Beruflich Dokumente

Kultur Dokumente

The RB211-535E4

Hochgeladen von

sas100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

521 Ansichten1 SeiteRB211

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenRB211

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

521 Ansichten1 SeiteThe RB211-535E4

Hochgeladen von

sasRB211

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Engine report

The RB211-535E4

he RB211-535E4 engine was

introduced on the Boeing

757 in 1984 and has since

proved to be one of the

worlds most reliable large

turbofan engines.

Launch of the RB211-535E4 marked

the entry into service of the wide-chord

fan blade, which has become the standard

design of all medium and large commercial aero engines produced by Rolls-Royce

and its collaborative ventures. The engine

has become the airlines first choice for

the 757 fleets with 79 of 109 operators

operating the -535E4 compared to 30

using the PW2037/PW2040 models.

Those 79 757 535E4 operators fly 572

aircraft compared to 430 PW-powered aircraft, and of the 572 aircraft operated, an

estimated 187 are under operating lease

contracts.

The RB211-535E4 was certificated in

July 1997 as the sole western powerplant

on the Tupolev Tu-204. The engine has

also been selected by Boeing as their proposal for the B52 re-engining programme.

However, these programmes have not significantly impacted the market for the

-535E4. The -535E4 has low operating

costs, one of the longest on-wing lives and

excellent reliability.

Since beginning production of the

engine, two additional models have been

added: the RB211-535E4-B and RB211535E4-C but the most popular is the first

model. The engine was designed in accordance with the traditional three-spool

Rolls Royce design low pressure compressor (including fan) driven by the low

pressure turbine (LPT), a compressor and

turbine intermediate (IP) and the high

pressure rotor (HP).

The -E4 variant is one of the quietest

engines in its class, enabling operations

from airports where noise regulations

could exclude other engines. Improvements over the original 1984 specification

engine include the introduction of a

scaled Trent combustor in 1999, giving

still lower emissions and compliance with

all planned environmental legislation.

Wide-chord fan blades provide greater

strength and resistance to foreign object

damage such as collision with birds

and have set industry standards for reliability. Well over 18 million hours of operation have now been accumulated by the

RB211-534E fleet.

Over the years, the -535E4 has been

considerably developed. It has a remarkable performance record, and is in operation with airlines all over the world. The

longevity of the -535E4 version is well

known, with one engine on an America

West Airlines Boeing 757 accruing 2,047

days on-wing, flying over 12 million miles

(the equivalent of 25 return trips to the

moon) over 24,100 hours of operation

and 8,742 cycles. The RB211-535 model

was also the first Rolls-Royce engine

authorised by the airworthiness authorities to operate under the ETOPS

(extended twin-engine operations).

With the RB211-535, Rolls-Royce

achieved its ambition of developing an

engine with long on-wing life and low

maintenance costs. America West and Icelandair have experienced 24,000 hour

engines and Monarch Airlines had a

29,000 hour first-run engine.

Rolls-Royce has managed to jump from

being a medium player in the market with

the -524 variant and success of the -535

variant to being a major player in the

wide-body market with the Trent family.

The foundation for this jump was the

-535E4s technical and commercial

platform.

There is still scope to improve the

-535E4 further and there was some discussion to upgrade it with the Trent 500

core, which could give a projected 8%

decrease in SFC. The economic life-cycle

of the 757 fleet could be extended if the

upgrade of the engine SFC could be

made, increasing it another 10 years.

Rolls-Royce RB211-535

Engine variants

Engine model

RB211-535E4

RB211-535E4-B

RB211-535E4-C

Number of engines

currently operated

688

432

24

Value Report | September 2005

Number of

flying aircraft

344

216

12

RB211-535E4

typical engine details

Bypass Ratio

4.3

Pressure Ratio

25.8

Fan Diameter

74.1 inches

Cruise Fuel Consumption 0.598 lb/hr/lb

Length

117.9 inches

Service entry

1984

Thrust Ratings

40,100 to 43,100 lbs

Over the last 24 months, there have

been two airworthiness directives (AD)

issued covering changes to the Group A

critical part life limits applied at next

shop visit and eddycurrent inspection of

high pressure turbine disc for cracking.

The Trent engine has had 12 ADs issued

in the last 24 months. Other ADs from the

last four years, which operators and

lessors need to be cognisant of, are the

radial drive bearing inspection, low pressure fuel filter and high pressure pump

integrity improvement and introduction of

increased low idle fuel flow governor.

IASG believes that there is no evidence

that the AD load represents an excessive

workload or impediment to investments.

Availability of the -535E4 in the tertiary

market is limited, with only six engines

available for sale or lease with ACI, ELFC,

Finova, RPK Capital and ACG. IASG is

sure that Rolls-Royce Capital would also

have engines available. The -535E4 has a

developed market with predominantly

lessors. The continuing low levels of used

engine availability is driving values

upwards. IASG is aware of one engine

purchased and broken for spares. Typical

values for half-life bare engines have been

between $3m and $3.5m, with lease rates

around $60,000 a month.

Maintenance costs are in the region of

$90 to $120 per hour dependent on hours

to cycle ratio and aircraft operating

weight and thrust de-rated policy. Shop

visit costs are estimated in the $1.4m to

$1.8m bracket.

IASG believes that the RB211-535E4 is

a reliable engine, with a sound investment

potential, despite the limited spares availability and restricted choice of overhaul

providers.

