Beruflich Dokumente

Kultur Dokumente

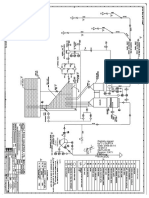

Design Manual for Bag Filter Datasheet

Hochgeladen von

Rexx MexxOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Manual for Bag Filter Datasheet

Hochgeladen von

Rexx MexxCopyright:

Verfügbare Formate

SAMSUNG ENGINEERING CO.

, LTD

SAMSUNG SEI TOWER, 467-14 Dogok 2 Dong,

Kangnam-Ku, Seoul, KOREA 135-280

DESIGN MANUAL

SEM-9483E

PROCESS DESIGN MANUAL

Preparation of Datasheet

for Bag Filter

REV.

DATE

:0

: 2006.8.23

SAMSUNG ENGINEERING CO., LTD.

DATE : 2006. 8. 23

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE i OF ii

CONTENTS

Page

1

GENERAL................................................................................................1

SHEET NO. AND REVISION NO.............................................................1

PROJECT INFORMATION......................................................................1

3.1

3.2

OPERATING CONDITIONS.....................................................................2

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

4.14

4.15

4.16

4.17

5.

SUPPLIER.......................................................................................1

NO. REQD.....................................................................................1

MATERIAL HANDLED........................................................................2

DENSITY (BULK/REAL)....................................................................2

VISCOSITY......................................................................................2

TEMPERATURE................................................................................2

MOISTURE CONTENT......................................................................2

PARTICLE CONTENT........................................................................3

PARTICLE SIZE DISTRIBUTION.........................................................3

ANGLE OF REPOSE.........................................................................3

PARTICLE SIZE (TO BE REMOVED)...................................................3

DUST LOADING (TO BE REMOVED)...................................................3

PRESSURE DROP (MAX. AVAILABLE)................................................3

FLOW RATE.....................................................................................4

SUCTION AND DISCHARGE PRESSURE.............................................4

OPERATING TYPE...........................................................................4

OPERATING TIME............................................................................4

MATERIAL PROPERTIES...................................................................5

INSTALLATION.................................................................................5

CONSTRUCTIONS..................................................................................5

5.1

5.2

5.3

5.4

DESIGN PRESSURE AND TEMPERATURE..........................................5

CORROSION ALLOWANCE................................................................5

THICKNESS.....................................................................................6

CONNECTIONS................................................................................6

DATE : 2006. 8. 23

5.5

5.6

5.7

5.8

5.9

5.10

5.11

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE ii OF ii

FILTERING AREA.............................................................................6

FILTER............................................................................................6

BAG CLEANING METHOD.................................................................6

DUST REMOVAL METHOD................................................................6

CYCLE TIME...................................................................................6

INSULATION....................................................................................7

OVERALL SIZE AND WEIGHT...........................................................7

MATERIALS.............................................................................................7

DRIVER....................................................................................................7

ACCESSORIES........................................................................................7

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

ROTARY VALVE WITH ROTOR..........................................................8

LOCAL PANEL.................................................................................8

SETTING (ANCHOR) BOLT AND NUTS...............................................8

AIR CONTROL UNIT.........................................................................8

PLATFORM, LADDER, HANDRAIL......................................................8

AIR KNOCKER.................................................................................8

DIFFERENTIAL PRESSURE INDICATOR..............................................8

SCREW CONVEYOR........................................................................9

ACCESS DOORS.............................................................................9

DUST BOX WITH GATE....................................................................9

TIMER............................................................................................9

LEVEL SWITCH...............................................................................9

REMARKS................................................................................................9

10

REVISION HISTORY................................................................................9

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 1 OF 10

DATE : 2006. 8. 23

GENERAL

In a principle, the data sheet for BUCKET ELEVATOR is composed of a

data sheet and a sketch form. But if the data sheet is enough to

describe the structure and the size of it, sketch sheet can be omitted.

SHEET NO. AND REVISION NO.

A Sheet number is admissible up to 3 pages as the number of data

sheet itself. The first revision no. shall be "0" and the new revision no.

1,2,3,... shall be given in order under the same rules for the drawings.

PROJECT INFORMATION.

The customer item is described as the full name as possible, and the

location item as location name and nationality, the service item as its

system or process.

