Beruflich Dokumente

Kultur Dokumente

Installation of Underground 2"stainless Steel (1sdou) .

Hochgeladen von

AldrinOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Installation of Underground 2"stainless Steel (1sdou) .

Hochgeladen von

AldrinCopyright:

Verfügbare Formate

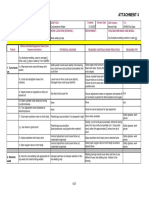

JOB SAFETY ANALYSIS

PCD PROJECT: WATER TREATMENT FACILITIES 3

FACILITY/PLANT LOCATION:

WTF-3 PJ

JSA PARTICIPANTS:

DESCRIPTION OF WORK:

INSTALLATION OF U/G

2STAINLESS STEEL (1SDOU).

APPROVED BY:

CONTRACTOR:

JGULF Intl. Co.

Ltd.

REVISION: 0

JSA No.: MACE - 2020

M.S. No.: V-3154-004-A-266

REVIEWED BY:

Aldrin C. Alcantara

Ghassan D. Matta

(Sub-contractor HSE / Construction Manager)

DATE:

S.NO.

1.

Mr.Vera

T. Saravanan

(Contractor HSE Supervisor)

(PCD Safety Engineer)

DATE:

STEPS REQUIRED TO COMPLETE TASK

Planning/Site preparation

DATE:

IDENTIFY HAZARDS & ASSESS RISK

Movement of Vehicle/Equipment.

Excavations.

Sharp edges.

Personal injury.

Pinch point.

Slip, trip, fall

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

1 of 8

CONTROLS TO ELIMINATE/REDUCE RISK

Obtain PTW prior to the commencement of

the work and 1st copy to be kept at the work

site in compliance to KJO work permit

procedure.

Survey work area and address safe work

method, hazards and precautions.

All KJO departments concerned shall have

a walkthrough/inspection to the site prior to

commencement of work.

JSA shall be followed and to be explained

to all employees during Tool Box Talk

(STARRT) prior to start of activities and it

must be made available at the site.

Crane and other equipment shall not be

driven or positioned at least 1 meter away

from the edge of excavations. Excavations

shall have barricades and safety signages.

All hand and power tools shall be

inspected; color coded. Equipment shall

have valid 3rd party inspection certificates.

Crane operator/s and truck drivers shall

have in their possession current 3rd party

certificates and SAG driving license

respectively.

2.

Dedicated & trained flagman shall be

assigned to assist the operator by signaling

using his red and green flag.

Rigger/s shall have current 3rd party

certificate and shall wear high visibility vest

for proper identification. Whistle shall be

provided for them to use.

All personnel to wear appropriate PPE

required for the job.

All personnel shall be made aware through

tool box talks and trainings about safe

movement in the area to avoid slip, trip &

fall, pinch points, safe manual lifting

procedure, damage to property and stored

energy.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Area shall be clear from slipping hazards.

Workers shall watch their steps while doing

inspection of pipes.

Workers shall wear safety glasses in

addition to other basic PPE requirement

while doing pipe inspection activities.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

Material Handling

2.1 Inspection of Pipes.

Slip, Trips & Fall.

Flying Object.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

2 of 8

prior to use at site.

2.2 Loading and Unloading of Pipes by

crane or boom truck.

Equipment/Vehicle Movement.

Manual lifting. Ergonomic Hazard.

Pipe damage during handling.

Rigging Equipment Failure.

Incompetent Operator or Rigger.

Improper Pipe Supports.

Pinch Points.

Slip, Trips & Fall.

Crane Failure.

Failure of ground supporting the

crane.

Entry of unauthorized persons in

lifting area.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor

KJO 6425 Crane and Lifting Safety

procedure shall be followed during rigging

operation.

Crane Operator and Rigger/s shall have

current 3rd party certificate and shall wear

high visibility vest for proper identification.

Crane operator shall have valid SAG

license.

Equipment (crane/side boom) shall have

valid 3rd party certificates. All rigging tools

and equipments shall be inspected, color

coded. Slings for lifting pipe shall be nylon

to prevent damage to the pipe surface.

Dedicated flagman shall be assigned to

assist the equipment operator by signaling

using red and green flag.

