Beruflich Dokumente

Kultur Dokumente

HM15001E

Hochgeladen von

mohamadreza1368Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HM15001E

Hochgeladen von

mohamadreza1368Copyright:

Verfügbare Formate

Equipment for Engineering Education

Test Instructions

HM150.01 Pipe Friction

Apparatus

G.U.N.T. Gertebau GmbH

P.O. Box 1125

D-22881 Barsbttel Germany

Phone (040) 670854-0

Fax

(040) 670854-41

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

HM150.01 Pipe Friction Apparatus

Test Instructions

Publication no.: 917.00001A15012

12/96

HM150.01 Pipe Friction Apparatus

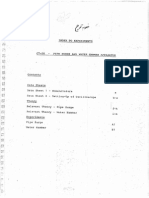

Contents

1 Unit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Preparing the experiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

3 Experiments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1

Laminar flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2

Measured values for laminar flow . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3

Turbulent flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4

Measured values for turbulent flow . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5

Graph of measured values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

HM150.01 Pipe Friction Apparatus

Unit description

The HM150.01 unit is used to examine pipe friction

losses in laminar and turbulent flow.

The pipe section used is a brass pipe with an inside

diameter of 3 mm and a length of 400 mm.

The pressure losses are measured in laminar flow

with a water manometer. The static pressure difference is indicated.

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

In turbulent flow the pressure difference is measured with a mercury-filled U-tube manometer.

A level tank is provided to generate the laminar

flow. It ensures a constant water inflow pressure

on the pipe section at a constant water level.

The level tank is not used to generate turbulent

flow. The water is fed directly from the water main

into the pipe section.

The flow rate is set by means of needle valves at

each end of the pipe.

The water is supplied either from the HM150 fluid

technics base module or from the laboratory main.

An enclosed water circuit can be established with

the HM150.

1 Unit description

HM150.01 Pipe Friction Apparatus

The unit basically comprises:

12

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

11

10

Demonstration board

Inlet needle valves

U-Tube manometer

Discharge needle valve

Hose connection

Water supply

Pressure tapping at the

end of the pipe

Ball cock

Pressure tapping at the

beginning of the pipe

11 Water tank

Pipe section

1 Unit description

10 Overflow

12 Water manometer

HM150.01 Pipe Friction Apparatus

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

Preparing the experiment

Set up the experiment on the HM150

so that the discharge directs the water into

the sewer.

Connect a hose between the HM150 and the

unit.

Open the HM150 discharge.

Experiments

Pressure lost of laminar flow is to be compared

with turbulent flow.

3.1

Laminar flow

-

Connect the water manometer to the two

pressure measuring nipples.

Open the needle valve at the discharge fully.

Close the valve [1] fully.

Open the valve [2] fully.

Switch the HM150 pump on and adjust the

ball-cock so that a constant water level is

created at the overflow.

Overflowf

Level

Valve [2]

Ball cock

Valve[1]

2 Preparing the experiment

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

HM150.01 Pipe Friction Apparatus

Close the needle valve at the discharge until

a constant pressure difference of 2 cm is established on the water manometer.

This corresponds to the fall hv.

Determining the volume flow.

Increase the flow in increments (hv increases) and repeat the volume flow measurements.

Discharge

needle valve

It also needs to be investigated whether the flow

is laminar or turbulent.

The switch from laminar to turbulent flow form

occurs when:

Hose connection

Rekr 2300

Relam. 2300 means laminar flow

Retur. 2300 means turbulent flow

The Reynolds number is calculated from

Re =

hv

wd

where

d= inside diameter of the pipe section [m]

h1

w= flow rate [m/s]

h2

Mearurement of the fall hv

on the water manometer

= viscosity of the medium [m2/s]

Fall hv = h1 h2

h1: static pressure at the entrance to the pipe.

3 Experiments

HM150.01 Pipe Friction Apparatus

.

The volume flow V is best measured with a measuring vessel and a stopwatch.

V

.

V = t

The flow rate is produced from:

.

V

w=

A

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

.

V= volume flow

A= cross-sectional area of the pipe

d2

where A =

and d = 3 mm.

4

The fall hv is set with the drain valve. From the fall

the pipe coefficient of friction is calculated as:

=

2 hv d

H2o l w2

where l = 400 mm pipe section, the value for

hv has to be inserted in Pa

The theoretical pipe coefficient of friction th is to

be compared with the measured value. For laminar

flow:

64

th = Re

3 Experiments

HM150.01 Pipe Friction Apparatus

3.2

Measured values for laminar flow

The following measured values were produced for

laminar flow. While performing the experiment,

ensure that the water level in the tank remains

constant.

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

Measured values:

3 Experiments

hv

[cm]

t

[s]

V

[l]

.