The REQ'N NO. is described by the mechanical engineering team at the

requisition issue, so it is followed up after the requisition issue.

3.1

Supplier

It is determined after purchase contract of equipments, so its

item is described after confirming 1st vendor print.

3.2

No. Reqd

It means the number of the equipments and the unit. If required,

the stand-by It is determined after purchase contract of

equipments, so its item is described after confirming 1st vendor

print.

OPERATING CONDITIONS

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 2 OF 10

DATE : 2006. 8. 23

Mainly the data related with the process is described fully.

4.1

Material Handled

It is the feeding fluid to the bag filter. If there are multiple

materials, their analytical method is needed. Each the

component of raw materials is expressed as %WT or % VOL. If

the space is not enough, mark the Remark No. at the blank and

describe at the below remarks space.

4.2

Density (Bulk/Real)

For transportation of raw material, generally bulk density is

needed. But the bag filter is to separate the mixed particles, the

bulk and real density both are specified.

4.3

Viscosity

In case of attachable materials, they are classified. But for

reference, it is specified.

4.4

Temperature

It means the temperature feeding to the bag filter. If materials are

not handled at the prior process, it can be specified as ambient

temperature.

4.5

Moisture Content

It means the fluid's containing moisture contents, is necessary to

the filter design.

4.6

Particle Content

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 3 OF 10

DATE : 2006. 8. 23

It means the particle contents in feeding fluid to bag filters. As it

is related with the design, it should be specified.

4.7

Particle Size Distribution

If there are various sizes in the feeding fluid, its distribution is

specified by size. If the particle distribution is uneven, it is noted

as %WT or %VOL. In that case, remarks no is noted and it is

noted below remark space in detail.

4.8

Angle of Repose

It means the angle of the repose, used hopper volume design

mainly. It is necessary or referable according to the kinds of the

equipments. Here, it is to be used to the hopper design at the

bottom of the casing in the back filter.

4.9

Particle Size (to be removed)

It means the size to be eliminated. Must consider the

environmental regulation.

4.10

Dust loading (to be removed)

It means the dust contents filtered in the bag filter. So it can be

contents in the fluid.

4.11

Pressure Drop (Max. available)

It is about 100 mmH2O at the operating condition because of

pressure drop at the filter.

4.12

Flow rate

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 4 OF 10

DATE : 2006. 8. 23

It means the ability and capacity of handling; the capacity is

showed at the normal and design item on the data sheet. The

normal item must be described. Design capacity can be the

rated capacity in the equipment detail design and motor power

calculation to vender.

4.13

Suction and Discharge Pressure

They are the inlet and outlet pressures of the bag filter

respectively. The discharge pressure is normally ATM.

4.14

Operating Type

Operating type is composed of continuous or intermittent and

auto start/stop or manual start/stop as showed on the data

sheet. If the special operating type, it is noted on the remark

space. Whether start/stop type is automatic or manual, it is

necessary to confirm the supply of start/stop push button box.

For all equipments at the start of project, it is necessary that the

determination between form each vendor and from instrument

engineering team. If automatic, it is necessary to confirm the

needs of remote switch on the local push button box. If

continuous on-off operation, it is noted in the remarks space.

(For example, on-off cycle time: 3min.)

4.15

Operating Time

It is expressed as operating cycle, means the operating time per

day. It is related with the plant operating time of client. If 2-shift, it

is 16Hr/day. If 3-shift, it is 24Hr/day.

4.16

Material Properties

It means the chemical and physical properties of the transported

DATE : 2006. 8. 23

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 5 OF 10

material as an engineering view. It is good to select the related

property on the data sheet.

If there is need to express the power of property, select it and it

is reasonable to mark the high or severe at the blank. If multiple

properties, select and mark multiple options. If no listed

properties, select other option, and describe it.

4.17

Installation

It means the construction location of equipments on the lay out,

either indoor or outdoor. If extra condition like under roof, make a

note.

5. CONSTRUCTIONS

It shows the equipment structure and specification. Only process options

are marked, the others are marked by vendor.

5.1

Design Pressure and Temperature

Because the bag filter only removing the dust equipped on the

hopper is contacted with atm., design pressure is not

considerable. But if it is equipped in the process, the

temperature and pressure are to be considered.

5.2

Corrosion Allowance

The casing of the bag filter is mainly carbon steel, so corrosive

allowance should be considered.

