Beruflich Dokumente

Kultur Dokumente

Drilling Tools Codes Rev1

Hochgeladen von

jpmateosCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drilling Tools Codes Rev1

Hochgeladen von

jpmateosCopyright:

Verfügbare Formate

FTDS - FICEP Training and Documentation Service

Drilling tools codes

definition

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

The CNC fixes an identification

code (Details list) to the different

working operations.

Every single code defines a

different tool.

The following slides show some

tools we can put into a drilling

spindle

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

To install the tool into the drilling unit we will use some connections and tapers:

ISO 45 [40] connection with :

..Morse Taper

..Weldon Taper

HSK A80 [A63] connection with.. :

..Morse Taper

by Bruno Turati revised by Ing. Pascucci

..Weldon Taper

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

DRILL

Sensitive twist drilling

Tool type:

standard HSS drill-bit

Working operation: standard hole

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

HSS drill-bit - DRILL

Technical features:

1. Low cutting speed

2. Inexpensive

3. Grinding frequently

4. Long life

5. Long chips

6. Int/Ext coolant

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

DRILL_32

Special programmed drilling

Tool type:

Working operation:

inserts drill-bit

programmed hole

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

INSERTS drill-bit DRILL 32/33

Technical features:

1. High cutting speed

2. Expensive

3. Not grinding inserts

4. Inserts short life

5. Short chips

6. Int. Coolant only

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

DRILL_33

Twist programmed drilling

Tool type:

Working operation:

inserts/carbide and HSS drill-bit

blind and/or standard hole

by Bruno Turati revised by Ing. Pascucci

INSERTS or CARBIDE drill-bit DRILL_33/32

FTDS - FICEP Training and Documentation Service

Technical features:

See DRILL_32 code tools

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

DEBURR

Normal deburring

Tool type:

Working operation:

deburring tool

removing burrs from the hole output

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

FLARE

Countersink

Tool type:

Working operation:

countersink at 90

countersinking

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

COUNTERSINK at 90

Technical features:

1.Pre hole already

made

2. Low feedrate

3. Virtual tool length

4. Two diameter to

define a working

range

5. No coolant

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

Tool type:

Working operation:

DEBURR_36

Deburring with NBT

special deburring tool

removing burrs from the hole

output passing across

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

Tool type:

Working operation:

POINT_37

Twist pointing

standard HSS drill-bit

pointing and marking

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

POINTING with DRILL - BIT

Technical features:

1. Roughness (on time)

2. Depth on time

3. Low feedrate

4. Known tool length

5. No coolant

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

SPOT - FACING

Spot - Facing

Tool type:

Working operation:

counterbore

enlarging a preformed hole

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

COUNTERBORE SPOT FACING

Technical features:

1. Pre hole already made

2. Rigth speeds

3. Virtual tool length

4. Coolant

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POINT

Pointing with point

Tool type:

Working operation:

small tool only for pointing

pointing and marking

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

POINTING with POINT TOOL

Technical features:

1. Depth on time

2. Low feedrate

3. Known tool length

4. No coolant

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

TAP _ xx

Tapping type

Tool type:

Working operation:

screw tap

tapping different threads

by Bruno Turati revised by Ing. Pascucci

ISO METRIC TAPPING

FTDS - FICEP Training and Documentation Service

Measuring unit : mm

TAP

: Standard (gross pitch)

TAP 42 : Fine pitch

M10

M10x1*

[*Size of pitch in mm]

WHITWORTH TAPPING

Measuring unit : inches or inch fractions

TAP 43

: Standard (gross pitch) 13/8 W

TAP 44

: Fine pitch

11/4x11* W

[*Threads per inch]

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

UNF and UNC American TAPPING

Measuring unit : inches or inch fractions

TAP 45 : Standard (fine pitch )

-16* UNF

TAP 47 : Standard (gross pitch )

-10* UNC

[*Threads per inch]

