Beruflich Dokumente

Kultur Dokumente

161401

Hochgeladen von

Orlando E Cabrera RojasCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

161401

Hochgeladen von

Orlando E Cabrera RojasCopyright:

Verfügbare Formate

Standard LV Variable Frequency Drives

IP 16-14-1

Page 1 of 6

INTERNATIONAL

PRACTICE

(This practice is appropriate for attachment to Inquiry or Purchase Document)

Rev. 0

June 1997

SCOPE

I

1.1

1.2

1.3

1.4

This practice covers Variable Frequency Drives (VFDs) made to a Manufacturers standard design. This

type VFD is a complete, stand-alone converter equipment, fully specified in a printed catalog or data sheet

which is current at the date of this Inquiry, and capable of speed and torque control of a three-phase

squirrel-cage induction motor.

Thermal capabilities, voltage, insulation and all other design aspects of the VFD, motor and cabling

system shall be compatible.

Standard VFDs are supplied directly, without transformer, from a low voltage power bus supply with a

maximum voltage rating of 690 V rms a-c.

The contents of this practice are arranged as follows:

TABLE OF CONTENTS

SCOPE.......................................................................................................................... 1

SUMMARY OF ADDITIONAL REQUIREMENTS ........................................................... 1

DOCUMENTATION ....................................................................................................... 1

CONSTRUCTION REQUIREMENTS ............................................................................. 2

PERFORMANCE REQUIREMENTS .............................................................................. 3

ALARMS....................................................................................................................... 4

TESTING....................................................................................................................... 4

SPECIFICATION SHEET FOR STANDARD LV VARIABLE FREQUENCY DRIVES ...... 6

I

1.5

1.6

An asterisk (V) indicates that a decision or approval by the purchaser is required or that additional

information is to be furnished by the purchaser.

The following references are synonymous: BP and IP.

SUMMARY OF ADDITIONAL REQUIREMENTS

I

2.1

The following practices shall be used with this practice.

PRACTICES

IP 15-7-2

Protective Systems

IP 16-9-1

Low Voltage A-C Motors up to 200 HP (150 kW)

IP 16-9-2

A-C Motors: Medium Voltage and Low Voltage

over 200 HP (150 kW)

IP 16-12-1 Switchgear, Control Centers and Bus Duct

2.2

The following standards shall be used with this practice when specified by the purchaser.

STANDARDS

IEC Standards

IEEE Standards

34-1

Rotating Electrical Machines-Rating and

Performance Section 14: Electromagnetic

Compatibility (EMC)

519

146-1

Semiconductor Convertors (3 Parts)

541

529

Classification of Degrees of Protection Provided by

Enclosures

1800-3

Adjustable Speed Electrical Power Drive Systems

Part 3: EMC Product Standard Including Specific

Test Methods First Edition

Recommended Practices and Requirements for Harmonic

Control in Electric Power Systems

API Standard

Form-Wound Squirrel-Cage Induction Motors - 250

Horsepower and Larger

DOCUMENTATION

I

3.1

Catalog data for VFD and motor shall provided with all proposals, along with a copy of the standard

instructions for safe installations, commissioning, operation, and maintenance for the VFD(s) offered.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

IP 16-14-1

Standard LV Variable Frequency Drives

Page 2 of 6

Rev. 0

June 1997

(This practice is appropriate for attachment to Inquiry or Purchase Document)

INTERNATIONAL

PRACTICE

3.2

VFD data specified in Table 1, shall be furnished by the vendor with all proposals. Additionally, all other

drawings and documentation specified herein shall be supplied with the proposal.

3.3

Vendor shall provide documentation showing that the equipment meets the approval requirements

of the local authority. Approval requirements may include labeling, listing, or certification by a nationallyrecognized testing organization acceptable to the local authority.

3.4

When motor is included, the vendor shall supply documentation to confirm motor compliance with

applicable national and local authority requirements for hazardous areas. If this is not available, suitable

factory heat run tests shall be carried out and documented as required by the authority.