5.3

Thickness

It means the thickness of casing fixed up by vendor.

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 6 OF 10

DATE : 2006. 8. 23

5.4

Connections

The type and size of the connections between suction and

discharge of body are specified.

5.5

Filtering Area

It means the surface area of filter where the fluid goes through,

and based on vendor standard.

5.6

Filter

If the type of filter options is fixed, the others of filter options are

specified by vendor.

5.7

Bag Cleaning Method

If the filter is operated for a long time, the dust is attached to the

filter surface. So, after the power is removed, the filter can be

used continuously. If continuous operation, the air jet pulse type

is applicable, and if intermittent operation, the motor shaking

type is applicable.

5.8

Dust Removal Method

It means the method the remove the dust pile up at the bottom of

the filter.

5.9

Cycle Time

It means the air pulse cycle or shaking cycle, and is fixed up by

vendor.

DATE : 2006. 8. 23

5.10

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 7 OF 10

Insulation

If necessary, fix up the whether insulation is needed or not.

5.11

Overall Size and Weight

It is informed by vendor.

MATERIALS

It is general that the materials are fixed according to the properties of

the raw material and the operating purpose. The material contacted with

raw material on process should be specified. After at least, the material

of the filter and casing are fixed up, the others are fixed up by vendor.

The selection of the materials is fixed by referring the material properties

on operating condition.

DRIVER

If normal, supplied-by/mounted-by is fixed by vendor. Because the

things with drivers are fixed by other detail associating teams, the driver

needs not to be fixed by process engineering team. So no. needs no.

marks.

ACCESSORIES

Because the supply scope of accessories is related with the supply

scope of the equipments and fixed up according to operation/system. it

can fixed up at the process data description possibly. They are specified

if fully explainable as process requirements and special requirements.

So, it is possible that the detail associated teams select them.

8.1

Rotary Valve with Rotor

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 8 OF 10

DATE : 2006. 8. 23

The its requirements are fixed up by dust removal method.

8.2

Local Panel

If no special case, it is always supplied.

8.3

Setting (Anchor) Bolt and Nuts

Must supply them.

8.4

Air Control Unit

If air pulse type, consider its requirements.

8.5

Platform, Ladder, Handrail

They are considered according to the height of equipment. Even

though enough high, it can be not equipped.

8.6

Air Knocker

When the dust assembled at the bottom of bag filter is removed,

if the dust is very attachable, the air knocker is equipped for the

fluid to flow well.

8.7

Differential Pressure Indicator

Because It is for the decision of the replacement time with the

differential pressure, it must be equipped.

8.8

Screw Conveyor

In case of the big-sized bag filter, it is equipped to be remove the

dust easily.

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 9 OF 10

DATE : 2006. 8. 23

8.9

Access Doors

They must always be equipped on the body.

8.10

Dust Box with Gate

When the dust removal type has the dust box, the dust box with

gate is applicable.

8.11

Timer

Must always supply it.

8.12

Level Switch

In order to know the level of dust accumulated at the bottom of

the bag filter and remove it, the level switch is equipped. But it

not always be necessary.

REMARKS

Remarks are for the description of requirements if data sheet format is

difficult and impossible to describe. Also if there are the added special

process requirements.

10 REVISION HISTORY

Rev

Date

Page

Revision Status

DESIGN MANUAL

SEM 9483E

Preparation of Datasheet

REV. : 0

for Bag Filter

PAGE 10 OF 10

DATE : 2006. 8. 23

06.08.23

All

- Team : Process Eng'g Team

- Made by : D.K. Shin

- Checked by : J.C. Ro, E.D. Lee, Henry Sung, B.S. Son

- Approved by : C.S. Jung

Das könnte Ihnen auch gefallen

- Digitally signed wet dust extraction system design reportDokument17 SeitenDigitally signed wet dust extraction system design reportmathan_aeNoch keine Bewertungen

- Is 14164 2008Dokument45 SeitenIs 14164 2008Pukhraj DagaNoch keine Bewertungen

- THERMAX BAG FILTER TECHNICAL DATA SHEETDokument18 SeitenTHERMAX BAG FILTER TECHNICAL DATA SHEETpavaniNoch keine Bewertungen

