Beruflich Dokumente

Kultur Dokumente

132434909555-3800-1 Ballistic8 Instr

Hochgeladen von

xerwaneOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

132434909555-3800-1 Ballistic8 Instr

Hochgeladen von

xerwaneCopyright:

Verfügbare Formate

MOTOR MAINTENANCE

BALLISTIC 8

BRUSHLESS MOTOR INSTRUCTIONS

55-3800-1 Rev. A 8/2011

PRECAUTIONS

NEVER FREE-REV THE MOTOR Free-running your brushless

motor in a no-load condition can result in rotor failure and ESC

transistor damage & will void the products warranty!

Never free-rev your system to see how it runs or you may not get to drive it again!

WATER & ELECTRONICS DONT MIX Never allow water, moisture, or

other foreign materials to get inside motor, or on PCBs.

NOVAK MOTORS & ESCs FOR BEST RESULTS Use Novak sensored

motors with Novak Brushless ESCs for best performance & protection. Only

use motors with the proper number of turns to match ESCs rating.

Use of this brushless motor with ESCs that advance motor

timing can result in excessive current draw & severe motor

damage that will NOT be covered by the products warranty!

DO NOT use Ballistic 8 motors above 50,000RPM.

INSULATE EXPOSED WIRES Use heat shrink tubing to prevent shorts.

NO SOLVENTS Do NOT expose the motor to any type of solvents.

SET GEAR MESH PROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage--be sure to adjust mesh properly.

ACCESSORIES

51XX

51XX

5351

5352

5353

5508

5512

5514

5644

5731

5741

5832

5850

5851

5980

5981

5982

5983

5984

5985

5986

5987

5988

5989

6801

6802

(5100-5123) 5mm Mod-1 Steel Pinion Gears--9T to 20T--Hardened steel, 5mm bore.

(5152-5161) 5mm 32-Pitch Steel Pinion Gears--12T to 17T--Hardened steel, 5mm bore.

Brushless Shielded Sensor Harness--4--Double-ended motor sensor harness.

Brushless Shielded Sensor Harness--6--Double-ended motor sensor harness.

Brushless Shielded Sensor Harness--9--Double-ended motor sensor harness.

14GA Brushless Wire Set--2 pieces each of 9 silicone blue, yellow, orange, black & red.

12GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

14GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

Black Cooling Fan: 40mm x 40mm x 10mm--2-pin JST connector, 5.7CFM @ 5VDC.

3.5mm Power Connectors--5 pair--Gold plated low-loss connectors for 12-14G wire.

4mm Power Connectors--5 pair--Gold plated low-loss high-amp 12-14G connectors.

Lead-Free 3% Silver Racing Solder--15g--Low-resistance, high-conductivity solder.

Heat Shrink Tubing Assortment--6pc--6 long tubing in six sizes from 1/16-3/8.

Heat Shrink Tubing Assortment--24pc--6 long tubing in six sizes from 1/16-3/8.

Ballistic 8 Sintered Rotor--Replacement 16mm 4-pole Kevlar-wrapped/epoxied rotor.

Ballistic 8L Sintered Rotor--Replacement 16mm 4-pole Kevlar-wrapped/epoxied rotor.

Ballistic 8/8L Front & Rear Flanged Bearing Set--Replacement bearing set.

Ballistic 8/8L Back End Cap/Bearing--Replacement back end cap w/bearing factory-installed.

Ballistic 8/8L Timing Assembly--Replacement timing & sensor section of Ballistic 8/8L.

Ballistic 8 Outer Sleeve/Heat Sink--Replacement outer sleeve for Ballistic 8.

Ballistic 8L Outer Sleeve/Heat Sink--Replacement outer sleeve for Ballistic 8L.

Ballistic 8/8L Front End Cap/Back Ring--Front end cap (w/bearing) & back end ring.

Ballistic 8 Motor Hardware Set--Replacement screws & shims for Ballistic 8 motor.

Ballistic 8L Motor Hardware Set--Replacement screws & shims for Ballistic 8L motor.

Ballistic 8 Hand-Wound Stator--Y1.5T--Ballistic 8 Wye-wound 1.5-turn stator.

Ballistic 8 Hand-Wound Stator--D2.0T--Ballistic 8 Delta-wound 2.0-turn stator.

Novak Electronics, Inc.