Crane/side boom shall not be allowed near

the edge of excavation. A safe distance

shall be maintained.

3 of 8

Area shall be well barricaded with safety

sign boards in place Lifting in Progress.

Personnel shall be briefed / trained on

proper

manual

material

handling

techniques.

Pipe stacking shall be made in a manner

which will not damage the pipe or the

coating.

Pipe shall not be rolled or dropped off

trucks.

End bevel protectors shall remain on pipes

and fittings while in lifting progress,

Protectors shall not damage internal or

external coating.

Pipe shall be placed on Sand Bags, not be

stored directly on the ground

.Outrigger pads of adequate size shall be

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Placing of Pipes on Stands/Jack Screw.

Pinch Points.

Pipe Movement/rolling of pipes from

stands.

Tilting of pipe stand.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area

4 of 8

placed under the crane outrigger floats to

increase stability. Ground to be compacted

if necessary.

Pipe supports shall be positioned on a

stable and rigid ground and leveled with

rollover supports at both ends.

All parts of the body specially upper and

lower extremities shall be kept away from

pinch points.

Area shall be clear from slipping & tripping

hazards.

Supervisor

concerned

shall

closely

supervise equipment operation in his area.

All parts of the body specially upper and

lower extremities shall be kept away from

pinch points.

Pipe shall be properly placed on stand with

wedges at both sides to prevent from

rolling. Pipe stands shall also be welded

with stoppers at back ends.

Pipe shall be placed equally on pipe stands.

Pipe stand shall be properly and safety

positioned on stable ground.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

3.

Confined Space Entry.

Presence of H2S, Flammable

Gases/Vapors or Oxygen Deficiency

inside the Confined Space.

Unauthorized entry.

No proper access and egress.

Improper use of Ladders.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

5 of 8

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Obtain PTW prior to the commencement of

the work and 1st copy to be kept at the work

site in compliance to KJO work permit

procedure.

Gas testing prior to start of activity must be

done and continuously monitored and log.

Gas test monitor shall have a valid

calibration certificate.

Toolbox talk shall be conducted prior to

start the activity to address and explain all

the hazards.

Maintain all necessary checklists such as

entry log and gas testing log sheet.

Entrant/s/standby man must train in

Confined Space Entry Safety as well as the

work permit receiver.

Dedicated standby man/attendant posted

outside the space at all time to monitor and

communicates to the authorized entrant/s.

Ladder for access and egress for workers

shall be provided in proper position.

Workers shall be trained ladder safety and

how to use it properly and safely.

Provide necessary barricades and

signages. Barricades shall be hard enough

to protect entrants from vehicles/equipment

that may fall into excavations.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

4.

Welding, grinding & cutting.

Fire

Hot Surface.

Pinch Point.

Welding Sparks.

Damage to equipment.

Incompetent welder.

Electrical hazard.

Flying particles.

Welding rays.

Welding fumes.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

6 of 8

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Gas test should be conducted before hot

work is started and throughout the shift.

Prior to start any hot work activity,

dedicated fire watch and standby man with

firefighting equipment such as fire

extinguisher, fire blanket, water truck

currently inspected and color coded must

available on site.

Hot work area shall be adequately covered

with fire blankets to prevent hot sparks from

spreading around the area.

Trained fire watch on orange vest posted.

Remains in the area until 30minutes after

work completion to detect smoldering fire

and ensure safe condition.

Fire water barrel, drums and buckets to be

maintained.

Wear appropriate PPE. (Safety glass, face

shield, leather gloves, apron & fire resistant

clothing.)

JSA and Method Statement must be

available and implement.

Only certified welder with valid certificate

must perform the job.

Welding machine power outlet must be

GFCI protected and adequately earthed

grounded.

Spark arrester shall be fitted and drip tray

shall be placed underneath to contain fuel

or oil leaks.

Maintain surrounding free of combustible

materials.

Worker involved shall be fully aware of

newly welded joints to prevent accidental

contact with hot surfaces.

5.

Associated manual handling of materials.

Ensure before welding, that pieces of

support to be welded are appropriately

secured (tie-off) if exposed to potential fall.