- Liquid Overfeed Systems by R. P. ParanjpeyDokument15 SeitenLiquid Overfeed Systems by R. P. Paranjpeyurp30234Noch keine Bewertungen

- Dust extraction system bag filter detailsDokument6 SeitenDust extraction system bag filter detailsAnonymous W9VINoTzaNoch keine Bewertungen

- By Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahanDokument18 SeitenBy Pass System RCD-1 to SP3 RCD-2 to SP2 Pelabuhan Batubara TarahansutanuprojectsNoch keine Bewertungen

- S 101 Sodium Chloride Silo Specification Sheet and DesignDokument8 SeitenS 101 Sodium Chloride Silo Specification Sheet and DesignBenedick Jayson MartiNoch keine Bewertungen

- Data and Result Calculation Bag FilterDokument2 SeitenData and Result Calculation Bag FilterUmmiey SyahirahNoch keine Bewertungen

- Dyke Calculation and TechnicalDokument17 SeitenDyke Calculation and Technicalsiva_aelNoch keine Bewertungen

- Calculate Bucket Elevator CapacityDokument2 SeitenCalculate Bucket Elevator CapacityBùi Hắc HảiNoch keine Bewertungen

- College of Engineering and Technology Chemical Engineering DepartmentDokument6 SeitenCollege of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (2)

- Calculator Centrifugal Fan - Google SearchDokument2 SeitenCalculator Centrifugal Fan - Google SearchJebDesNoch keine Bewertungen

- Method of Heat Exchanger Sizing Kern MethodDokument10 SeitenMethod of Heat Exchanger Sizing Kern Methodvazzoleralex6884Noch keine Bewertungen

- Interstitial Velocity GuidelinesDokument6 SeitenInterstitial Velocity GuidelinesnaushadNoch keine Bewertungen

- Types of Emissions & ESP-Bag Filter TechnologiesDokument50 SeitenTypes of Emissions & ESP-Bag Filter TechnologiesHeryantoXiaoNoch keine Bewertungen

- 1200m3 Ash Silo Mechanical ReportDokument15 Seiten1200m3 Ash Silo Mechanical Reporttranceintt0% (1)

- Datasheet For Side Entry MixerDokument4 SeitenDatasheet For Side Entry Mixervinoj chandranNoch keine Bewertungen

- Dedusting SystemDokument4 SeitenDedusting SystemdanmertzNoch keine Bewertungen

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDokument2 SeitenAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanNoch keine Bewertungen

- Screw ConveyorDokument4 SeitenScrew ConveyorRaji SuriNoch keine Bewertungen

- DheerajDokument7 SeitenDheerajSaksham KakarNoch keine Bewertungen

- Storage Tank Venting CalculationDokument1 SeiteStorage Tank Venting Calculationام يمنى ايمنNoch keine Bewertungen

- Silo Capacity CalculationDokument1 SeiteSilo Capacity Calculationlbc123Noch keine Bewertungen

- TS of Travelling TripperDokument10 SeitenTS of Travelling TripperShashank HegdeNoch keine Bewertungen

- 100cub API 650 STEEL SiloDokument19 Seiten100cub API 650 STEEL SiloUDayNoch keine Bewertungen

- Belt Filter Press TBEDokument2 SeitenBelt Filter Press TBEmayukhguha1988Noch keine Bewertungen

- GranulatorDokument2 SeitenGranulatorNess SanchezNoch keine Bewertungen

- Draft of Chimney CalculationDokument7 SeitenDraft of Chimney Calculationshani5573Noch keine Bewertungen

- Kalkulasi Steam Trap MFO Rev 00Dokument20 SeitenKalkulasi Steam Trap MFO Rev 00Rifka AisyahNoch keine Bewertungen

- Tank Venting API 2000Dokument3 SeitenTank Venting API 2000Gusfi CarsurinNoch keine Bewertungen

- InsulationDokument10 SeitenInsulationJyotiNoch keine Bewertungen

- Pressure Vacuum Breather ValvesDokument4 SeitenPressure Vacuum Breather ValvesAdhitya DarmadiNoch keine Bewertungen

- Design and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerDokument6 SeitenDesign and Analysis of Screw Conveyor at Inlet of Ash/Dust ConditionerMohd HafizzNoch keine Bewertungen