V

[l/s]

w

[m/s]

Re

th

(calculated)

195

0,2

0,00102

0,144

403

0,141

0,158

138

0,2

0,00145

0,205

574

0,105

0,114

105

0,2

0,00190

0,265

754

0,081

0,085

78

0,2

0,00256

0,362

1014

0,056

0,063

72

0,2

0,00277

0,391

1096

0,057

0,058

58

0,2

0,00344

0,486

1362

0,050

0,047

15

77

0,4

0,00519

0,734

2060

0,040

0,031

HM150.01 Pipe Friction Apparatus

3.3

Turbulent flow

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

In this experiment the level tank is not used. For

turbulent flow a higher flow rate is required. The

water is therefore fed directly from the HM150 or

from the main into the pipe section. Proceed as

follows:

-

Close the ball-cock fully.

Close valve [2] fully.

Close valve [1] fully.

Connect the Mercury U-tube manometer to

the two pressure measuring nipples.

Open the needle valve at the discharge fully.

Switch the HM150 pump on.

Open valve [1] fully.

Valve [2]

Ball cock

Valve [1]

Discharge

needle valve

Hose connections

3 Experiments

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

HM150.01 Pipe Friction Apparatus

Close the needle valve at the discharge until

a constant pressure difference of 20 mbar is

established on the U-tube manometer.

This corresponds to a fall hv of 15 mm.

(1 mm Mercury Column = 1,33322 mbar)

Determining the volume flow.

Increase the flow in increments (hv increases) and repeat the volume flow measurements.

Fall hv = h1 h2

hv

h1: static pressure at the entrance to the

pipe section.

h1

h2

Measurement of the Fall hv

on the U-tube manometer

h2: static pressure at the outlet from the

pipe section.

The calculations are made in the same way as for

the laminar flow.

According to Blasius, however, the theoretical pipe

coefficient of friction th

for turbulent flow is calculated as follows:

th =

3 Experiments

0,3164

4

Re

HM150.01 Pipe Friction Apparatus

3.4

Measured values for turbulent flow

The following measured values were produced for

turbulent flow.

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

Measured values:

p

[mbar]

t

[s]

V

[l]

.

V

[l/s]

w

[m/s]

Re

th

(calculated)

20

67,42

0,40

0,0059

0,838

2349

0,0420

0,0454

30

5791

0,40

0,0069

0,976

2736

0,0460

0,0437

40

46,09

0,40

0,0086

1,22

3420

0,0390

0,0413

60

3545

0,40

0,0112

1,59

4458

0,0348

0,0387

80

32,79

0,40

0,0121

1,724

4834

0,0395

0,0379

100

27,91

0,40

0,0143

2,027

5683

0,0357

0,0364

120

25,48

0,40

0,0157

2,22

6224

0,0358

0,0356

140

22,47

0,40

0,0178

2,52

7066

0,0324

0,0345

160

21,26

0,40

0,0188

2,66

7957

0,0330

0,0335

200

19,31

0,40

0,0207

2,93

8214

0,0342

0,0332

3 Experiments

10

HM150.01 Pipe Friction Apparatus

3.5

Graph of measured values

0,12

Coefficient of pipe friction

All rights reserved G.U.N.T. Gertebau GmbH, Barsbttel , Germany, 12/96

0,14

0,10

0,08

0,06

0,04

0,02

1000

Laminar

3000

5000

7000

Re

Turbulent

Reynolds number

measured

th theoretical

3 Experiments

11

Das könnte Ihnen auch gefallen

- Datis Cataloug-1Dokument8 SeitenDatis Cataloug-1mohamadreza1368Noch keine Bewertungen

- H16 Losses in Piping DatasheetDokument5 SeitenH16 Losses in Piping Datasheetmohamadreza1368Noch keine Bewertungen

- MFY-01 Brief Procedure (New Pressure Gauge)Dokument2 SeitenMFY-01 Brief Procedure (New Pressure Gauge)mohamadreza1368Noch keine Bewertungen

- DRK109A&B Touch-Screen Bursting Strength TesterDokument2 SeitenDRK109A&B Touch-Screen Bursting Strength Testermohamadreza1368Noch keine Bewertungen

- Experiment Instructions: WL 352 Free and Forced Convection UnitDokument98 SeitenExperiment Instructions: WL 352 Free and Forced Convection Unitmohamadreza1368Noch keine Bewertungen

- Manual Laborartory CHE 309Dokument109 SeitenManual Laborartory CHE 309mohamadreza1368Noch keine Bewertungen

- Ec3X Burst Tester Instruction Manual: Bűchel B.VDokument45 SeitenEc3X Burst Tester Instruction Manual: Bűchel B.Vmohamadreza1368Noch keine Bewertungen

- Experiment 11 4 Hydraulics Lab 2Dokument5 SeitenExperiment 11 4 Hydraulics Lab 2mohamadreza1368Noch keine Bewertungen

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDokument15 SeitenComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368Noch keine Bewertungen

- Cooling TowersDokument11 SeitenCooling TowersSlim Kat Nkosi0% (2)

- Hydrostatics BenchDokument83 SeitenHydrostatics Benchmohamadreza1368100% (1)

- MEC701 Lab Manual W2015Dokument36 SeitenMEC701 Lab Manual W2015Isra SajjadNoch keine Bewertungen

