Beruflich Dokumente

Kultur Dokumente

AppxE-CNC Setups 12142006

Hochgeladen von

Vagner Aux CadCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AppxE-CNC Setups 12142006

Hochgeladen von

Vagner Aux CadCopyright:

Verfügbare Formate

CNC Setups

CNC Setups

Parts must be located precisely and held securely during the machining

process. Work holding devices are referred to as fixtures. A fixture can

be as simple as a vise with hard jaws. Very complex fixtures, like those

used in the aerospace industry, may cost many thousands of dollars and be

designed by highly experienced tooling engineers.

Devising efficient and effective fixtures is one of the most challenging

tasks of programming a CNC Mill, requiring a high level of knowledge,

skill, and ingenuity. A few of the many factors influencing work holding

include:

Type of material being machined.

Number of sides of part to machine.

Feature tolerances.

Machining forces.

Rigidity of the part; before an after material is machined away.

Cost to manufacture the fixture.

Number of times the fixture will be used.

Skill level of the machine operator.

For example, many parts can be accurately located and held in a vise. If

the part is machined on several sides, pay careful attention to the order

each face is machined and how the part is flipped between operations.

Production quantity is an important consideration. Higher production

volumes usually justify more expensive tooling to speed production and

reduce scrap rate.

Size and type of material and cutting forces also affect fixture choice. A

foam or plastic visual prototype may be simply glued or taped down.

More substantial parts can be bolted, clamped, or held with a vacuum.

Mastercam Handbook Volume 1

E-1

Appendix E

CNC

Setups

Vise

A basic vise setup uses a vise, step jaws, vise stop, and stock material

machined to size. The back edge of the fixed step jaw is dial indicated

parallel to the machine x-axis. The vise stop sets a limit to slide the stock

against as fresh stock material is loaded.

Vise

Stop

Back Edge of

Fixed Jaw

Parallel To

Machine X-Axis

Fixed

Jaw

Movable

Jaw

Y

X

Stock cut

To size.

Stock

Back Edge

Step Jaw

Step

Jaws

Warning

E-2

Improperly designed setups are extremely dangerous. Parts, tooling, or

fixture components can shatter or be ejected at high speed, causing

serious injury or death. Always wear safety glasses and observe all

machine safety procedures. Unless you are completely confident your

setup will securely hold the part, do not use it.

Mastercam X5

CNC Setups

The following diagram shows the layout of a typical VMC and location of

the spindle when the machine is at its Home Position.

Z

Y

Top

Iso

Front

Side

CNC programs are written in terms of the tool tip motion; not table

motion. For example, a command of X1.0 moves the tool to the right

(though on a VMC the table will move to the left).

Mastercam Handbook Volume 1

E-3

Appendix E

Fixture

Offsets

Your probably noticed that when the machine is at its home position, its

coordinate system datum is far away from the part datum. Here is why.

When you first power-up a CNC machine, it has no idea where the spindle

is located in the workspace. The machine finds its position during the

startup-home process by simply driving each machine axis towards its

(-) limit. Just before the machine hits an axis limit, it trips a micro-switch.

This signals the control that the axis is at a known location; called the

Machine Home. Home is usually defined as the center-face of the

spindle when the machine is at its (-) axes limits.

Once homed, the machine keeps track of its position by counting how far

each axis moves in reference to Home. Coordinates in reference to

Machine Home are called Machine Coordinates.

Of course, no one programs using Machine Coordinates. The Machine

Home position is far from the work piece, so programs written in Machine

Coordinates would have numbers that bear no obvious relation to

coordinates on the part.

If the fixture were removed, it would be difficult to put it back exactly

where it was, so the NC program would have to be re-written to account

for any difference. Besides, the part has its own datum, and NC programs

written in reference to the Part Datum are lot easier to understand.

E-4

Mastercam X5

CNC Setups

Any point on the part or fixture can be used to find the part datum, as long

as you can reliably measure its position.