- Conventional JacketsDokument4 SeitenConventional JacketskayeNoch keine Bewertungen

- Vessel Weight CheckDokument8 SeitenVessel Weight ChecknileshNoch keine Bewertungen

- Bulk Handling Global - Bulk Handling GlobalDokument2 SeitenBulk Handling Global - Bulk Handling Globalpvc333Noch keine Bewertungen

- Design Check List Viii-1 Rev1Dokument2 SeitenDesign Check List Viii-1 Rev1nirmalNoch keine Bewertungen

- ATEC Cyclone Datasheet EnglDokument1 SeiteATEC Cyclone Datasheet EnglDilnesa EjiguNoch keine Bewertungen

- P103e Gas Scrubbing PlantsDokument12 SeitenP103e Gas Scrubbing PlantsAswad Ali100% (1)

- Ambient Heat Loss From A VesselDokument3 SeitenAmbient Heat Loss From A VesselJaveed KhanNoch keine Bewertungen

- Bag Filter Datasheet ModelDokument6 SeitenBag Filter Datasheet ModeldgmprabhakarNoch keine Bewertungen

- Water Treatment Clarifier Data SheetDokument2 SeitenWater Treatment Clarifier Data SheetgffNoch keine Bewertungen

- Internal Floating Roof DesignDokument38 SeitenInternal Floating Roof DesigncrnewsomNoch keine Bewertungen

- WHRS and PP For Cement Plants - Todays Boiler Spring 2014Dokument2 SeitenWHRS and PP For Cement Plants - Todays Boiler Spring 2014ash22202Noch keine Bewertungen

- Air Receiver SizingDokument2 SeitenAir Receiver Sizingsiby josephNoch keine Bewertungen

- Conveyor Design Summary ReportDokument1 SeiteConveyor Design Summary ReportAlejandro Castro0% (1)

- Technodyne International Limited: Refrigerated Project ListDokument3 SeitenTechnodyne International Limited: Refrigerated Project ListSir AlaaNoch keine Bewertungen

- Titanium Bellows Design CalculationsDokument8 SeitenTitanium Bellows Design CalculationsNamıkNoch keine Bewertungen

- Compressed Air GuidelinesDokument7 SeitenCompressed Air Guidelinesj_moellersNoch keine Bewertungen

- Conveyor Screws PDFDokument9 SeitenConveyor Screws PDFldavilaluceralNoch keine Bewertungen

- AST Heating Coil Design Calculation Rev 0Dokument3 SeitenAST Heating Coil Design Calculation Rev 0Pieter Grendel100% (3)

- SEM-9521E Vibrating ScreenDokument16 SeitenSEM-9521E Vibrating ScreenRexx MexxNoch keine Bewertungen

- Ahlstar IOM 20031215 English (Links)Dokument121 SeitenAhlstar IOM 20031215 English (Links)Drese Chahaize100% (4)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Autoclave URSDokument29 SeitenAutoclave URSamit.srimal100% (3)

- VEDST003 - Shell and Tube Heat Exchanger Specification SheetDokument23 SeitenVEDST003 - Shell and Tube Heat Exchanger Specification SheetyuganterNoch keine Bewertungen

- CPT IOM 20051101 EnglishDokument87 SeitenCPT IOM 20051101 EnglishEnoch TwumasiNoch keine Bewertungen

- American Society of Heating, Refrigerating and Air-Conditioning Engineers Thermal Guidelines For Data Processing EnvironmentsDokument91 SeitenAmerican Society of Heating, Refrigerating and Air-Conditioning Engineers Thermal Guidelines For Data Processing Environmentsffernan10Noch keine Bewertungen

- Sbo 20Dokument563 SeitenSbo 20Benz Thanakom75% (8)

- PNE00004-Steam Trap GuidelinesDokument11 SeitenPNE00004-Steam Trap GuidelinesPratik Ray Chaudhury100% (2)

- Tanks Breathing CalculationDokument1 SeiteTanks Breathing CalculationRexx MexxNoch keine Bewertungen

- Volcanic Alliance Bro 200311 PDFDokument4 SeitenVolcanic Alliance Bro 200311 PDFRexx MexxNoch keine Bewertungen

- Hydraulic Cal - Tanks Vent To FlareDokument1 SeiteHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- FSU Case 1 PerformanceDokument2 SeitenFSU Case 1 PerformanceRexx MexxNoch keine Bewertungen