17032 Armstrong Avenue

Irvine, CA 92614

(949) 833-8873 FAX (949) 833-1631

Customer Service e-mail: cs@teamnovak.com

Monday-Friday: 8:00am-5:00pm (PST)

www.teamnovak.com

MOTOR MAINTENANCE

CHECK ALL MOTOR SCREWS for loosening at regular intervals, just like

other hardware on your vehicle. Note: The 3 main socket head screws

that hold the motor together may require tightening after a few runs of

the motor. Also check the 3 flat head screws securing the end cap on

the back of the motor--DO NOT OVER-TIGHTEN THESE SCREWS.

CHECK MOTOR BEARING WEAR after extensive use. The motors

closed design will keep most dirt & debris out, but some will get in

and eventually cause wear. If the shaft does not spin freely, you may

need bearing replacement (replacement bearing accessory kits are available

from Novak). A small drop of light oil on the bearings periodically can

help extend bearing life--however, too much oil will attract dirt and will

cause problems, so apply sparingly.

CLEAN INSIDE MOTOR periodically by removing front end cap,

removing the rotor, and blowing out the inside of the motor with

compressed air. Be sure not to lose any small shim washers that may be

on the ends of the rotor shaft & keep them in the correct location.

SENSOR HARNESS WIRING

Should any of the small Teflon wires pull out of the motors sensor

harness connector, re-insert them in the connectors appropriate

slot as shown below. There is a small plastic tab that grabs a small

raised barb on the back of the metal socket crimped onto the Teflon

wires end. Check the plastic tab to make sure it has not deformed

excessively before inserting the socket into the plastic connector

housing with the barb toward the plastic tabs.

Note: Remove or loosen the bearing cap to remove or insert a sensor harness.

black

orange

white

plastic

tabs

red

blue

green

metal

barbs

raised

metal

barb

metal socket on end of

Teflon sensor harness wires

SERVICE PROCEDURES

Consider changing out motor parts yourself. All of the Ballistic 8/8Ls main components

are available as service items--Refer to Accessories section or check out our web site. In

most cases, replacing motor parts is less expensive than sending in your motor for service.

After reviewing instructions, tech section and how-to video section of website, if you feel

your motor requires service (motor may appear to have failed when other problems exist), obtain

the most current product service options & pricing by one of the following methods:

WEB: Print out the product SERVICE FORM from CUSTOMER SERVICE section of the web

site. Fill out required information on form & return it with the product requiring service.

PHONE/FAX/E-MAIL: Contact our customer service department by phone, fax, or

e-mail, and we will supply you with current service options.

WARRANTY SERVICE: You MUST CLAIM WARRANTY on product PRODUCT SERVICE FORM &

include a valid cash register receipt with purchase date, dealer name, & phone # on it, or a

previous service invoice. If warranty provisions have been voided, there will be service charges.

ADDITIONAL NOTES:

Dealers/distributors are not authorized to replace products thought to be defective.

If a hobby dealer returns your product for service, submit a completed product SERVICE

FORM to dealer & make sure its included with items.

PRODUCT WARRANTY

Novak Brushless motors are guaranteed to be free from defects in materials or workmanship for a period of 120

days from the original date of purchase (verified by dated, itemized sales receipt). Warranty does not cover incorrect installation, components worn by use, cross-connection of battery/motor power wires, overheating solder

tabs, damage resulting from thermal overload or operation above 175F, use of excessive timing or overheating,

splices or damage to the sensor harness, damage from disassembling motor, tampering with internal electronics,

allowing water, moisture, or any other foreign material to enter motor or get onto the PC board, short-circuiting

of motor by allowing exposed wiring or solder tabs to cross-connect or ESC applying simultaneous power to

more than one phase at a time from switching to Brush Mode, free-revving motor, or any damage caused by

a crash, flooding, or natural disaster. In no case shall our liability exceed the products original cost. We reserve

the right to modify warranty provisions without notice.

Because Novak Electronics, Inc. has no control over the connection & use of motor or other related electronics, no

liability may be assumed nor will be accepted for damage resulting from the use of this product. Every motor is

thoroughly tested and cycled before leaving our facility and is, therefore, considered operational. This product is not

a toy, and is not intended for use by children under 14 years of age without the strict supervision of an adult. Use

of this product in a uncontrolled manner may result in physical damage or injuries. Take extra care when operating

any remote control vehicle. By the act of connecting/operating speed control, the user accepts all resulting liability.

No part of these instructions may be reproduced without the written permission of Novak Electronics, Inc.

Novak Electronics, Inc. Irvine, CA, U.S.A. All Rights Reserved. Novak motors are proudly designed in the U.S.A.

BALLISTIC 8

BRUSHLESS MOTOR INSTRUCTIONS

55-3800-1 Rev. A 8/2011

PRECAUTIONS

NEVER FREE-REV THE MOTOR Free-running your brushless

motor in a no-load condition can result in rotor failure and ESC

transistor damage & will void the products warranty!