In this example, Exercise 3-9, Fixture Plate, the material is machined to

finished size before loading it into a standard six-inch vise with step jaws.

The top of the finished material is Z-Datum.

The fixed (back) vise jaw is dial indicated parallel to the machine X-axis.

A Vise Stop, in this case an adjustable rod, allows stock material to be

loaded into the vise in the exact same position each time.

The part datum must be located precisely; typically +/- .001 or less. There

are many ways to find the part datum. In this example, the XY-Datum is

easily found using and Edge Finder to locate the back and left edges of the

part.

Vise

Stop

Back Edge of

Fixed Jaw

Parallel To

Fixed

Jaw

Movable

Jaw

Back

Edge

Stock c ut

Step

Jaws

Z

Y

Mastercam Handbook Volume 1

E-5

Appendix E

Fixture

Offset

Registers

(G54-G59)

The coordinate system is shifted from Machine Home to the Part Datum

using a Fixture Offset. A fixture offset is simply a record machine

control keeps of the distance between the Machine Home position and the

Part Datum point. Each time the NC program commands a move, the

control checks this record, or Register, and internally adds this value to

that move.

Fixture offsets are usually assigned G-codes G54 thru G59, though some

machines allocate more. Each fixture offset has a XYZ shift value. When

a fixture offset G-code appears in the NC program, the control looks at the

register values for that offset, and adds these values to any subsequent

moves.

In this example, the G54 offset register is called on line (N2) of the NC

program. This line of code moves the center of the spindle from the

Machine Home position to directly above the Part Datum.

Mac hine

Home

Shift_X

N1

N2

Fixture Offset Table On Control

G54 X12.6830 Y -7.1590 Z00.0000

G55 X 00.0000 Y00.0000 Z00.0000

G56 X 00.0000 Y00.0000 Z00.0000

G57 X 00.0000 Y00.0000 Z00.0000

G58 X 00.0000 Y00.0000 Z00.0000

Shift_Y

-7.159

12.683

N1

Part

Datum

N2

G54

Tool

Motion

Sample NC Program

N1 T1 M6

N2 G90 G54 G0 X0. Y0.

N3 S7200 M3

N4 G43 H1 Z1. M8

E-6

Mastercam X5

CNC Setups

You probably noticed that the fixture offset in this example was used only

to shift the datum in X-Y, not Z. This is because the Z shift distance

changes depending on the tool length how far the tool extends below

the center-face of the spindle. Most tools are different lengths. Length

may even change when you replace a worn or broken tool.

Tool

Length

Offsets

(H)

Shifting the Z-datum is accomplished using Tool Length Offsets. Tool

offsets work similar to fixture offsets; letting the machine know the

location of the tip of the tool in relation to the part Z-datum. Each tool has

its own Tool Length Offset number. For most machines, this is an Hvalue that is the same number as the tool (T1 uses H1, T2 uses H2, etc).

The H-value is called in the G-code file with the first rapid move to depth

along with a G43 (Read Tool Height Offset Register). This causes the

machine to look at the H-register value and add this to the move.

Mac hine

Home

Tool Offset Ta ble On Control

Tool# Height (H) Dia (D)

1

-11.913

00.0000

2

00.000

00.0000

3

00.0000

00.000

N2

N4

Part

Datum

N5

Shift_Z

Tool

Length

Home Z-Datum

To

Part Z-Datum

Sample NC Program

N1 T1 M6

N2 G90 G54 G0 X0. Y0.

N3 S7200 M3

N4 G43 H1 Z1. M8

N5 Z0. F3.

Mastercam Handbook Volume 1

Shift_Z

(-11.913)

N4

N5

E-7

Appendix E

The previous illustration shows the simplest way to use tool length offsets.

This method is widely used in prototype and short production work.

The tool is jogged to the Part Z-Datum (in this case, the top of the

part).

