Beruflich Dokumente

Kultur Dokumente

Design of Masonry Structures With Bed Joint Reinforcemnt

Hochgeladen von

Subhranshu DwibediCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Masonry Structures With Bed Joint Reinforcemnt

Hochgeladen von

Subhranshu DwibediCopyright:

Verfügbare Formate

See

discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/237628228

DESIGN OF MASONRY STRUCTURES WITH BED

JOINT REINFORCEMENT

ARTICLE JANUARY 2007

DOWNLOADS

VIEWS

90

48

1 AUTHOR:

Andrea Penna

University of Pavia

84 PUBLICATIONS 421 CITATIONS

SEE PROFILE

Available from: Andrea Penna

Retrieved on: 29 June 2015

Seminrio sobre Paredes de Alvenaria, P.B. Loureno et al. (eds.), 2007

21

DESIGN OF MASONRY STRUCTURES WITH BED JOINT

REINFORCEMENT

Andrea PENNA

Researcher

EUCENTRE

Pavia, Italy

Gian Michele CALVI

Professor and Head

EUCENTRE

avia, Italy

Davide BOLOGNINI

Research Engineer

EUCENTRE

avia, Italy

ABSTRACT

Bed joint reinforcement is a easy solution to improve significantly the structural performance

of masonry walls, both for in-plane and out-of-plane response. The experimental tests

summarised in the paper show the increment of lateral strength and displacement capacity, as

well as energy dissipation, of both horizontally reinforced in-fill panels and masonry bearing

walls. The comparison with other reinforcement techniques shows relevant advantages of bed

joint reinforcement. Design tools have been developed for bed joint reinforcement made of

prefabricated steel trusses and strength criteria are proposed for masonry piers with only

horizontal reinforcement.

1. INTRODUCTION

The use of bed joint reinforcements in brick or block masonry is a easy and intuitive method which

has been traditionally used and suggested in many reinforced masonry solutions, both for infill

panels and bearing walls.

Among others, the benefit of such technical improvement are both structural and practical:

Bed joint reinforcements can be easily placed in the horizontal mortar layers, without any significant

modification to the construction scheme;

Rebar horizontal reinforcement can be lodged within the thickness of traditional mortar layers (1 2

cm) or, in case of thin mortar layers (1.5-3 mm), they have to be combined with special grooved

blocks;

Truss reinforcement improve the structural effectiveness of bed joint reinforcement both reducing

anchoring lengths and allowing the transversal connection of double veneer walls;

Design of masonry structures with bed joint reinforcement

22

Rounded truss reinforcement can be used in masonry walls with traditional mortar layers and flat

truss reinforcement in thin mortar layers;

The presence of even slight horizontal reinforcement is very effective in cracking control;

Masonry spandrel beams and lintels can be easily built using bed joint reinforcements which

provide flexural strength;

As shown in the following strength, displacement capacity and energy dissipation can be

significantly enhanced in horizontally reinforced masonry piers, with an important improvement of

the seismic response, in particular;

Horizontal slight reinforcement of infill panels provides damage reduction and enhancement of both

in plane and out of plane lateral capacity, with possible beneficial effects also on the overall

structural behaviour to wind and earthquake loading.

Although these technology has been planned for new constructions and typically it is carried out

using steel reinforcement, various attempts have been done in order to obtain feasible retrofitting

techniques which benefit from the use of horizontal reinforcements, but, even using stainless steel of

other materials which are protected against corrosion, no generally applicable methods have been

developed

2. IN-FILL MASONRY WALLS WITH BED JOINT REINFORCEMENT

As suggest first by Klingner and Bertero [5] and Brokken and Bertero [2], who have investigated

the behaviour reinforced infill panels, slight reinforcements can provide superior performance, in

terms of strength, stiffness, and energy dissipation, compared with a bare frame.

Starting form suggestions Calvi and Bolognini [3] have performed researches oriented to

compare the in plane response of traditional and slightly reinforced hollow masonry infill

panels, for different intensity level earthquakes, in order to assess the potentially different

damage level attained; to assess the potential for out of plane expulsion of traditional and

slightly reinforced masonry infill panels, at different level of damage induced by in plane

action; to evaluate the effects of different properties of the infill panels on the response of

buildings with different geometrical configurations and different distribution of the infill

panels, in terms of PGA required to induce given level of damage.

Penna et al. [9] have then extended these experimental results in order to assess their value to a

different kind of infill walls, made of aerated autoclaved concrete blocks, with a significant

thickness (30 cm) and with thin mortar layers.

2.1. Hollow clay bricks with traditional bed joints

The main test campaign was performed on one-bay, one-storey full scale infilled frames,

considering one single geometry and one single type of clay unit, for obvious budget reasons.

Three possible reinforcement conditions were compared: no reinforcement, reinforcement in

the mortar layers at 600 mm distance and light wire meshes in the external plaster. Interstorey

drifts equal to 0.1, 0.2, 0.3 and 0.4 % were considered relevant for serviceability low damage

limits states and drifts equal to 1.2 and 3.6 % were considered significant to explore heavy

damage or close to collapse limit states. At different levels of in plane drifts, out of plane tests

were performed to define strength domains as a function of in plane damage.