Never free-rev your system to see how it runs or you may not get to drive it again!

WATER & ELECTRONICS DONT MIX Never allow water, moisture, or

other foreign materials to get inside motor, or on PCBs.

NOVAK MOTORS & ESCs FOR BEST RESULTS Use Novak sensored

motors with Novak Brushless ESCs for best performance & protection. Only

use motors with the proper number of turns to match ESCs rating.

Use of this brushless motor with ESCs that advance motor

timing can result in excessive current draw & severe motor

damage that will NOT be covered by the products warranty!

DO NOT use Ballistic 8 motors above 50,000 RPM.

INSULATE EXPOSED WIRES Use heat shrink tubing to prevent shorts.

NO SOLVENTS Do NOT expose the motor to any type of solvents.

SET GEAR MESH PROPERLY Too tight of a gear mesh can result in

motor pinion shaft breakage--be sure to adjust mesh properly.

ACCESSORIES

51XX

51XX

5351

5352

5353

5508

5512

5514

5644

5731

5741

5832

5850

5851

5980

5981

5982

5983

5984

5985

5986

5987

5988

5989

6801

6802

(5100-5123) 5mm Mod-1 Steel Pinion Gears--9T to 20T--Hardened steel, 5mm bore.

(5152-5161) 5mm 32-Pitch Steel Pinion Gears--12T to 17T--Hardened steel, 5mm bore.

Brushless Shielded Sensor Harness--4--Double-ended motor sensor harness.

Brushless Shielded Sensor Harness--6--Double-ended motor sensor harness.

Brushless Shielded Sensor Harness--9--Double-ended motor sensor harness.

14GA Brushless Wire Set--2 pieces each of 9 silicone blue, yellow, orange, black & red.

12GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

14GA Super-Flex Wire--Black, Red, & Blue--3 ft each color, silicone.

Black Cooling Fan: 40mm x 40mm x 10mm--2-pin JST connector, 5.7CFM @ 5VDC.

3.5mm Power Connectors--5 pair--Gold plated low-loss connectors for 12-14G wire.

4mm Power Connectors--5 pair--Gold plated low-loss high-amp 12-14G connectors.

Lead-Free 3% Silver Racing Solder--15g--Low-resistance, high-conductivity solder.

Heat Shrink Tubing Assortment--6pc--6 long tubing in six sizes from 1/16-3/8.

Heat Shrink Tubing Assortment--24pc--6 long tubing in six sizes from 1/16-3/8.

Ballistic 8 Sintered Rotor--Replacement 16mm 4-pole Kevlar-wrapped/epoxied rotor.

Ballistic 8L Sintered Rotor--Replacement 16mm 4-pole Kevlar-wrapped/epoxied rotor.

Ballistic 8/8L Front & Rear Flanged Bearing Set--Replacement bearing set.

Ballistic 8/8L Back End Cap/Bearing--Replacement back end cap w/bearing factory-installed.

Ballistic 8/8L Timing Assembly--Replacement timing & sensor section of Ballistic 8/8L.

Ballistic 8 Outer Sleeve/Heat Sink--Replacement outer sleeve for Ballistic 8.

Ballistic 8L Outer Sleeve/Heat Sink--Replacement outer sleeve for Ballistic 8L.

Ballistic 8/8L Front End Cap/Back Ring--Front end cap (w/bearing) & back end ring.

Ballistic 8 Motor Hardware Set--Replacement screws & shims for Ballistic 8 motor.

Ballistic 8L Motor Hardware Set--Replacement screws & shims for Ballistic 8L motor.

Ballistic 8 Hand-Wound Stator--Y1.5T--Ballistic 8 Wye-wound 1.5-turn stator.

Ballistic 8 Hand-Wound Stator--D2.0T--Ballistic 8 Delta-wound 2.0-turn stator.

Novak Electronics, Inc.

17032 Armstrong Avenue

Irvine, CA 92614

(949) 833-8873 FAX (949) 833-1631

Customer Service e-mail: cs@teamnovak.com

Monday-Friday: 8:00am-5:00pm (PST)

www.teamnovak.com

CHECK ALL MOTOR SCREWS for loosening at regular intervals, just like

other hardware on your vehicle. Note: The 3 main socket head screws

that hold the motor together may require tightening after a few runs of

the motor. Also check the 3 flat head screws securing the end cap on

the back of the motor--DO NOT OVER-TIGHTEN THESE SCREWS.