Article contributed by Paolo Lironi of

IASG Powerplant Support Services

7

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- 1HD-T - 1 Land Cruiser Engine Service ManualDokument26 Seiten1HD-T - 1 Land Cruiser Engine Service ManualMichael Dzidowski86% (7)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- MTBE Presintation For IMCODokument26 SeitenMTBE Presintation For IMCOMaryam AlqasimyNoch keine Bewertungen

- SEPprep PDFDokument17 SeitenSEPprep PDFMike DurkeeNoch keine Bewertungen

- PIA Booking Offices:: City Contact DetailsDokument3 SeitenPIA Booking Offices:: City Contact DetailssasNoch keine Bewertungen

- How the scientific method works in 4 stepsDokument1 SeiteHow the scientific method works in 4 stepssasNoch keine Bewertungen

- Information Modeling of Conceptual Process PlanningDokument9 SeitenInformation Modeling of Conceptual Process PlanningsasNoch keine Bewertungen

- The RB211-535E4Dokument1 SeiteThe RB211-535E4sas100% (1)

- 1 s2.0 S0257897298006677 MainDokument7 Seiten1 s2.0 S0257897298006677 MainsasNoch keine Bewertungen

- 4975Dokument2 Seiten4975sasNoch keine Bewertungen

- Guide For Developing A Quarterly Project Progress ReportDokument4 SeitenGuide For Developing A Quarterly Project Progress Reportsas0% (1)

- Tricks To Get EmploymentDokument3 SeitenTricks To Get EmploymentsasNoch keine Bewertungen

- Tricks To Get EmploymentDokument3 SeitenTricks To Get EmploymentsasNoch keine Bewertungen

- TrademarksDokument1 SeiteTrademarksluizdtNoch keine Bewertungen

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Dokument5 SeitenLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNoch keine Bewertungen

- Tyre ManufacturingDokument18 SeitenTyre ManufacturingniteshkrisNoch keine Bewertungen

- Applying The Haar Wavelet Transform To Time Series InformationDokument27 SeitenApplying The Haar Wavelet Transform To Time Series InformationJohn LemonNoch keine Bewertungen

- L04-L05 Parts 13-25-550 v05 42021Dokument84 SeitenL04-L05 Parts 13-25-550 v05 42021Brandi HillNoch keine Bewertungen

- Tur C PDFDokument86 SeitenTur C PDFWilliam LambNoch keine Bewertungen

- Dsd-060 Earthquake Shutdown Unit: DescriptionDokument2 SeitenDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifNoch keine Bewertungen

- Model Railroad Plans and DrawingsDokument7 SeitenModel Railroad Plans and DrawingsBán ZoltánNoch keine Bewertungen

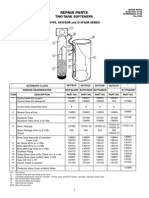

- Star S07FS32DR Water Softener Repair PartsDokument1 SeiteStar S07FS32DR Water Softener Repair PartsBillNoch keine Bewertungen

- X-Span & Setting ToolsDokument18 SeitenX-Span & Setting ToolsDenier RubianoNoch keine Bewertungen

- Sample Cover Letter: No Work ExperienceDokument4 SeitenSample Cover Letter: No Work ExperienceMaya ElvisaNoch keine Bewertungen

- Microstructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic DeformationDokument10 SeitenMicrostructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic Deformationsoni180Noch keine Bewertungen

- Chapter 11B: Survey of Database SystemsDokument17 SeitenChapter 11B: Survey of Database SystemsMurtaza MoizNoch keine Bewertungen

- Surging & Blow Out of Loop Seals in A CFBC BoilerDokument9 SeitenSurging & Blow Out of Loop Seals in A CFBC Boilermohamed faragNoch keine Bewertungen

- LNMIIT Course Information Form: A. B. C. D. E. FDokument2 SeitenLNMIIT Course Information Form: A. B. C. D. E. FAayush JainNoch keine Bewertungen

- OFFICE 365 PROXY GUIDEDokument4 SeitenOFFICE 365 PROXY GUIDErossloveladyNoch keine Bewertungen

- MC 8051Dokument85 SeitenMC 8051Sonu SatishNoch keine Bewertungen

- Brake Pedals and ValveDokument4 SeitenBrake Pedals and Valveala17Noch keine Bewertungen

- Ranking 4Dokument34 SeitenRanking 4Deepti BhatiaNoch keine Bewertungen

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDokument23 SeitenItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNoch keine Bewertungen

- Questionnaire For Future BLICZerDokument1 SeiteQuestionnaire For Future BLICZerAlejandra GheorghiuNoch keine Bewertungen

- PMO ProceduresDokument21 SeitenPMO ProceduresTariq JamalNoch keine Bewertungen

- Introduction To PLCsDokument42 SeitenIntroduction To PLCsArun Kumar YadavNoch keine Bewertungen

- Sample Style GuideDokument5 SeitenSample Style Guideapi-282547722Noch keine Bewertungen

- Geo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterDokument5 SeitenGeo-Informatics and Nano-Technology For Precision FARMING (AGRO-301) 5 SemesterVinod Vincy67% (3)

- Astral Column Pipe PricelistDokument4 SeitenAstral Column Pipe PricelistVaishamNoch keine Bewertungen

- Prefabricated Structures ComponentsDokument16 SeitenPrefabricated Structures ComponentsKrish KrishNoch keine Bewertungen

- General Purpose Relay SpecsDokument2 SeitenGeneral Purpose Relay SpecsAndres DiazNoch keine Bewertungen

- Unit V DSS Development: Arun Mishra 9893686820Dokument17 SeitenUnit V DSS Development: Arun Mishra 9893686820Arun MishraNoch keine Bewertungen