CONSTRUCTION REQUIREMENTS

MECHANICAL

R

4.1

Unless otherwise specified, the VFD will be located indoors in an unclassified area with ambient

temperature range of 50-104F (10-40C) and below 3200 ft (1000 m) elevation. The VFD shall have a

minimum ingress protection of NEMA12 or IP21.

4.2

The vendor shall provide drawings to show the minimum spacing around the VFD essential to maintain

proper ventilation and cooling, whether mounted alone in an enclosure, or as part of a multiple VFD

installation within the same enclosure.

ELECTRICAL

R

4.3

The VFD shall be capable of withstanding the thermal and mechanical forces resulting from a short

circuit.

* 4.4

Vendors equipment shall comply with installation and electrical interlocking details shown on the oneline diagram, when supplied by the purchaser.

4.5

Vendors equipment supply shall include the following when needed to meet the requirements of this

practice:

a.

Output line reactors or other equipment required to ensure the motor and cable insulation systems

are suitable for reliable operation with the VFD drive technology employed and comply with EMC

emissions requirements.

b.

Input filters and reactors

4.6

Vendor shall provide electrical details on the VFD(s) offered including:

a.

Output waveform from the VFD imposed on the motor and cable, including the maximum voltage

rate of rise and peak values, and output carrier frequencies for various load conditions.

b.

Physical sizes, installation requirements and electrical connections of any reactor or filter

equipment that cannot be supplied within the VFD cubicle.

c.

Maximum size of input fuse rating and type.

CONTROL

O,M

4.7

Minimum controls shall be provided at the VFD control panel, and also be available as external hardwired control circuit inputs as follows:

a.

Run, forward and reverse.

b.

Stop.

c.

d.

4.8

Speed reference. A smooth bump-less transfer shall be provided between the local and remote

speed reference/control signals. The local speed reference shall override external signals.

Reset for any alarm or trip condition.

Other control features that can be offered for the proposed VFD shall be listed, including:

a.

Hard-wired outputs for monitoring circuits

b.

Local or hard-wired remote indications.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

Standard LV Variable Frequency Drives

Page 3 of 6

INTERNATIONAL

PRACTICE

O,M

4.9

R

O

I

IP 16-14-1

(This practice is appropriate for attachment to Inquiry or Purchase Document)

Rev. 0

June 1997

The following minimum information applicable to the VFD shall be displayed at the VFD control panel:

a.

Local or Remote selected

b.

c.

VFD ready to start

VFD running

d.

e.

Alarm

VFD tripped

f.

g.

Output frequency

Output current

4.10

Indication lamps and displays shall be long life LED type.

4.11

Input speed reference signal shall be configurable for isolated signals for both 4-20 mA and 0 to +10 V.

4.12

Vendor shall provide control details including:

a.

Microprocessor scan time, and response times for analog, digital and serial communications

signals.

b.

Interface and protocol data for serial communications.

LABELS

S

4.13

Warning labels shall advise the proximity of live components and discharge times of power capacitors.

4.14

One rating plate shall be fitted to each VFD.

M,O

4.15

Labeling shall clearly identify all: terminals, removable links, fuses, fans, control and indication devices,

and internal wiring.

VFD BY-PASS POWER SUPPLY

M,O

4.16

When specified, an electrical by-pass shall be provided. The by-pass shall be manually operated and

provided with mechanical interlocks to prevent paralleling of the VFD and by-pass power supplies.

PERFORMANCE REQUIREMENTS

GENERAL

R

O,R

5.1

VFD shall be capable of 5 years run length between shutdowns.

5.2

Vendor shall select the motor frame size, design and number of poles to meet the rated load and

application requirements specified in Table 1. Use of external motor fan(s) shall be approved by the

Owners Engineer.

INPUT POWER SUPPLY

O

5.3

VFD shall operate successfully at rated load over the entire operating speed range under the following

system conditions:

a.

