Beruflich Dokumente

Kultur Dokumente

Manual Installation UnifiedValveAssembly en

Hochgeladen von

nader0123Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manual Installation UnifiedValveAssembly en

Hochgeladen von

nader0123Copyright:

Verfügbare Formate

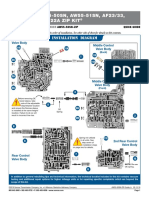

Installation of Unified Valve Assembly

for ZVA Slimline 2 / ZVA Slimline 2 GR

TECHNISCHE NDERUNGEN VORBEHALTEN NACHDRUCK UND KOPIEN NUR MIT UNSEREM EINVERSTNDNIS Specifications subject to change without notice Copyright ELAFLEX

From April 2014, all ZVA Slimline 2 and ZVA Slimline 2 GR contain the Unified Valve Assembly EA 055 see

Information 5.14 E. For the retrofitting and repair of old nozzles we recommend only to use the new parts shown below.

Note, old and new spare parts shall not be mixed to avoid malfunction.

OLD

top view:

'H' (HiFlo)

Standard

EG 068,

EV 067,

EF 063,

EC 094

EG 069,

EV 066,

EF 065.1,

EC 014

'H' (HiFlo):

EA 058

EF 061

Standard:

EF 064

NEW

top view:

EA 055

EA 058.1

EF 060.1

EF 064.1

(Unified Valve Assembly)

EF 060

EA 037

Disassembling

Recommended tools (left to right):

Remove slogan badge EK 145,

product sleeve EK 043, scuffguard

EK 044, vacuum cap EK 148.1 or

EA 052 (DSA) with EW 19/22.

Remove diaphragm spring EF 250.2,

diaphragm assembly EA 151.

Unscrew guard screw assembly

EB 438 with two screwdrivers

EW 669/2 and rear screw assembly

EB 278.

Pull off the guard EG 281.

On both sides pull out lever pins

EB 235 with EW 2 CV.

Lift up lever assembly EA 030 by

levering with a screwdriver.

Clamp ZVA in a vice. Put assembling

tool EW 3 into diapgragm chamber

to secure pull rod assembly EA 058.

Remove valve seat EG 069 / 068 with

double box spanner EW 19/22.

Use assembling tool EW 5-3 to push

the pull rod assembly EA 058 inside,

against the force of the main spring.

Remove assembling tool EW 3 from

the diaphragm chamber. Release

spring tension by removing EW 5-3.

Tilt nozzle body and remove pull rod

assembly EA 058, main spring

EF 060 or EF 061 and return spring

EF 064.

EW 669/2, EW 19/22, EW 5-3, EW 3,

EW 7, EW 2 CV, EW-M 41/46

July 2014

Assembling

Oil pull rod assembly EA 058.1 thoroughly. Push return spring EF 064.1

with main spring EF 060.1 onto pull

rod assembly.

Push this group onto assembling tool

EW 5-3, oil it and insert it as shown

into the nozzle body.

Push EW 5-3 into nozzle body and

compress main spring. Put EW 3 into

diaphragm chamber to fix EA 058.1

Remove EW 5-3. Put valve assembly

EA 055 on EW 5-3 and apply oil.

Screw it in with EW 3.

Remove assembling tools.

Check alignment of pull rod assembly recess. It should show upwards.

Oil lever bolt and insert lever EA 030

into nozzle body.

Align lever to the holes in the nozzle

body. On both sides insert lever pins

EB 235 to secure lever.

Push guard EG 281 onto nozzle

body. Align the guards to the holes

of the nozzle body.

Insert guard screw assembly

EB 438.

Tighten screws with screwdrivers

EW 669/2.

Insert rear screw EB 278 and tighten

it with a torque of 3 Nm (hand-tight).

Clamp the nozzle tilted into the vice.

With rollers showing downside insert

diaphragm assembly EA 151 into

diaphragm chamber.

Squeeze lever to check that rollers

are engaged into pull rod assembly.

If ok, position diaphragm spring

EF 250.2 centred on the diaphragm

assembly.

