Beruflich Dokumente

Kultur Dokumente

Bps Series Pumps in Series For High Pressure Applications: PL-2024-02 Rev00 Application Note

Hochgeladen von

shinkentom2Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bps Series Pumps in Series For High Pressure Applications: PL-2024-02 Rev00 Application Note

Hochgeladen von

shinkentom2Copyright:

Verfügbare Formate

BPS SERIES PUMPS IN SERIES

FOR HIGH PRESSURE

APPLICATIONS

PL-2024-02 Rev00

Application Note

Introduction

In contrast to positive displacement pumps like diaphragm or bellows pumps,

centrifugal pumps can be put in series to increase pressure. A series arrangement

also provides redundancy. In case of a pump failure the pump design allows the

flow to go through the defective pump and the remaining pumps can still deliver

pressure.

Putting BPS

Pumps

Systems in

Series

If the pressure that can be achieved with one pump is not high enough, it can be

raised by putting additional pumps in series. The total differential pressure of the

series arrangement is the sum of the differential pressures of all pumps (in Figure 1

the pressure that can be measured with PM2 is the sum of the pressure of PM1 and

the differential pressure of pump P2)

PM2

PM1

Process

P1

P2

Figure 1: Two Pumps in Series

T: Tank

P1-P2: Levitronix pump (BPS Series)

PM1-PM2: Pressure Measurement

Characteristic

Curve of a

Series

Arrangement

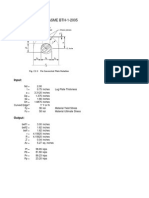

Figure 2 shows the characteristic curve of two BPS-3 pump systems in series. To

get uniformly distributed pump power, both pumps are running at the same speed.

7.0

2x 9000 RPM

6.0

5.0

2x 8000 RPM

4.0

[bar]

3.0

2x 7000 RPM

2.0

2x 6000 RPM

1.0

2x 4000 RPM

0.0

0

10

20

30

40

[liters/min]

50

60

2x 5000 RPM

70

80

Figure 2: Characteristic curve of two BPS-3 pumps in series

(both running at the same speed)

1

BPS Series Pumps in series for high pressure applications

Control

Method

The preferable method to control a system of BPS pumps in series is controlling the

speed, which should be the same for all pumps. Although it is possible to run the

pumps at different speeds, the distribution of pump power among the pumps and

therefore also the heat distribution is at its optimum if the pumps are running at the

same speed (sometimes a slightly higher power consumption of the first pump can

be observed, which is negligible in most cases).

If the pressure has to be set with a very high resolution, it is still possible to change

the speed of just one pump. A small difference of the pump speed wont have a

significant effect on the heat distribution.

Redundancy

of BPS Pumps

in Series

Redundant Systems

An important aspect of a series arrangement is redundancy. In case of a pump

failure the pump design allows the flow to go through the defective pump without a

significant pressure drop and the remaining functional pumps still deliver pressure

to the system. The loss of pressure due to the failure can be compensated by

ramping up the speed of the remaining pumps. Depending on the point of operation

the loss of pressure can be partly or completely compensated. Since the pump

power of the remaining pumps goes up in that case, careful thermal design must be

considered to avoid overheating.

Figure 3 picture A.) shows three pumps in series running at 5100RPM, which

results in a pressure of 3 bar at the end of the series arrangement. Picture B.)

shows the same series arrangement with a pump failure of pump P2. The two

remaining pumps P1 and P3 can compensate the loss of pressure if their speed is

changed to 6200RPM. The overall pressure remains 3 bar.

PM1

1

0

PM2

A.)

2

0

PM3

1

0

2

3

Process

P1

P2

P3

(5100 RPM)

(5100 RPM)

(5100 RPM)

PM1

1

0

PM3

PM2

2

3

B.)

Process

P1

(6200 RPM)

P2

P3

(0 RPM)

(6200 RPM)

Figure 3: Three pumps running at same speed (A.)

Two pumps running at higher speed to compensate loss of pressure (B.)

P1-P3: Levitronix pump (BPS-3 Series)

PM1-PM3: Pressure Measurement

2

Application Note PL-2024-02 Rev00.