The clay blocks were selected as typical highly perforated units used in the European

earthquake-prone countries, with the following properties.

A. Penna, M.G. Calvi, D. Bolognini

23

The horizontal reinforcement used for the mortar layers consisted of either two 6 mm re-bars with

578 MPa yield strength, 638 MPa ultimate strength and 24 % elongation capacity measured on 5

diameters, or by a welded truss made with two 5 mm bars with 630 MPa yield strength, 690 MPa

ultimate strength and 16.5 % elongation capacity measured on 5 diameters (10.5 % on ten

diameters, 3.34 uniform at maximum stress).

Figure 1: Details of the position of the steel bars and of the meshes to reinforce masonry

panels (after [3])

As already pointed out, a single geometry was considered for the main test campaign on full scale

infilled frames. The overall dimensions were selected to be 4.5 3 (height) m. The concrete frame

was designed as the lowest part of a four storey building, applying thoroughly the rules given by

Eurocode 2 and Eurocode 8. The structure was designed according to the high ductility class of

EC8, applying fully the capacity design rules. The plastic hinges were therefore forced to form in

the beams and all critical sections were well confined. The standard EC8 spectrum defined for

medium density soils was used. All infill panels had identical geometry, with dimensions equal to

4200 2750 135 mm. The thickness resulted from the combination of block thickness (115 mm)

plus 10-mm plaster on both sides.

As already indicated, three reinforcement types were then considered: no reinforcement,

reinforcement in the mortar layers, and external reinforcement. The mortar layer reinforcement was

spaced at 600 mm, resulting in a geometrical percentage between 0.08 and 0.1 %, depending on the

Design of masonry structures with bed joint reinforcement

24

diameter of the bars used (see the previous section). Note that the total steel weight used for each

panel was less than 100 N for the case of layer reinforcement.

All tests were performed applying first two vertical loads on the columns, to simulate the presence

of the upper storeys. No vertical load was placed on the beam, accepting this small difference from

reality. The total vertical load was then kept constant during the tests, allowing the redistribution

generated by the application of horizontal forces.

The in-plane tests were performed applying horizontal displacements cycles, according to predefined targets between 0.1 and 3.6 % drift, as discussed later. As standard, three cycles were

performed at each target displacement.

The out-of-plane tests were performed at different levels of in-plane damage (i.e. after

having reached different drift levels in the in-plane tests) .

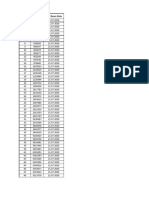

A summary of the in-plane tests performed is presented in Table 1. The sequence of drift

targets has been adjusted during the test campaign, to explore the response for close-tocollapse limit states (drifts at 1.2 % or larger) and for serviceability limit states (drift below

0.4 %). In some cases, the in-plane tests were continued after out of plane expulsion of the

infill panels, essentially to verify the ultimate response of the frame alone.

Table 1: Summary of the in-plane tests

Reinforcement

Test

n.

Drift

0.1%

0.2%

0.3%

0.4%

1.2%

3.6%

0.4%

bare frame

non-reinforced

3*

6 mm bars

5 mm bars

3*

mesh

3*

non-reinforced

3*

6 mm bars

3*

5 mm bars

3*

9

3

3

3

3*

* = cycles preceding the out-of-plane test

mesh

The force-displacement curves obtained from the first five tests are depicted in Figure 2.

25

450

450

400

400

350

350

300

300

250

250

200

200

150

150

100

100

50

F [kN]

F[kN]

A. Penna, M.G. Calvi, D. Bolognini

0

-50

50

0

-50

-100

-100

-150

-150

-200

-200

-250

-250

-300

-300

-350

-350

-400

-400

-450

-450

-120

-100

-80

-60

-40

-20

20

40

60

80

100

120

-120

displacement [mm]

-100

-80

-60

-40

-20

20

40

60

80

100

120

40

60

80

100

120

displacement [mm]

Test 2: unreinforced panel

450

400

400

350

350

300

300

250

250

200

200

150

150

100

100

50

F [kN]

F[kN]

Test 1: bare frame

450

50

0

-50

-50

-100

-100

-150

-150

-200

-200

-250

-250

-300

-300

-350

-350

-400

-400

-450

-450

-120

-100

-80

-60

-40

-20

20

40

60

80

100

120

-120

Displacement [mm]

Test 3: 6 mm re-bars mortar layer

reinforcement

-100

-80

-60

-40

-20

20

Displacement [mm]

Test 4: 5 mm truss mortar layer reinforcement

Figure 2: Force-displacement curves obtained from tests

The initial stiffness of infilled frames is significantly larger than the stiffness of the bare frame,

with no significant influence from the presence of the reinforcement. In all cases the curves

produced by the infilled frame response tend to return to the bare frame curve at drifts values

relevant to a collapse limit state, being therefore confirmed that the equivalent period of

vibration for high intensity earthquakes is not significantly affected by the presence of the

infills, since the effective stiffness essentially corresponds to the stiffness of the bare frame.

The energy dissipation for low amplitude cycles is much larger for infilled than for bare

frames, confirming that a reduced global response can be expected if local failure modes can be

excluded. All kinds of reinforcement are effective in avoiding or significantly reducing the

strength deterioration of the panels. The presence of 5 or 6 mm diameter bars, in the form of rebars or trusses does not significantly affect the results.