- Thermal Fluid Heaters: 75,000 TO 40 MM BTU/HRDokument16 SeitenThermal Fluid Heaters: 75,000 TO 40 MM BTU/HRRexx MexxNoch keine Bewertungen

- CORP-FRM-HSE-006 - 1 DNO Quick Risk V4.0Dokument1 SeiteCORP-FRM-HSE-006 - 1 DNO Quick Risk V4.0Rexx MexxNoch keine Bewertungen

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDokument4 SeitenTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNoch keine Bewertungen

- Tank Pressure During Pump OutDokument1 SeiteTank Pressure During Pump OutRexx MexxNoch keine Bewertungen

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDokument4 SeitenTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNoch keine Bewertungen

- GPCDOC - X - Cbe - 24855 - Key - 140002282412 - 1C93 (Thermia B) PDFDokument2 SeitenGPCDOC - X - Cbe - 24855 - Key - 140002282412 - 1C93 (Thermia B) PDFfadilah permata sariNoch keine Bewertungen

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDokument4 SeitenTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNoch keine Bewertungen

- Thermal Oil Heaters 3Dokument8 SeitenThermal Oil Heaters 3Jose Lorenzo ToralNoch keine Bewertungen

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDokument4 SeitenTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNoch keine Bewertungen

- TWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBDokument4 SeitenTWK-FD-21529 Drakken SDVs - KU-TWK-40-IC-DTS-0291 RBRexx MexxNoch keine Bewertungen

- KU-TWK-40-PR-PID-0018-27-dwg - A - Condensate HeaderDokument1 SeiteKU-TWK-40-PR-PID-0018-27-dwg - A - Condensate HeaderRexx MexxNoch keine Bewertungen

- Thermal Fluid Heaters: Model HHC and VHCDokument4 SeitenThermal Fluid Heaters: Model HHC and VHCRexx MexxNoch keine Bewertungen

- Desalter Operation OptimizationDokument3 SeitenDesalter Operation OptimizationRexx MexxNoch keine Bewertungen

- Catalog Fabricante TechnipDokument9 SeitenCatalog Fabricante Technipjimy GutiérrezNoch keine Bewertungen

- Microsoft PowerPoint - Lesson 10 SpecificationsDokument32 SeitenMicrosoft PowerPoint - Lesson 10 SpecificationsPranayNoch keine Bewertungen

- Iraq Oil and Gas Final Tender Protocol - Round1Dokument67 SeitenIraq Oil and Gas Final Tender Protocol - Round1Rexx Mexx100% (1)

- Alternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseDokument5 SeitenAlternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseRexx MexxNoch keine Bewertungen

- Alternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseDokument5 SeitenAlternatives: Alternative 1 System Delivered in 2 Phases Alternative 2 System Delivered in 1 PhaseRexx MexxNoch keine Bewertungen

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDokument7 SeitenKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDokument16 SeitenGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- WP Best Practices TuningDokument13 SeitenWP Best Practices Tuningnixsol75Noch keine Bewertungen

- TT 14 062 PF Cpf1 Smokeless Flare - Final - 10.08.2014Dokument87 SeitenTT 14 062 PF Cpf1 Smokeless Flare - Final - 10.08.2014Rexx MexxNoch keine Bewertungen

- 16.dynamic Simulation Services ExternalDokument20 Seiten16.dynamic Simulation Services Externalrahul281081Noch keine Bewertungen

- SEM-9520E Vibrating ConveyorDokument14 SeitenSEM-9520E Vibrating ConveyorRexx MexxNoch keine Bewertungen

- 00251121DPFM02101 - EXCO01 - 01 - Crude Oil Storage TankDokument1 Seite00251121DPFM02101 - EXCO01 - 01 - Crude Oil Storage TankRexx Mexx100% (1)

- SEM-9521E Vibrating ScreenDokument16 SeitenSEM-9521E Vibrating ScreenRexx MexxNoch keine Bewertungen

- Delhi Mumbai Award Status Mar 23Dokument11 SeitenDelhi Mumbai Award Status Mar 23Manoj DoshiNoch keine Bewertungen