Protect / cover all nearby existing plant

facilities from falling hot splatters (cable,

wires, gauges, valves, etc.) with fire

blankets.

Oxy-Acetylene cylinders to be kept away

from welding/cutting operations falling hot

splatters.

Hose shall be free from any damage.

Flashback arrestors to be installed at oxyacetylene cutting outfit.

Only standard spark lighter shall be used to

ignite the torch.

No welding / cutting start unless the area is

clear of combustible materials.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Personnel shall be briefed / trained on

proper manual material handling

techniques. Demonstrate how to do safe

manual lifting.

Non-observance of personnel on

proper techniques in manual

handling / lifting of materials.

Over exertion.

Back pain / injury.

Falls / dropped objects due to

mishandling.

Observe buddy system when carrying

lengthy / pipes / supports on access / stairs.

H2S/Flammable Gas Leaks/Release

from Adjacent Ground Flares to the

work Area.

No hand-to-hand passing of materials at

height outside work platform.

Use rope / buckets to lower / hoist up light

materials / tools.

7 of 8

6.

Housekeeping.

Accumulation of debris.

Tripping hazards.

Access obstruction

Remove all debris from site daily as

minimum.

Designate

housekeeping

crew

and

equipment.

Maintain good housekeeping standards. All

walkways must kept obstruction free.

Keep all pipes organized / secured / free

from potential displacement/falls.

Continuous gas testing and monitoring shall

be done in the area before starting the work

until completion due to possible gas

migration in the area.

Gas monitor shall be currently calibrated

prior to use at site.

All workers working in the area shall

undergo H2S training awareness prior to

assignment for work.

Each group working in the area shall have

at least one (1) H2S gas personal monitor.

Required Training.: Safety Orientation;H2S Safety, Manual Handling; Hand and Power Tools; Hot Works, Fire Protection and

Prevention; Fire Watch Training; JSA and Risk Assessment; Crane and Rigging; Electrical Safety.

REQUIRED SAFETY EQUIPMENT

Hard Hats

Yes

Other Gloves

Yes

Face Shield

Yes

Safety Glass

Steel Toe

Boots

Leather

Gloves

Yes

Work Vest

Yes

Goggles

Yes

Hand Tools & Power

Tools

Compactor

Yes

Safety Harness

Yes

Barricades

Yes

Yes

Self Retracting Lifeline

(SRL)

No

Fire

Extinguihsers

Yes

8 of 8

Yes

Cranes

Yes

No

Forklift

No

Lifting Gear

Yes

Jackhammer

No

Air Hoist/Man Rider

No

Other

Equipments/Materials

Yes

Das könnte Ihnen auch gefallen

- JSA M36 Hydro Testing Spool Pieces & PipeworkDokument4 SeitenJSA M36 Hydro Testing Spool Pieces & PipeworkMianNoch keine Bewertungen

- JSA For Erection Modification QSTECDokument7 SeitenJSA For Erection Modification QSTECMohamed NouzerNoch keine Bewertungen

- JSA for Confined Space Entry SafetyDokument5 SeitenJSA for Confined Space Entry SafetyM Waqas HabibNoch keine Bewertungen

- Basic Safety Instructions For All Employees Visiting or Working in The Construction of The HgpepDokument42 SeitenBasic Safety Instructions For All Employees Visiting or Working in The Construction of The Hgpepmalik jahanNoch keine Bewertungen

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDokument13 SeitenJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNoch keine Bewertungen

- Job Safety Analysis Sheet: Manual ExcavationDokument1 SeiteJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalNoch keine Bewertungen

- JSA Format Erection of Column 903-C-02,03Dokument5 SeitenJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- HSE Alert - Pipe Roll Over TBT PDFDokument19 SeitenHSE Alert - Pipe Roll Over TBT PDFrodman823Noch keine Bewertungen

- PM 01 Hira For Excavation of Boiler FoundationDokument3 SeitenPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- Monthly Inspection Color CodeDokument1 SeiteMonthly Inspection Color CodeRabbanNoch keine Bewertungen