GAS TAPPING (only on pipes)

Measuring unit : inches or inch fractions

TAP 46 : Standard

G 1 *

[*Size of pipe]

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

TAP

Technical features:

1. Preformed hole

2. Feedrate = Screwpitch

3. Special taper (return)

4. Flat tool (180)

5. Rigth tool length

6. Long output stroke

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

MILL

Milling

Tool type:

Working operation:

end mill

milling on single pass

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

END MILLING TOOL

Technical features:

1. Hole already made

2. Contouring speed

3. Good connection and taper

4. Fast downstroke

5. Milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET

Pocketing

Tool type:

Working operation:

face and round inserts mill

multi steps pocketing or drawing

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

INSERTS POCKETING TOOL

Technical features:

1. Slow downstroke

2. Contouring speed

3. Locked material

4. Pocketing

parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_63

Chamfering

Tool type:

Working operation:

Tecnical features :

side and square inserts mill

top multi steps bevelling

milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_64

Back Chamfering

Tool type:

Working operation:

Tecnical features :

side and square inserts mill

bottom multi steps bevelling

milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_65

Round insert face milling

Tool type:

face and rounds inserts mill

Working operation: top multi steps bevelling or pocketing

Tecnical features : milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_66

Round insert back face milling

Tool type:

face and rounds inserts mill

Working operation: bottom multi steps bevelling or pocketing

Tecnical features : milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_67

Pocketing helical interpolation

Tool type:

Working operation:

Tecnical features :

side inserts mill (rouds or rect.)

helical interpolation hole

milling parameters

by Bruno Turati revised by Ing. Pascucci

FTDS - FICEP Training and Documentation Service

Programming code:

Comment:

POCKET_68

Scribing

Tool type:

Working operation:

Tecnical features :

face square insert mill

drawing or pocketing

milling parameters

by Bruno Turati revised by Ing. Pascucci

Das könnte Ihnen auch gefallen

- MT HW2 Muratbekov Miras Anpdoy PDFDokument13 SeitenMT HW2 Muratbekov Miras Anpdoy PDFMiras MuratbekovNoch keine Bewertungen

- FH190SPDokument69 SeitenFH190SPAlexandre MartinsNoch keine Bewertungen

- Adsorption Dryer: Revision 02 - 2016/EN Cod: 398H272167Dokument60 SeitenAdsorption Dryer: Revision 02 - 2016/EN Cod: 398H272167RUN GONoch keine Bewertungen

- ProductSupportGuide A2238CDokument20 SeitenProductSupportGuide A2238CRicoh Company LtdNoch keine Bewertungen

- Machinery Canada - DC Swiss Taps NPTDokument2 SeitenMachinery Canada - DC Swiss Taps NPTmachineCanNoch keine Bewertungen

- Milling Is The Most Common Form of Machining SCRDokument3 SeitenMilling Is The Most Common Form of Machining SCRshado94Noch keine Bewertungen

- Canon I860, I865 SM - Printer1.BlogspotDokument35 SeitenCanon I860, I865 SM - Printer1.BlogspotRoger BurfordNoch keine Bewertungen

- 143 13 English Catalogue 2014 PDFDokument319 Seiten143 13 English Catalogue 2014 PDFJa Pa JaNoch keine Bewertungen

- Manual Inglês MB-L REV08Dokument44 SeitenManual Inglês MB-L REV08matheus oliveira100% (1)

- Aaa0030imb02 FDokument30 SeitenAaa0030imb02 FJvr Omar EspinozaNoch keine Bewertungen

- SDM290 User GuideDokument21 SeitenSDM290 User Guideayhaneln3230Noch keine Bewertungen

- Production of Chess PiecesDokument19 SeitenProduction of Chess PieceshoanghuanNoch keine Bewertungen

- Catalogo Mitsubishi PDFDokument88 SeitenCatalogo Mitsubishi PDFanon_268991287Noch keine Bewertungen

