Beruflich Dokumente

Kultur Dokumente

International Organization For Standardization

Hochgeladen von

tracy chenOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

International Organization For Standardization

Hochgeladen von

tracy chenCopyright:

Verfügbare Formate

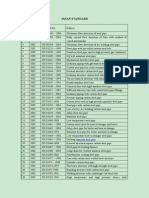

International organization for standardization

No.

1

2

Type

ISO

ISO

Standard Number

Subject

ISO 651981

Carbon steel pipe for threading

according to ISO 7l

ISO 11291980

Dimensions, tolerances and unit

weight of steel pipe for boiler,

superheater, and heat exchanger

ISO

ISO 11791981

Industrial flat end steel pipe and

other metal pipe joints threading

conforming to ISO 2281

ISO

ISO 29371974

Mechanical light end seamless steel

pipe

ISO 3183-1-1996

Oil and gas industry pipeline steel

pipe delivery technical conditions in

the first part: requirement for grade A

steel tube

ISO 3183-2-1996

Oil and gas industry pipeline steel

pipe delivery technical conditions in

the second part: requirement for

grade B steel tube

ISO 3183-3-1999

Oil and gas industry pipeline steel

pipe delivery technical conditions in

the third part: requirement for grade

C steel tube

ISO 3183-3 Technical

corrigendum 1-2000

Oil and gas industry pipeline steel

pipe delivery technology condition

part 3: the requirement and technical

correction of grade C steel pipe

ISO

ISO

ISO

ISO

ISO

ISO 33041985

The light end precision

seamless steel tube

technical delivery

conditions.

10

ISO

ISO 3305-1985

Light side welding precision steel

pipe delivery condition

ISO 3306-1985

Precision steel tube sizing light end

after welding technical conditions of

delivery

ISO 3545-1-1989

Symbols used in the steel pipe and

pipe fittings specification part 1:

circular cross section of the pipe and

11

12

ISO

ISO

tube attachment

13

14

15

16

17

ISO

ISO

ISO

ISO

ISO

ISO 3545-2-1989

Steel pipe and pipe fittings in the

specification part 2: symbols used in

a square and rectangular hollow

section

ISO 3545-3-1989

Symbols used in the steel pipe and

pipe fittings specification part 3:

circular cross section pipe fittings

ISO 4200-1991

Light welded and seamless steel pipe

of the size and weight per unit length

of the list

ISO 4394-1-1980

The fluid drive system and

components. Cylinder. The first part l

requirements for special finishing

diameter of steel pipe

ISO 5256-1985

Underground or underwater pipeline

steel pipe and pipe fittings pipe

internal and external coating or tar

oil derivatives

Shipbuilding steel pipe flange

welding flux tank tube PN6, PN10,

and PN16

18

ISO

ISO 5625-1978

19

20

ISO

ISO

ISO 6758-1980

ISO 6759-1980

21

ISO

ISO 6761-1981

Pretreatment of steel pipe welding of

pipe and accessories

ISO 8535-1-1996

Compression ignition engine high

pressure fuel nozzle with steel tube

part l: seamless cold drawn single

wall tube requirements

ISO 8535-2-2003

Compression ignition engine high

pressure fuel nozzle with steel tube

part 2: the requirements of the

composite tube

22

ISO

Welded tubes for heat exchanger

Welded tubes for heat exchanger

23

ISO

24

ISO

Steel pipe material with continuous

symbols and color code

ISO

Seamless steel tube and the welding

pressure purpose (except for

submerged arc welding) steel pipe

hydraulic seal validation

electromagnetic test method

ISO 90951990

25

ISO 9302-1994

26

27

28

29

30

31

32

33

34

ISO

ISO

ISO

ISO

ISO

ISO

ISO

ISO

ISO

ISO 9303-1989

Seamless steel pipe pressure purpose

and (except for submerged arc

welding) welding steel pipe detection

longitudinal defects with all around

the ultrasonic test

ISO 9304-1989

Seamless steel tube and the welding

pressure purpose (except for

submerged arc welding) steel tube

defects in eddy current testing

ISO 9305-1989

Pressure purpose of seamless steel

pipe transverse defects all around

ultrasonic current test

ISO 9329-1-1989

Pressure for the first part l: seamless

steel tube technical delivery

conditions specified room

temperature performance of alloy

steel

ISO 9329-2-1997

Pressure purpose of part 2: seamless

steel tube technical delivery

conditions provisions in the

performance of high temperature

alloy steel and alloy steel

ISO 9329-3-1997

Pressure purpose part 3: seamless

steel tube technical delivery

conditions prescribed low

temperature performance of the alloy

steel and alloy steel

ISO 9329-4-1997

Seamless steel pipe pressure

purpose. Part 4: delivery technology

conditions of austenitic stainless

steel

ISO 9330-1-1990

Pressure application conditions of

welded steel pipe delivery

technology part l: provisions in room

temperature properties of the alloy

steel pipe

ISO 9330-2-1997

Pressure purpose of welded steel

pipe delivery part 2: technical

conditions stipulated the

performance of high temperature

resistance welding and induction

welding of alloy steel and alloy steel

pipe

35

36

37

38

ISO

ISO

ISO

ISO

ISO 9330-3-1997

Pressure purpose of welded steel

pipe delivery technology condition

part 3: the low temperature

performance of resistance welding

and induction welding of alloy steel

and alloy steel pipe

ISO 9330-4-2000

Pressure purpose part 4: welded steel

pipe delivery technology conditions

stipulated high temperature

performance of submerged arc

welding of alloy steel and alloy steel

pipe

ISO 9330-5-2000

Pressure purpose of welded steel

pipe delivery technology condition

part 5: provisions in the low

temperature performance of

submerged arc welding alloy steel

and alloy steel pipe

ISO 9330-6-1997

Pressure purpose of welded steel

pipe delivery conditions part 6: the

length of the austenitic stainless steel

pipe welding

39

ISO

ISO 9402-1989

Stress the use of seamless steel tube

and (except for submerged arc

welding) welding steel pipe detection

longitudinal defects in ferromagnetic

steel tube all surrounding magnetic

conversion/flux test part 5: the

provisions in the low temperature

performance of submerged arc

welding alloy steel and alloy steel

pipe

40

ISO

ISO 9455-12-1992

Soft soldering flux test method part

12: steel tube corrosion test

ISO 9598-1989

Pressure purpose of seamless steel

tube to detect transversal defects

with ferromagnetic steel tube all

surrounding magnetic switch/flux

test

ISO 9764-1989

Pressure for resistance welding and

induction welding steel pipe weld

defect of longitudinal ultrasonic

inspection

41

42

ISO

ISO

43

44

45

46

47

48

49

ISO

ISO

ISO

ISO

ISO

ISO

ISO

ISO 9765-1990

Pressure application of submerged

arc welding steel pipe weld

longitudinal ultrasonic testing and/or

transverse defects

ISO 10124-1994

Seamless steel pipe and the welding

pressure purpose (except for

submerged arc welding) steel pipe

layer defect detection by ultrasonic

inspection

ISO 10332-1994

Seamless steel tube and the welding