- JSA For Erection & Dismantling of ScaffoldingDokument4 SeitenJSA For Erection & Dismantling of ScaffoldingNoe AranelNoch keine Bewertungen

- IPCC Near Miss Form ReviewDokument2 SeitenIPCC Near Miss Form Reviewkirandevi1981Noch keine Bewertungen

- SWMS Bored PilingDokument17 SeitenSWMS Bored PilingnaraNoch keine Bewertungen

- Confined SpaceDokument31 SeitenConfined SpacegshdavidNoch keine Bewertungen

- Night Work NotificationDokument1 SeiteNight Work NotificationSreekumarNoch keine Bewertungen

- JSA For Pressure Test 2ND REVISIONDokument10 SeitenJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- SBOI Chklist PDFDokument1 SeiteSBOI Chklist PDFRajanNoch keine Bewertungen

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Dokument5 SeitenCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNoch keine Bewertungen

- Safety Training PassportDokument2 SeitenSafety Training PassportAbhaySnghNoch keine Bewertungen

- Nataraj HSE EngineerDokument6 SeitenNataraj HSE EngineerAnonymous ooFMlZNoch keine Bewertungen

- JHA Blowing PressDokument5 SeitenJHA Blowing PressLuqman OsmanNoch keine Bewertungen

- JSA Pile Concrete Works OkDokument9 SeitenJSA Pile Concrete Works OkMon Trang NguyễnNoch keine Bewertungen

- Pera JackhammerDokument7 SeitenPera Jackhammerjumansyahamid1988Noch keine Bewertungen

- Safety certificate for EOT craneDokument1 SeiteSafety certificate for EOT cranemt1742k4Noch keine Bewertungen

- Job Hazard Analysis for Confined Space EntryDokument6 SeitenJob Hazard Analysis for Confined Space EntryArun ArunbolluNoch keine Bewertungen

- Adverse Weather Condition HIRADokument5 SeitenAdverse Weather Condition HIRAVenkadesh PeriathambiNoch keine Bewertungen

- Safe Work Practice: Title General Application Protective MechanismsDokument1 SeiteSafe Work Practice: Title General Application Protective MechanismseankiboNoch keine Bewertungen

- HSE Alert - LTI Fall From Heights TBTDokument12 SeitenHSE Alert - LTI Fall From Heights TBTrodman823Noch keine Bewertungen

- Non-Routine Hazards and Risk Assessment SummaryDokument42 SeitenNon-Routine Hazards and Risk Assessment SummaryGanesh Murugesan0% (1)

- Safety Alert For Gantry CraneDokument2 SeitenSafety Alert For Gantry CraneporbyNoch keine Bewertungen

- Hazard Identification FormDokument1 SeiteHazard Identification Formabdulrazzaq hatem100% (1)

- JP Jo Interview QuestionsDokument10 SeitenJP Jo Interview QuestionsMuhammad MehboobNoch keine Bewertungen

- JRA Exxon Format - Insulation Removal and ReinstatementDokument3 SeitenJRA Exxon Format - Insulation Removal and ReinstatementJayesh J PillaiNoch keine Bewertungen

- JSA - Suface Preparationand Brush PaintingDokument5 SeitenJSA - Suface Preparationand Brush PaintingAzad pravesh khanNoch keine Bewertungen

- JSA For Flare Pit Area Including Night WorksDokument4 SeitenJSA For Flare Pit Area Including Night WorksMohammed MinhajNoch keine Bewertungen

- JHA for Unloading Product from Ship at Port of SalalahDokument4 SeitenJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- HSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringDokument16 SeitenHSE Department Graduate Associate Program and IJM Scholar Program Project MonitoringRoza AzaleaNoch keine Bewertungen

- Heavy Vehicle/ Forklift Spotter.: Health, Safety and EnvironmentDokument24 SeitenHeavy Vehicle/ Forklift Spotter.: Health, Safety and EnvironmentsitiNoch keine Bewertungen

- Interview Questions For EHS EngineerDokument6 SeitenInterview Questions For EHS EngineerWasifNoch keine Bewertungen