The apparent state of damage of the panels at drifts equal to 0.2 % and 0.4 % is depicted in

Figure 3. The beneficial effect of a mortar layer reinforcement is evident. The evidence for this

latter case is that during the test large cracks open between panel and frame, without significant

damage in the panel. Not only then the damage is limited, but also easy to be repaired.

Design of masonry structures with bed joint reinforcement

Unreinforced panel: 0.2 % drift

26

Unreinforced panel:0.4 % drift

Mortar layer reinforcement: 0.4 % drift

Mortar layer reinforcement: 0.2 % drift

Figure 3: State of damage after three cycles at 0.2 % and 0.4 % drift; test 9 at 2 % drift showed

essentially no damage

The main results obtained from the out-of-plane tests are summarised in Table 2 and in Figures

4. The effects of presence of reinforcement and of previous in-plane damage on the failure

domain of the panels are evident in the figures and quantitatively shown in the table. For the

unreinforced, undamaged panel, the local acceleration required to induce collapse is around 2.5

g, but reduces to 0.5 0.7 g after some in-plane damage. The presence of some bed joint

reinforcement increases these values approximately to 2.8 and 1.4 g.

The limited displacement capacity of unreinforced panels, results in longer period of vibration,

which in turn may result in larger amplification when combined with the main period of vibration of

the building. While these figures have obviously a relative meaning, being related to a specific panel

geometry, it is immediately clear that very large PGAs would be necessary to induce out-of-plane

collapse in reinforced panels.

Table 2: Summary of the out-of-plane tests. For all panels the total area was 11.55 m2 and the

total mass 1360 kg

Reinforcement

Test

n.

Previous

in-plane drift

Force

[kN]

Displ. 2

[mm]

Acceleration 3

[g]

Eq. Pressure 4

[kPa]

Stiffness 5

[kN/m]

Period

[s]

non-reinforced

1.2%

6.00

0.460

1.00

180

0.546

bars

Murfor

0.4%

17.20

53

1.289

2.87

5160

0.102

mesh

1.2%

21.41

22

1.605

3.57

2676

0.142

non-reinforced

0.4%

9.00

37

0.675

1.50

720

0.273

bars

0.4%

19.70

44

1.477

3.28

2814

0.138

Murfor

0.4%

17.50

48

1.312

2.92

1400

0.196

0.4%

46.60

28

3.493

7.77

11184

0.069

10

11

33.70

36.77

13

45

2.526

2.756

5.62

6.13

11642

11977

0.068

0.067

mesh

non-reinforced

1

Murfor

1 Test executed on the panel with no damage

2 Ultimate displacement

3 Acceleration corresponding to the maximum transversal force (with the total mass participating)

4 Equivalent uniform pressure giving to the panel the same maximum bending moment as the four concentrated forces

5 Secant stiffness calculated between the 10% and 40% of the strength of the panel

A. Penna, M.G. Calvi, D. Bolognini

27

50

30

20

5mm bars (test 11)

Non-reinforced (test 10)

5mm bars (test 08)

Non-reinforced (test 06)

30

Force [kN]

40

Force [kN]

40

Non-reinforced (test 06)

6mm bars (test 07)

5mm bars (test 08)

Mesh (test 09)

20

10

10

0

0

-10

-20

-30

-40

-50

Average displacement [mm]

-60

-10

-20

-30

-40

-50

Average displacement [mm]

After three cycles at 0.4 % in-plane drift

Undamaged panels and panels previously

driven to 0.4 % in-plane drift

Figure 4: Comparison of force-displacement curves obtained from out-of-plane tests performed

on differently reinforced panels

2.2. AAC infill walls with thin mortar layer

The same frame geometry and testing conditions were adopted for the in plane cycic tests of

the infilled frames and for the out-of-plane test on the in-plane damaged infill panels. In this

case AAC blocks with thin mortar layer and filled vertical joints were used for all the infill

panels with the different reinforcement solutions.

The experimental campaign on AAC masonry infilled r.c. frames included the following

reinforcement techniques:

Unreinforced AAC infill panel;

AAC infill panel reinforced by horizontal bars lodged in special grooved blocks every second

mortar layer (i.e. with a vertical spacing of 500 mm);

AAC infill panel reinforced by a mid-height r.c. tie beam realized special U-shaped blocks;

AAC infill panel reinforced by flat truss reinforcement every second bed joint;

AAC infill panel with a central opening (door) reinforced by flat truss reinforcement every

second bed joint

The AAC blocks used for the tests had the following dimensions: 250 mm height, 300 mm

thickness and 625 mm length. U-shaped blocks and blocks with circular vertical holes (150

mm diameter) were used to cast in place the r.c. light frame surrounding the door in the last

specimen. No mechanical devices were placed at the interfaces between the frame structure and

the infill panel.

The in-plane cyclic force-diplacement response of the unreinforced panel is represented in

Figure 5 and the final damage is reported in Figure 6.

Design of masonry structures with bed joint reinforcement

28

500

400

300

200

Force [kN]

1,20%

100

1,00%

0,80%

0,60%

0,40%

0

-40

-30

-20

-10

10

20

30

40

0,20%

0,10%

Interp.