pressure purpose (except for

submerged arc welding) steel pipe

with ultrasonic inspection validation

hydraulic leakage protection

ISO 10543-1993

Seamless and hot stretching welded

steel pipe used in pressure

surrounding the whole ultrasonic

thickness detection

ISO 10763-1994

Hydraulic transmission end face

flush of seamless and welded type

precision steel pipe size and nominal

working pressure

ISO 11120-1999

Cylinder 150 liters ~ 3000 liters of

water capacity can be repeated filling

seamless steel cylinder design,

structure and test

ISO 11484-1994

Pressure to use steel pipe

nondestructive testing personnel

qualification and certification

50

ISO

ISO 11496-1993

Confined pressure purpose seamless

and welded steel pipe layer between

the integrity check pipe ultrasonic

testing

51

ISO

ISO 11960-2001

Oil and gas industry oil well casing

and tubing

52

ISO

ISO 11960 Technical

corrigendum-1-2002

Oil and gas industry. The well casing

or tubing with steel pipe. Technical

corrections I

53

ISO

ISO 11961-1996

Oil and gas industry drilling rod steel

pipe specification

ISO 12094-1994

Pressure for pressure welding steel

pipe welded steel pipe with steel

strip/plate lamination defect

detection with ultrasonic test

54

ISO

55

56

57

58

59

60

ISO

ISO

ISO

ISO

ISO

ISO

ISO 12095-1994

Confined pressure purpose seamless

and welded steel pipe liquid

penetrant test

ISO 12096-1996

Pressure USES pressure submerged

arc welding steel pipe weld defect

Ling measured by X-ray examination

ISO 13663-1995

Pressure USES pressure welded steel

pipe weld around the delamination

defect detection with ultrasonic test

ISO 13664-1997

Pressure USES pressure seamless

and welded steel pipe tube side

hierarchical organization defects

detection using magnetic particle

inspection

ISO 13665-1997

Confined pressure purpose seamless

and welded steel pipe pipe body

surface defects detection by

magnetic particle inspection

ISO 13680-2000

Oil and gas industry used as casing,

tubing and coupling of anti-corrosion

alloy seamless steel tube technical

conditions of delivery

61

ISO

ISO 15741-2001

Paint and varnish Marine and

offshore non-corrosive gas reduces

friction coating the inside of the pipe

62

ISO

ISO 13-1978

Grey cast iron pipe, special gray iron

castings and pressure pipe main parts

63

ISO

ISO 49-1994

ISO 7-1 malleable cast iron pipe

nipple

64

ISO

ISO 49 Technical

corrigendum-1-1997

Meet ISO 7-1 l nipple malleable cast

iron pipe technology errata

ISO 2531-1998

Water and gas using ductile iron

pipes, fittings, accessories and

fittings

65

ISO

66

ISO

ISO 4179-1985

Pressure and the pressure pipeline

with nodular cast iron pipe from

method to cement mortar lining

general requirements

67

ISO

ISO 7005-2--1988

Metal flange part 2: cast iron pipe

flanges

ISO 8179-1-1995

Ductile iron pipe external galvanized

part 1: finishing layer with metal

zinc

68

ISO

69

ISO

ISO 8179-2--1995

Ductile iron pipe external galvanized

part 2: finishing layer with zinc

coating

70

ISO

ISO 8180-1985

Ductile iron pipes, PE casing

71

ISO

ISO 9349-1991

Insulation nodular cast iron pipe

system

72

ISO

ISO 10802-1992

Ductile iron pipe hydraulic test after

installation

73

ISO

ISO 10803-1999

Design method of ductile iron pipes

ISO 10804-1-1996

Ductile iron pipes connected by

damping system, part 1: design rules

and finalize the test

74

ISO

75

ISO

ISO 1127-1992

Stainless steel pipe size, tolerance,

and the quality of unit length of

nominal

76

ISO

ISO 2037-1992

Food industrial stainless steel pipe

77

ISO

ISO 7598-1988

Suitable for according to ISO 7/1

threading tube of stainless steel pipe

ISO 9330-6-1997

Pressure purpose of welded steel

pipe delivery conditions part 6: the

length of the austenitic stainless steel

pipe welding

78

ISO

79

BSI

BS EN ISO 1127-1997

Stainless steel pipe. Dimensions,

tolerances and per unit length of

standard quality

80

BSI

BS EN ISO 9455-12-1994

Soft fluxes. Test methods. Steel tube

corrosion test

81

BSI

BS EN ISO 11120-1999

Gas bottle. 1501 litres to 30001 litres

of water to fill the capacity of the

seamless steel tube. The design,

structure and test

82

BSI

BS EN ISO 11960-2001

Oil and gas industry. The well casing

and tubing with steel pipe

83

BSI

BS EN ISO 11961-1997

Oil and gas industry. Drilling work

steel pipe. Specifications

BS EN ISO 13680-2002

Oil and gas industry. Used as casing,

tubing and coupling of anti-corrosion

alloy seamless steel pipe. Technical

conditions of delivery

BS EN ISO 3183-3-1999

Oil and gas industry. Pipe with steel

pipe technical delivery conditions. C

level requirement of steel pipe

84

85

BSI

BSI

86

87

BSI

BSI

BS EN ISO 8535-1-1997

Compression ignition engine.

