Beruflich Dokumente

Kultur Dokumente

Coalesce R

Hochgeladen von

nandhamech250 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten1 Seitefilter

Originaltitel

Coalesce r

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenfilter

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

9 Ansichten1 SeiteCoalesce R

Hochgeladen von

nandhamech25filter

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Introduction

flowing and the opposing forces of buoyancy and viscous drag balance (Figure 1), the droplet has achieved

its Terminal Settling Velocity. This vertical velocity is

constant because there are no net forces acting upon

the droplet. This mechanism of separating liquids by

gravity is called Stokes Settling after the nineteenth

century English researcher Sir George Stokes.

Whether engineering a new coalescer vessel, or

debottlenecking an existing separator, full knowledge

and understanding of the basic principles involved are

required. Often overlooked are the capabilities of properly selected and designed internals for the enhancement of simple gravity separation. This Liquid-Liquid

Coalescer Design Manual describes the use of various The equation he developed for the terminal settling

media and methods employed for decades to increase velocity is still used today:

plant productivity. Typical applications include:

Removal of Bottlenecks in existing

Decanters and Three Phase Separators.

Reduction in New Vessel Sizes Up to five

times relative to gravity settling alone.

Improvements in Product Purity Carry-over

entrainment reduced to 1 ppm and less.

Compliance with Environmental Regulations

Cost effective solutions to wastewater

treatment and oil spill cleanups.

When two liquids are immiscible, or non-soluble in

one another, they can form either an emulsion or a

colloidal suspension. In either of these mixtures, the

dispersed liquid forms droplets in the continuous

phase. In a suspension, the droplets are less than one

micron in diameter and the liquids cannot readily be

separated with the technologies described here.

Fortunately, in the chemical and hydrocarbon process

industries droplet sizes are typically greater than this

and/or the purities required can be achieved without

addressing the ultra-light colloidal component of the

stream.

Stokes Settling Using Gravity

Traditionally, gravity separators were used to handle

emulsions before the use of coalescing media became

commonplace. In this

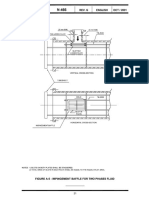

FIGURE 1

equipment, differences in

Forces on a light droplet

densities of the two liquids

dispersed in a heavy liquid

cause droplets to rise or

fall by their buoyancy. The

Bouyant Force

greater the difference in

densities, the easier the

Inertial Force

separation

becomes.

d

Rising (or falling) droplets

are slowed by frictional

forces from viscous effects

of the opposing liquid.

Viscous Drag

Force

When the stream is not

vt = 1.78 X 10-6 (S.G.) (d)2 /

vt = Terminal Settling Velocity, ft/s

(1)

d = Droplet Diameter, microns

S.G. = Specific Gravity Difference

between the Continuous

and Dispersed Phases

= Continuous Phase Viscosity, centipoise

The size of a gravity decanter is derived from 1) the

terminal settling velocity of a minimum sized droplet

and 2) the inertial force imparted to the droplet due to

the velocity of the emulsion through the vessel. At

these conditions, all droplets larger than a minimum

will be removed at a quicker rate and hence need not

be considered. The minimum sized droplet must be

estimated if empirical data is not available. Typically

the minimum droplet size is estimated to be between

75 to 300m. For example, API Publication 421 uses

minimum sized droplets of 150m for oil/water systems in refineries. Note that in Stokes Settling the

vessel must be sized to ensure laminar or streamline

flow; turbulent flow causes remixing. An example of

this sizing method in a decanter is contained in Case

Study 2, see page 12.

In order to settle fine droplets and ensure laminar flow,

large vessels and long residence times are required.

It may take five, ten, and or even thirty minutes to

make a separation, depending on the physical properties of the stream. With the capacity intensification

forced on modern refineries and chemical plants and

achieved with advanced mass transfer internals, catalysts, and heat exchanger designs, operators find

that their separators only have half or a third of the

time originally anticipated. This results in hazy, off

spec products or intermediates that cause problems

in downstream equipment.