-100

-200

-300

-400

-500

Displacement [mm]

Figure 5. Cyclic force-displacement response of the r.c. frame infilled with the unreinforced

AAC masonry panel

With respect to the bare frame, the lateral strength in more than doubled, the initial stiffness

significantly increased and the hysteresis cycles enlarged. The test has been carried out up to

1.2 % drift.

Cracking pattern after 0.8 % drift cycles

The specimen at the end of the in plane tests

Figure 6. Final damage pattern to the AAC unreinforced infill panel after the in-plane tests

In Figure 7 it is reported the cyclic in plane response of the frame with mid-height reinforcement

obtained by r.c. tie beam, cast in place in special U-shaped AAC blocks.

600

500

400

300

200

2,40%

1,80%

1,20%

Collante

Forza [kN]

100

5 barre 10 mm +

staffe 6 mm passo 20 cm

1,00%

0,80%

0

-80

-60

-40

-20

20

40

60

80

0,60%

0,40%

-100

0,20%

0,10%

calcestruzzo

-200

-300

canaletta armata

-400

-500

-600

Spostamento [mm]

Scheme of the mid-height beam reinforced

specimen

Cyclic force-displacement curve

Figure 7. Scheme and in-plane lateral response of the mid-heigth reinforced specimen

Interp.

A. Penna, M.G. Calvi, D. Bolognini

29

The force-displacement response of these tests, carried out up to 3.6 % drift, show a similar

cyclic behaviour with a further increase lateral strength. On the other hand, Figure 8 show that

a significant damage distribution to the infill panel is concentrated along the r.c. beam and, as

shown in Figure 9, cracks also occur in the frame columns

Cracking pattern after 1.0 % drift cycles

The specimen at the end of the in

plane tests

Figure 8. Final damage pattern to the AAC infill panel with mid-height tie beam after the inplane tests

Figure 9. Damage to the frame columns due to the mid-height r.c. beam

In Figure 10 it is reported the cyclic in plane response of the frame with bed joint reinforced infill

panel by means of grooved special blocks every second layer.

Design of masonry structures with bed joint reinforcement

30

600

500

400

300

200

2,40%

1,80%

1,20%

Force [kN]

100

1,00%

0,80%

0

-80

-60

-40

-20

0,60%

0

20

40

60

80

0,40%

0,30%

-100

0,20%

0,10%

-200

Interp.

-300

-400

-500

-600

Displacement [mm]

Figure 10. Cyclic force-displacement response of the bed joint reinforced infilled frame (rebars

in special blocks)

The initial stiffness in not affected by the presence of the reinforcement, the displacementductility capacity is increased and a softening branch of the envelope curve can be related to

the observed shear failure mode (Figure 11).

Cracking pattern after 1.8 % drift cycles

The specimen at the end of the in plane

tests

Figure 11. Final damage pattern to the AAC infill panel with rebar reinforcement

In Figure 12 it is reported the cyclic in plane response of the frame with horizontal flat truss

reinforcement placed every second mortar layer.

A. Penna, M.G. Calvi, D. Bolognini

31

600

500

400

300

200

3,60%

2,40%

1,80%

Force [kN]

100

collante

1,20%

1,00%

0

-150

-100

-50

0,80%

0

50

100

150

0,60%

0,40%

-100

0,20%

0,10%

-200

Interp.

-300

-400

Giunto con traliccio Murfor piatto:

-500

-600

Displacement [mm]

Scheme of the flat truss horizontally reinforced

specimen

Cyclic force-displacement curve

Figure 12. Scheme and in-plane lateral response of the AAC infilled frame with flat truss

reinforcement

The initial stiffness in not affected by the presence of the reinforcement, the displacementductility capacity is increased and the strength plateau is due to the sliding mechanism, with

friction, on the unreinforced mortar joints.

Cracking pattern after 1.0 % drift cycles

The specimen at the end of the in plane tests

Figure 12. Final damage pattern to the AAC infill panel with flat truss reinforcement

Figure 13 shows the cyclic the final damage pattern and the force-displacement curve obtained

for the horizontally reinforced AAC infilled frame with a central door. Although the lateral

strength is obviously reduced, it is anyhow significant and the displacement capacity is not

affected by the presence of the opening. The presence of the bed joint reinforcement controls

the damage to the infill panel.

Design of masonry structures with bed joint reinforcement

32

400

300

200

FORZA [kN]

100

0

-120

-100

-80

-60

-40

-20

20

40

60

80

100

120

-100

-200

0,05%

0,10%

0,20%

0,30%

0,40%

0,60%

0,80%

1,00%

1,20%

1,80%

2,40%

3.60%

INVILUPPO

-300

-400

SPOSTAMENTO [mm]

Cyclic force-displacement curve

The specimen at the end of the tests

Figure 13. Results of the test on the infilled frame with a central opening and the horizontal flat

truss reinforcement

A comparison of the envelope curves of the whole experimental campaign is presented in

Figure 14.