Input voltage variation up to 10% of rated to the VFD or auxiliaries, at rated frequency.

b.

Input frequency variation up to 5% of rated, at rated voltage.

c.

Combined voltage and frequency variation of up to 10% of rated.

O,R

5.4

Following any momentary voltage dip not exceeding 0.5 sec duration and 20% dip in the input voltage

supply or the auxiliary voltage supply or both; the VFD shall be able to automatically ride through, return to

set-point speed, or reaccelerate if load torque demand resulted in reduced speed.

O,R

5.5

VFD shall be capable of automatically re-accelerating the driven equipment, following voltage dips

greater than 20% of rated in the input power supply, and up to 5 seconds duration, without the need to

come to a complete stop. Following the voltage dip or loss, the VFD shall automatically reaccelerate when

the input voltage has recovered to 90% or more of rated voltage. The vendor shall state the maximum

time delay before re-acceleration begins following restoration of the supply voltage, and if this time delay is

adjustable.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

IP 16-14-1

Standard LV Variable Frequency Drives

Page 4 of 6

Rev. 0

June 1997

(This practice is appropriate for attachment to Inquiry or Purchase Document)

INTERNATIONAL

PRACTICE

VFD POWER OUTPUT

O

5.6

Overload capability of the VFD. VFD shall be capable of delivering the output currents listed by the

vendor on the specification sheet, with input voltages variations between 90% and 110% of rated, taking

into account the capacitive current requirements for the cable length and size.

5.7

Magnitude and duration of external voltage surges that the VFD can withstand at its terminals shall be

listed.

5.8

VFD frequency (speed) output shall be within 1% of any given set point over the entire operating

frequency range.

O,R

5.9

On loss of an external speed reference signal, the VFD shall be capable of defaulting to any of the

following speeds: maximum, minimum, or hold to the operating speed prior to loss of signal.

ELECTROMAGNETIC COMPATIBILITY (EMC), HARMONICS

I

5.10

Local and national standards for radio-frequency emissions and susceptibility shall be met.

5.11

The value of total harmonic voltage distortion at the VFD supply bus caused by current harmonics in

the line current of the VFD, shall be calculated by the vendor based on the short circuit level of the supply

system at the VFD supply bus.

O,R

5.12

Motor current harmonics shall not exceed 5% of the rms amplitude of the fundamental over the complete

design speed range, unless a more restrictive value is specified.

O,R

5.13

Total harmonic voltage distortion caused by the VFD current harmonics measured at VFD input

terminals shall not exceed 5% of the fundamental value at the most onerous condition, unless a lower

value is specified. The vendor shall provide filter equipment to meet this requirement.

PROTECTION

R

5.14

VFD input protection shall include incoming fuse and voltage protection features as required for overload,

short circuit and ground fault, voltage transients, and be consistent with the power supply short circuit

level.

O,R

5.15

Motor protection against overload, stall, locked rotor, single-phasing, phase and ground fault, and

internal motor fault shall be provided by trip features in the VFD.

O,R

5.16

Relays which trip the VFD for fault conditions shall have a manually-reset lockout feature. The trip

information shall be memorized and this memory will not be lost if the drive is isolated or deenergized.

5.17

Overvoltage protection devices for VFD power circuits, auxiliary power circuits, motor and motor cable

shall be provided.

5.18

Overspeed protection shall immediately shut down the VFD if the frequency exceeds 105% of input set

point or exceeds a preset maximum speed limit. Response time of the protection system shall prevent any

damage to the driven equipment from overspeed.

5.19

Underspeed (stall) protection shall immediately shut down the VFD if the output frequency falls below

90% of minimum set point for 20 seconds.

5.20

One pair of fail-safe contacts (one open and one closed), that change state for conditions that could

lead to damage of the VFD or driven equipment, for use with external control or external trip circuits shall

be provided.

5.21

Table 1 indicates if motor temperature protection is required and the type specified. Vendor shall advise if

protection is required by motor certification.

