Beruflich Dokumente

Kultur Dokumente

Volumetria Nist Cenam

Hochgeladen von

vicocalanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Volumetria Nist Cenam

Hochgeladen von

vicocalanCopyright:

Verfügbare Formate

metrologia

International Comparison

International comparison of volume measurement standards at 50 l

at the CENAM (Mexico), PTB (Germany), Measurement Canada

and NIST (USA)

J. M. Maldonado, R. Arias, H.-H. Oelze,

V. E. Bean, J. F. Houser, C. Lachance

and C. Jacques

Abstract. The Centro Nacional de Metrologa (CENAM), the Physikalisch-Technische Bundesanstalt (PTB),

Measurement Canada (MC), and the National Institute of Standards and Technology (NIST) maintain the national

primary standard facilities for the measurement of volume in Mexico, Germany, Canada and the United States,

respectively. These laboratories have compared volume measurements at 50 l. The comparison was accomplished

by each laboratory calibrating a transfer standard volume that was circulated among the laboratories, with the

CENAM acting as pilot laboratory. All the participants used gravimetric methods. The maximum and minimum

reported volumes differ by 0.0098 %.

1. Introduction

Comparison of primary standard measurement facilities

is an essential activity of national metrology institutes as

this is the best way to detect flaws in instruments and/or

procedures. Experience has shown that when the results

of such comparisons differ by more than expected, given

the respective uncertainties, the participants search for

and correct problems and their metrology is improved.

Since volume measurements are the basis for the

transfer of custody of valuable fluids, comparison of

primary standards of volume is particularly significant.

The CENAM, PTB, MC and NIST maintain the

national primary standard facilities for the measurement

of volume in Mexico, Germany, Canada and the United

States, respectively. These laboratories compared

volume measurements at 50 l. The CENAM, acting

as the pilot laboratory, provided the transfer standard,

J. M. Maldonado and R. Arias: Centro Nacional de Metrologa

(CENAM), CP 76900, Queretaro, Mexico.

H.-H. Oelze: Physikalisch-Technische Bundesanstalt (PTB),

D-38023 Braunschweig, Germany.

V. E. Bean and J. F. Houser: National Institute of Standards and

Technology (NIST), Gaithersburg, MD 20899, USA.

C. Lachance: Measurement Canada, Ottawa, K1A 0C9 Ontario,

Canada.

C. Jacques: Institute for National Measurement Standards, National

Research Council of Canada (NRC), Ottawa, K1A 0R6

Ontario, Canada.

Metrologia, 2002, 39, 91-95

measured the standard before and after shipment to the

other laboratories, and organized the comparisons.

2. Transfer standard

The transfer standard, with the exception of the

plumbing for filling and draining, was designed by the

PTB; the plumbing was designed by the CENAM. The

test measure, designed to measure delivered volumes,

was made in Mexico from 304-grade stainless steel with

welded seams and polished surfaces, inside and out.

Figure 1 is a schematic diagram of the transfer

standard. The body is a short, circular cylinder with

lobes welded to the sides to allow it to be mounted in

a supporting frame. The bottom is closed with a cone

welded to the cylinder with the apex downward. The

tube welded into the apex branches into the fill line and

the drain line, each terminated by a ball valve. The top

of the cylinder is similarly closed with a cone. About

mid-height, the top cone has a pair of bolted flanges,

perpendicular to the cone axis, allowing access to the

inside for cleaning. The gasket between the flanges is a

negligibly thin coating of silicone grease. A short tube

of 8 mm inner diameter is welded into the apex of the

top cone. The transfer standard is filled with distilled

water until the water protrudes above this tube to the

maximum extent permitted by surface tension, thereby

defining the filled condition. A transparent acrylic cover

91

J. M. Maldonado et al.

Figure 1. Schematic diagram of the transfer standard. Material 304-grade stainless steel, mirror-quality inner surface,

thickness 2 mm, metal-to-metal seal. Dimensions in millimetres.

with an appropriate drain handles any overflow during

filling. A thermometer well allows a platinum resistance

thermometer to be located near the geometrical centre

of the volume.

which the water in the transfer standard was drained

for weighing.