600

500

Force [kN]

400

300

200

100

0

REBAR REINFORCEMENT

-100

MID-HEIGHT R.C. BEAM

-200

MURFOR REINFORCEMENT

-300

UNREINFORCED

-400

BARE FRAME

-500

INFILL PANEL WITH OPENING

-600

-120

-100

-80

-60

-40

-20

20

40

60

80

100

120

Displacement [mm]

Figure 14. Force-displacement envelope curves of the performed tests

3. DESIGN OF INFILL BED JOINT REINFORCEMENT

The design of bed joint reinforcement for infill panels is usually governed by the need of reducing

their out-of-plane vulnerability. For these reason the application reported in the following refer to

design tools and applications aiming at this scope.

A. Penna, M.G. Calvi, D. Bolognini

33

3.1. Seismic design tool for steel truss reinforcement

A simple Excel-based tool for seismic design of infill bed joint reinforcement has been developed

by EUCENTRE for Bekaert, according to the EC8 and Italian Seismic Code Ordinanza 3274.

Figure 15. Layout of the infill reinforcement design tool

The structural period of vibration is evaluated according to the EC8 simplified formula

Design of masonry structures with bed joint reinforcement

T1 = Ct H

34

3

4

where Ct is a coefficient depending on the structural typology and construction material, while H is

the total height of the building.

The modulus of elasticity is evaluated as a function of the compressive strength.

In order to evaluate the dynamic interaction effects between the building structure and the infill

wall, it is necessary to evaluate the out-of-plane period of vibration of the infill panel. According to

the simplified hypotesis of a panel restrained to the frame structure by cylindrical hinges, the period

of vibration can be approximated by the following formula:

2 1

1 E t3

Tp = +

L2 H 2 12 m

Where L, H and t are panel length, height and thickness respectively and E is the masonry elastic

modulus, m the mass of a volume unit.

The reinforcement trusses can be subdivided into two typologies depending on the type of line

wirecross section. Horizontal mortar layers can be indeed traditionaI (filled with general purpose

mortar) or very thin ones (with glue-mortar).

The considered seismic action is characterised by an expected maximum Magnitude and by a soil

class.

The importance factor of the non-structural elements is calculated in accordance with the typology

as defined in EC8 (4.3.5.3).

Consistently with the previous assumptions it is possible to define the following values:

Non-structural element importance factor

Peak Ground Acceleration

Soil amplification coefficient

The adopted panel behavoiour factor (q = 2)

The equivalent seismic force acting on the infill wall orthogonally to its plane is given by the

following formula, keeping into account the dynamic interaction between global structural response

and infill panel behaviour:

Fa = Wa S a I / qa

where Wa is the element weight, gI and qa are the importance factor and the behaviour factor

respectively.

The amplification coefficient Sa is given by:

Sa =

ag S

a g S 3 (1 + Z H )

0.5

g 1 + (1 Ta T1 )2

g

where ag S / g is the ratio between the maximum structural acceleration and gravity, Z/H is the ratio

between the panel centroid height from the foundation and the total height of the building (assumed

A. Penna, M.G. Calvi, D. Bolognini

35

equal to 1 for sake of safety), Ta and T1 are the panel vibration period and the structural vibration

period respectively.

The ultimate resisting moment is evaluated according to the hypothesis of 'horizontal beam': by this

calculations the maximum resulting vertical spacing of Murfor joint reinforcements is obtainend: a

minimum vertical spacing of 500 mm is considered according to what reported in the Italian seismic

code, Annex 2 of OPCM 3274/03, at point 5.6.4.

The described method, for safety sake, takes into account the effect of a previous in-plane damage

corresponding approximately to a 0.4% in-plane drift.

4. MASONRY PIERS WITH BED JOINT REINFORCEMENT

Reinforced masonry solutions typically provide that horizontal reinforcement solution are combined

with vertical reinforcement (Tomazevic, 1999 [12]).

Vertical reinforcement improve the flexural lateral strength of a masonry pier, with a significant

upgrading of the cyclic response.

Figure 16. Reinforced masonry (after [12])

The use of bed joint reinforcement is certainly the easiest possibility to provide horizontal

reinforcement. It provides cracking control, flexural reinforcement in masonry spandrel beams and

lintels and, above all, shear reinforcement in masonry piers.

Figure 17. Truss type bed joint reinforcement (after [12])

The truss type reinforcement solution (Figure 17) can be a valid option both for its superior

structural effectiveness and in case of unconnected multi-layered walls (Figure 18).

Design of masonry structures with bed joint reinforcement

36

Figure 18. Use of truss type reinforcement in multi-layered walls (after [12]).

Vertical reinforcement require a different constructive sequence, proper detailing of anchorages and

overlapping zones and the use of special blocks with vertical holes which are typically filled with

concrete.

Bed joint reinforcements, on the other hand, do not require masonry execution modifications, nor

special anchoring solutions. For these reasons the use of this kind of reinforcement is typically well

accepted, also by the workmanships.

Therefore, because of the stated advantages, structural reinforced masonry schemes with only bed

joint reinforcement would be very interesting.

The contribution of horizontal reinforcement to the shear resistance of masonry piers does not really

requires the presence of vertical rebars.

Figure 19. Influence of diffused vertical and horizontal reinforcement on the shear failure mode

(after [10])

The experimental response of horizontally reinforced masonry was initially investigated by

Tomazevic and Zarnic [13]. Penna et al. [9] have recently compared, through an extensive

experimental campaign on full scale AAC bearing walls, the role played by horizontal

reinforcement in improving the seismic performances of such masonry typology.