Das könnte Ihnen auch gefallen

- Pumps in ParallelDokument6 SeitenPumps in ParallelMazen AliNoch keine Bewertungen

- Characteristic Curve: A Graph Showing The Relationship Between Two QuantitiesDokument7 SeitenCharacteristic Curve: A Graph Showing The Relationship Between Two QuantitiesShahbaz HaiderNoch keine Bewertungen

- What Is Characteristic CurveDokument7 SeitenWhat Is Characteristic Curvehafiz hassanNoch keine Bewertungen

- Pump Performance - Double PumpsDokument8 SeitenPump Performance - Double PumpsAshNoch keine Bewertungen

- Series and Parallel Operation of Centrifugal PumpsDokument12 SeitenSeries and Parallel Operation of Centrifugal PumpsdatonizamNoch keine Bewertungen

- Parallel Pump OperationDokument5 SeitenParallel Pump Operationarunima04100% (1)

- Sizing Pulsation Dampeners Is Critical To Effectiveness P47E11 010Dokument6 SeitenSizing Pulsation Dampeners Is Critical To Effectiveness P47E11 010Othoniel KanoNoch keine Bewertungen

- Why Bladder Tanks - 8!16!17Dokument10 SeitenWhy Bladder Tanks - 8!16!17bla blaNoch keine Bewertungen

- 3 PumpingSystems Performance PDFDokument23 Seiten3 PumpingSystems Performance PDFEngHazem AlsharifNoch keine Bewertungen

- Variable Vol Fundamentals PDFDokument11 SeitenVariable Vol Fundamentals PDFSharon LambertNoch keine Bewertungen

- Pump Networks BranchesDokument9 SeitenPump Networks BranchesGeorge MarkasNoch keine Bewertungen

- Pumps in Serial - Head Added: Pump Performance Curve HeadsDokument2 SeitenPumps in Serial - Head Added: Pump Performance Curve HeadsMateusDinizNoch keine Bewertungen

- Parallel Pump Analysis and The System CurveDokument2 SeitenParallel Pump Analysis and The System CurveHanin IkaNoch keine Bewertungen

- Chapter 5 Rotating EquipmentDokument32 SeitenChapter 5 Rotating EquipmentAeffandii SamawiNoch keine Bewertungen

- Chapter - 6 Variable Speed Pressure Booster SystemsDokument6 SeitenChapter - 6 Variable Speed Pressure Booster Systemsosamamae100% (1)

- Fluid Pump Report 2013Dokument33 SeitenFluid Pump Report 2013M Shahrul Izuan100% (1)

- Pumps CurvesDokument14 SeitenPumps CurvesAhmedNoch keine Bewertungen

- 4 PumpsDokument4 Seiten4 PumpsAnonymous uBHlPny5Z5Noch keine Bewertungen

- Positive Displacement Vs Centrifugal PumpDokument11 SeitenPositive Displacement Vs Centrifugal PumpArslan BhattiNoch keine Bewertungen

- Guide To Reading A Positive Displacement Pump CurveDokument10 SeitenGuide To Reading A Positive Displacement Pump CurveLluís Vidales SerresNoch keine Bewertungen

- Chapter 3.6part3Dokument14 SeitenChapter 3.6part3Sidharth RazdanNoch keine Bewertungen

- Wk11 - Chap9 Pumping FluidsDokument32 SeitenWk11 - Chap9 Pumping Fluidsmohdyashfi mppNoch keine Bewertungen

- Multiple Pump OperationDokument2 SeitenMultiple Pump OperationChingapooh2008Noch keine Bewertungen

- Op Tim Ization 1001Dokument4 SeitenOp Tim Ization 1001sebaversaNoch keine Bewertungen

- Clinic: Single Versus Parallel Operation of Centrifugal PumpsDokument4 SeitenClinic: Single Versus Parallel Operation of Centrifugal PumpsSandesh ShenoyNoch keine Bewertungen

- Positive Displacement PumpsDokument10 SeitenPositive Displacement PumpsJan JareNoch keine Bewertungen

- Experiment 5 - Series Parallel Centrifugal PumpDokument15 SeitenExperiment 5 - Series Parallel Centrifugal PumpEiyra Nadia33% (3)