Apply oil on nozzle thread, o-ring

zone and outer border of the

diaphragm. Screw vacuum cap

EK 148.1 or EA 052 (DSA) hand-tight

into the nozzle body.

The ribs of of the vacuum cap must

be in 3 or 9 o'clock position, in order

that product badges EK 145 can be

fixed correctly.

Elaflex recommends to mark nozzles equipped with the

Unified Valve Assembly on the nozzle body (above the

serial number) with an "E".

This is our standard marking for ZVA 2 / ZVA 2 GR containing

the Unified Valve Assembly.

It helps to quickly recognize the new inner parts of a nozzle.

Das könnte Ihnen auch gefallen

- Toyotau250 IntroductionDokument48 SeitenToyotau250 IntroductionUka JosephNoch keine Bewertungen

- Manual Angle Stop Valve EA: Ausgabe: 05/2007Dokument3 SeitenManual Angle Stop Valve EA: Ausgabe: 05/2007Behnam AshouriNoch keine Bewertungen

- A 084 BDokument12 SeitenA 084 BDenis JimenezNoch keine Bewertungen

- ELWE Separation Sleeve Technical DatasheetDokument3 SeitenELWE Separation Sleeve Technical DatasheetEvolution Oil ToolsNoch keine Bewertungen

- Válve Relay Air Starters CAT E WaukeshaDokument8 SeitenVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraNoch keine Bewertungen

- Tháo Lắp Và Cài Đặt Lại Trục Cam XảDokument7 SeitenTháo Lắp Và Cài Đặt Lại Trục Cam Xảduc tai buiNoch keine Bewertungen

- Wheel Horse Hydraulic Lift Valve & Cylinder Repair ManualDokument12 SeitenWheel Horse Hydraulic Lift Valve & Cylinder Repair ManualwordswainNoch keine Bewertungen

- Flowcon ABM InstructionDokument4 SeitenFlowcon ABM InstructionJeff Anderson CollinsNoch keine Bewertungen

- Oversized C1/K1 Clutch Control Valve Kit: Aisin AW TF-60SN, TF-80SC, TF-81SC Mini 6F21WA VW/Audi 09G, 09K, 09MDokument2 SeitenOversized C1/K1 Clutch Control Valve Kit: Aisin AW TF-60SN, TF-80SC, TF-81SC Mini 6F21WA VW/Audi 09G, 09K, 09MOmar CPNoch keine Bewertungen

- PF5700 00 1.8TS Master US Dec 06Dokument1.654 SeitenPF5700 00 1.8TS Master US Dec 06mohammedNoch keine Bewertungen

- 001 - Valvuals, AjustarDokument6 Seiten001 - Valvuals, AjustarAparecidaMarquesNoch keine Bewertungen

- Valvulas 02Dokument7 SeitenValvulas 02Janderson LacerdaNoch keine Bewertungen

- Transmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesDokument5 SeitenTransmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesFDONoch keine Bewertungen

- Technical Information Bulletins Ajax # 010717Dokument28 SeitenTechnical Information Bulletins Ajax # 010717harley florezNoch keine Bewertungen

- AE14 Automatic Air Vents For Liquid SystemsDokument8 SeitenAE14 Automatic Air Vents For Liquid SystemsUtku KepcenNoch keine Bewertungen

- LS Furmanite OyMDokument26 SeitenLS Furmanite OyMDanny Carrasco Vicharra0% (2)

- Oversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)Dokument2 SeitenOversized Primary Pulley Regulator Valve Kit: Jatco/Nissan JF015E (RE0F11A)marranNoch keine Bewertungen

- Maintenance Manual Resilent-seated-Valves - EN - MarkupDokument6 SeitenMaintenance Manual Resilent-seated-Valves - EN - MarkupP GNoch keine Bewertungen

- 1 Thru 6in E Series Globe Valves ED ET PDFDokument16 Seiten1 Thru 6in E Series Globe Valves ED ET PDFakhileshkuniyilNoch keine Bewertungen

- AW55-50SN, AW55-51SN, AF23/33, Re5F22A Zip Kit: Installation DiagramDokument10 SeitenAW55-50SN, AW55-51SN, AF23/33, Re5F22A Zip Kit: Installation DiagramRomeo Taranu100% (2)

