Beruflich Dokumente

Kultur Dokumente

Fast Response Liquid Flow Controller

Hochgeladen von

Matheus RibeiroCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fast Response Liquid Flow Controller

Hochgeladen von

Matheus RibeiroCopyright:

Verfügbare Formate

Fast Response Liquid Flow Controller

< 1 second Response Time

Piezoelectric Control Valve

Compact Size

1% of Reading Accuracy

Metal Seal Construction

1/8" Face Seal or Compression Fitting

The Porter D2000i Series Liquid Mass Flow Controller is designed to address the

need for fast, precise control of liquid precursors in semiconductor manufacturing

processes, as well as various applications in the biotechnology, pharmaceutical,

chemical, petrochemical and surface treatment industries. Closed-loop digital

control circuitry, combined with the integral proportional piezoelectric-actuated

control valve, offer response times of less than one second and stable control at low

flows. Clean room assembly and all metal seal construction ensure high purity and

leak integrity. A unique laminar bypass and sensor assembly provide accurate

measurement with only a 5C rise in fluid temperature. The compact package size of

the D2000i Series simplifies system integration. A D2000i Series Liquid Mass

Flowmeter is available for applications requiring flow monitoring only.

Specifications

Response Time: <1 second to within 5% of

rate (up to 6 stored valve jump voltages)

Accuracy and Linearity: 1% of reading

Repeatability: <0.2% of rate at any

constant temperature within

operating temperature range

Rangeability (Control Range): 20:1

(5%-100% full scale) (accuracy & control)

Ambient and Operating Temperature

Range: -10 to 40C (+14 to 104F)

Maximum Allowable Operating Pressure:

125 psig

Temperature Coefficient: < 0.1%/C

Setpoint Input/Flow Signal Output: 0-5 Vdc

( 2k ohm minimum load resistance for

flow output signal)

Power Supply Requirements:

(Current Consumption < 200 mAdc): +15

(10%) Vdc

Flow Capacity:

Following are the available flow

ranges based on isopropyl

alcohol (IPA). To determine the

flow range for process fluids

other than IPA, multiply the IPA

flow range by the appropriate

correction factor.

Leak Integrity: 1 x 10-9 atm. cc/sec.He

Warm-up Time: 20 minutes

Materials of Construction(wetted surfaces):

Body 316L stainless steel

Sensor Assembly 316L

stainless steel

Valve Components 316L

stainless steel

O-rings 316L stainless steel

Control Valve: Normally open

piezoelectric-actuated

External Electrical Connector:

Nine (9)-pin D-connector

Process Connections: 1/8 male metal gasket

face seal or 1/8 compression fitting

Internal Volume: < 1 ml

Mounting Orientation: Horizontal (5)

Weight: <1.5 lbs.

IPA Flow Ranges

(in ml/min):

.007 - 0.14

.020 - 0.40

.050 - 1.00

.175 - 3.50

.375 - 7.50

CupraSelect Schumacher

.650 - 13.00

Correction Factors for

Process Fluids other than IPA:

Liquid

Correction Factor

CupraSelect

Hexane

Octane

OMCTS

TDEAT

TEOS

TMB

TMP

Water

1.164

1.492

1.532

1.927

1.258

1.583

1.156

1.413

0.492

Contact Porter to size fluids not listed or when operating parameters are questionable

D2000i Series

Ordering Information

Model Number and Description

Mass Flow Controller

Example: D 2 0 0 0 i C A A 3 E A

Basic Model

D2000iC (Flow Controller)

D2000iM (Flowmeter)

2.60

Model Revision

A - Production Release

Input/Output Signal

A - 0-5 Vdc/0-5 Vdc

Detail A

Pinout

5.20

1/8" Male

Metal Gasket

Face Seal

1.13

Fitting Size & Type

2 1/8" Compression Fitting

3 1/8" Male Metal

Gasket Face Seal

Flow Designatorml/min Isopropyl Alcohol

A - 0.14

B - 0.40

C - 1.00

D - 3.50

E - 7.50

G - 13.0

Assembly/Test Procedures

A - Factory Standard

1.06

TYP.

4.80

1/8 " Compression

Fitting

PIN

NO.

FUNCTION

1

2

3

4

5

Transmit RS232

Flow Signal

Setpoint

Signal Common

Valve Voltage

Monitor

Receive RS232

Power In

Power Common

Cable Shield

6

7

8

9

1.22

TYP.