- Lab 3 Background On G-Code GenerationDokument4 SeitenLab 3 Background On G-Code GenerationRaymond KwonNoch keine Bewertungen

- Turning Tools 2015 ENGDokument1.253 SeitenTurning Tools 2015 ENGMaria MarinNoch keine Bewertungen

- Technical Drawing StandardsDokument20 SeitenTechnical Drawing StandardsGeorge Maliaris57% (14)

- PT Programming Manual KxtdaDokument74 SeitenPT Programming Manual Kxtdazdenko68Noch keine Bewertungen

- Deep Hole Drilling Tools: BotekDokument48 SeitenDeep Hole Drilling Tools: Botekcarolina lopesNoch keine Bewertungen

- 250x16 Shs Column Base - Pa2123Dokument5 Seiten250x16 Shs Column Base - Pa2123ihpeterNoch keine Bewertungen

- HDD Recovery Mpg3409at - EfDokument3 SeitenHDD Recovery Mpg3409at - EfAlexander IvanchykauNoch keine Bewertungen

- Intru-Lok Flareless Bite Type FittingsDokument8 SeitenIntru-Lok Flareless Bite Type FittingsPartsGopher.comNoch keine Bewertungen

- Project Report: Design of Mould & Press ToolDokument67 SeitenProject Report: Design of Mould & Press ToolBharat SinghNoch keine Bewertungen

- Lantek Expert2 Manual. PstRum21Dokument34 SeitenLantek Expert2 Manual. PstRum21thulabaramNoch keine Bewertungen

- Spot Drill, Chamfer Tool With Carbide Insert TaiwantradeDokument1 SeiteSpot Drill, Chamfer Tool With Carbide Insert Taiwantradert8dv4qpkcNoch keine Bewertungen

- Davico KabelsaruDokument47 SeitenDavico KabelsaruKovács TamásNoch keine Bewertungen

- IM Series-LaunchDokument3 SeitenIM Series-LaunchArun KumarNoch keine Bewertungen

- ISO DTR 17243-2 Spindle Vibration EvaluationDokument27 SeitenISO DTR 17243-2 Spindle Vibration EvaluationzenoNoch keine Bewertungen

- Curricula Simplificada UPDATED Oct 2019Dokument3 SeitenCurricula Simplificada UPDATED Oct 2019BJ JOs100% (1)

- Okuma Static and Live Tooling For Lbex - 11252014 - Web - 2 PDFDokument32 SeitenOkuma Static and Live Tooling For Lbex - 11252014 - Web - 2 PDFaaamil13Noch keine Bewertungen

- Flygt Mixer Parts ListDokument36 SeitenFlygt Mixer Parts Listmjl47Noch keine Bewertungen

- Bab I Pendahuluan 1.1 Latar BelakangDokument11 SeitenBab I Pendahuluan 1.1 Latar BelakangDzikri FaizalNoch keine Bewertungen

- Grinding EquipmentDokument24 SeitenGrinding EquipmentCrawlerXNoch keine Bewertungen

- BOBCAT TRENCHER LT313 ManualDokument100 SeitenBOBCAT TRENCHER LT313 ManualAtutRentalNoch keine Bewertungen

- TN 100 USB VID-PID Guidelines PDFDokument12 SeitenTN 100 USB VID-PID Guidelines PDFMastaj KrzysztofNoch keine Bewertungen

- UNOMAT TRX-II K319-Manual-Psi TrxiiDokument60 SeitenUNOMAT TRX-II K319-Manual-Psi TrxiiRangga K NegaraNoch keine Bewertungen

- Drill Pipe PDFDokument32 SeitenDrill Pipe PDFMEHDINoch keine Bewertungen

- SI LO FR 016XX V01 Bolts TorqueingDokument13 SeitenSI LO FR 016XX V01 Bolts TorqueingAron MariusNoch keine Bewertungen