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- N-466 Mechanical Design of Shell-And-Tube Heat Exchanger: ProcedureDokument4 SeitenN-466 Mechanical Design of Shell-And-Tube Heat Exchanger: Procedurenandhamech25Noch keine Bewertungen

- 4Dokument1 Seite4nandhamech25Noch keine Bewertungen

- 5 He PDFDokument2 Seiten5 He PDFnandhamech25Noch keine Bewertungen

- 5Dokument1 Seite5nandhamech25Noch keine Bewertungen

- 5 He PDFDokument2 Seiten5 He PDFnandhamech25Noch keine Bewertungen

- Heat Exchanger Crossover AnalysisDokument5 SeitenHeat Exchanger Crossover AnalysisMuhammad KhurramNoch keine Bewertungen

- Tube Material Compatibility Heat Exchanger StandardsDokument6 SeitenTube Material Compatibility Heat Exchanger Standardsnandhamech25Noch keine Bewertungen

- Rev. G English OCT / 2001Dokument5 SeitenRev. G English OCT / 2001nandhamech25Noch keine Bewertungen

- Shell and Tube Heat Exchanger Design PDFDokument3 SeitenShell and Tube Heat Exchanger Design PDFBaha Eddine Gharbi100% (1)

- Horizontal FiltersDokument1 SeiteHorizontal Filtersnandhamech25Noch keine Bewertungen

- Heat ExchangerDokument21 SeitenHeat ExchangerArun Prakash NatesanNoch keine Bewertungen

- UseDokument2 SeitenUsenandhamech25Noch keine Bewertungen

- Studding Outlet1Dokument2 SeitenStudding Outlet1nandhamech25Noch keine Bewertungen

- FVC Studding OutletDokument1 SeiteFVC Studding Outletnandhamech25Noch keine Bewertungen

- FVC Catalog 150#Dokument2 SeitenFVC Catalog 150#nandhamech25Noch keine Bewertungen

- FVC 25Dokument2 SeitenFVC 25nandhamech25Noch keine Bewertungen

- FVC Studding OutletDokument1 SeiteFVC Studding Outletnandhamech25Noch keine Bewertungen

- Dish Metal FormingDokument1 SeiteDish Metal Formingnandhamech25Noch keine Bewertungen

- JIS FittingsDokument1 SeiteJIS Fittingsnandhamech25Noch keine Bewertungen

- JIS Fittings 2Dokument1 SeiteJIS Fittings 2nandhamech25Noch keine Bewertungen

- JIS FittingsDokument1 SeiteJIS Fittingsnandhamech25Noch keine Bewertungen

- JIS FittingsDokument1 SeiteJIS Fittingsnandhamech25Noch keine Bewertungen

- Metal Forming SequenceDokument1 SeiteMetal Forming Sequencenandhamech25Noch keine Bewertungen

- Head MaterialDokument1 SeiteHead Materialnandhamech25Noch keine Bewertungen

- Dish Metal FormingDokument1 SeiteDish Metal Formingnandhamech25Noch keine Bewertungen

- Dish Metal FormingDokument1 SeiteDish Metal Formingnandhamech25Noch keine Bewertungen

- Agitated Vessel Heat Transfer DesignDokument2 SeitenAgitated Vessel Heat Transfer Designnandhamech25Noch keine Bewertungen

- Ansi b16 WeightDokument3 SeitenAnsi b16 Weightvincentvin111Noch keine Bewertungen

- 40kg/Cm 30kg/Cm: JIS B 2220-1984 (KS B 1503-1999) 30 / Slip-On Welding Steel Pipe FlangesDokument1 Seite40kg/Cm 30kg/Cm: JIS B 2220-1984 (KS B 1503-1999) 30 / Slip-On Welding Steel Pipe Flangesnandhamech25Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- X. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionDokument4 SeitenX. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionKolddeNoch keine Bewertungen

- MIG/MAG Pulse - MIG/MAG Synergic - MIG/MAG Manual Tig DC Lift - MmaDokument6 SeitenMIG/MAG Pulse - MIG/MAG Synergic - MIG/MAG Manual Tig DC Lift - MmaBadr NassibNoch keine Bewertungen