CHECK MOTOR BEARING WEAR after extensive use. The motors

closed design will keep most dirt & debris out, but some will get in

and eventually cause wear. If the shaft does not spin freely, you may

need bearing replacement (replacement bearing accessory kits are available

from Novak). A small drop of light oil on the bearings periodically can

help extend bearing life--however, too much oil will attract dirt and will

cause problems, so apply sparingly.

CLEAN INSIDE MOTOR periodically by removing front end cap,

removing the rotor, and blowing out the inside of the motor with

compressed air. Be sure not to lose any small shim washers that may be

on the ends of the rotor shaft & keep them in the correct location.

SENSOR HARNESS WIRING

Should any of the small Teflon wires pull out of the motors sensor

harness connector, re-insert them in the connectors appropriate

slot as shown below. There is a small plastic tab that grabs a small

raised barb on the back of the metal socket crimped onto the Teflon

wires end. Check the plastic tab to make sure it has not deformed

excessively before inserting the socket into the plastic connector

housing with the barb toward the plastic tabs.

Note: Remove or loosen the bearing cap to remove or insert a sensor harness.

black

orange

white

plastic

tabs

red

blue

green

metal

barbs

raised

metal

barb

metal socket on end of

Teflon sensor harness wires

SERVICE PROCEDURES

Consider changing out motor parts yourself. All of the Ballistic 8/8Ls main components

are available as service items--Refer to Accessories section or check out our web site. In

most cases, replacing motor parts is less expensive than sending in your motor for service.

After reviewing instructions, tech section and how-to video section of website, if you feel

your motor requires service (motor may appear to have failed when other problems exist), obtain

the most current product service options & pricing by one of the following methods:

WEB: Print out the product SERVICE FORM from CUSTOMER SERVICE section of the web

site. Fill out required information on form & return it with the product requiring service.

PHONE/FAX/E-MAIL: Contact our customer service department by phone, fax, or

e-mail, and we will supply you with current service options.

WARRANTY SERVICE: You MUST CLAIM WARRANTY on product PRODUCT SERVICE FORM &

include a valid cash register receipt with purchase date, dealer name, & phone # on it, or a

previous service invoice. If warranty provisions have been voided, there will be service charges.

ADDITIONAL NOTES:

Dealers/distributors are not authorized to replace products thought to be defective.

If a hobby dealer returns your product for service, submit a completed product SERVICE

FORM to dealer & make sure its included with items.

PRODUCT WARRANTY

Novak Brushless motors are guaranteed to be free from defects in materials or workmanship for a period of 120

days from the original date of purchase (verified by dated, itemized sales receipt). Warranty does not cover incorrect installation, components worn by use, cross-connection of battery/motor power wires, overheating solder

tabs, damage resulting from thermal overload or operation above 175F, use of excessive timing or overheating,

splices or damage to the sensor harness, damage from disassembling motor, tampering with internal electronics,

allowing water, moisture, or any other foreign material to enter motor or get onto the PC board, short-circuiting

of motor by allowing exposed wiring or solder tabs to cross-connect or ESC applying simultaneous power to

more than one phase at a time from switching to Brush Mode, free-revving motor, or any damage caused by

a crash, flooding, or natural disaster. In no case shall our liability exceed the products original cost. We reserve

the right to modify warranty provisions without notice.

Because Novak Electronics, Inc. has no control over the connection & use of motor or other related electronics, no

liability may be assumed nor will be accepted for damage resulting from the use of this product. Every motor is

thoroughly tested and cycled before leaving our facility and is, therefore, considered operational. This product is not

a toy, and is not intended for use by children under 14 years of age without the strict supervision of an adult. Use

of this product in a uncontrolled manner may result in physical damage or injuries. Take extra care when operating

any remote control vehicle. By the act of connecting/operating speed control, the user accepts all resulting liability.

No part of these instructions may be reproduced without the written permission of Novak Electronics, Inc.

Novak Electronics, Inc. Irvine, CA, U.S.A. All Rights Reserved. Novak motors are proudly designed in the U.S.A.

TIMING WARNING (Important)

INSTALLATION INSTRUCTIONS

1. NO MOTOR CAPACITORS & SCHOTTKY NEEDED

Novak brushless motors do not need motor capacitors or external

Schottky diodes--Schottky diode usage will damage ESC.

2. CHECK MOTOR SCREW LENGTH & INSTALL MOTOR

Insert the motor mounting screws that came with your vehicle

through the motor mounting plate. Ballistic8 motors need no

more than about 3/16 of screw extending past the vehicles

mounting plate (4-5mm)--Too little can strip the motors threads,

too much will cause internal motor damage & will void warranty.