The incremental distance moved in Z from the home position to

the top of the part is recorded and entered in the appropriate Tool

Length Register.

This value represents the shift in Z from the machine home to the

Z-Datum of the part.

The value is usually negative; the machine subtracts this value

from the Z-position of the spindle, shifting the tool down towards

the part.

Another method uses what is called preset tooling. This is used more

often in larger companies and long production run work:

The tool length (distance from the center-face of the spindle to the

tip of the tool) is accurately measured in the tool room.

This gage length is entered in the tool-offset register as a positive

value.

The fixture offset Z-value represents the distance from the centerface of the spindle to the part Z-datum.

Internally, the control first subtracts the fixture offset from a

command move. It then adds the tool gage length to the move.

Some machines have automatic tool probes which measure the length

automatically. Follow the instructions in the machine operator manual

for use of tool and fixture offsets with a probe.

There are other ways to use fixture and tool offsets. They all work, and

companies have good reasons to adopt a particular method. But, once

you understand how fixture and tool offsets work, will easily adapt to

whatever method your company or school uses.

E-8

Mastercam X5

CNC Setups

Plate work refers to machining sheets or plates of material. The material

is manufactured to a specified thickness that is the same as the finish

thickness of the part, so no facing operation is required.

CNC

Setups

The purpose of the fixture plate is to accurately locate the stock material

and then keep the part from moving during machining.

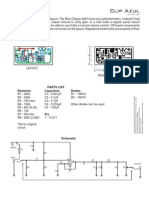

The illustration below shows a typical fixture plate. The fixture base is

machined flat, square, and parallel. Notice the plate is engraved with the

part name and coordinates of the part datum in reference to the upper-left

corner. This makes it easier to reuse the fixture plate.

A) Fixture Base

B) Clamp (2X)

C) Dowel Pin (3X)

D) Washer (2X)

E) Bolt (4X)

Mastercam Handbook Volume 1

E-9

Appendix E

Example

Fixture

Plate

The fixture plate below shows the setup just before the first machining

operation. After the holes are drilled and bolts inserted through the part,

the dowel pins and clamps should be removed if there is any possibility of

a collision with the tool or holder.

Stock Material

Aluminum Sheet

5.0 x 2.5 x .063

Aluminum Base

6.0 x 5.0 x .625

Clamp

.5 x 1 x .25

Dowel Pin

.250 x .625

Bolt

1/4-20 x .75

1/4-20 Tapped Thru

E-10

Reamed Hole

.251 x .375 Deep

Vent Hole

.093 Thru

Mastercam X5

CNC Setups

Component

Fixture

Plate

Stock

Description

This is the base on which the fixture is built. For short

production and prototype parts, an aluminum plate is

commonly used. It is machined flat, square and parallel.

Fixture

Plate

Components

De-burr all sharp edges and holes so the stock lies flat on

the surface and is not scratched.

Sheet aluminum stock that is within specification in

thickness.

Since a OD contour cut is made all around the part, stock

can be sheared or saw cut to approximate size.

Dowel Pins

Washers

Cap

Screws

Clamps

De-burr and inspect material before placing it in the

fixture.

Dowel holes are drilled and reamed to a diameter of .251 x

.375 deep providing a slip fit in the holes.

A .093 vent hole is drilled from the bottom of the reamed

hole through the bottom of the plate. This allows air to

enter into the space between the bottom of the dowel pins.

Without it, the dowel may become impossible to remove

due to the vacuum created with a blind hole.

Steel cap screws will mar aluminum. Place an aluminum

washer or pad between clamps and an aluminum surface.

Two screws hold the clamps in place during drilling

operations. Others are installed to hold the plate down

during the OD contour cut.

Simple shop-made aluminum clamps hold the part during

drilling.

