Beruflich Dokumente

Kultur Dokumente

SATIP-A-004-01 Rev 7

Hochgeladen von

Bebin MathewCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SATIP-A-004-01 Rev 7

Hochgeladen von

Bebin MathewCopyright:

Verfügbare Formate

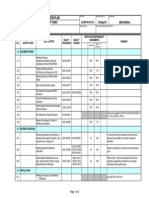

SAUDI ARAMCO ID/PID FORM REV 1 - 010109

Rev 7

COS 03/31/2013

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

Pneumatic Pressure Testing

SATIP-A-004-01

PROJECT TITLE:

ITEM

NO.

1.0

PROJECT PHASE &

Activity Code

DOCUMENT REVIEW

APPROVED DATE

WBS/BI/JO/NO.

TASK / ACTIVITY

QUALITY

PROCEDURE

QUALITY

RECORD

DISCIPLINE:

MECHANICAL

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

CNTRCTR

REMARKS

SAUDI

ARAMCO

SPECIAL PROCESS (PRESSURE TESTING) REQUIRES BEST QUALITY PRACTICE, CPI & EFFICIENT METHODS IN PROCEDURES. PROPOSE BEST METHODS.

1.1

Pressure Testing Procedure

SAIC-A-2001

SAIC-A-2001

RH

RH

For all Pressure Testing (Pneumatic Test, Hydrotest)

1.2

Pressure Test Package Preparation

SAIC-A-2003

SAIC-A-2003

RH

Submit Sample Test Package & Proposed Pressure

Testing Procedure, *See also Notes 1 & 6

In Conjunction with SATIP-A-004-05 (Leak Testing)

Note: A Leak Test at 5-10 psig is mandatory

after all pneumatic strength tests & in systems where service tests

are performed in lieu of pneumatic strength tests (Utility air and

inert gases)

1.3

Leak Testing Procedure

SAIC-A-2005

SAIC-A-2005

RH

RH

1.4

Post-Test Re-Instatement Procedure

SAIC-A-2006

SAIC-A-2006

RH

RH

Required Per SAEP-1160, Section 8

1.5

Line Flushing or Internal Cleanliness

Procedure

SAIC-L-2001

SAIC-L-2001

RH

RH

In conjunction with SATIP-L-350-01 or the applicable

Pipeline or Equipment SATIP.

Verify Pneumatic Test Medium & Bubble

Test Solution (Snoop, etc)

SAIC-A-2004

SAIC-A-2004

RH

In Conjunction with SATIP-A-004-05 for Leak Testing

Data Sheet req'd for solution. Soap Prohibited.

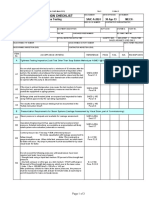

3.1

Internal Cleanliness or Flushing

SAIC-L-2017

SAIC-L-2017

Use SATR-A-2008 In conjunction with SATIP-L-350-01 or

the applicable Pipeline or Equipment SATIP.

3.2

Verification Inspection of Testing

Equipment

SAIC-A-2009

SAIC-A-2009

Use SATR-A-2001 Safety Assessment on Equipment

3.3

Pre-Test Punch Listing

SAIC-A-2010

SAIC-A-2010

Use SATR-A-2007 In conjunction with SATIP-L-350-01 or

the applicable Pipeline or Equipment SATIP.

3.4

Verification of Test Preparation Including

safeguards & safety reqmts

SAIC-A-2011

SAIC-A-2011

3.5

Filling & Pressurization

a) Strength test

b) Service test

SAIC-A-2020

3.6

Inspection of Pneumatic Pressure Test

SAIC-A-2021

3.7

Safe De-Pressurization

SAIC-A-2022

2.0

MATERIAL RECEIVING

2.1

3.0

APPLICATION

Include applicable Quality Records referenced

SATR-A-2001, SATR-A-2002, SATR-A-2003

SATR-A-2006

In Conjunction with SATIP-A-004-05 (Leak Testing)

SAIC-A-2020

SAIC-A-2021

SAIC-A-2022

Page 1 of 2

Note: A Leak Test at 5-10 psig is mandatory

after all pneumatic strength tests & in systems where service tests

are performed in lieu of pneumatic strength tests (Utility air and

inert gases)

Use SATR-A-2001 In Conjunction with SATIP-A-004-05

(Leak Testing)

Use SATR-A-2001

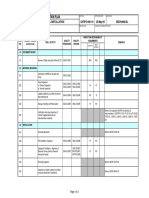

SAUDI ARAMCO ID/PID FORM REV 1 - 010109

Rev 7

COS 03/31/2013

SATIP No.