Example:

Model D 2 0 0 0 i C A A 3 E A

D2000iC = Model D2000i Flow

Controller

A = Production Release

A = 0-5 Vdc/0-5 Vdc

3 = 1/8" Male Face Seal

E = 7.50 ml/min Isopropyl

Alcohol Flow Designator

A = Factory Standard

Assembly/Test

Procedures

To order, specify:

5.13

Model Number

Fitting Type

.24

Flow Capacity

1.18

.700

Liquid Type - Include: Density, Heat

Capacity, Thermal Conductivity,

Viscosity, and Boiling Point

Operating Temperature

Mounting Holes

M4 x 0.7 Threads

.17 Deep

2 Plcs.

.74

.750

Upstream Pressure

Downstream Pressure (not required

for flowmeters)

Dimensions shown in inches

Specifications subject to change

Additional Accessories Required

Parker Hannifin Corporation

Porter Instrument Division

245 Township Line Road

P.O. Box 907

Hatfield, PA 19440-0907 USA

Phone (215)723-4000

Fax (215)723-2199

www.porterinstrument.com

FM-998 Rev. D 2/06

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Basic Set of Devices Found in PCDokument25 SeitenBasic Set of Devices Found in PCJelyn OkekeNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Desmontaje Mando Final D155AX-6Dokument3 SeitenDesmontaje Mando Final D155AX-6claudioNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Altec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFDokument31 SeitenAltec - Loudspeaker Enclosure - Their Design and Use (Circa 1975) PDFRaju100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Hydraulic Rod EndsDokument10 SeitenHydraulic Rod EndsRolffoTelloNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- BREEAM Application GuideDokument2 SeitenBREEAM Application GuidekocmustNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- MSE6-E2M 2014-04 8037121g1Dokument136 SeitenMSE6-E2M 2014-04 8037121g1SAABNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Panasonic GH3 Service ManualDokument129 SeitenPanasonic GH3 Service Manualdeejjjaaaa100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Catalogue PROAUDIO With Pricelist 13-07-2015Dokument104 SeitenCatalogue PROAUDIO With Pricelist 13-07-2015AntonioPalloneNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- HovalDokument46 SeitenHovalCristina OisteNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- 433.92MHz FM ReceiverDokument8 Seiten433.92MHz FM ReceiverraduseicaNoch keine Bewertungen

- FBS Ii enDokument10 SeitenFBS Ii enunsalNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

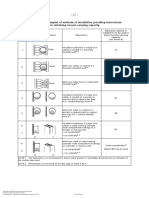

- Table A.52.3 - Examples of Methods of Installation Providing Instructions For Obtaining Current-Carrying CapacityDokument7 SeitenTable A.52.3 - Examples of Methods of Installation Providing Instructions For Obtaining Current-Carrying Capacityvasu1984Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Service Manual: Microwave OvenDokument38 SeitenService Manual: Microwave OvenpabloNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Dimage Dimage Scan Multi ProDokument129 SeitenDimage Dimage Scan Multi ProdoomanNoch keine Bewertungen

- YA50 Product Datasheet 1Dokument3 SeitenYA50 Product Datasheet 1wanto sitinjakNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 60x60 Led PanelDokument3 Seiten60x60 Led PanelKarthikeyan .NNoch keine Bewertungen

- Weigh BridgeDokument10 SeitenWeigh BridgeRajnish MishraNoch keine Bewertungen

- VSI 80 Shriniwas Stone CrusherDokument2 SeitenVSI 80 Shriniwas Stone CrusherRitesh BomdyalNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Practicum Report On Switch Gear EquipmentDokument72 SeitenPracticum Report On Switch Gear EquipmentRashedul Islam100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Chap10 CapacitorsDokument22 SeitenChap10 Capacitorsbree789Noch keine Bewertungen

- Consult-Ii Repair Procedures: This Bulletin Applies To The CONSULT-II TesterDokument8 SeitenConsult-Ii Repair Procedures: This Bulletin Applies To The CONSULT-II TesterJose M. Cerna AbarcaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Catalog: Performance and Durability CountDokument32 SeitenCatalog: Performance and Durability CountVanoni ClimatizaciónNoch keine Bewertungen

- Gear Selector Control Module (GSCM) MID 223, Diagnostic Trouble Code (DTC), GuideDokument9 SeitenGear Selector Control Module (GSCM) MID 223, Diagnostic Trouble Code (DTC), GuideJohnsito Leal67% (3)

- Spare Parts List: Pusher Leg RockdrillsDokument16 SeitenSpare Parts List: Pusher Leg RockdrillsMatheus Tavares100% (1)

- Eaton AT-1202 Transmission Service ManualDokument58 SeitenEaton AT-1202 Transmission Service Manualbernad evendiNoch keine Bewertungen

- Catalogo RacoresDokument36 SeitenCatalogo Racoresalix beltranNoch keine Bewertungen

- Yale FIGURE 500 & 500R Closure Installation Instructions: Important InformationDokument12 SeitenYale FIGURE 500 & 500R Closure Installation Instructions: Important InformationAnonymous bHh1L1Noch keine Bewertungen

- EE 330 HW 1 Solutions Fall 2011Dokument3 SeitenEE 330 HW 1 Solutions Fall 2011murphy111Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- SC RF - Safety Edge ReceiverDokument8 SeitenSC RF - Safety Edge ReceiverDmitriiȘtirbuNoch keine Bewertungen

- SILOS COMPONENTS MORE Kunststoffindustrie ENDokument15 SeitenSILOS COMPONENTS MORE Kunststoffindustrie ENАлександр МихайловичNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)