Mastercam Handbook Volume 1

E-11

Appendix E

Components

Specifications

Component

Fixture

Plate

Stock

Dowel Pins

Specification

6061-T6 Aluminum

Width: 6.00

Height: 4.25

Thickness: .625 (5/8)

6061-T6 Sheet Aluminum

Width: 6.00

Height: 4.25

Thickness: .063

Ground Steel

Diameter: .250

Height: .625 (5/8)

Install: .375 Deep

McMaster-Carr p/n:

Washers

Cap

Screws

Aluminum

ID:.266

OD:.50

Thickness: .064

-20 Socket Head

OD: .250 Thread

Head Dia: .375

Grip Length: .75

McMaster-Carr p/n:

Clamps

E-12

6061-T6 Aluminum

Width: .5

Height: 1.0

Thickness: .25

Step: .063

D-Hole: .26 WD x .50 HT

Shop Made

Mastercam X5

CNC Setups

The following steps show how a simple fixture plate may be setup and

used on a vertical machining center.

Process

Overview

Setup

1) Fixture can be clamped to

machine table or clamped in a

vise.

2) Vise fixed jaw is aligned with

machine X-axis.

3) Left-Back edge of fixture can

be located as a reference point.

Step 1: Load Material

1) Inspect stock material

2) Slide Stock Against Dowels

3) Tighten Clamps

4) Remove Dowel Pins if any

Possibility of collision.

Step 2: Drill Holes

1) Spot Drill (2X)

2) Drill .250 Holes Thru Part (2X)

Remove dowel pins after clamps are tightened if there is any

chance of the tool impacting the pins.

Mastercam Handbook Volume 1

Warning

E-13

Appendix E

Step 3: Install Bolts

1) Ensure holes are clear

2) Install 1/4-20 Cap Screws

and Aluminum Washers

Step 4: Contour OD

1) Machine OD with 3/16 End

Mill.

2) Provide sufficient lead-in to

Clear stock.

Step 5: Prepare For Next Part

1) Remove remnant

2) Clear area and holes

3) Install Dowel Pins

4) Inspect part

5) Handle part carefully to

Prevent marring or damage.

The machine operator is responsible for part quality. This is more

than just adjusting a machine offset to ensure the part is within

specification.

Remember

E-14

Exercise care when handling parts, and keep a clean work area.

Strive to deliver quality in everything you do. Parts that are

properly de-burred and are not marred in any way by mishandling

are the mark of a professional machinist.

Mastercam X5

CNC Setups

In cases where you need to position a plate with existing holes, never rely

on threaded holes to locate the part. Instead us Shoulder Bolts (aka

Stripper Bolts).

Shoulder

Bolts

Counterbore a hole in the fixture plate the diameter of the bolt shank.

Drill and tap a hole in the bottom of this counterbore to screw in the

shoulder bolt.

Shoulder Bolt

Ground Shank

Located in Counterbore Hole

Shoulder Bolt Usage

Mastercam Handbook Volume 1

E-15

Appendix E

Notes:

E-16

Mastercam X5

Das könnte Ihnen auch gefallen

- Readme MillplusDokument2 SeitenReadme MillplusVagner Aux CadNoch keine Bewertungen

- Smoke On The Water TablatureDokument1 SeiteSmoke On The Water Tablaturetanuxi2Noch keine Bewertungen

- Mill Post InfoDokument1 SeiteMill Post InfoVagner Aux CadNoch keine Bewertungen

- EdgeCAM 2015Dokument12 SeitenEdgeCAM 2015Daniela UlianNoch keine Bewertungen

- Victim of Partner ViolenceDokument1 SeiteVictim of Partner ViolenceVagner Aux CadNoch keine Bewertungen

- Post Processor ManualDokument16 SeitenPost Processor ManualVagner Aux CadNoch keine Bewertungen

- Install and Activate CAMWorks LicenseDokument3 SeitenInstall and Activate CAMWorks LicenseminizeusNoch keine Bewertungen