- Fundamentals of CompressorDokument16 SeitenFundamentals of CompressorSanjoy Kr. DeyNoch keine Bewertungen

- Compressor WorkingDokument21 SeitenCompressor WorkingShooeib100% (1)

- Pump System CurveDokument6 SeitenPump System CurveMohan MalavNoch keine Bewertungen

- Single-Stage, Double Suction Vertical PumpsDokument20 SeitenSingle-Stage, Double Suction Vertical Pumpsسامح الجاسمNoch keine Bewertungen

- Chapter 3 - Pump and CompressorDokument30 SeitenChapter 3 - Pump and CompressorRaziff HamsanNoch keine Bewertungen

- Pumps in Series and ParallelDokument6 SeitenPumps in Series and ParallelSuhadahafiza Shafiee0% (1)

- 5 Parallel and Series Pump Operation 5Dokument15 Seiten5 Parallel and Series Pump Operation 5Omar AhmedNoch keine Bewertungen

- Constant Pressure and LoadDokument2 SeitenConstant Pressure and Loadandrija_ganzbergerNoch keine Bewertungen

- Experiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Dokument6 SeitenExperiment No. 7 Pump Performance - Single Pump: MEHB221 Fluids Mechanics Lab 2016Syahmi ShahimanNoch keine Bewertungen

- FluidDokument6 SeitenFluidMoosa NaseerNoch keine Bewertungen

- Objective of PumpsDokument6 SeitenObjective of PumpsTomide OlasupoNoch keine Bewertungen

- Pump BasicsDokument72 SeitenPump BasicsVineeth VsNoch keine Bewertungen

- Assignment 2 - CompressedDokument56 SeitenAssignment 2 - CompressedAbdul Hannan SandhuNoch keine Bewertungen

- 1 - Constant Pressure BoostersDokument13 Seiten1 - Constant Pressure BoostersChevronelleNoch keine Bewertungen

- Flowcheck Guide To PumpsDokument3 SeitenFlowcheck Guide To PumpsFA AyNoch keine Bewertungen

- News Vol2 I11 Nov PDFDokument3 SeitenNews Vol2 I11 Nov PDFPower PowerNoch keine Bewertungen

- PumpsDokument103 SeitenPumpsKevin HuangNoch keine Bewertungen

- Fluid Lab - Pump in Parallel and SeriesDokument8 SeitenFluid Lab - Pump in Parallel and SeriesYukiYukina100% (2)

- Pressure Changers On Aspen PlusDokument19 SeitenPressure Changers On Aspen PlusAlexReituNoch keine Bewertungen

- Understanding Centrifugal Compressor - Equipment InteractionDokument12 SeitenUnderstanding Centrifugal Compressor - Equipment Interactionsoumya19800000000Noch keine Bewertungen

- 03 - AFT - Know Your Pump & System Curves - Part 2BDokument8 Seiten03 - AFT - Know Your Pump & System Curves - Part 2BAlfonso José García LagunaNoch keine Bewertungen

- Pump FundamentalsDokument127 SeitenPump FundamentalsSheik Mohd50% (2)

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDokument16 SeitenGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Pump CurvesDokument8 SeitenPump CurvesKrishna Chaitanya KalagaNoch keine Bewertungen

- Lab3E6 - Series and Parallel Pump PDFDokument13 SeitenLab3E6 - Series and Parallel Pump PDFShimal De Silva50% (2)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- SS Innovation Manager - LinkedInDokument5 SeitenSS Innovation Manager - LinkedInshinkentom2Noch keine Bewertungen

- Lifting Lug Design Per ASME BTH-1-2005: InputDokument2 SeitenLifting Lug Design Per ASME BTH-1-2005: Inputshinkentom2Noch keine Bewertungen

- New SpeedDokument1 SeiteNew Speedshinkentom2Noch keine Bewertungen

- Faculty of EngineeringDokument129 SeitenFaculty of EngineeringtuyencntnNoch keine Bewertungen

- WEG Synchronous Motors Technical Article EnglishDokument17 SeitenWEG Synchronous Motors Technical Article EnglishSuraj ThapaNoch keine Bewertungen