- Tool Maintenance - CU-Profi - ENDokument18 SeitenTool Maintenance - CU-Profi - ENRodrigoNoch keine Bewertungen

- Parts Reference List: MODEL: MFC-P2500 / HL-P2500Dokument27 SeitenParts Reference List: MODEL: MFC-P2500 / HL-P2500zdjulicgmailcomNoch keine Bewertungen

- Manual Imprimante FH190SPDokument69 SeitenManual Imprimante FH190SPChristophe SEVERACNoch keine Bewertungen

- Course: ME 2252 - Manufacturing Technology - II - Class: BEMEC-2012-4-A Course Objective(s)Dokument7 SeitenCourse: ME 2252 - Manufacturing Technology - II - Class: BEMEC-2012-4-A Course Objective(s)Jackson ..Noch keine Bewertungen

- Tohnichi - Katalog 2009 ENDokument56 SeitenTohnichi - Katalog 2009 END.T.Noch keine Bewertungen

- B276-B277 PSGDokument33 SeitenB276-B277 PSGDarwin HernandezNoch keine Bewertungen

- Canon Service Bulletin CopierDokument2 SeitenCanon Service Bulletin CopierutilscNoch keine Bewertungen

- Panasoni - kxtg4031, Kxtg4032, Kxtg4033, Kxtg4034 eDokument60 SeitenPanasoni - kxtg4031, Kxtg4032, Kxtg4033, Kxtg4034 etulmesurduNoch keine Bewertungen

- Holmatro Rescue Tools enDokument32 SeitenHolmatro Rescue Tools enZane Ionel100% (2)

- RUKO Catalogue 2016-KierukkaporatDokument86 SeitenRUKO Catalogue 2016-KierukkaporatEduardo Antonio Duran SepulvedaNoch keine Bewertungen

- Cutting Roller Ms 2007Dokument10 SeitenCutting Roller Ms 2007DjuangNoch keine Bewertungen

- Opticon NFT-7175 RS232 I Type (DISCONTINUED)Dokument2 SeitenOpticon NFT-7175 RS232 I Type (DISCONTINUED)Nana Dwi WahanaNoch keine Bewertungen

- Section C1 Technical Specifications For GYM EquipmentsDokument13 SeitenSection C1 Technical Specifications For GYM EquipmentsAbhiram BNoch keine Bewertungen

- ITT ValvesDokument40 SeitenITT Valvesseramon100% (1)

- Bahco Concept EnglishDokument31 SeitenBahco Concept EnglishAlda Santos SantosNoch keine Bewertungen

- RFQ - Wellhead VALVES and AccessoriesDokument6 SeitenRFQ - Wellhead VALVES and AccessoriesMouResNoch keine Bewertungen

- Parts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Dokument40 SeitenParts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Maks ProstNoch keine Bewertungen

- Parts Reference List MODEL: DCP4020C / MFC4820C: Facsimile EquipmentDokument22 SeitenParts Reference List MODEL: DCP4020C / MFC4820C: Facsimile EquipmentSerge MaciaNoch keine Bewertungen

- Brother PT-530, 550 Service ManualDokument103 SeitenBrother PT-530, 550 Service ManualDuplessisNoch keine Bewertungen

- Production Engineering - Jig And Tool DesignVon EverandProduction Engineering - Jig And Tool DesignBewertung: 3.5 von 5 Sternen3.5/5 (3)

- CEN TOOL Standard Padeyes V4 Rollup Padeye SheaveDokument5 SeitenCEN TOOL Standard Padeyes V4 Rollup Padeye SheaveMarvan100% (1)

- 2p36907 SwivelDokument42 Seiten2p36907 SwivelIFI ARGENTINA S.A.Noch keine Bewertungen

- Sandvik DD321Dokument4 SeitenSandvik DD321Anonymous Dm7iMmt0% (2)