- MosFET BoosterDokument1 SeiteMosFET BoosterGustavoTfLaNoch keine Bewertungen

- Boost your CAM workflow with an integrated WinTool libraryDokument23 SeitenBoost your CAM workflow with an integrated WinTool libraryVagner Aux CadNoch keine Bewertungen

- Win. Loader W7Dokument26 SeitenWin. Loader W7Roberto Giner PérezNoch keine Bewertungen

- Pepe fk40 v3 2012 11 16Dokument1 SeitePepe fk40 v3 2012 11 16Vagner Aux CadNoch keine Bewertungen

- Espritsolution ReportgeneratorDokument2 SeitenEspritsolution ReportgeneratorVagner Aux CadNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeVagner CncNoch keine Bewertungen

- Blue ClipperDokument1 SeiteBlue ClipperAugusto FigueiraNoch keine Bewertungen

- Boost your CAM workflow with an integrated WinTool libraryDokument23 SeitenBoost your CAM workflow with an integrated WinTool libraryVagner Aux CadNoch keine Bewertungen

- LicenseDokument6 SeitenLicensemerrysun22Noch keine Bewertungen

- Introduction To The ESPRIT Post ProcessorDokument21 SeitenIntroduction To The ESPRIT Post Processordaedalus0x1a4100% (8)

- Lgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerDokument2 SeitenLgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerVagner Aux CadNoch keine Bewertungen

- Lgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerDokument2 SeitenLgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerVagner Aux CadNoch keine Bewertungen

- Tonepad OctaviarmDokument1 SeiteTonepad OctaviarmVagner Aux CadNoch keine Bewertungen

- LicenseDokument6 SeitenLicensemerrysun22Noch keine Bewertungen

- Lgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerDokument2 SeitenLgjo Sdijhgosdjrgoásejhnrgnedgrstmb Weropbym W4ipe5uqvo 4hrt5i9q43r5tykwerjnguiertnghoeratmnhbioerVagner Aux CadNoch keine Bewertungen

- Fanuc LogDokument1 SeiteFanuc LogVagner Aux CadNoch keine Bewertungen

- ReadmeDokument3 SeitenReadmeAbhiyan Anala ArvindNoch keine Bewertungen

- HistoryDokument7 SeitenHistoryVagner Aux CadNoch keine Bewertungen

- Siemens CommandsDokument4 SeitenSiemens Commandsemaster1Noch keine Bewertungen

- Offset BugDokument1 SeiteOffset BugVagner Aux CadNoch keine Bewertungen

- GhvkgfhkgfgvjhfgulfyljgvuyfjlhgvuylfjlhgulyfjlguyfjlhfgvuyfutfljvulfuDokument1 SeiteGhvkgfhkgfgvjhfgulfyljgvuyfjlhgvuylfjlhgulyfjlguyfjlhfgvuyfutfljvulfuVagner Aux CadNoch keine Bewertungen

- The Complete Book of Scales and Arpeggios For Guitar PDFDokument50 SeitenThe Complete Book of Scales and Arpeggios For Guitar PDFLais Garcia75% (4)

- Album ReviewDokument1 SeiteAlbum ReviewVagner Aux CadNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Milling Machine Report DelyDokument10 SeitenMilling Machine Report DelyFazdly Azilan0% (2)

- Advanced Fixture Design For FMSDokument214 SeitenAdvanced Fixture Design For FMSM MNoch keine Bewertungen

- Machining Process Guide: Drilling & Related OperationsDokument34 SeitenMachining Process Guide: Drilling & Related OperationsNajshhs100% (1)

- Broaching NotesDokument5 SeitenBroaching NotesfaNoch keine Bewertungen

- 7.clamping and Clamping DevicesDokument87 Seiten7.clamping and Clamping Deviceskalu kioNoch keine Bewertungen

- Jigs and FixturesDokument16 SeitenJigs and FixturesSwayan Prakash KhuntiaNoch keine Bewertungen