3. Methods

The CENAM and the NIST used electronic balances

with double-substitution weighing designs. Twelve

measurements are required for one volume determination using a double-substitution design: eight

weighings, plus measurements of water temperature,

air temperature, atmospheric pressure and relative

All the laboratories participating in the comparison used

gravimetrically based primary standard facilities for the

determination of volume. All used a weigh tank into

92

3.1 CENAM and NIST

Metrologia, 2002, 39, 91-95

International comparison of volume measurement standards at 50 l

humidity. The steps for the double-substitution

technique are [1]:

16. Calculate delivered volume of transfer standard at

20 C via

1. Load calibrated weights, e , nominally equivalent

to weight of empty weigh tank, on balance and

record balance reading as 1e .

2. Remove weights, load empty tank on balance and

record reading as 2e .

3. Add sensitivity weight,

and record reading as

s,

say 100 g, to balance

3e .

4. Remove tank, reload

e , add

balance reading as 4e .

s,

and record

5. Fill transfer standard with distilled water.

6. Record water temperature, air temperature, barometric pressure and relative humidity.

7. Drain transfer standard into weigh tank and close

drain valve 60 s after cessation of main flow. The

CENAM, as pilot laboratory, determined the 60 s

(drip-off time).

8. Load calibrated weights, f , nominally equivalent

to weight of weigh tank and 50 l of water, and

record reading as 1f .

where

is the volume thermal expansion

coefficient of the stainless steel from which the

transfer standard is made (4.77 105 / C), and

ss is the density of the material from which the

calibrated weights are made.

3.2 MC

The MC used an electronic balance and a singlesubstitution weighing design without a sensitivity

weight. The single-substitution design requires eight

measurements for one volume determination: four

weighings, plus measurements of water temperature,

air temperature, atmospheric pressure and relative

humidity. The steps are the same as for the doublesubstitution design with the omission of steps 3, 4, 10,

11, 13, 14 and 16. The delivered volume at 20 C is

calculated via

9. Remove weights, load weigh tank with water on to

balance and record reading as 2f .

10. Add

and record reading as

11. Remove weigh tank, reload

reading as 4f .

f,

3f .

add

and record

12. Calculate density of air, air , from measured

values of air temperature, atmospheric pressure and

relative humidity using an appropriate equation,

for example, Davis [2], Giacomo [3], Jaeger and

Davis [4], or Jones [5].

13. Calculate

readings of

e,

e

the difference between balance

and that of empty weigh tank, via

where s is the density of the material from which

the sensitivity weight is made.

14. Calculate

readings of

water, via

f,

f

the difference between balance

and that of weigh tank and distilled

15. Calculate density of distilled water, water , from

measured water temperature using an appropriate

empirical equation, for example, Patterson and

Morris [6], Kell [7], Watanabe [8], Takenaka and

Masui [9], Wagenbreth and Blanke [10], or Bettin

and Spieweck [11].

Metrologia, 2002, 39, 91-95

3.3 PTB

The PTB used an equal-arm balance with a singlesubstitution weighing design. The steps are:

1. Fill transfer standard with distilled water.

2. Load empty weigh tank and 50 kg of calibrated

weights, std , nominally equivalent to the weight

of water in the transfer standard, on one pan of

the balance. Load counterweights on the other pan

to bring pointer to near mid-scale. Record scale

reading as 1 .

3. Unload

std .

4. Record water temperature, air temperature, barometric pressure and relative humidity.

5. Drain transfer standard into weigh tank and close

drain valve 60 s after cessation of main flow.

6. Add calibrated weights,

std , to pan with weigh

tank to bring pointer to near mid-scale. Record

scale reading as 2 .

7. Add sensitivity weight,

scale reading as 3 .

s,

to balance pan. Record

8. Calculate density of air, air , from measured

values of air temperature, atmospheric pressure and

93

J. M. Maldonado et al.

relative humidity using an appropriate equation,

for example, Davis [2], Giacomo [3], Jaeger and

Davis [4], or Jones [5].

9. Calculate density of distilled water, water , from

measured water temperature using an appropriate

empirical equation, for example, Patterson and

Morris [6], Kell [7], Watanabe [8], Takenaka and

Masui [9], Wagenbreth and Blanke [10], or Bettin

and Spieweck [11].

10. Calculate delivered volume of transfer standard at

20 C via

Figure 2. Measured volumes of the transfer standard, in

chronological order. The error bars represent the expanded

uncertainties

listed in Table 1.

5. Conclusions

The transfer standard was disassembled, cleaned and

reassembled prior to the series of calibrations conducted

by each participant.