- Darcy-Weisbach Head Loss and Flow VelocityDokument1 SeiteDarcy-Weisbach Head Loss and Flow VelocityAlan FloresNoch keine Bewertungen

- Natural Gas Sweetening Process DesignDokument13 SeitenNatural Gas Sweetening Process DesignJeyakumar Raja100% (1)

- Engineering Information to Calculate Water ContentDokument28 SeitenEngineering Information to Calculate Water ContentMohamed ElmakkyNoch keine Bewertungen

- Density of LiquidsDokument5 SeitenDensity of LiquidsJose GalvanNoch keine Bewertungen

- 12-Circulating Water Systems PDFDokument32 Seiten12-Circulating Water Systems PDFAbah JamalNoch keine Bewertungen

- Grade (12) Chemistry (Myanmar)Dokument171 SeitenGrade (12) Chemistry (Myanmar)HlaMinNaingNoch keine Bewertungen

- Welding: Telegram - Contact - 7887811411Dokument4 SeitenWelding: Telegram - Contact - 7887811411shreyas jadhavNoch keine Bewertungen

- Luyben 2012Dokument7 SeitenLuyben 2012JAN JERICHO MENTOYNoch keine Bewertungen

- Boiler Feed Water Pumps & Water Analysis (PB QBook)Dokument8 SeitenBoiler Feed Water Pumps & Water Analysis (PB QBook)Ehsan Pappu100% (1)

- Combustion Table Industrial Energy ProcessDokument4 SeitenCombustion Table Industrial Energy Processsara_ghaemNoch keine Bewertungen

- BBQ Orfice SizingDokument1 SeiteBBQ Orfice SizingPubcrawlNoch keine Bewertungen

- Pressure Vessels Data SheetDokument1 SeitePressure Vessels Data SheetAndrés SepúlvedaNoch keine Bewertungen

- Dicet Flow Module 1Dokument27 SeitenDicet Flow Module 1Julius ChavezNoch keine Bewertungen

- Proposed Gas Connection Design PlansDokument7 SeitenProposed Gas Connection Design PlanskarimNoch keine Bewertungen

- Au 3Dokument439 SeitenAu 3Amit SinghNoch keine Bewertungen

- PY4118-08 Generation and RecombinationDokument15 SeitenPY4118-08 Generation and RecombinationNadia F Mohammad Al-RoshdeeNoch keine Bewertungen

- Thermodynamics Lecture 2Dokument18 SeitenThermodynamics Lecture 2Rashaq AL-HeetyNoch keine Bewertungen

- Isobaric Vapor Liquid Equilibria of The Water 1-Propanol System at 30, 60, and 100 KpaDokument5 SeitenIsobaric Vapor Liquid Equilibria of The Water 1-Propanol System at 30, 60, and 100 KpaRafael HenriqueNoch keine Bewertungen

- Lesson 4.4 HeatDokument18 SeitenLesson 4.4 HeatRais RahimiNoch keine Bewertungen

- Boyles LawDokument31 SeitenBoyles LawJanetMagnayeLapitan100% (1)

- Engineering Chemistry 1Dokument49 SeitenEngineering Chemistry 1Rasha HajaratNoch keine Bewertungen

- Liquid-Liquid Equilibrium DiagramDokument15 SeitenLiquid-Liquid Equilibrium DiagramAshlie GrasaNoch keine Bewertungen

- FluidDokument121 SeitenFluidnaefmubarakNoch keine Bewertungen

- IFSE ParameterDataDictionary V04 2017Dokument30 SeitenIFSE ParameterDataDictionary V04 2017KelvinatorNoch keine Bewertungen

- 4.method of Producing Low TempDokument25 Seiten4.method of Producing Low TempInby FlamesNoch keine Bewertungen

- Steam Production and Usage: Properties of Dry SaturatedDokument13 SeitenSteam Production and Usage: Properties of Dry SaturatedATUL MISRANoch keine Bewertungen

- Materials Changes with HeatDokument4 SeitenMaterials Changes with HeatMae GuerreroNoch keine Bewertungen

- Basic Principles and DefectsDokument18 SeitenBasic Principles and DefectsAkshaj NevgiNoch keine Bewertungen