- Apv Delta Sv1Dokument20 SeitenApv Delta Sv1VLASTARNoch keine Bewertungen

- Vlaim029 - Position Pac Iom 07-2000Dokument8 SeitenVlaim029 - Position Pac Iom 07-2000rodrurenNoch keine Bewertungen

- 1300 Edi Series 60 SplitDokument10 Seiten1300 Edi Series 60 Split何青Noch keine Bewertungen

- Oversized 3/5/reverse & Underdrive Pressure Control Valve KitDokument2 SeitenOversized 3/5/reverse & Underdrive Pressure Control Valve KithidraulicNoch keine Bewertungen

- Masoneilan+ +87+and+88+Series+Spring+and+Diaphragm+Actuator+IOMDokument24 SeitenMasoneilan+ +87+and+88+Series+Spring+and+Diaphragm+Actuator+IOMAsterixNoch keine Bewertungen

- Automatic Transaxle (Service) (Gf4ax-El)Dokument53 SeitenAutomatic Transaxle (Service) (Gf4ax-El)МаксNoch keine Bewertungen

- Aw5550SnZip 1580008475 PDFDokument10 SeitenAw5550SnZip 1580008475 PDFyhovany100% (1)

- SEAINSvs 4880Dokument3 SeitenSEAINSvs 4880Rui PintoNoch keine Bewertungen

- FlowCon EVS Instruction 04 2012Dokument8 SeitenFlowCon EVS Instruction 04 2012Jeff Anderson CollinsNoch keine Bewertungen

- Fuel Control ValveDokument12 SeitenFuel Control ValveALVARO OLACHICANoch keine Bewertungen

- AFC Sensor de Presion PDFDokument10 SeitenAFC Sensor de Presion PDFCharlie BrownNoch keine Bewertungen

- Needle Valve Maintenance Instructions - Alco Valves PM-221Dokument5 SeitenNeedle Valve Maintenance Instructions - Alco Valves PM-221AzaelNoch keine Bewertungen

- 1300 Edi Series 80 SplitDokument10 Seiten1300 Edi Series 80 Split何青Noch keine Bewertungen

- Abs Wabco Manutec3Dokument12 SeitenAbs Wabco Manutec3Bom_Jovi_681Noch keine Bewertungen

- Operator'S Manual Exxxxx-Xxx-X: E Series ValvesDokument24 SeitenOperator'S Manual Exxxxx-Xxx-X: E Series ValvesMauricio GarciaNoch keine Bewertungen

- Valve Linkages Models Q455C, Q455D, Q455F: GeneralDokument8 SeitenValve Linkages Models Q455C, Q455D, Q455F: GeneralSopian PianNoch keine Bewertungen

- Jamesbury Butterfly Valves 8000 and 8200Dokument8 SeitenJamesbury Butterfly Valves 8000 and 8200Uday GokhaleNoch keine Bewertungen

- 30 - EC210B - MCV, Válvula Lógica EmperradaDokument4 Seiten30 - EC210B - MCV, Válvula Lógica EmperradaAparecidaMarquesNoch keine Bewertungen

- CAT3512 Valve Lash and Valve Bridge AdjustmentDokument7 SeitenCAT3512 Valve Lash and Valve Bridge AdjustmentEfrain FlorezNoch keine Bewertungen

- W-2119 & W-2120 Series: Parts Manual 823036ENDokument12 SeitenW-2119 & W-2120 Series: Parts Manual 823036ENsolrac4371Noch keine Bewertungen

- 4r44e 5r55e Zip BookletDokument8 Seiten4r44e 5r55e Zip BookletDaniel BernardNoch keine Bewertungen

- Reglaje de Valvulas D6DDokument7 SeitenReglaje de Valvulas D6DJhunior MorenoNoch keine Bewertungen

- Verroulliage Outil 2Dokument20 SeitenVerroulliage Outil 2voisinNoch keine Bewertungen

- FCV COMBO Manual ABZ Valve W Actuator J032Dokument28 SeitenFCV COMBO Manual ABZ Valve W Actuator J032corasaulNoch keine Bewertungen