4.1. Experimental research on bed joint reinforced AAC masonry piers

The experimental campaign performed at EUCENTRE included in plane cyclic tests on full

scale masonry piers with the following structural solutions:

Unreinforced masonry;

Confined masonry with horizontal truss-type bed joint reinforcement;

A. Penna, M.G. Calvi, D. Bolognini

37

Horizontally reinforced masonry, with flat truss steel reinforcement or rebar reinforcement

placed in grooved blocks.

The dimensions of the blocks is the same used for the infill panel tests.

Three in-plane slenderness configurations have been considered and two levels of vertical force

have been applied and kept constant during the test.

A total of 9 specimen have been tested, with constant height (2.75 m) and thickness (30 cm),

and lengths ranging from 1.5 m to 4.5 m.

By means of hydraulic jacks the static vertical loading of 200 kN and 300 kN has been applied.

The considered experimental configurations are reported in the matrix in Figure 20.

REINFORCED MASONRY

PARTIAL REINFORCEMENT UNREINFORCED MASONRY

1500 mm x 2750 mm

20 t

3000 mm x 2750 mm

30 t

20 t

HORIZONTAL

REBARS

20 t

MURFOR +

VERTICAL REBARS

4500 mm x 2750 mm

30 t

30 t

30 t

MURFOR

30 t

HORIZONTAL REBARS

30 t

MURFOR +

VERTICAL REBARS

Figure 20. Matrix of the considered experimental schemes

In Figures 21 and 22 a synthetic comparison of the experimental results, in terms of lateral

force-displacement envelope curves in presented, squat walls (3 m x 2.75 m) and slender walls

(1.5 m x 2.75 m), respectively.

38

Design of masonry structures with bed joint reinforcement

300

250

200

150

FORZA [kN]

100

50

0

-50

-40

-30

-20

-10

10

20

30

40

50

-50

-100

NON ARMATO

-150

ARMATURA ORIZZONTALE - BARRE

-200

ARMATURA ORIZZONTALE - MURFOR

CONFINATO + ARMATURA ORIZZONTALE

-250

-300

SPOSTAMENTO [mm]

Figure 21. Force-displacement envelopes for the squat AAC walls (blue: unreinforced; black;

confined and horizontally reinforced; red: horizontally reinforced).

120

100

80

60

FORZA [kN]

40

20

0

-50

-40

-30

-20

-10

10

20

30

40

50

-20

-40

NON ARMATO

-60

ARMATURA ORIZZONTALE

-80

-100

CONFINATO + ARMATURA

ORIZZONTALE

-120

SPOSTAMENTO [mm]

Figure 22. Force-displacement envelopes for the slender AAC walls (blue: unreinforced;

black; confined and horizontally reinforced; red: horizontally reinforced).

All the slender walls have shown a clear flexural behaviour. The confined masonry solution

provided, with respect to the unreinforced one a significant increment of strength and stiffness

and a relevant upgrading of the displacement capacity. In the case of the bed joint reinforced

wall, the strength and stiffness has been not altered but, due to the reduction of vertical and

diagonal cracking, the lateral displacement capacity has been highly increased.

The unreinforced squat wall has shown a clear shear failure, the horizontally reinforced one a

flexural one and for the confined wall a mixed failure mode has been observed. The confined

masonry solution provided, with respect to the unreinforced one, a significant increment of

strength and displacement capacity. In the case of the bed joint reinforced wall, the stiffness

has been not modified but, due to the prevention of the shear failure mode, the lateral strength

has been slightly increased and the displacement capacity has been enlarged to the same level

of the confined solution.

A. Penna, M.G. Calvi, D. Bolognini

39

4.2. Proposed criterion for shear strength of horizontally reinforced masonry piers

In order to assess the lateral strength of masonry piers with only bed joint reinforcement, the

following shear strength criterion is proposed:

V R = V R, M + V R, H = f v l ' t + f y Ash d ' / s f v lt

Where fv

is the masonry shear strength,

l

is the wall length,

l

is the length of the compressed portion of the wall,

is the steel yield strength,

fy

Ash is the area of the cross section of the bed joint reinforcement,

s

is the vertical spacing of the bed joint reinforcement,

h

is the wall height

and

d = min(l,h)

The results of such a criterion, combined with the flexural strength criteria, well match the

experimental values obtained for the AAC masonry walls, but further investigations and tests

should be addressed to this direction.

5. CONCLUSIONS

Bed joint reinforcement is a easy and practical technique which provides significant

improvements to the in plane and out of plane performances of both masonry walls and infill

panels.

In the infill panels with bed joint reinforcement there is an evident increase in strength,

ductility, energy dissipation capacity and the beneficial effects on the frame structural response

also include a more regular response and damage limitations both to the panel and to the frame.

A easy to use excel based tool has been presented in the paper. It allows the designer to

calculate the required bed joint reinforcement in order to prevent damage and collapse to the

infill panels.

Horizontally reinforced masonry (HRM) can be a valid alternative to currently used

unreinforced, confined and vertically reinforced masonry. The obtained experimental results

show, in particular, the great increment in displacement capacity and the significant

contribution to the shear strength. Truss-type reinforcements appear equivalent to rebars, but

they are easier to use, more regular and requiring shorter anchorage lengths are more effective

in controlling cracking.