- Water HammerDokument12 SeitenWater Hammermohamadreza1368Noch keine Bewertungen

- Pump ManualDokument10 SeitenPump Manualmohamadreza1368Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Optimal Control Development System For ElectricalDokument7 SeitenOptimal Control Development System For ElectricalCRISTIAN CAMILO MORALES SOLISNoch keine Bewertungen

- Parts Catalog MAXSYM400iDokument70 SeitenParts Catalog MAXSYM400iAntonio CoelhoNoch keine Bewertungen

- Conversation Class - Video GamesDokument4 SeitenConversation Class - Video GamesMaíra MouraNoch keine Bewertungen

- De Thi Khao Sat HSG 12 Mon Tieng AnhDokument8 SeitenDe Thi Khao Sat HSG 12 Mon Tieng AnhbuitinhNoch keine Bewertungen

- 5 Levels of Leadership AnswersDokument4 Seiten5 Levels of Leadership Answersk98hk8wnnbNoch keine Bewertungen

- Role of Optimizer in Neural NetworkDokument2 SeitenRole of Optimizer in Neural NetworkMuhammad AlianNoch keine Bewertungen

- Cloud Computing 101 TutorialDokument203 SeitenCloud Computing 101 TutorialYunis Iklil100% (1)

- MYP Unit Planner - MathDokument5 SeitenMYP Unit Planner - MathMarija CvetkovicNoch keine Bewertungen

- Advanced Communication SystemDokument13 SeitenAdvanced Communication SystemZohaib AhmadNoch keine Bewertungen

- Engineers House Fire Fighting Course FP 01Dokument54 SeitenEngineers House Fire Fighting Course FP 01Muhammad ElbarbaryNoch keine Bewertungen

- Cibse TM65 (2020)Dokument67 SeitenCibse TM65 (2020)Reli Hano100% (1)

- Ped 5 FTDokument39 SeitenPed 5 FTJoy Grace TablanteNoch keine Bewertungen

- Geometallurgical Modelling of The Collahuasi Flotation CircuitDokument6 SeitenGeometallurgical Modelling of The Collahuasi Flotation CircuitFrancisco CampbellNoch keine Bewertungen

- Chapter Two Sector Analysis: (MBAM)Dokument23 SeitenChapter Two Sector Analysis: (MBAM)Ferlyn PelayoNoch keine Bewertungen

- Esinex: R Resinated Lignite Is Designed ToDokument2 SeitenEsinex: R Resinated Lignite Is Designed ToWaleed Barakat MariaNoch keine Bewertungen

- Saudi Arabia Companies Contact DetailsDokument64 SeitenSaudi Arabia Companies Contact DetailsYAGHMOURE ABDALRAHMAN86% (69)

- WEEK 11 - LAB 2 LEVEL 0 - BS Lab Electrical Supply - Domestic House Wiring & Accessories Including Lighting - DONEDokument6 SeitenWEEK 11 - LAB 2 LEVEL 0 - BS Lab Electrical Supply - Domestic House Wiring & Accessories Including Lighting - DONEMuhd Alif MikhailNoch keine Bewertungen

- A Guide To Become A Succesful Marine EngineerDokument99 SeitenA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- Section 02870 Site FurnishingsDokument19 SeitenSection 02870 Site FurnishingsMØhãmmed ØwięsNoch keine Bewertungen

- Jurnal Ari Maulana Ullum Sasmi 1801038Dokument12 SeitenJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10Noch keine Bewertungen

- Problems Involving Sequences: Grade 10Dokument9 SeitenProblems Involving Sequences: Grade 10Jhiemalyn RonquilloNoch keine Bewertungen

- IG Client Sentiment Report 2020-12-03 12 - 00 PDFDokument36 SeitenIG Client Sentiment Report 2020-12-03 12 - 00 PDFEno Ronaldfrank OguriNoch keine Bewertungen

- Background of The Study: Than IdealDokument3 SeitenBackground of The Study: Than IdealClint CamilonNoch keine Bewertungen

- PCI Express Test Spec Platform 3.0 06182013 TSDokument383 SeitenPCI Express Test Spec Platform 3.0 06182013 TSDeng XinNoch keine Bewertungen

- 17333Dokument2 Seiten17333Nithya RaviNoch keine Bewertungen

- Exercicios de PhonicsDokument51 SeitenExercicios de Phonicsms. TeixeiraNoch keine Bewertungen

- Time Series Data Analysis For Forecasting - A Literature ReviewDokument5 SeitenTime Series Data Analysis For Forecasting - A Literature ReviewIJMERNoch keine Bewertungen

- APCO CSAA ANS2 101 1webfinalDokument38 SeitenAPCO CSAA ANS2 101 1webfinalJUAN CAMILO VALENCIA VALENCIANoch keine Bewertungen

- Jesper Kyd - Flight Over Venice (Assassin's Creed II)Dokument9 SeitenJesper Kyd - Flight Over Venice (Assassin's Creed II)Aldert de VriesNoch keine Bewertungen