- Rack & Pinoin Rotary AvtutarDokument24 SeitenRack & Pinoin Rotary AvtutarTanmoy DuttaNoch keine Bewertungen

- FlowCon EVC Instruction 05.2010Dokument4 SeitenFlowCon EVC Instruction 05.2010Jeff Anderson CollinsNoch keine Bewertungen

- !warning!: ME225 Powertorq Series Actuator Instruction ManualDokument2 Seiten!warning!: ME225 Powertorq Series Actuator Instruction ManualCarlos RondonNoch keine Bewertungen

- Technical Bulletin: CopierDokument22 SeitenTechnical Bulletin: CopiernickypanzeNoch keine Bewertungen

- "A" Pilotair Valve Block Type and Panel MountedDokument24 Seiten"A" Pilotair Valve Block Type and Panel MountedJairoHernanLoperaNoch keine Bewertungen

- Table (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)Dokument5 SeitenTable (4b) Actuator Dimensions (OM-2 To OM-3, OM-4 To OM-6) Table (4a) Actuator Dimensions (OM-1)NaveenRajNoch keine Bewertungen

- A750 VBDokument6 SeitenA750 VBMothana Husban100% (1)

- BALON Floating Valve - Installation and Repair Manual 2Dokument13 SeitenBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapNoch keine Bewertungen

- Es Acv M115F M1115FDokument4 SeitenEs Acv M115F M1115FWattsNoch keine Bewertungen

- A750E ManualDokument6 SeitenA750E Manualruslan158080% (10)

- Nissan Re4Fo4A, Ford 4F20E: Accumulator Valve KitDokument2 SeitenNissan Re4Fo4A, Ford 4F20E: Accumulator Valve Kitflash_24014910Noch keine Bewertungen

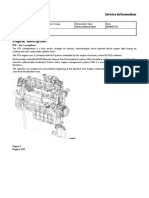

- Engine, Description: Service InformationDokument15 SeitenEngine, Description: Service InformationDeepak D PillaiNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsVon EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNoch keine Bewertungen

- Technical Interview Candidate GuideDokument10 SeitenTechnical Interview Candidate Guidenader012371% (7)

- Spare Parts CMS RevADokument26 SeitenSpare Parts CMS RevAnader0123Noch keine Bewertungen

- Fact Sheet - Fitter GeneralDokument5 SeitenFact Sheet - Fitter Generalnader0123Noch keine Bewertungen

- Logoline 500: Pen Recorder With Text PrintingDokument92 SeitenLogoline 500: Pen Recorder With Text Printingnader0123Noch keine Bewertungen

- Fiber Glass PipeDokument4 SeitenFiber Glass Pipenader0123Noch keine Bewertungen

- PTE Speaking Describe ImageDokument8 SeitenPTE Speaking Describe Imagenader012388% (8)

- PTE Speaking Describe ImageDokument8 SeitenPTE Speaking Describe Imagenader012388% (8)

- Hydrostatically Testing APT SumpsDokument1 SeiteHydrostatically Testing APT Sumpsnader0123Noch keine Bewertungen

- Vapor Recovery System ProductsDokument8 SeitenVapor Recovery System Productsnader0123Noch keine Bewertungen

- 61JSK Jack Screw DeviceDokument1 Seite61JSK Jack Screw Devicenader0123Noch keine Bewertungen

- Flexworks Next Generation Supply PipingDokument4 SeitenFlexworks Next Generation Supply Pipingnader0123Noch keine Bewertungen

- Piping FG Smith FiberglassDokument12 SeitenPiping FG Smith Fiberglassnader0123100% (1)

- ELAFLEX Information 5.08EDokument2 SeitenELAFLEX Information 5.08Enader0123Noch keine Bewertungen

- IMIR - 066 - G2 For CS Seamless Pipe 150NB Pipe For Group IIDokument1 SeiteIMIR - 066 - G2 For CS Seamless Pipe 150NB Pipe For Group IIFredin FrancisNoch keine Bewertungen