A specific strength criterion has been developed and presented in the paper, in order to provide

simple calculation rules which can be well combined to the easiness of construction which can

promote this technology in different countries in the world, improving structural and seismic

safety.

Design of masonry structures with bed joint reinforcement

40

6. REFERENCES

Anthoine A., G. Magonette and G. Magenes, Shear-compression testing and analysis of brick

masonry walls, in G. Duma (ed.), Proc. 10th European conf. on earthquake eng., Vol. 3,

Balkema, Rotterdam, 1995, pp. 16571662.

Brokken, S. and Bertero, V.V. Studies on effects of infills in seismic resistant RC

construction, 1981, Report UCB/EERC, 81-12, University of California, Berkeley

Calvi G. M. and Bolognini, D., Seismic response of reinforced concrete frames infilled with

masonry panels weakly reinforced Journal of Earthquake Engineering, 2001, 5, 153-185.

Costa A. A., Experimental Testing of Lateral Capacity of Masonry Piers. An application to

Seismic Assessment of AAC Masonry Buildings, MSc Dissertation, ROSE School, IUSS

Pavia, 2007.

Klingner R.E. and Bertero V.V. Infilled frames in earthquake-resistant construction Report

EERC/76-32. Earthquake Engineering Research Center, University of California, Berkeley,

CA, USA 1976.

Magenes, G. and Calvi, G.M., In-plane seismic response of brick masonry walls, Earthquake

Engineering and Structural Dynamics, Vol. 26, 1997, pp. 1091-1112.

Magenes G., In-plane cyclic testing of reinforced masonry shear walls, Proc. 11th European

Conference on Earthquake Engineering, 1998 Balkema, Rotterdam, ISBN 90 5410 982 3.

OPCM, no.3274, 2003. Primi elementi in material di criteri generali per la classificazione

sismica del territorio nazionale e di normative tecniche per le costruzioni in zona sismica.

Penna A., Costa A.A., Calvi G.M., 2007, Seismic performance of AAC masonry, Proc. 12th

Italian Nat. Conf. on Earthquake Engineering, Pisa, Italy.

Priestley, M.J.N. and Bridgeman D.O., 1974, Seismic resistance of brick masonry walls,

Bull. Of the New Zealand Nat. Soc. for Earthquake Engineering, 7 (4), pp. 167-187.

Yez, F., Astroza, M., Holmberg, A., Ogaz, O., Behavior of confined masonry shear walls

with large openings. 13th World Conference on Earthquake Engineering, Paper n 3438,

Vancouver, B.C., Canada, August 1-6 2004

Tomazevic, M., 1999. Earthquake Resistant Design of Masonry Buildings, Imperial College

Press, London.

Tomazevic, M. and Zarnic, R., 1984. The behaviour of horizontally reinforced masonry walls

subjected to cyclic lateral load reversals, Proc. 8th European Conference on Earthquake

Engineering, Vol. 4 (LNEC, 1984), pp. 7.6/1-8, Lisbon.

Das könnte Ihnen auch gefallen

- IASbabas Daily Quiz 22nd AugustDokument3 SeitenIASbabas Daily Quiz 22nd AugustSubhranshu DwibediNoch keine Bewertungen

- HTTPSWWW - Irctc.co - Inngettxnmy-Transactionspage Booked Ticket History&eWallet FalseDokument1 SeiteHTTPSWWW - Irctc.co - Inngettxnmy-Transactionspage Booked Ticket History&eWallet FalseSubhranshu DwibediNoch keine Bewertungen

- PreSpot30 Important Keywords Regarding Budgeting, Fiscal PolicyDokument6 SeitenPreSpot30 Important Keywords Regarding Budgeting, Fiscal PolicySubhranshu DwibediNoch keine Bewertungen

- USBR Types Stilling Basins PDFDokument11 SeitenUSBR Types Stilling Basins PDFSubhranshu DwibediNoch keine Bewertungen

- Insights Daily Current Affairs 01 September 2018Dokument10 SeitenInsights Daily Current Affairs 01 September 2018Subhranshu DwibediNoch keine Bewertungen

- PreSpot26 Various FInancial Sector and External Sector KeywordsDokument12 SeitenPreSpot26 Various FInancial Sector and External Sector KeywordsSubhranshu DwibediNoch keine Bewertungen

- Upload List Cse 2019 ME - 0Dokument13 SeitenUpload List Cse 2019 ME - 0Subhranshu DwibediNoch keine Bewertungen

- Sfe (5TH) May15Dokument1 SeiteSfe (5TH) May15Subhranshu DwibediNoch keine Bewertungen

- Hispital List PDFDokument230 SeitenHispital List PDFSubhranshu DwibediNoch keine Bewertungen

- PAR ProcedureDokument116 SeitenPAR ProcedureSubhranshu DwibediNoch keine Bewertungen

- Byju NoemberDokument141 SeitenByju NoemberSubhranshu DwibediNoch keine Bewertungen

- NSP-Traing Canals&Canal Lining ModifiedDokument46 SeitenNSP-Traing Canals&Canal Lining ModifiedSubhranshu Dwibedi100% (1)

