14 (Compatibility Mode)Chintan PatelNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- EEE 11 12 (Compatibility Mode)Dokument12 SeitenEEE 11 12 (Compatibility Mode)Chintan PatelNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- EEE - 13-14 (Compatibility Mode)Dokument11 SeitenEEE - 13-14 (Compatibility Mode)Chintan PatelNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Tutorial On Fuzzy Logic Applications in Power SystemsDokument87 SeitenTutorial On Fuzzy Logic Applications in Power Systemseomr20Noch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Electrical India April 2014 SelectionDokument12 SeitenElectrical India April 2014 SelectionChintan PatelNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- EEE - 13-14 (Compatibility Mode)Dokument11 SeitenEEE - 13-14 (Compatibility Mode)Chintan PatelNoch keine Bewertungen

- 301075Dokument5 Seiten301075Chintan PatelNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Ieee PaperDokument5 SeitenIeee PaperSai Pavan Kumar NandigamNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- FC TCRDokument10 SeitenFC TCRChintan PatelNoch keine Bewertungen

- EEE 037 - Final PaperDokument5 SeitenEEE 037 - Final PaperChintan PatelNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Energy Storage SystemDokument18 SeitenEnergy Storage SystemChintan PatelNoch keine Bewertungen

- D StatcomDokument4 SeitenD StatcomChintan PatelNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Important Formula's From EfficiencyDokument2 SeitenImportant Formula's From EfficiencyChintan PatelNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Lab Manual 180906 APS-IIDokument30 SeitenLab Manual 180906 APS-IIChintan PatelNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Ch-5 Preventive, Emergency & Restorative Control PDFDokument35 SeitenCh-5 Preventive, Emergency & Restorative Control PDFChintan PatelNoch keine Bewertungen

- Norton Rohde LankfordDokument2 SeitenNorton Rohde LankfordJ PelrickNoch keine Bewertungen

- Fortiap AccessoriesDokument8 SeitenFortiap AccessoriesIvan KasparekNoch keine Bewertungen

- ICEpower125ASX2 DatasheetDokument29 SeitenICEpower125ASX2 DatasheetJose Benavides100% (1)

- CE Amplifier With Emitter Resistor - From Microelectronics Circuit Analysis and Design (Neamen)Dokument4 SeitenCE Amplifier With Emitter Resistor - From Microelectronics Circuit Analysis and Design (Neamen)Carlos GamioNoch keine Bewertungen

- LITHIUM POLYMER BATTERYCHARGER BY MICROCONTROLLERFROM 50Hz 220V AC SUPPLYDokument31 SeitenLITHIUM POLYMER BATTERYCHARGER BY MICROCONTROLLERFROM 50Hz 220V AC SUPPLYOzgur M. DumanNoch keine Bewertungen

- HEA Igniter CatalogueDokument4 SeitenHEA Igniter Cataloguemohan babuNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- PDZ B Q - SerDokument11 SeitenPDZ B Q - SerntchtdNoch keine Bewertungen

- Netsure Acu+ (Advanced Control Unit Plus) : User ManualDokument160 SeitenNetsure Acu+ (Advanced Control Unit Plus) : User ManualPermana AgungNoch keine Bewertungen

- User Manual ERER 3Dokument16 SeitenUser Manual ERER 3aleksandrNoch keine Bewertungen

- Designing A 100kHz 32 Watt Push-Pull ConverterDokument13 SeitenDesigning A 100kHz 32 Watt Push-Pull Converterjayduy298136100% (1)

- 8BT2 - Installation and Operating InstructionsDokument96 Seiten8BT2 - Installation and Operating Instructionsalanetn100% (1)

- Compressor EMI60HER (LBP) - DatasheetDokument5 SeitenCompressor EMI60HER (LBP) - DatasheetSamuel OsmagNoch keine Bewertungen

- M800Dokument6 SeitenM800receh ceritaNoch keine Bewertungen

- MSE Mono 60 - v3 (270-280)Dokument2 SeitenMSE Mono 60 - v3 (270-280)amitNoch keine Bewertungen

- F70MC光纤陀螺仪 英文 改Dokument4 SeitenF70MC光纤陀螺仪 英文 改Liu AllieNoch keine Bewertungen

- LEARJET 45 AC Electrical SystemDokument4 SeitenLEARJET 45 AC Electrical SystemRAFAEL MANZANILLANoch keine Bewertungen

- Electrical Engineering 2022-2023Dokument2 SeitenElectrical Engineering 2022-2023Frank David Castellanos HermoNoch keine Bewertungen

- Remplace NC - PCBDokument7 SeitenRemplace NC - PCBAntonio de la TorreNoch keine Bewertungen

- 7145 7222 7228 7235SM PDFDokument448 Seiten7145 7222 7228 7235SM PDFevpsasaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- EXPERIMENT NO 3 (Comparator)Dokument2 SeitenEXPERIMENT NO 3 (Comparator)Jaideep Singh100% (2)

- Fisika ListrikDokument5 SeitenFisika ListrikYopi RachmanaNoch keine Bewertungen

- What'S New Inc37.113 - 2015, Ieee Guide For Protective Relay Applications To Transmission LinesDokument36 SeitenWhat'S New Inc37.113 - 2015, Ieee Guide For Protective Relay Applications To Transmission LinesaryanNoch keine Bewertungen

- VIQUA VH410 UV System Spec SheetDokument2 SeitenVIQUA VH410 UV System Spec SheetJonathan ManullangNoch keine Bewertungen

- User Manual: ACT2000 All-Electric ActuatorDokument64 SeitenUser Manual: ACT2000 All-Electric ActuatorMilo TigNoch keine Bewertungen

- Circuit Theory Notes PDFDokument147 SeitenCircuit Theory Notes PDFSaNdeepNoch keine Bewertungen

- Be1-Flex (Uub)Dokument2 SeitenBe1-Flex (Uub)Eliyanto E BudiartoNoch keine Bewertungen

- Job Card Cable Pulling PDFDokument6 SeitenJob Card Cable Pulling PDFHERWIN SEPTIYANNoch keine Bewertungen

- PEGA Manual V1.4 202006 ENDokument228 SeitenPEGA Manual V1.4 202006 ENYohanes TriatmojoNoch keine Bewertungen

- K3478N HMSDokument9 SeitenK3478N HMSOscar BarronNoch keine Bewertungen

- APT3200 Manual PDFDokument46 SeitenAPT3200 Manual PDFMehmetNoch keine Bewertungen