Attach motor to vehicles motor mount using one of the sets of

threaded mounting holes--select a mounting position that keeps the

solder tabs clear of conductive surfaces like aluminum or graphite.

3. INSTALL PINION GEAR (see GEAR SELECTION)

Install pinion on motor and test fit in vehicle to align pinion and

spur gears. Tighten pinions set screw on the flat of motor shaft.

4. ADJUST MOTOR FOR PROPER GEAR MESH

Adjust the motor position for proper amount of free play. You

NEED to have a small amount of play between the pinion gear

and the spur gear (about the thickness of piece of paper)--check

the free play at several positions around the spur gear to

ensure a proper mesh (just in case the gears are out of round).

MAKE SURE THE PINION/SPUR GEAR MESH IS NOT TOO TIGHT!

If gear mesh is too tight, motor shaft breakage can occur.

Tighten motor mounting screws--Avoid using excessive force,

as the threaded holes in motor could become stripped.

5. SOLDER MOTOR POWER WIRES (skip this step if motor is wired to ESC)

Determine the best routing in vehicle for the motors silicone

power wires--avoid any moving parts & suspension.

Prepare ends of power wires by stripping 3/16-1/4 of

insulation from end of wire. Tin wire ends with solder.

Lay tinned end of the wire flat on the proper solder tab

(refer to phase markings on end ring above solder tabs) and solder

wires to the motor. Apply heat with a high-power soldering

iron to the power wire and solder tab--begin adding solder to

tip of iron and to wire--Add just enough solder to form a clean

& continuous joint from the solder tab up onto the wire.

WARNING: Be sure no phase wires make contact with an adjacent solder

tab--this will cause short-circuiting, damage electronics, & void warranty.

IMPORTANT NOTE: DO NOT OVERHEAT SOLDER TABS

Prolonged/excessive heating will damage tabs & void the warranty.

6. CONNECT MOTOR SENSOR HARNESS

Determine the best routing in vehicle for the motors sensor

harness--securing sensor harness to the motor power wires with a

tie-wrap can provide a good location & also act as a strain relief.

Connect one end of sensor harness to ESC & the other end

to the motors sensor harness connector located under the

back bearing cover--remove two flat head screws to remove

cover to access connector. Be sure the plug on the ends of the

harness insert all the way into the sensor harness connectors--the

plug & connector are keyed and will only go together one direction.

Due to the nature of timing advance speed controls, motor tolerances & settings, vehicle

performance, and track conditions, it has become virtually impossible to provide installation and operation recommendations that will allow you to use these speed controls and

motors at their highest performance levels without the potential for unwanted damage.

You must, use extreme caution when setting up these electronics and carefully test your

application to avoid overloading and overheating either the speed control or the motor.

These are racing electronics used in racing conditions, and therefore damage as the

result of excessive overheating will not be covered under the products factory warranty.

GEAR SELECTION (Important)

Motor operating temperature is the ONLY

way to properly set the maximum vehicle gearing

The motor should be 160-175F MAX at end of run!

Temperatures above 175F will weaken the magnet & may

melt the coils! This voids warranty & can damage ESC!

Change the gearing to avoid overheating.

Because of potential ESC/Motor overheating, damage, & failure, you must start

with VERY small pinion sizes and check ESC & motor temperatures multiple

times during initial runs to ensure that you are not causing excessive heating.

If ESC/Motor temperatures remain low & stable, you can slowly increase the pinion size

while again monitoring the temperatures to determine safe gearing for your vehicle,

motor, & track conditions. Because these variables can change, you MUST continually

monitor ESC & motor temperatures to protect your electronics from damage.

Because of the broad power band of brushless, you can go 1-2 teeth higher

pinion than the above recommendations for more top speed, but remember any

higher will produce excessive ESC & motor heating.

See our website or contact us for additional gearing information & recommendations.

MOTOR TIMING ADJUSTMENT

The Ballistic 8/8L motors timing is adjustable by simply loosening the three M2.5

flat head screws on the back bearing cap, rotating the bearing cap to desired setting,

and then re-tightening the screws.

The motors factory timing is marked with a timing label located on the side of the

back bearing cap and lines up with a groove milled into the top of the back end ring.

Novak motors are factory timed to the most efficient setting for their given wind.

Note: Wye-wound motors are timed to the Y mark on the motors timing

label and Delta-wound motors are timed to the D mark on the label. When

replacing a stator with a different wind type (Wye/Delta) rotate the end cap to

line up with the appropriate wind type for proper motor operation.

Advancing the timing will increase the motors RPM range & reduce its torque, but

will also make the motor less efficient and it will in turn pull more current, resulting

in higher speed control & motor operating temperatures.