- Manual For TC5013 (Elemento Painel)Dokument74 SeitenManual For TC5013 (Elemento Painel)WevertonNoch keine Bewertungen

- Concrete PoolDokument2 SeitenConcrete Pooljorge010% (2)

- ME302: Materials Mechanics: Chap. 1 StressDokument16 SeitenME302: Materials Mechanics: Chap. 1 StressMat MatttNoch keine Bewertungen

- Kohn-Sham Equations For DFTDokument15 SeitenKohn-Sham Equations For DFTRikardo Pino RiosNoch keine Bewertungen

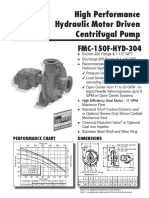

- FMC-150F-HYD-304 - 04-13 Bomba AceDokument2 SeitenFMC-150F-HYD-304 - 04-13 Bomba AceEmerson GomesNoch keine Bewertungen

- PrimeRoyal HPD LE IOMDokument82 SeitenPrimeRoyal HPD LE IOMTadeo FajardoNoch keine Bewertungen

- Pford 2Dokument7 SeitenPford 2primavera1969Noch keine Bewertungen

- Interacción Suelo EstructuraDokument10 SeitenInteracción Suelo EstructuraDar FallNoch keine Bewertungen

- A2249 Digital Diesel Electronics Control Unit: Connector Location ViewsDokument2 SeitenA2249 Digital Diesel Electronics Control Unit: Connector Location Viewskoks_s3Noch keine Bewertungen

- Simulation and Analysis of Ballistic Impact UsingDokument8 SeitenSimulation and Analysis of Ballistic Impact UsingSaeid VarmazyariNoch keine Bewertungen

- WB140 2N PDFDokument12 SeitenWB140 2N PDFLuisAlbertoVerdejoTapiaNoch keine Bewertungen

- Tut-371 No.2Dokument8 SeitenTut-371 No.2fletusdiabloiNoch keine Bewertungen

- Simpson Fence Base and BracketDokument3 SeitenSimpson Fence Base and BracketAloNoch keine Bewertungen

- HydrantDokument18 SeitenHydrantNhat CaoNoch keine Bewertungen

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Dokument34 SeitenValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaNoch keine Bewertungen

- Finite Element Anlysis of HookDokument28 SeitenFinite Element Anlysis of HookHabtamu GeremewNoch keine Bewertungen

- Elmex P ListDokument47 SeitenElmex P Listbasantjain12345Noch keine Bewertungen

- Fluids and LubricantsDokument2 SeitenFluids and LubricantsRUN GONoch keine Bewertungen

- Mechanical VibrationDokument3 SeitenMechanical VibrationChenNoch keine Bewertungen

- Treadmill 93T-04 - THH100000 - PARTS LISTDokument19 SeitenTreadmill 93T-04 - THH100000 - PARTS LISTpowerliftermiloNoch keine Bewertungen

- BTD SyllabusDokument3 SeitenBTD SyllabusSubuddhi DamodarNoch keine Bewertungen

- Santilli 1994Dokument12 SeitenSantilli 1994aminardakaniNoch keine Bewertungen

- Oil and Gas ProcessingDokument3 SeitenOil and Gas ProcessingRaghav AgrawalNoch keine Bewertungen

- CAESAR II Expansion JointsDokument26 SeitenCAESAR II Expansion Jointskamal_md100% (4)

- MIDAS ChecklistDokument27 SeitenMIDAS ChecklistBhagirath JoshiNoch keine Bewertungen

- F885-84 (2011) Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS 1ظ - - 4 to 2Dokument3 SeitenF885-84 (2011) Standard Specification for Envelope Dimensions for Bronze Globe Valves NPS 1ظ - - 4 to 2islamakthamNoch keine Bewertungen

- Lesson 1.1: Effective StressDokument6 SeitenLesson 1.1: Effective StressYam-yam RemotoNoch keine Bewertungen