High-pressure jet fuel pipe steel pipe.

Seamless cold drawn single wall

tube requirements

BS EN ISO 8535-2-2004

The requirements of compression

ignition engine, high pressure fuel

nozzle with steel tube and the

composite tube

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Cat To-4Dokument65 SeitenCat To-4srcattozziNoch keine Bewertungen

- Welcome To The Online Farnsworth-Munsell 100 Hue Color Blindness TestDokument8 SeitenWelcome To The Online Farnsworth-Munsell 100 Hue Color Blindness TestNandha KumarNoch keine Bewertungen

- Brightness Color MeterDokument4 SeitenBrightness Color MeterkmacleonNoch keine Bewertungen

- Introduction of Corrosion Resistant Oil Well Pipe and Pipeline PipeDokument2 SeitenIntroduction of Corrosion Resistant Oil Well Pipe and Pipeline Pipetracy chenNoch keine Bewertungen

- National Standard GB 18248-2008 Seamless Steel Tube For CylinderDokument2 SeitenNational Standard GB 18248-2008 Seamless Steel Tube For Cylindertracy chenNoch keine Bewertungen

- Japan StandardDokument3 SeitenJapan Standardtracy chenNoch keine Bewertungen

- Common Methods For The Corrosion Detection of Oil and Gas PipelinesDokument2 SeitenCommon Methods For The Corrosion Detection of Oil and Gas Pipelinestracy chen100% (2)

- Development of Powder Coatings For Fire PipelineDokument2 SeitenDevelopment of Powder Coatings For Fire Pipelinetracy chenNoch keine Bewertungen

- Li Keqiang's Visit To Latin AmericaDokument3 SeitenLi Keqiang's Visit To Latin Americatracy chenNoch keine Bewertungen

- Repair Measures of LSAW Steel Pipe Transverse CracksDokument2 SeitenRepair Measures of LSAW Steel Pipe Transverse Crackstracy chenNoch keine Bewertungen

- Analysis of Different Line Pipe Standard Requirement For Nondestructive TestingDokument4 SeitenAnalysis of Different Line Pipe Standard Requirement For Nondestructive Testingtracy chenNoch keine Bewertungen

- The Guidance Opinions On Promoting The International Production and Equipment Manufacturing CooperationDokument4 SeitenThe Guidance Opinions On Promoting The International Production and Equipment Manufacturing Cooperationtracy chenNoch keine Bewertungen

- Oil and Gas Pipeline Construction in VenezuelaDokument2 SeitenOil and Gas Pipeline Construction in Venezuelatracy chenNoch keine Bewertungen

- Calculate Method of Steel WeightDokument2 SeitenCalculate Method of Steel Weighttracy chenNoch keine Bewertungen

- 2014 Steel Pipe Exports and Imports of ChinaDokument1 Seite2014 Steel Pipe Exports and Imports of Chinatracy chenNoch keine Bewertungen

- New Favorite of Offshore PipeDokument2 SeitenNew Favorite of Offshore Pipetracy chenNoch keine Bewertungen

- Miit Issued The Steel Industry Restructuring Policy (Draft)Dokument10 SeitenMiit Issued The Steel Industry Restructuring Policy (Draft)tracy chenNoch keine Bewertungen

- New Type Martensitic Stainless HFW Steel PipeDokument2 SeitenNew Type Martensitic Stainless HFW Steel Pipetracy chenNoch keine Bewertungen

- Developing Direction of Welded Steel PipeDokument2 SeitenDeveloping Direction of Welded Steel Pipetracy chenNoch keine Bewertungen

- Ship With Seamless Steel Pipe and Fertilizer Equipment High Pressure Seamless Steel PipeDokument3 SeitenShip With Seamless Steel Pipe and Fertilizer Equipment High Pressure Seamless Steel Pipetracy chenNoch keine Bewertungen

- Different Standards of Steel PipeDokument3 SeitenDifferent Standards of Steel Pipetracy chenNoch keine Bewertungen

- Important Link For Class XII - 1Dokument3 SeitenImportant Link For Class XII - 1Utsaw SagarNoch keine Bewertungen