- WWW - Tatatele.in EtradeGSM EBillDeskActionDokument1 SeiteWWW - Tatatele.in EtradeGSM EBillDeskActionSubhranshu DwibediNoch keine Bewertungen

- Re: Can Somebody Identify A One Celled Creature?Dokument2 SeitenRe: Can Somebody Identify A One Celled Creature?Subhranshu DwibediNoch keine Bewertungen

- 21 Feb 1992 Male GEN No: Communication Address GATE Exam DetailsDokument1 Seite21 Feb 1992 Male GEN No: Communication Address GATE Exam DetailsSubhranshu DwibediNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 87 - Peter and Lawrence Van Der Merwe - Sanctum of The DeadDokument1 Seite87 - Peter and Lawrence Van Der Merwe - Sanctum of The DeadОлег КацыNoch keine Bewertungen

- Airbus Structural Design ProjectsDokument2 SeitenAirbus Structural Design ProjectsHugues de PayensNoch keine Bewertungen

- Plumbing Plan TipsDokument6 SeitenPlumbing Plan TipsTan Jhie EiyNoch keine Bewertungen

- Design Procedure For Steel Frame Structures According To Bs 5950Dokument46 SeitenDesign Procedure For Steel Frame Structures According To Bs 5950Ali Gaffar100% (2)

- Navi Mumbai Municipal CorpDokument22 SeitenNavi Mumbai Municipal Corppraths100% (2)

- Nfpa 4-7Dokument2 SeitenNfpa 4-7mujahid1137Noch keine Bewertungen

- BT-BD 701 ManualDokument54 SeitenBT-BD 701 ManualIvan BenginNoch keine Bewertungen

- Enclosed Shower BaysetDokument2 SeitenEnclosed Shower BaysetstarykltNoch keine Bewertungen

- Taylor House. Floor Plan W/ Longitudinal and Diagonal Axes. Image Barbara LamprechtDokument8 SeitenTaylor House. Floor Plan W/ Longitudinal and Diagonal Axes. Image Barbara LamprechtJordi TorresNoch keine Bewertungen

- Types of ConstructionDokument2 SeitenTypes of Constructionapo_mallariNoch keine Bewertungen

- Mechanical Design ChecklistDokument2 SeitenMechanical Design Checklisteng_bilalNoch keine Bewertungen

- Borland-Clifford House NominationDokument19 SeitenBorland-Clifford House NominationReno Gazette JournalNoch keine Bewertungen

- Truss ManualDokument10 SeitenTruss ManualRiyaz SiddiqueNoch keine Bewertungen

- High Risebuildingfiresmanual 141130150127 Conversion Gate01Dokument72 SeitenHigh Risebuildingfiresmanual 141130150127 Conversion Gate01hagar18Noch keine Bewertungen

- Khorsabad II. The Citadel and The TownDokument244 SeitenKhorsabad II. The Citadel and The TownLeniad Wolfschanze MuñeiraNoch keine Bewertungen

- Etabs GuidelinesDokument2 SeitenEtabs GuidelinesMudit GandhiNoch keine Bewertungen

- Atest Eco Panel Mohammad AdilDokument8 SeitenAtest Eco Panel Mohammad AdilEckyAbdulahNoch keine Bewertungen

- 9 Specification For Mechanical Pipework Insulation PDFDokument4 Seiten9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiNoch keine Bewertungen

- PFS Unit 1Dokument23 SeitenPFS Unit 1jss_devNoch keine Bewertungen

- Swimming Pool & Spa Safety: PurposeDokument12 SeitenSwimming Pool & Spa Safety: PurposekenNoch keine Bewertungen

- Section 220500 - Common Work Results For Plumbing Part 1 - GeneralDokument7 SeitenSection 220500 - Common Work Results For Plumbing Part 1 - GeneralMac ShaikNoch keine Bewertungen

- Rezoning The WaterfrontDokument16 SeitenRezoning The WaterfrontThe Lo-DownNoch keine Bewertungen

- Mahindra College PuneDokument79 SeitenMahindra College PuneDhananjayHeteNoch keine Bewertungen

- Generalized Geologic Map For Land-Use Planning: Carter County, KentuckyDokument1 SeiteGeneralized Geologic Map For Land-Use Planning: Carter County, KentuckyTracy James Justice JrNoch keine Bewertungen

- SSMA DetailsDokument47 SeitenSSMA DetailsTony MendozaNoch keine Bewertungen

- Liquid Applied Waterproofing - ProtectowrapDokument3 SeitenLiquid Applied Waterproofing - ProtectowrapYndia SorianoNoch keine Bewertungen

- DB 200 SLDokument2 SeitenDB 200 SLkanchanabalajiNoch keine Bewertungen

- The Haunted Past (An Abandoned Trollskull Manor Adventure) - GM BinderDokument6 SeitenThe Haunted Past (An Abandoned Trollskull Manor Adventure) - GM BinderLeonartNoch keine Bewertungen

- Bed RM Bed RM CLO BTH: Floor PlanDokument1 SeiteBed RM Bed RM CLO BTH: Floor PlanSumowulu HarrisjrNoch keine Bewertungen

- Use of Fuzzy Logic For Tall BuildingDokument40 SeitenUse of Fuzzy Logic For Tall BuildingShashank ZutshiNoch keine Bewertungen