- JSA Hand ToolsDokument1 SeiteJSA Hand ToolsInoy dy hesusNoch keine Bewertungen

- Safety Observation Formate - 01Dokument3 SeitenSafety Observation Formate - 01Peter LuvisNoch keine Bewertungen

- Risk Assessment ConcreteDokument1 SeiteRisk Assessment Concretemohamed ghaly0% (1)

- Job Safety Practices FirefightingDokument16 SeitenJob Safety Practices Firefightingmohammed tofiqNoch keine Bewertungen

- Hazard Register TemplateDokument1 SeiteHazard Register TemplateShe Chee WahNoch keine Bewertungen

- Risk Assess T-23 - Hilti Cartridge Tool OperationDokument2 SeitenRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDokument168 SeitenAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNoch keine Bewertungen

- ARK JSA Manual ExcavationDokument8 SeitenARK JSA Manual ExcavationMohammed Ali QaziNoch keine Bewertungen

- Fire Fighting Mock Drill Report of Al KhuwaimaDokument8 SeitenFire Fighting Mock Drill Report of Al KhuwaimaMobin Thomas AbrahamNoch keine Bewertungen

- TRA Welding and Stringing 6 PipelineDokument2 SeitenTRA Welding and Stringing 6 PipelineAhmedAmer1Noch keine Bewertungen

- Piling Safety PlanDokument8 SeitenPiling Safety PlanBalogun Isaac100% (1)

- Safety AlertsDokument1 SeiteSafety AlertsChristine RossNoch keine Bewertungen

- JSA-03 Shed DismantlingDokument3 SeitenJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Job Safety Analysis (JSA) SheetDokument26 SeitenJob Safety Analysis (JSA) SheetGMANoch keine Bewertungen

- ZFP Sor 2023-1-10Dokument7 SeitenZFP Sor 2023-1-10irfan shafiqueNoch keine Bewertungen

- Form-58 Confined Space Entry LogDokument1 SeiteForm-58 Confined Space Entry LogRajesh Kumar SinghNoch keine Bewertungen

- All Forms HSE Docs by Hseprof Com 1697423389Dokument76 SeitenAll Forms HSE Docs by Hseprof Com 1697423389ahmedalderbi801Noch keine Bewertungen

- Doku - Pub Risk-AssessmentDokument10 SeitenDoku - Pub Risk-AssessmentUlviyye ElesgerovaNoch keine Bewertungen

- Tower Scaffolds: What You Need To DoDokument3 SeitenTower Scaffolds: What You Need To DoMario Marasigan100% (1)

- HIRA in Process Safety PDFDokument16 SeitenHIRA in Process Safety PDFAlvin AlfiyansyahNoch keine Bewertungen

- JOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESDokument8 SeitenJOB SAFETY ANALYSIS FOR WATER TREATMENT FACILITIESAldrinNoch keine Bewertungen

- Malaria in The Who European Region: Key MessagesDokument8 SeitenMalaria in The Who European Region: Key MessagesAldrinNoch keine Bewertungen

- Plasmodium Plasmodium Falciparum Plasmodium: Life Cycle of The Malaria ParasiteDokument1 SeitePlasmodium Plasmodium Falciparum Plasmodium: Life Cycle of The Malaria ParasiteAbeer FatimaNoch keine Bewertungen

- Safe School Reopening ProtocolsDokument1 SeiteSafe School Reopening ProtocolsAldrinNoch keine Bewertungen

- Travel Packing Check List PDFDokument1 SeiteTravel Packing Check List PDFAldrinNoch keine Bewertungen

- Description: Tags: NclbchecklistDokument4 SeitenDescription: Tags: Nclbchecklistanon-379623Noch keine Bewertungen

- Checklist Tool Guide: Create Organized ChecklistsDokument2 SeitenChecklist Tool Guide: Create Organized ChecklistsAldrinNoch keine Bewertungen

- Back to School Checklist for AdministratorsDokument1 SeiteBack to School Checklist for AdministratorsAldrinNoch keine Bewertungen

- Hiv/Aids:: Confronting A KillerDokument16 SeitenHiv/Aids:: Confronting A KillerAnisarNoch keine Bewertungen