- NY Regents Chemistry Exam Scoring KeyDokument12 SeitenNY Regents Chemistry Exam Scoring KeyAAVANINoch keine Bewertungen

- Lap Reoprt 1Dokument9 SeitenLap Reoprt 1api-350815927Noch keine Bewertungen

- Sandwich Panel Anchors - Precast ConcreteDokument40 SeitenSandwich Panel Anchors - Precast ConcreteCorbean AlexandruNoch keine Bewertungen

- Factors Affecting The Velocity of Sound in A GasDokument2 SeitenFactors Affecting The Velocity of Sound in A GasShuvam ShahNoch keine Bewertungen

- Dokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Dokument19 SeitenDokumen - Tips - Cotter Joint PPTX 58f9ab8d3dbc9Good YagNoch keine Bewertungen

- Photography March 2016Dokument32 SeitenPhotography March 2016ArtdataNoch keine Bewertungen

- Ultrasonic FlowmetersDokument30 SeitenUltrasonic Flowmetersvcharles0% (1)

- Cobar 1400 Yumlu Mining With Paste FillDokument26 SeitenCobar 1400 Yumlu Mining With Paste FillSayantan ChakrabortyNoch keine Bewertungen

- Ion Exchange ChromatographyDokument3 SeitenIon Exchange ChromatographysherfudeenNoch keine Bewertungen

- Column C section and tie detailsDokument1 SeiteColumn C section and tie detailsبه شدار ازاد عبدالرحمن عليNoch keine Bewertungen

- Understanding FRP BoomsDokument4 SeitenUnderstanding FRP BoomsFernandoNoch keine Bewertungen

- ETEN4001 Tute1 2017Dokument3 SeitenETEN4001 Tute1 2017Orlando CalderasNoch keine Bewertungen

- William Tell LiteracyDokument29 SeitenWilliam Tell LiteracyAndrés Romero SeguraNoch keine Bewertungen

- Preparation, Structure and Morphology of Polymer Supports: David C. SherringtonDokument12 SeitenPreparation, Structure and Morphology of Polymer Supports: David C. Sherringtonkishorkumarn8212Noch keine Bewertungen

- Reading List - Philosophy of Quantum MechanicsDokument13 SeitenReading List - Philosophy of Quantum MechanicsDinh Quy DuongNoch keine Bewertungen

- 316 316l Data SheetDokument2 Seiten316 316l Data SheetDiman Aditya KardiNoch keine Bewertungen

- CLMD4A Science8Dokument39 SeitenCLMD4A Science8GreyNoch keine Bewertungen

- Titrimetry (anEm'pnmQwQy)Dokument102 SeitenTitrimetry (anEm'pnmQwQy)AchindA FernandoNoch keine Bewertungen

- PHY 102 Quantum Physics Wave Functions and the Schrodinger EquationDokument24 SeitenPHY 102 Quantum Physics Wave Functions and the Schrodinger EquationSuhardi EffendyNoch keine Bewertungen

- Refractory Degradation in Glass Tank Melters. A Survey of Testing MethodsDokument5 SeitenRefractory Degradation in Glass Tank Melters. A Survey of Testing MethodsRizqi Ahmad FauzanNoch keine Bewertungen

- Liebherr Hs DimensionsDokument12 SeitenLiebherr Hs DimensionsLiebherrNoch keine Bewertungen

- Asymptotic Orthogonality Analysis of Sparse Massive MIMO ChannelsDokument5 SeitenAsymptotic Orthogonality Analysis of Sparse Massive MIMO Channelshendra lamNoch keine Bewertungen

- 26 - Jaxa-Rozen Cold Work Stainless Steell PDFDokument13 Seiten26 - Jaxa-Rozen Cold Work Stainless Steell PDFSergio MuñozNoch keine Bewertungen

- Imp 4Dokument38 SeitenImp 4nikhilNoch keine Bewertungen

- 4 - 002 Qafco Urea3 Plant High PressureDokument13 Seiten4 - 002 Qafco Urea3 Plant High PressureJUNAID RAFEYNoch keine Bewertungen

- Anupampriya@bhu Ac inDokument12 SeitenAnupampriya@bhu Ac inPrityyyNoch keine Bewertungen