4. Results

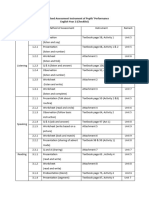

Table 1 and Figure 2 give in chronological order the

volumes and their expanded uncertainties as reported

by the laboratories, and the number of measurements,

, that were averaged to obtain each reported volume.

The expanded uncertainties, , were calculated via

where 2 is the coverage factor and A is the standard

deviation of the average expressed as [12]:

The value B is determined by the characterization

of the measurement process by each laboratory.

Reproducibility of the transfer standard was not

considered for the reported uncertainties.

Table 1. Measured volumes of the transfer standard. The

numbers following the symbols are the numerical values

.

of the expanded uncertainties

Laboratory

Date

Volume/ml

CENAM1

PTB

NIST1

CENAM2

CENAM3

NIST2

MC

October 1997

November 1997

December 1997

March 1998

August 1998

September 1998

September 1998

50 000.6

50 003.8

50 002.8

50 005.5

50 001.8

50 001.7

50 000.8

94

3.6

1.7

0.8

3.6

3.7

1.2

1.2

9

8

10

22

12

11

3

The maximum and minimum reported volumes differ

by 0.0098 %. As there are seven sets of measurements,

there are twenty-one possible comparisons between

pairs of measurements. There is significant overlap

of the uncertainties for eighteen of the twenty-one

comparisons. The exceptions are PTB/MC, NIST1/MC

and CENAM2/MC. The upper limit of the MC error bar

is 0.1 ml less than the lower limit of the PTB error bar,

indicating no overlap within the expanded uncertainties

for PTB/MC. The upper limit of the MC

error bar is identical to the lower limit of the NIST1

error bar, indicating no overlap within the expanded

for NIST1/MC. The upper limit

uncertainties

of the MC error bar is 0.1 ml greater than the lower limit

of the CENAM2 error bar, indicating an overlap of only

for

0.1 ml between the expanded uncertainties

CENAM2/MC.

Measurements carried out over short intervals,

October 1997 to December 1997 and August 1998 to

September 1998, show close agreement and significant

overlap of results, with maximum differences of

0.0064 % and 0.002 % respectively.

According to the results, and taking into consideration that the transfer standard was not subject to any

thermal stress relaxation process, it is considered that

thermal stresses could be a reasonable explanation of

the differences among laboratories.

The use of special tools, such as a torque meter,

could be of benefit in reducing the variation of the

results when using a transfer standard such as that

illustrated in Figure 1.

References

1. Houser J. F., Procedures for the Calibration of Volumetric

Test Measures, Natl. Bur. Stand. (U.S.), NBSIR 73-287,

1973, 22 p.

2. Davis R. S., Metrologia, 1992, 29, 67-70.

3. Giacomo P., Metrologia, 1982, 18, 33-40.

4. Jaeger K. B., Davis R. S., A Primer for Mass Metrology,

Natl. Bur. Stand. (U.S.), Spec. Publ. 700-1, Industrial

Measurement Series, 1984, 79 p.

5. Jones F. E., J. Res. Natl. Bur. Stand. (U.S.), 1978, 83,

419-428.

Metrologia, 2002, 39, 91-95

International comparison of volume measurement standards at 50 l

6. Patterson J. B., Morris E. C., Metrologia, 1994, 31,

277-288.

7. Kell G. S., J. Chem. Eng. Data, 1975, 20, 97-105.

8. Watanabe H., Metrologia, 1991, 28, 33-43.

9. Takenaka M., Masui R., Metrologia, 27, 1990, 165-171.

10. Wagenbreth H., Blanke W., PTB-Mitteilungen, 1971, 81,

412-415.

11. Bettin H., Spieweck F., PTB-Mitteilungen, 1990, 100,

195-196.

Metrologia, 2002, 39, 91-95

12. Guide to the Expression of Uncertainty in Measurement,

Geneva, International Organization for Standardization,

1993.