- Synchronous MotorsDokument16 SeitenSynchronous Motorsshinkentom2Noch keine Bewertungen

- WEGSM1 ManualDokument15 SeitenWEGSM1 Manualshinkentom2Noch keine Bewertungen

- G8150BEV21 - 1 - Subaru Forester Manual PartsDokument2 SeitenG8150BEV21 - 1 - Subaru Forester Manual Partsshinkentom2Noch keine Bewertungen

- Dependability ClassificationDokument1 SeiteDependability Classificationshinkentom2Noch keine Bewertungen

- Chabot ENGR Successful UC Personal Statements 121029Dokument20 SeitenChabot ENGR Successful UC Personal Statements 121029shinkentom2Noch keine Bewertungen

- Chabot ENGR Successful UC Personal Statements 121029Dokument20 SeitenChabot ENGR Successful UC Personal Statements 121029shinkentom2Noch keine Bewertungen

- Personal Statement For Uni StudentsDokument20 SeitenPersonal Statement For Uni Studentsshinkentom2100% (1)

- Burger RecipeiesDokument1 SeiteBurger Recipeiesshinkentom2Noch keine Bewertungen

- Reliability BasicsDokument1 SeiteReliability Basicsshinkentom2Noch keine Bewertungen

- Ev3 User Guide enDokument69 SeitenEv3 User Guide enpierdonneNoch keine Bewertungen

- Continuing Education Catalogue Technology and Skilled TradesDokument17 SeitenContinuing Education Catalogue Technology and Skilled Tradesshinkentom2Noch keine Bewertungen

- Comanche 4 - Quick Reference Card - PCDokument1 SeiteComanche 4 - Quick Reference Card - PCszitis100% (1)

- Continuing Education Catalogue Technology and Skilled TradesDokument17 SeitenContinuing Education Catalogue Technology and Skilled Tradesshinkentom2Noch keine Bewertungen

- Continuing Education Catalogue Technology and Skilled TradesDokument17 SeitenContinuing Education Catalogue Technology and Skilled Tradesshinkentom2Noch keine Bewertungen

- Ev3 User Guide enDokument69 SeitenEv3 User Guide enpierdonneNoch keine Bewertungen

- Flooring Grating NZDokument12 SeitenFlooring Grating NZshinkentom2Noch keine Bewertungen

- FS2004 Keyboard ReferenceDokument3 SeitenFS2004 Keyboard Referenceo280765Noch keine Bewertungen

- AMERICAN RED CROSS 2006 Project Design and ProposalDokument55 SeitenAMERICAN RED CROSS 2006 Project Design and ProposalAleksandar BogdanovicNoch keine Bewertungen

- iPAQ h5400 Series Pocket PC Reference GuideDokument258 SeiteniPAQ h5400 Series Pocket PC Reference Guideshinkentom2Noch keine Bewertungen

- Section 2Dokument2 SeitenSection 2shinkentom2Noch keine Bewertungen

- AISC Shapes TablesDokument64 SeitenAISC Shapes TablesJose ManuelNoch keine Bewertungen

- Section 2Dokument2 SeitenSection 2shinkentom2Noch keine Bewertungen

- Section 2Dokument2 SeitenSection 2shinkentom2Noch keine Bewertungen

- Section 2Dokument2 SeitenSection 2shinkentom2Noch keine Bewertungen

- Scooptram ST LP: Low-Profile, Underground Loader With 6.8-Tonne CapacityDokument8 SeitenScooptram ST LP: Low-Profile, Underground Loader With 6.8-Tonne CapacityDanielReyesMondacaNoch keine Bewertungen

- 6 Meter GS-35B Amplifier ConstructionDokument3 Seiten6 Meter GS-35B Amplifier Constructiontheodorakis017781Noch keine Bewertungen

- Pbat 10 eDokument16 SeitenPbat 10 eapi-290101261Noch keine Bewertungen

- Basic Ideas: 1.1. The Born-Oppenheimer ApproximationDokument3 SeitenBasic Ideas: 1.1. The Born-Oppenheimer ApproximationWafaa NNoch keine Bewertungen