Adjusting the timing more than 2 timing marks on the timing label

will result in dangerously high current draw and heating that can lead

to ESC & motor failure, and will void the products warranty.

Retarding the timing will reduce the motors RPM range & increase its torque--this

also usually reduces current draw and lowers operating temperatures. For each timing mark (on label) reduced, you should increase the pinion gear size by one tooth

to accommodate for the lower RPM range.

1. NO MOTOR CAPACITORS & SCHOTTKY NEEDED

Novak brushless motors do not need motor capacitors or external

Schottky diodes--Schottky diode usage will damage ESC.

2. CHECK MOTOR SCREW LENGTH & INSTALL MOTOR

Insert the motor mounting screws that came with your vehicle

through the motor mounting plate. Ballistic8 motors need no

more than about 3/16 of screw extending past the vehicles

mounting plate (4-5mm)--Too little can strip the motors threads,

too much will cause internal motor damage & will void warranty.

Attach motor to vehicles motor mount using one of the sets of

threaded mounting holes--select a mounting position that keeps the

solder tabs clear of conductive surfaces like aluminum or graphite.

3. INSTALL PINION GEAR (see GEAR SELECTION)

Install pinion on motor and test fit in vehicle to align pinion and

spur gears. Tighten pinions set screw on the flat of motor shaft.

4. ADJUST MOTOR FOR PROPER GEAR MESH

Adjust the motor position for proper amount of free play. You

NEED to have a small amount of play between the pinion gear

and the spur gear (about the thickness of piece of paper)--check

the free play at several positions around the spur gear to

ensure a proper mesh (just in case the gears are out of round).

MAKE SURE THE PINION/SPUR GEAR MESH IS NOT TOO TIGHT!

If gear mesh is too tight, motor shaft breakage can occur.

Tighten motor mounting screws--Avoid using excessive force,

as the threaded holes in motor could become stripped.

5. SOLDER MOTOR POWER WIRES (skip this step if motor is wired to ESC)

Determine the best routing in vehicle for the motors silicone

power wires--avoid any moving parts & suspension.

Prepare ends of power wires by stripping 3/16-1/4 of

insulation from end of wire. Tin wire ends with solder.

Lay tinned end of the wire flat on the proper solder tab

(refer to phase markings on end ring above solder tabs) and solder

wires to the motor. Apply heat with a high-power soldering

iron to the power wire and solder tab--begin adding solder to

tip of iron and to wire--Add just enough solder to form a clean

& continuous joint from the solder tab up onto the wire.

WARNING: Be sure no phase wires make contact with an adjacent solder

tab--this will cause short-circuiting, damage electronics, & void warranty.

IMPORTANT NOTE: DO NOT OVERHEAT SOLDER TABS

Prolonged/excessive heating will damage tabs & void the warranty.

6. CONNECT MOTOR SENSOR HARNESS

Determine the best routing in vehicle for the motors sensor

harness--securing sensor harness to the motor power wires with a

tie-wrap can provide a good location & also act as a strain relief.

Connect one end of sensor harness to ESC & the other end

to the motors sensor harness connector located under the

back bearing cover--remove two flat head screws to remove

cover to access connector. Be sure the plug on the ends of the

harness insert all the way into the sensor harness connectors--the

plug & connector are keyed and will only go together one direction.

www.teamnovak.com

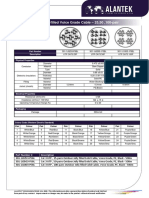

BALLISTIC 8/8L MOTOR

Exploded View

drill balanced

Kevlar-wrapped

4-pole rotor

low-loss solder tabs

You must, use extreme caution when setting up these electronics and carefully test your

application to avoid overloading and overheating either the speed control or the motor.

These are racing electronics used in racing conditions, and therefore damage as the

result of excessive overheating will not be covered under the products factory warranty.

GEAR SELECTION (Important)

Motor operating temperature is the ONLY

way to properly set the maximum vehicle gearing

The motor should be 160-175F MAX at end of run!

Temperatures above 175F will weaken the magnet & may

melt the coils! This voids warranty & can damage ESC!

Change the gearing to avoid overheating.

Because of potential ESC/Motor overheating, damage, & failure, you must start

with VERY small pinion sizes and check ESC & motor temperatures multiple

times during initial runs to ensure that you are not causing excessive heating.

If ESC/Motor temperatures remain low & stable, you can slowly increase the pinion size

while again monitoring the temperatures to determine safe gearing for your vehicle,

motor, & track conditions. Because these variables can change, you MUST continually

monitor ESC & motor temperatures to protect your electronics from damage.