SAUDI ARAMCO TYPICAL INSPECTION PLAN

Pneumatic Pressure Testing

SATIP-A-004-01

PROJECT TITLE:

ITEM

NO.

PROJECT PHASE &

Activity Code

3.8

4.0

APPROVED DATE

WBS/BI/JO/NO.

QUALITY

PROCEDURE

QUALITY

RECORD

Bubble Leak Test @ 5-10 psig

SAIC-A-2023

Post-Test Re-Instatement Inspection

SAIC-A-2006

TASK / ACTIVITY

DISCIPLINE:

MECHANICAL

30-Apr-13

CONTRACTOR/SUBCONTRACTOR

INSPECTION RESPONSIBILITY

ASSIGNMENTS

REMARKS

CNTRCTR

SAUDI

ARAMCO

SAIC-A-2023

Use SATR-A-2010 In Conjunction with SATIP-A-004-05

(Leak Testing)

SAIC-A-2006

Use SATR-A-2007, SATR-A-2011 Verify completion of

Reinstatement & Certify Test Pkg. Incomplete items go to

FEIL for MCC

POST- TEST

4.2

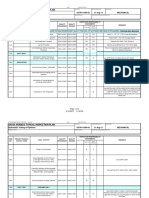

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the levels of

Saudi Aramco participation based upon the Contractors performance.

Surveillance: QA/QC organization to monitor work in progress without notice from Construction Organization.

Witness: QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC organization representative is not

present.

4

5

Hold: QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in attendance.

For Test Package Preparation & review on large projects, each new system designed for testing is thoroughly reviewed & approved. All subsequent packages within a given system shall be built following the

"Copy & Paste" theme for Test Package efficiency and R2 (Sample Review of documents) may be performed.

100% Hold Point for QC Inspection or Test.

Witness Inspection/Test

Surveillance

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

LEGEND

R

Review of Documents

RH

I

Review and Approval of Documents

100% Contractor Inspection

Page 2 of 2

Das könnte Ihnen auch gefallen

- One Page AdventuresDokument24 SeitenOne Page AdventuresPotato Knishes100% (1)

- SAIC-A-2013 Rev 0Dokument2 SeitenSAIC-A-2013 Rev 0philipyapNoch keine Bewertungen

- SAIC-L-2136 Rev 0Dokument3 SeitenSAIC-L-2136 Rev 0philipyapNoch keine Bewertungen

- Dialectical Behavior Therapy With Adolescents - Settings, Treatments, and DiagnosesDokument254 SeitenDialectical Behavior Therapy With Adolescents - Settings, Treatments, and DiagnosesAlguém100% (2)

- SAIC-D-2006 Rev 2Dokument2 SeitenSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Curtain WallDokument11 SeitenCurtain WallZameer AhmedNoch keine Bewertungen

- Saep 31Dokument5 SeitenSaep 31brecht1980100% (1)

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Dokument15 SeitenSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- 1 Checklists Index (Dec 2006-Rev 2 - A SATIP)Dokument2 Seiten1 Checklists Index (Dec 2006-Rev 2 - A SATIP)احمد حسنNoch keine Bewertungen

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Dokument4 Seiten1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764Noch keine Bewertungen

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANDokument3 SeitenSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- SAIC-A-2003 Rev 7 Review of Test Package PreparationDokument7 SeitenSAIC-A-2003 Rev 7 Review of Test Package PreparationPrince JoseNoch keine Bewertungen

- Food ProcessingDokument5 SeitenFood ProcessingMarycris Doria100% (2)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDokument2 SeitenInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument6 SeitenSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNoch keine Bewertungen

- Satip D 001 01Dokument11 SeitenSatip D 001 01Rijwan Mohammad0% (1)

- SatipDokument5 SeitenSatipMuhammad Abdul Kadher100% (3)

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- SAIC-A-2009 Rev 2Dokument5 SeitenSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saic L 2008 PDFDokument4 SeitenSaic L 2008 PDFHesham HelalNoch keine Bewertungen