ALARMS

R

6.1

Any out-of-range and/or trip condition shall cause the VFD local control panel to display an alarm signal

and shall cause an alarm contact to open for use by an external alarm circuit.

O,M

6.2

Control logic shall permit interrogation to determine the cause of the alarm and distinguish between

mechanical and electrical type faults. The data shall not be lost if its drive is isolated or deenergized.

TESTING

I

7.1

Standard factory tests shall be given to prove satisfactory operation. When specified, these tests shall

be witnessed.

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

Standard LV Variable Frequency Drives

IP 16-14-1

Page 5 of 6

INTERNATIONAL

PRACTICE

(This practice is appropriate for attachment to Inquiry or Purchase Document)

Rev. 0

June 1997

7.2

VFD input current harmonics, when specified, shall be measured at all operating conditions.

7.3

Tests to prove satisfactory operation of the VFD and motor, if specified, may include an 8-hour heat

run test in the most onerous conditions, power factor measurements, demonstration of stable operation

when applying and removing load at all speeds and supply conditions, and ability to ride through or

reaccelerate following short power supply interruptions.

7.4

If specified, vendor shall participate in a complete string test to be performed by others.

12/90

6/97

Revision Memo

Original Issue of Basic Practice

Revision 0 - Original Issue of International Practice

Purpose Codes added throughout. Complete Revision. This practice has been completely revised to cover

purchase of Standard LV VFDs.

Exxon Research and Engineering Company, 1990, 1997

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

IP 16-14-1

Standard LV Variable Frequency Drives

Page 6 of 6

Rev. 0

June 1997

INTERNATIONAL

PRACTICE

(This practice is appropriate for attachment to Inquiry or Purchase Document)

TABLE 1

SPECIFICATION SHEET FOR STANDARD LV VARIABLE FREQUENCY DRIVES

PURCHASER'S REQUIREMENTS

ONE-LINE DIAGRAM NO., IF PROVIDED:

RATED MOTOR POWER (MAX SPEED): _____hp _____kW

VFD IDENTIFICATION:

MOTOR POLES:

DRIVEN EQUIPMENT ID:

MOTOR CABLE LENGTH:

RATED VOLTAGE: __________V

50 Hz 60 Hz

SYSTEM SHORT CIRCUIT LEVEL:

_______kA _______MVA

__________POLES

__________FT __________m

DRIVEN EQUIPMENT: PUMP FAN CONST. TORQUE

LOAD TORQUE AT STARTING:

__________% FULL LOAD

VFD INGRESS PROTECTION: NEMA ____ IP____

MOTOR CABLE CROSS SECTION:

SERIAL COMMUNICATIONS CONTROL REQD: YES NO

PROTOCOL DESIRED: _______________________

MOTOR AREA CLASSIF:

________GAS GROUP

MOTOR TEMPERATURE PROTECTION REQD:

YES NO

IF YES: TYPE ____________

SYSTEM GROUNDING:

SOLID HIGH RESISTANCE OTHER _____________

MOTOR SPEED RANGE REQD: _____MIN _____MAX RPM

FACTORY TESTING: VENDOR STD HEAT RUN WITNESS

______kCM ______mm2

________Class

________Zone

________Div.

________T Class

PURCHASERS COMMENTS AND SPECIAL REQUIREMENTS

MANUFACTURER'S DATA (VENDOR TO COMPLETE)

MANUFACTURER:

OUTLINE DRAWING NUMBER:

YES NO

OUTPUT A-C REACTOR INCLUDED:

YES NO

INPUT REACTOR INCLUDED:

TYPE OF VFD PROPOSED: CSI PWM OTHER

TYPE POWER SEMICONDUCTORS: IGBT GTO OTHER

MAXIMUM CONTINUOUS CURRENT:

__________% FLC

OVERLOAD CAPABILITY:

__________% FLA FOR 20 SEC

SWITCHING FREQUENCY RANGE (PWM): ___kHz to ___kHz

OVERLOAD CAPABILITY:

__________% FLA FOR 60 SEC

AVAILABILITY OF SKIP FREQUENCIES:

_______SKIPS

ACCURACY OF OUTPUT FREQ.:

TORQUE BOOST AVAILABLE:

YES NO

MAXIMUM TORQUE AT ZERO SPEED:

HEAT LOSS AT MAXIMUM LOAD:

___________W

AUTO RESTART FACILITY AVAILABLE:

YES NO

VOLTAGE SURGE WITHSTAND AT VFD INPUT TERMINALS:

PH-PH _____kV(peak)/sec, PH-GROUND _____kV(peak)/sec

TIME DELAY BEFORE REACCELERATION AFTER VOLTAGE RESTORATION:

_________SEC

SERIAL COMMUNICATION PROTOCOLS AVAILABLE:

YES NO

IF YES, LIST TYPE: ___________

MOTOR TEMPERATURE PROTECTION REQUIRED

FOR CERTIFICATION:

YES NO

MOTOR INSULATION:

INCOMING FUSE SIZE: _______A

TYPE________ LEVEL________kV

_______% SET POINT Hz

__________% FLT

TYPE: _______

MAXIMUM PERMISSIBLE MOTOR CABLE LENGTH:

__________ft __________m

FAIL-SAFE CONTACT AVAILABLE FOR EXTERNAL

ALARM / TRIP:

YES NO

MOTOR NOISE LEVEL:

MAXIMUM CABLE SIZE:

__________dBA

_______kCM _______mm2

MOTOR ENCLOSURE TYPE: TEFC EX IP______

DEVIATIONS TO THIS PRACTICE (BY VENDOR):

LISTED BELOW LIST ATTACHED

THIS INFORMATION FOR AUTHORIZED COMPANY USE ONLY

EXXON RESEARCH AND ENGINEERING COMPANY FLORHAM PARK, N.J.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- History Background Document: IP 9-1-1 Spacing and Dikes For Storage Vessels and TanksDokument4 SeitenHistory Background Document: IP 9-1-1 Spacing and Dikes For Storage Vessels and TanksOrlando E Cabrera RojasNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- History Background Document: IP 3-10-1 Piping Selection and Design CriteriaDokument1 SeiteHistory Background Document: IP 3-10-1 Piping Selection and Design CriteriaOrlando E Cabrera RojasNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Field Installation and IP 16-13-1 Testing of Electrical EquipmentDokument8 SeitenField Installation and IP 16-13-1 Testing of Electrical EquipmentOrlando E Cabrera RojasNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- fmds0508 - 0412 STATIC ELECTRICITY PDFDokument28 Seitenfmds0508 - 0412 STATIC ELECTRICITY PDFOrlando E Cabrera Rojas100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- FMDS0504 0713 Transformers PDFDokument41 SeitenFMDS0504 0713 Transformers PDFOrlando E Cabrera RojasNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Electrical SymbolDokument14 SeitenElectrical SymbolOrlando E Cabrera RojasNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- K68i PC ManualDokument101 SeitenK68i PC ManualjjcanoolivaresNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Iec 61643 11 2011Dokument15 SeitenIec 61643 11 2011m0fauziNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Video 5 - MCB CatalogueDokument146 SeitenVideo 5 - MCB CatalogueArt RaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Spec For Low Voltage Switchboard-MCCDokument19 SeitenSpec For Low Voltage Switchboard-MCCMohamed Jahirhussain50% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Electrical Power System Studies PDFDokument7 SeitenElectrical Power System Studies PDFjhuskanovicNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 2006 VA Powertrain SprinterDokument292 Seiten2006 VA Powertrain Sprinteractuator79100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Operation & Maintenance Manual: For Khartoum North Power Station-Phase Iii (2×100Mw) ProjectDokument28 SeitenOperation & Maintenance Manual: For Khartoum North Power Station-Phase Iii (2×100Mw) Projectمحمد خالدNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Lovag TEST INSTRUCTION IEC 60947-2 Ed. 5.0Dokument9 SeitenLovag TEST INSTRUCTION IEC 60947-2 Ed. 5.0electrical_1012000Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