Received on 7 August 2001 and in revised form on

8 October 2001.

95

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Abcc1103 - Introduction To CommunicationDokument16 SeitenAbcc1103 - Introduction To CommunicationSimon RajNoch keine Bewertungen

- 8086 Microprocessor Interfacing MCQ SDokument4 Seiten8086 Microprocessor Interfacing MCQ SDeepak Ahlawat67% (3)

- Analytics For Sustainable BusinessDokument6 SeitenAnalytics For Sustainable BusinessDeloitte AnalyticsNoch keine Bewertungen

- C Shock Press KitDokument10 SeitenC Shock Press KitSusan LiNoch keine Bewertungen

- Direct 3 DDokument406 SeitenDirect 3 Dxlam99Noch keine Bewertungen

- Lesson Plans For Sped 101Dokument3 SeitenLesson Plans For Sped 101api-271266618Noch keine Bewertungen

- Organization StructureDokument11 SeitenOrganization StructureKaran RoyNoch keine Bewertungen

- Ecdsa PDFDokument56 SeitenEcdsa PDFMarcos CariNoch keine Bewertungen

- Frankel 1991 PDFDokument17 SeitenFrankel 1991 PDFFábio SilvaNoch keine Bewertungen

- Collection of Fungal Material From Surfaces by Tape Lift: Standard Practice ForDokument3 SeitenCollection of Fungal Material From Surfaces by Tape Lift: Standard Practice ForasmaNoch keine Bewertungen

- Disha Computer KnowledgeDokument247 SeitenDisha Computer KnowledgeBalachandarMahadevanNoch keine Bewertungen

- Penyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Dokument2 SeitenPenyelarasan Instrumen Pentaksiran PBD Tahun 2 2024Hui YingNoch keine Bewertungen

- BOC Develop A Strategic Communication Plan of The Transformation Roadmap Phase 2Dokument25 SeitenBOC Develop A Strategic Communication Plan of The Transformation Roadmap Phase 2Mario FranciscoNoch keine Bewertungen

- End of Semester ReflectionDokument3 SeitenEnd of Semester Reflectionapi-242745290Noch keine Bewertungen

- Jigs BatacDokument28 SeitenJigs BatacZab Robledo RiveraNoch keine Bewertungen

- Introduction To Forensic Science Questioned DocumentsDokument50 SeitenIntroduction To Forensic Science Questioned DocumentsLyka C. De Guzman100% (2)

- 2005 - Quality Criteria of Transdisciplinary ResearchDokument78 Seiten2005 - Quality Criteria of Transdisciplinary Researchis03lcmNoch keine Bewertungen

- RHCSA Sa1 2 EXAM Questions (1) 1Dokument23 SeitenRHCSA Sa1 2 EXAM Questions (1) 1hosnitmiNoch keine Bewertungen

- 1 Lesson Plan in Formulating AssertionsDokument6 Seiten1 Lesson Plan in Formulating AssertionsGenelyn TimolaNoch keine Bewertungen

- An Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasDokument8 SeitenAn Inspector Calls Character Notes Key Quotations Key Language & Structural Features Priestley's IdeasPNoch keine Bewertungen

- DC LAB Report#11Dokument8 SeitenDC LAB Report#11rajasafeelNoch keine Bewertungen

- Reading Comprehension: Pratyush at Toughest QuestionsDokument40 SeitenReading Comprehension: Pratyush at Toughest QuestionsJaved AnwarNoch keine Bewertungen

- Statistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSDokument32 SeitenStatistics in Experimental Research: Mark Anthony F. Casimiro Marikina Science High School-JHSJeanne Emerose TalabuconNoch keine Bewertungen

- Usm StanDokument5 SeitenUsm StanClaresta JaniceNoch keine Bewertungen

- Introduction To The Web AnalysisDokument2 SeitenIntroduction To The Web AnalysisAbNoch keine Bewertungen

- Tower Crane Operation ManualDokument31 SeitenTower Crane Operation ManualMahmoud Sarhan100% (1)

- The Reading The Mind in The Eyes Test: Testretest Reliability and Preliminary Rsychometric Rroperties of The German VersionDokument9 SeitenThe Reading The Mind in The Eyes Test: Testretest Reliability and Preliminary Rsychometric Rroperties of The German VersionSEP-PublisherNoch keine Bewertungen

- Educational Planning (Felipe)Dokument102 SeitenEducational Planning (Felipe)Felipe Beranio Sullera Jr.100% (4)

- Direct SeriesDokument22 SeitenDirect SeriesSahil SethiNoch keine Bewertungen

- (One Village One Product) Berbasis KoperasiDokument11 Seiten(One Village One Product) Berbasis KoperasiIndah Kumala SariNoch keine Bewertungen