- Satip G 005 01Dokument2 SeitenSatip G 005 01Anonymous 4e7GNjzGWNoch keine Bewertungen

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Dokument4 Seiten1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- SAIC-A-2008 Rev 0Dokument3 SeitenSAIC-A-2008 Rev 0Kristine Caye DatarioNoch keine Bewertungen

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Dokument2 Seiten1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNoch keine Bewertungen

- SAUDI ARAMCO SHOP FABRICATION INSPECTION PLANDokument2 SeitenSAUDI ARAMCO SHOP FABRICATION INSPECTION PLANskychurch100% (1)

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDokument8 SeitenSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- SAIC-D-2023 Rev 2Dokument2 SeitenSAIC-D-2023 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAUDIPIPINGMATTRACEDokument9 SeitenSAUDIPIPINGMATTRACEMAZHARULNoch keine Bewertungen

- MST Gravity Test OwsDokument5 SeitenMST Gravity Test OwsJenson T VNoch keine Bewertungen

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDokument6 SeitenTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument15 SeitenSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Piping, Hydro QC List-InterviewDokument8 SeitenPiping, Hydro QC List-Interviewtayyab100% (1)

- Effects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersDokument45 SeitenEffects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersJoseph Xyrel Malacad100% (1)

- III. Applicable Codes & Standards for Aramco ProjectsDokument5 SeitenIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNoch keine Bewertungen

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDokument3 SeitenSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-A-2023 Rev 6 Prssure Test Air GasDokument5 SeitenSAIC-A-2023 Rev 6 Prssure Test Air Gaspookkoya thangalNoch keine Bewertungen

- 0049e CHB AcetyleneDokument1 Seite0049e CHB AcetyleneBebin Mathew50% (2)

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Dokument2 Seiten1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalDokument11 SeitenSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDokument12 SeitenSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNoch keine Bewertungen

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDokument3 SeitenSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNoch keine Bewertungen

- Saudi Aramco Reinstatement Procedure ChecklistDokument5 SeitenSaudi Aramco Reinstatement Procedure ChecklistpravinNoch keine Bewertungen

- SAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FDokument2 SeitenSAIC-D-2005 Pressure Vessel Storage, Handling & Preserv PDK-FAnonymous S9qBDVky100% (1)

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Dokument2 SeitenSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNoch keine Bewertungen

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Dokument3 Seiten1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Saudi Aramco Pressure Testing ProcedureDokument21 SeitenSaudi Aramco Pressure Testing ProcedureDilshad AhemadNoch keine Bewertungen

- SAEP-351 Bolted Flange Joint AssemblyDokument12 SeitenSAEP-351 Bolted Flange Joint AssemblyBebin Mathew75% (8)

- SAIC-A-2009 Rev 0Dokument3 SeitenSAIC-A-2009 Rev 0philipyapNoch keine Bewertungen

- Gom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Dokument5 SeitenGom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Bebin Mathew100% (2)

- Gom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Dokument5 SeitenGom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Bebin Mathew100% (2)

- SAIC-A-2015 Rev 7Dokument8 SeitenSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- 0188e CHB OxygenDokument2 Seiten0188e CHB OxygenBebin Mathew83% (6)

- SAIC-A-2015 Rev 2Dokument9 SeitenSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Satip A 004 03Dokument3 SeitenSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SATIP B 019 01 (Revision 4)Dokument2 SeitenSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Dokument3 SeitenSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNoch keine Bewertungen

- 01 Samss 010Dokument11 Seiten01 Samss 010doyenofcastleNoch keine Bewertungen

- Inspection Procedure EDRDokument8 SeitenInspection Procedure EDRaamirtec301Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saep 35Dokument6 SeitenSaep 35hendraox3996Noch keine Bewertungen

- Sa 6717Dokument1 SeiteSa 6717biplabpal2009Noch keine Bewertungen

- API 598 Testing Procedure-20130720-032647Dokument2 SeitenAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- Saep 351Dokument24 SeitenSaep 351Raj KumarNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDokument11 SeitenSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNoch keine Bewertungen

- SAIC-A-2016 Rev 0Dokument2 SeitenSAIC-A-2016 Rev 0philipyapNoch keine Bewertungen

- SAIC-L-2074 Rev 0Dokument1 SeiteSAIC-L-2074 Rev 0philipyapNoch keine Bewertungen