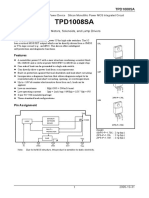

- TPD1008SA F High-Side Power SwitchDokument11 SeitenTPD1008SA F High-Side Power SwitchOlga PlohotnichenkoNoch keine Bewertungen

- WWW - Manaresults.Co - In: Electrical and Electronics EngineeringDokument3 SeitenWWW - Manaresults.Co - In: Electrical and Electronics EngineeringSrîkår SríNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Abb Acs880 - Error CodeDokument17 SeitenAbb Acs880 - Error Codenenulelelema0% (1)

- Vacuum CntactorDokument92 SeitenVacuum Cntactorabhi_26t100% (2)

- Cable Sizing Calculator AS - NZS3008Dokument1 SeiteCable Sizing Calculator AS - NZS3008kakagoNoch keine Bewertungen

- SM Si10-417 C Service Diagnosis tcm135-220033 PDFDokument255 SeitenSM Si10-417 C Service Diagnosis tcm135-220033 PDFVictor Fernández SerranoNoch keine Bewertungen

- Controller Panou Solar CX - 10 - CZ060913 PDFDokument7 SeitenController Panou Solar CX - 10 - CZ060913 PDFCristian PopescuNoch keine Bewertungen

- Littelfuse Arc-Flash Hazards White PaperDokument8 SeitenLittelfuse Arc-Flash Hazards White PaperVigneshwaran KandaswamyNoch keine Bewertungen

- BTU Measurement System: Foshan AKE Electronic Engineering Co., LTDDokument34 SeitenBTU Measurement System: Foshan AKE Electronic Engineering Co., LTDblindjaxxNoch keine Bewertungen

- Sri Inai (Pinang) SDN BHD V Yong Yit Swee & OrsDokument26 SeitenSri Inai (Pinang) SDN BHD V Yong Yit Swee & OrsgavinjayanandNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Design and Development of Condition Monitoring and Control System For Distribution TransformerDokument48 SeitenDesign and Development of Condition Monitoring and Control System For Distribution TransformerAddis Goshiye100% (2)

- Susol & Metasol ACB - NA Manual - ENDokument56 SeitenSusol & Metasol ACB - NA Manual - ENTruong HungNoch keine Bewertungen

- CodeDokument187 SeitenCodeIzz Bahar82% (17)

- Sieps80000066e 4 0 PDFDokument318 SeitenSieps80000066e 4 0 PDFnew587Noch keine Bewertungen

- GE Industrial Electrical Components Price List. IndiaDokument32 SeitenGE Industrial Electrical Components Price List. IndiaAnagha Deb0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- HIAB Safety Codes 042014Dokument14 SeitenHIAB Safety Codes 042014Dennis Xenos25% (4)

- Omega - N Interface Installation ManualDokument23 SeitenOmega - N Interface Installation ManualgpuonlineNoch keine Bewertungen

- HenselDokument1 SeiteHenseligorNoch keine Bewertungen

- CIGRE Vol1Dokument141 SeitenCIGRE Vol1reinscNoch keine Bewertungen

- PROJECT STANDARD and SPECIFICATIONS Electrical Specifications For Packaged Equipment Rev01webDokument4 SeitenPROJECT STANDARD and SPECIFICATIONS Electrical Specifications For Packaged Equipment Rev01webhiyeonNoch keine Bewertungen

- Pre Commissioning Check ListDokument4 SeitenPre Commissioning Check ListbajrangNoch keine Bewertungen

- Cebora S.P.A.: Service ManualDokument27 SeitenCebora S.P.A.: Service ManualJefferson ChangoluisaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)