- WHO Report On COVID-19 - April 24, 2020Dokument12 SeitenWHO Report On COVID-19 - April 24, 2020CityNewsTorontoNoch keine Bewertungen

- Checklist Tool Guide: Create Organized ChecklistsDokument2 SeitenChecklist Tool Guide: Create Organized ChecklistsAldrinNoch keine Bewertungen

- Homebuyers Checklist - A Newcomers' Guide and WorkbookDokument20 SeitenHomebuyers Checklist - A Newcomers' Guide and WorkbookHong WeiNoch keine Bewertungen

- Starting Your Business Checklist PDFDokument86 SeitenStarting Your Business Checklist PDFengr_dkNoch keine Bewertungen

- COVID-19 Safety Guide For Healthcare Workers Version 3.0Dokument40 SeitenCOVID-19 Safety Guide For Healthcare Workers Version 3.0Aldrin100% (1)

- PM 7379 119 119680-Di6h3qgi4xDokument169 SeitenPM 7379 119 119680-Di6h3qgi4xAldrinNoch keine Bewertungen

- COVID 19 Form 1 1 PDFDokument1 SeiteCOVID 19 Form 1 1 PDFTuguinay EmilynNoch keine Bewertungen

- Philippines: Situation Report 18Dokument6 SeitenPhilippines: Situation Report 18AldrinNoch keine Bewertungen

- Philippines: Situation Report 38Dokument8 SeitenPhilippines: Situation Report 38AldrinNoch keine Bewertungen

- Philippines: Situation Report 38Dokument8 SeitenPhilippines: Situation Report 38AldrinNoch keine Bewertungen

- Covid19.Indiasim - March23 2 EKDokument33 SeitenCovid19.Indiasim - March23 2 EKRichard Oswaldo Valenzuela MendietaNoch keine Bewertungen

- Guidelines on Preventing COVID-19 Spread in WorkplacesDokument7 SeitenGuidelines on Preventing COVID-19 Spread in WorkplacesAldrinNoch keine Bewertungen

- Saudi Moh Protocol For Patients Suspected Of/Confirmed With Covid-19Dokument15 SeitenSaudi Moh Protocol For Patients Suspected Of/Confirmed With Covid-19AldrinNoch keine Bewertungen

- COVID-19 in India: State-Wise Analysis and PredictionDokument30 SeitenCOVID-19 in India: State-Wise Analysis and PredictionAldrinNoch keine Bewertungen

- MoH Digital Health Strategy UpdateDokument39 SeitenMoH Digital Health Strategy UpdateAldrinNoch keine Bewertungen

- Facts Achievements Layout - Final - Email (SQ)Dokument21 SeitenFacts Achievements Layout - Final - Email (SQ)AldrinNoch keine Bewertungen

- Novel Corona Virus Infection GuidelinesDokument29 SeitenNovel Corona Virus Infection GuidelinesJennifer MarcatelliNoch keine Bewertungen

- Remote Implementation Certification and Auditing ServicesDokument1 SeiteRemote Implementation Certification and Auditing ServicesAldrinNoch keine Bewertungen

- MOH Pocket Manual in Emergency Medicine PDFDokument244 SeitenMOH Pocket Manual in Emergency Medicine PDFErandi Andrea100% (2)

- Facts Achievements Layout - Final - Email (SQ)Dokument21 SeitenFacts Achievements Layout - Final - Email (SQ)AldrinNoch keine Bewertungen

- Using A Table To Document Objectives and Planning To Meet Them PDFDokument1 SeiteUsing A Table To Document Objectives and Planning To Meet Them PDFAldrinNoch keine Bewertungen

- Step 3: Processes of The OH&S Management System: For Use Internally in The OrganizationDokument1 SeiteStep 3: Processes of The OH&S Management System: For Use Internally in The OrganizationAldrinNoch keine Bewertungen

- Manufacturing Technology SyllabusDokument4 SeitenManufacturing Technology Syllabushrana287Noch keine Bewertungen

- History and Processes of Metal JoiningDokument125 SeitenHistory and Processes of Metal JoiningPhani Sridhar ChNoch keine Bewertungen

- Compression Elements for Local BucklingDokument1.205 SeitenCompression Elements for Local BucklingMahelyNoch keine Bewertungen