- Saudi Aramco System Lay-up ReportDokument2 SeitenSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Satip A 004 04Dokument3 SeitenSatip A 004 04Ahmed GamalNoch keine Bewertungen

- Satip e 004 01Dokument2 SeitenSatip e 004 01Anonymous 4e7GNjzGWNoch keine Bewertungen

- SAIC-A-2023 Rev 0Dokument2 SeitenSAIC-A-2023 Rev 0philipyapNoch keine Bewertungen

- Leak Testing Procedure SATIPDokument2 SeitenLeak Testing Procedure SATIPpravinNoch keine Bewertungen

- Gi 2 .102 Pressure Testing SafelyDokument17 SeitenGi 2 .102 Pressure Testing SafelyBebin MathewNoch keine Bewertungen

- 016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualDokument26 Seiten016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualAndreyNoch keine Bewertungen

- Bioreactor For Air Pollution ControlDokument6 SeitenBioreactor For Air Pollution Controlscarmathor90Noch keine Bewertungen

- Frontier DL650 Maintenance Guide Ver 1.0Dokument25 SeitenFrontier DL650 Maintenance Guide Ver 1.0philippe raynalNoch keine Bewertungen

- PatternPro Variable Pitch GunDokument2 SeitenPatternPro Variable Pitch GunVõ HòaNoch keine Bewertungen

- Sodium Chloride MSDSDokument5 SeitenSodium Chloride MSDSIbaharmovic LpuNoch keine Bewertungen

- ESP Guidance For All Ships V13.7Dokument53 SeitenESP Guidance For All Ships V13.7Jayasankar GopalakrishnanNoch keine Bewertungen

- SinogramDokument2 SeitenSinogramNguyễn Thành CôngNoch keine Bewertungen

- Plant and Animal Cells Crossword Puzzle: FreebieDokument5 SeitenPlant and Animal Cells Crossword Puzzle: FreebieAref DahabrahNoch keine Bewertungen

- SPR MAN 4 14 ET Operating ManualDokument24 SeitenSPR MAN 4 14 ET Operating ManualJason WeeksNoch keine Bewertungen

- EMAAR HOUSING HVAC SYSTEM SPECIFICATIONSDokument91 SeitenEMAAR HOUSING HVAC SYSTEM SPECIFICATIONSBhuvan BajajNoch keine Bewertungen

- Computed Tomography (CT) - BodyDokument7 SeitenComputed Tomography (CT) - Bodyfery oktoraNoch keine Bewertungen

- Laccase Mediator Pretreatment of Wheat StrawDokument15 SeitenLaccase Mediator Pretreatment of Wheat StrawMeyerling RandfordNoch keine Bewertungen

- AC7101.1 Rev G 2Dokument37 SeitenAC7101.1 Rev G 2Namelezz ShadowwNoch keine Bewertungen

- 6th Class EM All LessonsDokument33 Seiten6th Class EM All LessonsSathish PurushothamNoch keine Bewertungen

- Sem-V Principle of Taxation Law PDFDokument3 SeitenSem-V Principle of Taxation Law PDFAnantHimanshuEkkaNoch keine Bewertungen

- Soni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyDokument1 SeiteSoni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyVishalNoch keine Bewertungen

- Knorr FinalDokument25 SeitenKnorr Finalimbree100% (3)

- A Text Book On Nursing Management AccordDokument790 SeitenA Text Book On Nursing Management AccordMohammed AfzalNoch keine Bewertungen

- Greek God and Goddess ListDokument3 SeitenGreek God and Goddess Listapi-359276609Noch keine Bewertungen

- A Humanistic Approach To Medical PracticeDokument3 SeitenA Humanistic Approach To Medical PracticeFilipos ConstantinNoch keine Bewertungen

- MicrosystemDokument5 SeitenMicrosystembabalalaNoch keine Bewertungen

- Cobb 500 PDFDokument14 SeitenCobb 500 PDFNeil Ryan100% (1)

- HRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and ReceptaclesDokument2 SeitenHRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and Receptaclesa wsNoch keine Bewertungen

- Paket 4Dokument6 SeitenPaket 4Lovis ShalahuddinNoch keine Bewertungen

- Surgical Item - Price ListDokument2 SeitenSurgical Item - Price ListRamnish MishraNoch keine Bewertungen