- Computer Aided Process Planning (CAPPDokument21 SeitenComputer Aided Process Planning (CAPPPethurajNoch keine Bewertungen

- Jig and Fixtures For 2023 GATE ESE & PSUs by S K MondalDokument8 SeitenJig and Fixtures For 2023 GATE ESE & PSUs by S K Mondallokeshkaushik125077Noch keine Bewertungen

- The Process Map by Doug Sanders, Bill Ross, and Jim ColemanDokument10 SeitenThe Process Map by Doug Sanders, Bill Ross, and Jim ColemanLuiza GonzattoNoch keine Bewertungen

- Woodworking US ElectronicDokument4 SeitenWoodworking US ElectronicAnonymous z4Fe39jNoch keine Bewertungen

- Project Jig & Fixture UTMDokument90 SeitenProject Jig & Fixture UTMadibah ismail100% (1)

- The Chopper Builders Handbook Notch-O-Matic' Tube Notcher The DesignDokument26 SeitenThe Chopper Builders Handbook Notch-O-Matic' Tube Notcher The Designgww25100% (2)

- 15mec243 - Tool Design: VII Semester - Elective Mechanical EngineeringDokument17 Seiten15mec243 - Tool Design: VII Semester - Elective Mechanical Engineeringvignesh100% (1)

- AAMA 320-10: General Guidelines For Troubleshooting Welded Thermoplastic CornersDokument17 SeitenAAMA 320-10: General Guidelines For Troubleshooting Welded Thermoplastic CornersDavidNoch keine Bewertungen

- Motorised Hammer Project ReportDokument35 SeitenMotorised Hammer Project ReportRaja ManeNoch keine Bewertungen

- Project Report on Time Study and Work Content of Captain Line ProductionDokument53 SeitenProject Report on Time Study and Work Content of Captain Line ProductionDipak TiwariNoch keine Bewertungen

- DJF51072 Jig & Fixture Design for Drilling ProcessDokument11 SeitenDJF51072 Jig & Fixture Design for Drilling ProcessAqwa LuffyNoch keine Bewertungen

- CNC Turning Center Operating ManualDokument84 SeitenCNC Turning Center Operating ManualCezar BalașeiNoch keine Bewertungen

- Astm D4541 09 PDFDokument16 SeitenAstm D4541 09 PDFBayron CardenasNoch keine Bewertungen

- Low Cost Automationlca A Case Study PDF Download A - 59822ea21723ddec5675c5bfDokument10 SeitenLow Cost Automationlca A Case Study PDF Download A - 59822ea21723ddec5675c5bfRobinson PrabuNoch keine Bewertungen

- F Tool EngineeringDokument23 SeitenF Tool EngineeringGiduthuri Es Prakasa RaoNoch keine Bewertungen

- Detroit Type of AutomationDokument84 SeitenDetroit Type of AutomationMunaf AcademyNoch keine Bewertungen

- AFM CFD Simulation ThesisDokument129 SeitenAFM CFD Simulation ThesisRanveer AubeeluckNoch keine Bewertungen

- Elements of Workshop Technology: U J I I IDokument357 SeitenElements of Workshop Technology: U J I I IRaunak Gupta100% (1)

- DEMMELER Katalog Proizvoda 2016Dokument190 SeitenDEMMELER Katalog Proizvoda 2016predragstojicicNoch keine Bewertungen

- Motorised Hammer Project ReportDokument35 SeitenMotorised Hammer Project ReportRaja ManeNoch keine Bewertungen

- MFIM08Dokument4 SeitenMFIM08Ermias AswessieNoch keine Bewertungen

- Gear SolutionDokument16 SeitenGear SolutionmadhavikNoch keine Bewertungen

- Chapter-1 3Dokument11 SeitenChapter-1 3berinolesterrickNoch keine Bewertungen

- Conveyor Assembly Manual PDFDokument68 SeitenConveyor Assembly Manual PDFzaiayra71Noch keine Bewertungen