- Welding FundamentalsDokument49 SeitenWelding FundamentalsJoNoch keine Bewertungen

- 05 Check List For Gas Cutting Set-1-1Dokument1 Seite05 Check List For Gas Cutting Set-1-1Gyanendra Narayan Nayak100% (1)

- 30-99-90-1650 Tie-In ProcedureDokument11 Seiten30-99-90-1650 Tie-In ProcedureEswar ReddyNoch keine Bewertungen

- 1-3 Cold Welding, EtcDokument50 Seiten1-3 Cold Welding, EtcUndertheroadNoch keine Bewertungen

- Old - KPS - Cop - MNT - 003 Oxy Fuel Gas Welding V1.0Dokument42 SeitenOld - KPS - Cop - MNT - 003 Oxy Fuel Gas Welding V1.0Norman CoetzeeNoch keine Bewertungen

- AUR30620 1 SummaryDokument3 SeitenAUR30620 1 SummaryAWAIS ALI UnknownNoch keine Bewertungen

- Inconel 600 PDFDokument16 SeitenInconel 600 PDF孙俊磊100% (1)

- ASME Section II Part A - Ferrous Material SpecificationsDokument8 SeitenASME Section II Part A - Ferrous Material SpecificationsGato Sesa100% (1)

- UWA Product ListDokument43 SeitenUWA Product Listganho.lareshNoch keine Bewertungen

- Gas Cutting Set ChecklistDokument1 SeiteGas Cutting Set ChecklistMOJIB83% (12)

- Cutting Edge HACO CNC MachinesDokument9 SeitenCutting Edge HACO CNC MachinesJaja SumarjaNoch keine Bewertungen

- Welder: Craftsmen Training Scheme (CTS) NSQF Level-4Dokument44 SeitenWelder: Craftsmen Training Scheme (CTS) NSQF Level-4Loganathan KNoch keine Bewertungen

- Grade 11: Automotive ServicingDokument39 SeitenGrade 11: Automotive ServicingBe MotivatedNoch keine Bewertungen

- 16 20 041 0R - Manual - 6W105S - EN - Aug2016 PDFDokument143 Seiten16 20 041 0R - Manual - 6W105S - EN - Aug2016 PDFErick Brante100% (2)

- Portable Machines and Gas Equipment: Product CatalogueDokument65 SeitenPortable Machines and Gas Equipment: Product CatalogueMiodrag TopalovicNoch keine Bewertungen

- Workshop Practice 1Dokument71 SeitenWorkshop Practice 1Stanley EkeneNoch keine Bewertungen

- Shipyard Training ReportDokument13 SeitenShipyard Training ReportrohitNoch keine Bewertungen

- 004 GHB Oxy-Fuel Cutting TechniquesDokument191 Seiten004 GHB Oxy-Fuel Cutting TechniquesMilan DurcovicNoch keine Bewertungen

- Safety Training: Hot WorksDokument66 SeitenSafety Training: Hot WorksMuneeb Ur Rehman100% (1)

- HARRIS Shipbuilding-CatalogDokument76 SeitenHARRIS Shipbuilding-CatalogCardoso MalacaoNoch keine Bewertungen

- Is 3016 1982 PDFDokument24 SeitenIs 3016 1982 PDFVARUN SHARMANoch keine Bewertungen

- Acrm 2 QDokument10 SeitenAcrm 2 QAdrian AquinoNoch keine Bewertungen

- Welding (Cadet Training)Dokument41 SeitenWelding (Cadet Training)Kyaw Bhone WinNoch keine Bewertungen

- Industrial Secrets of Ephedrine ProductionDokument36 SeitenIndustrial Secrets of Ephedrine ProductionAlessioSonaglio100% (3)

- MJPDokument22 SeitenMJPJatin BangaliNoch keine Bewertungen

- Soalan DDokument8 SeitenSoalan DSyi VeenaNoch keine Bewertungen

- Job Hazard Analysis Welding Operations: Attachment 4Dokument3 SeitenJob Hazard Analysis Welding Operations: Attachment 4mujahed.ahmed4253063Noch keine Bewertungen