Because of the broad power band of brushless, you can go 1-2 teeth higher

pinion than the above recommendations for more top speed, but remember any

higher will produce excessive ESC & motor heating.

See our website or contact us for additional gearing information & recommendations.

MOTOR TIMING ADJUSTMENT

The Ballistic 8/8L motors timing is adjustable by simply loosening the three M2.5

flat head screws on the back bearing cap, rotating the bearing cap to desired setting,

and then re-tightening the screws.

The motors factory timing is marked with a timing label located on the side of the

back bearing cap and lines up with a groove milled into the top of the back end ring.

Novak motors are factory timed to the most efficient setting for their given wind.

Note: Wye-wound motors are timed to the Y mark on the motors timing

label and Delta-wound motors are timed to the D mark on the label. When

replacing a stator with a different wind type (Wye/Delta) rotate the end cap to

line up with the appropriate wind type for proper motor operation.

Advancing the timing will increase the motors RPM range & reduce its torque, but

will also make the motor less efficient and it will in turn pull more current, resulting

in higher speed control & motor operating temperatures.

Adjusting the timing more than 2 timing marks on the timing label

will result in dangerously high current draw and heating that can lead

to ESC & motor failure, and will void the products warranty.

Retarding the timing will reduce the motors RPM range & increase its torque--this

also usually reduces current draw and lowers operating temperatures. For each timing mark (on label) reduced, you should increase the pinion gear size by one tooth

to accommodate for the lower RPM range.

BALLISTIC 8/8L MOTOR

Exploded View

drill balanced

Kevlar-wrapped

4-pole rotor

low-loss solder tabs

timing

assembly

4-40 socket

head cap screws

fiberglass

front insulator

front end cap

Due to the nature of timing advance speed controls, motor tolerances & settings, vehicle

performance, and track conditions, it has become virtually impossible to provide installation and operation recommendations that will allow you to use these speed controls and

motors at their highest performance levels without the potential for unwanted damage.

www.teamnovak.com

timing

assembly

4-40 socket

head cap screws

outer sleeve/heat sink

TIMING WARNING (Important)

INSTALLATION INSTRUCTIONS

epoxy-dipped

hand-wound

12 slot stator

fiberglass

stamping

insulators

back

end ring

sensor harness

connector

bearing

cap

bearing

cover

timing groove

M2.5x10mm

flat head

cap screws

Refer to Accessories section for

available replacement components.

fiberglass

front insulator

front end cap

outer sleeve/heat sink

epoxy-dipped

hand-wound

12 slot stator

fiberglass

stamping

insulators

back

end ring

sensor harness

connector

bearing

cap

bearing

cover

timing groove

M2.5x10mm

flat head

cap screws

Refer to Accessories section for

available replacement components.

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Pioneer ddj-s1 rrv4168 DJ Controller PDFDokument134 SeitenPioneer ddj-s1 rrv4168 DJ Controller PDFWilliam Rangel GarciaNoch keine Bewertungen

- Yaesu FT-680R Instruction ManualDokument50 SeitenYaesu FT-680R Instruction ManualYayok S. AnggoroNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Engine Tuning BibleDokument14 SeitenThe Engine Tuning BiblexerwaneNoch keine Bewertungen

- The Engine Tuning BibleDokument14 SeitenThe Engine Tuning BiblexerwaneNoch keine Bewertungen

- Electrical Design - Dax Generators: © BRUSH GroupDokument66 SeitenElectrical Design - Dax Generators: © BRUSH GroupKyleNoch keine Bewertungen

- Patof DMDokument1 SeitePatof DMxerwaneNoch keine Bewertungen

- Iso 29601-2011Dokument14 SeitenIso 29601-2011Carmen Rodriguez Polo100% (1)

- Fig 6 Wiring Diagram PDFDokument1 SeiteFig 6 Wiring Diagram PDFThe fountain of knowledgeNoch keine Bewertungen

- Initial Management:: First AidDokument6 SeitenInitial Management:: First AidxerwaneNoch keine Bewertungen

- Ppds June 2017 ResumeDokument315 SeitenPpds June 2017 ResumexerwaneNoch keine Bewertungen

- No Nama Barang Jumlah Pema-Kaian Harga BeliDokument19 SeitenNo Nama Barang Jumlah Pema-Kaian Harga BelixerwaneNoch keine Bewertungen

- tr15 060322-EDokument7 Seitentr15 060322-ExerwaneNoch keine Bewertungen

- Shock Oil ChartDokument4 SeitenShock Oil ChartxerwaneNoch keine Bewertungen

- FW 03Dokument13 SeitenFW 03xerwaneNoch keine Bewertungen

- KYOSHO SuperTen FW04Dokument36 SeitenKYOSHO SuperTen FW04xerwaneNoch keine Bewertungen