- Aeroacoustic Testing of Wind Turbine Air PDFDokument271 SeitenAeroacoustic Testing of Wind Turbine Air PDFAlexandre FariaNoch keine Bewertungen

- Savio Proxima ENGDokument39 SeitenSavio Proxima ENGmarioNoch keine Bewertungen

- Doosan DX225LCA Electric Circuit 110705Dokument1 SeiteDoosan DX225LCA Electric Circuit 110705Eduardo Ariel Bernal97% (30)

- Motor Caterpillar 3044ctDokument2 SeitenMotor Caterpillar 3044ctOscar Pardo Pardo67% (3)

- 221 1 Engineering Work Suwpport by Excel Based ProgramDokument1 Seite221 1 Engineering Work Suwpport by Excel Based ProgramZoebairNoch keine Bewertungen

- Solar TrackingDokument18 SeitenSolar Trackingkoti519100% (1)

- Organic Oil Recovery and The Miracle of Microbes: JANUARY 2019Dokument17 SeitenOrganic Oil Recovery and The Miracle of Microbes: JANUARY 2019Andrei IvanovichNoch keine Bewertungen

- LC X71 Service Manual FullDokument122 SeitenLC X71 Service Manual FullMaurilio CaetanoNoch keine Bewertungen

- DR - Swapna BhowmikDokument21 SeitenDR - Swapna BhowmikAnil Anil ChoudharyNoch keine Bewertungen

- HERAcell 150i 240i With Decontamination Routine PDFDokument156 SeitenHERAcell 150i 240i With Decontamination Routine PDFdeepthiNoch keine Bewertungen

- GA-I (H) D 1000 Series ROBOTDokument1 SeiteGA-I (H) D 1000 Series ROBOTmfarrukhkNoch keine Bewertungen

- ELSD IQ OQ ProtocolDokument7 SeitenELSD IQ OQ ProtocolRajan RamaswamiNoch keine Bewertungen

- Sigrity Flextronics Power Integrity System Design CPDokument26 SeitenSigrity Flextronics Power Integrity System Design CPDURGASI JYOTHINoch keine Bewertungen

- Hybrid PIC-Fluid Simulation of A Waveguide ECR Magnetic Nozzle Plasma ThrusterDokument13 SeitenHybrid PIC-Fluid Simulation of A Waveguide ECR Magnetic Nozzle Plasma ThrusterJack HondagneuNoch keine Bewertungen

- SAR Electrical and Electronics Engineering Technology - HCMUTE PDFDokument113 SeitenSAR Electrical and Electronics Engineering Technology - HCMUTE PDFTran Anh VuNoch keine Bewertungen

- 2010 Screamin Eagle Pro Racing PartsDokument78 Seiten2010 Screamin Eagle Pro Racing PartsanaNoch keine Bewertungen

- 5070 s03 QP 1 PDFDokument16 Seiten5070 s03 QP 1 PDFAnonymous wFLGHQ6ARNoch keine Bewertungen

- HMD01 Instruction ManualDokument72 SeitenHMD01 Instruction ManualLevonYeghyanNoch keine Bewertungen

- MOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Dokument95 SeitenMOC-Vasant Delivery Checklist For Crew REV - 0 Dated 31 Aug 2020Piyush KumarNoch keine Bewertungen

- Sr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsDokument13 SeitenSr. No. Name of The Experiment No.: Se-E&Tc Electrical Circuits and Machines List of ExperimentsjitbakNoch keine Bewertungen

- Procedure Qualification RecordDokument2 SeitenProcedure Qualification RecordDan ClarkeNoch keine Bewertungen

- WP310LDokument109 SeitenWP310Ljohn smithNoch keine Bewertungen

- Natco Dual Frequency: Electrostatic TreaterDokument2 SeitenNatco Dual Frequency: Electrostatic TreaterHERNANDO CASTAÑONoch keine Bewertungen

- DOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Dokument5 SeitenDOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Ahitworld 21Noch keine Bewertungen

- Parts y Guia Mantenimiento Torres BACDokument56 SeitenParts y Guia Mantenimiento Torres BACcris yanezNoch keine Bewertungen