- Arts9 q4 Mod1 Theatricalforms v5Dokument30 SeitenArts9 q4 Mod1 Theatricalforms v5Harold RicafortNoch keine Bewertungen

- Ce125-2500 Open FrameDokument48 SeitenCe125-2500 Open FrameRomão OliveiraNoch keine Bewertungen

- Writing A Formal Letter To The PresidentDokument1 SeiteWriting A Formal Letter To The PresidentPiaAnaisNoch keine Bewertungen

- Gregory University Library Assignment on Qualities of a Reader Service LibrarianDokument7 SeitenGregory University Library Assignment on Qualities of a Reader Service LibrarianEnyiogu AbrahamNoch keine Bewertungen

- LM385Dokument14 SeitenLM385vandocardosoNoch keine Bewertungen

- Quality Management - QuestionDokument4 SeitenQuality Management - QuestionLawzy Elsadig SeddigNoch keine Bewertungen

- Simulated Robot Football Team Uses Neural Networks to LearnDokument8 SeitenSimulated Robot Football Team Uses Neural Networks to LearnKishore MuthukulathuNoch keine Bewertungen

- Types of Stress: Turdalieva Daria HL 2-19 ADokument9 SeitenTypes of Stress: Turdalieva Daria HL 2-19 ADaria TurdalievaNoch keine Bewertungen

- MBA 2020: Research on Online Shopping in IndiaDokument4 SeitenMBA 2020: Research on Online Shopping in Indiaprayas sarkarNoch keine Bewertungen

- Project Report VajDokument15 SeitenProject Report VajTamil SelvanNoch keine Bewertungen

- The Clàsh The 0nly Band That MatteredDokument255 SeitenThe Clàsh The 0nly Band That MatteredNikos VaxevanidisNoch keine Bewertungen

- FeatureSelectionAccepted IEEE Review PDFDokument20 SeitenFeatureSelectionAccepted IEEE Review PDFrvsamy80Noch keine Bewertungen

- Ceeshsworkingstudents Abm Group2Dokument18 SeitenCeeshsworkingstudents Abm Group2kzz9c5hqrwNoch keine Bewertungen

- Strata KT Office OpportunityDokument41 SeitenStrata KT Office OpportunitySanskar SurekaNoch keine Bewertungen

- Security Testing MatDokument9 SeitenSecurity Testing MatLias JassiNoch keine Bewertungen

- Snorkeling: A Brief History and Guide to This Underwater AdventureDokument3 SeitenSnorkeling: A Brief History and Guide to This Underwater AdventureBernadette PerezNoch keine Bewertungen

- SomDokument191 SeitenSomVivek GosaviNoch keine Bewertungen

- Dryers in Word FileDokument5 SeitenDryers in Word FileHaroon RahimNoch keine Bewertungen

- MB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsDokument11 SeitenMB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsAli Asharaf Khan100% (3)

- Ownership and Governance of State Owned Enterprises A Compendium of National Practices 2021Dokument104 SeitenOwnership and Governance of State Owned Enterprises A Compendium of National Practices 2021Ary Surya PurnamaNoch keine Bewertungen

- PA2 Value and PD2 ValueDokument4 SeitenPA2 Value and PD2 Valueguddu1680Noch keine Bewertungen

- Moment Influence Line LabsheetDokument12 SeitenMoment Influence Line LabsheetZAXNoch keine Bewertungen

- S 212 Pre Course WorkDokument5 SeitenS 212 Pre Course Workafiwierot100% (2)

- Marketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Dokument20 SeitenMarketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Miaow MiaowNoch keine Bewertungen

- Electronics Foundations - Basic CircuitsDokument20 SeitenElectronics Foundations - Basic Circuitsccorp0089Noch keine Bewertungen

- Sample Interview Questions for Motivation, Communication, TeamsDokument6 SeitenSample Interview Questions for Motivation, Communication, TeamsSahibzada Muhammad MubeenNoch keine Bewertungen

- C++ NotesDokument129 SeitenC++ NotesNikhil Kant Saxena100% (4)

- F&B Data Analyst Portfolio ProjectDokument12 SeitenF&B Data Analyst Portfolio ProjectTom HollandNoch keine Bewertungen

- Philippine Politics Concepts ExplainedDokument3 SeitenPhilippine Politics Concepts ExplainedAngel Lyn A Lacerna100% (1)