- LOSLOSK0804EU Setup Drake-2010NEORace.K0804EU Setup Drake-2010NEORace PDFDokument1 SeiteLOSLOSK0804EU Setup Drake-2010NEORace.K0804EU Setup Drake-2010NEORace PDFxerwaneNoch keine Bewertungen

- Portable Plasma Torch Height Controller Manual: Type F1620Dokument46 SeitenPortable Plasma Torch Height Controller Manual: Type F1620Kanivalavan CNoch keine Bewertungen

- 8200 MotecDokument3 Seiten8200 Motecyera1Noch keine Bewertungen

- DBXLH 6565c VTMDokument1 SeiteDBXLH 6565c VTMPetreNoch keine Bewertungen

- Catalogo Thyripol Ingles - ExcitacaoDokument14 SeitenCatalogo Thyripol Ingles - ExcitacaoErbil KeskinNoch keine Bewertungen

- Alarms UpsDokument4 SeitenAlarms UpsAditya JaiswalNoch keine Bewertungen

- PTDFDokument2 SeitenPTDFMohammed AlsuffarNoch keine Bewertungen

- 4 - SIPROTEC 7SD60 Numerical Pilot-Wire Current Differential Protection Relay PDFDokument14 Seiten4 - SIPROTEC 7SD60 Numerical Pilot-Wire Current Differential Protection Relay PDFsaina124796010Noch keine Bewertungen

- CBSE Class 12 Physics Sample Paper 2018Dokument3 SeitenCBSE Class 12 Physics Sample Paper 2018Faculty, Shahid Matangini Hazra Government College for WomenNoch keine Bewertungen

- Industrial Motor StarterDokument8 SeitenIndustrial Motor Starterchidambaram kasiNoch keine Bewertungen

- Exp 12) Prbs Generator and Shift RegisterDokument5 SeitenExp 12) Prbs Generator and Shift RegisterMani BharathiNoch keine Bewertungen

- VKP 60 LT 515 CDokument8 SeitenVKP 60 LT 515 CBadar DayanNoch keine Bewertungen

- Step 2 Group 9 Jorge Ivan MendietaDokument18 SeitenStep 2 Group 9 Jorge Ivan Mendietayuli yimena ruedaNoch keine Bewertungen

- TI UC3906 Application Note-slua115-U104Dokument12 SeitenTI UC3906 Application Note-slua115-U104spidyheroNoch keine Bewertungen

- Over-The-Air Testing Fundamentals Po 5216-4162-82 v0100Dokument1 SeiteOver-The-Air Testing Fundamentals Po 5216-4162-82 v0100Sarajevski DuhNoch keine Bewertungen

- Outdoor Gel-Filled Cat3 2550100pair UTP v2.1Dokument1 SeiteOutdoor Gel-Filled Cat3 2550100pair UTP v2.1BinhNoch keine Bewertungen

- On The Root Mean Square Radius of The DeuteronDokument6 SeitenOn The Root Mean Square Radius of The DeuteronIis YuliaNoch keine Bewertungen

- CEAG Lighting Brochure 2019 2020Dokument24 SeitenCEAG Lighting Brochure 2019 2020Muhammad Rinaldy RinaldyNoch keine Bewertungen

- Micropumps-Past, Progress and Future Prospects: Peter WoiasDokument11 SeitenMicropumps-Past, Progress and Future Prospects: Peter WoiasChandra SekarNoch keine Bewertungen

- Artificial Neural Network Based MPPT of Solar Photovoltaic CellsDokument11 SeitenArtificial Neural Network Based MPPT of Solar Photovoltaic CellsVishal FernandesNoch keine Bewertungen

- EKC 315A Danfoss Rs8cS302Dokument16 SeitenEKC 315A Danfoss Rs8cS302davebigelow42Noch keine Bewertungen

- EDCh 4 RF IfDokument3 SeitenEDCh 4 RF IfsmileyNoch keine Bewertungen

- Fuji Eletric ContactorDokument2 SeitenFuji Eletric Contactorzi_ming86Noch keine Bewertungen

- Fig 1 - GE Optima CT660 CT ScannerDokument4 SeitenFig 1 - GE Optima CT660 CT Scannerarwa zeglamNoch keine Bewertungen

- Lightning Properties Derived From Lightning LocatiDokument6 SeitenLightning Properties Derived From Lightning LocatiCarlos Alberto Avendaño AvendañoNoch keine Bewertungen