- WCTE 2018 Conference Paper Stoner FinalVerDokument7 SeitenWCTE 2018 Conference Paper Stoner FinalVerMichael StonerNoch keine Bewertungen

- Warehouse 2Dokument1 SeiteWarehouse 2aliNoch keine Bewertungen

- Tension PileDokument81 SeitenTension PileVera CupezNoch keine Bewertungen

- Sans 1200 HDokument3 SeitenSans 1200 HfilipeNoch keine Bewertungen

- Subject: Structural Design III Introduction of Subject: Examination SchemeDokument63 SeitenSubject: Structural Design III Introduction of Subject: Examination SchemeKiran BandeNoch keine Bewertungen

- Intro. of Efficiency AwarenessDokument136 SeitenIntro. of Efficiency AwarenessFajrin Karza JuniarzalNoch keine Bewertungen

- JOHN - DEERE - 360plus Rotary Harvesting UnitDokument136 SeitenJOHN - DEERE - 360plus Rotary Harvesting UnitАлександр CheryNoch keine Bewertungen

- OHP Assignment 19122016 060442AMDokument3 SeitenOHP Assignment 19122016 060442AMPARMAR MAHENDRANoch keine Bewertungen

- Clutch Damper ChangeDokument6 SeitenClutch Damper ChangeAaron StaubNoch keine Bewertungen

- 6stroke EngineDokument5 Seiten6stroke EngineMitesh KumarNoch keine Bewertungen

- Motores: Tabla de Equivalencias para LubricantesDokument2 SeitenMotores: Tabla de Equivalencias para LubricantesPablo Luis Ojeda PaezNoch keine Bewertungen

- Structural Steel DesignDokument32 SeitenStructural Steel Designshaluka100% (1)

- Diesel Cycle AnalysisDokument16 SeitenDiesel Cycle AnalysisSarah AsgharNoch keine Bewertungen

- Chapter 15 BennetDokument91 SeitenChapter 15 BennetpapipapiiNoch keine Bewertungen

- Shipbulding Technology 7th & 8th Semester SyllabusDokument39 SeitenShipbulding Technology 7th & 8th Semester SyllabusDiploma in Engineering Shipbuilding TechnologyNoch keine Bewertungen

- Operation On Low Sulphur FuelsDokument24 SeitenOperation On Low Sulphur FuelsAlejandro Jose Malave RamosNoch keine Bewertungen

- NR 310102 Structural Analysis 1Dokument8 SeitenNR 310102 Structural Analysis 1Srinivasa Rao G100% (1)

- Can Id To Sae J1939 PGNDokument171 SeitenCan Id To Sae J1939 PGNdiana aragon100% (1)

- 04a - Hydrapak 3 Brochure - 2015-07 - RevisedDokument2 Seiten04a - Hydrapak 3 Brochure - 2015-07 - Revisedgavsta007Noch keine Bewertungen

- Cigweld Weldskill 170 HF PDFDokument48 SeitenCigweld Weldskill 170 HF PDFRizaNoch keine Bewertungen

- Japan: EDI CT OF GovernmentDokument23 SeitenJapan: EDI CT OF GovernmentHan Win AungNoch keine Bewertungen

- Atlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Dokument6 SeitenAtlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Thierry Nolla100% (1)

- XE145F Presentation AUMDokument21 SeitenXE145F Presentation AUMrudyNoch keine Bewertungen

- 460E - ADT - Uptime Maintenance PlannerDokument3 Seiten460E - ADT - Uptime Maintenance PlannerBassieNoch keine Bewertungen

- Direct Numerical SimulationDokument38 SeitenDirect Numerical SimulationddqylxgNoch keine Bewertungen

- Multi Pump Test Rig Positive Displacement Plunger PumpDokument9 SeitenMulti Pump Test Rig Positive Displacement Plunger PumpDaniel IsmailNoch keine Bewertungen

- Aircraft Materials and Processes - 2017 PDFDokument36 SeitenAircraft Materials and Processes - 2017 PDFDan Keith Mina DuadNoch keine Bewertungen

- Format - CISDokument8 SeitenFormat - CISgopichandallakaNoch keine Bewertungen