Beruflich Dokumente

Kultur Dokumente

Falk Series C, E, F, G, J, P, Q, S, Y Gear Drives - Service Manual

Hochgeladen von

Jorge Iván CarbajalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Falk Series C, E, F, G, J, P, Q, S, Y Gear Drives - Service Manual

Hochgeladen von

Jorge Iván CarbajalCopyright:

Verfügbare Formate

Falk Enclosed Gear Drives Lubrication Recommendations

All Series C, E, F, G, J, P, Q, S, & Y

(Page 1 of 4)

Introduction

Petroleum Based Lubricants

Carefully follow lubrication instructions on the gear drive

nameplate, warning tags and installation manuals furnished with

the gear drive.

R & O GEAR LUBRICANTS (Table 1 below) Industrial

type petroleum based rust and oxidation inhibited (R&O) gear

lubricants are the most common and readily available general

purpose gear lubricants.

Lubricants listed in this manual are typical ONLY and should

not be construed as exclusive recommendations. Industrial

type petroleum based rust and oxidation inhibited (R & O) gear

lubricants or industrial type sulfur-phosphorus extreme pressure

(EP) gear lubricants are the recommended lubricants for

ambient temperatures of 15 to 125F(9 to +52C). For drives

operating outside the above temperature range refer to Synthetic

Lubricants paragraphs. Synthetic lubricants can also be used in

normal climates.

VISCOSITY (IMPORTANT) For cold climate conditions refer to

Table 4, Page 2, and the Synthetic Lubricant paragraphs. Select

a lubricant which has a pour point at least 10F (5.5C) below the

expected minimum ambient starting temperature.

Usable temperature ranges can sometimes be widened if

specific application conditions are known.

If a gear drive (excluding semi-high speed and high speed

drives) operates in a typical indoor environment where the

ambient temperature is within 70 to 125F (21 to 52C), the oil

viscosity may be increased one AGMA grade above that shown

for the 50 to 125F(10 to 52C) range. That is, an AGMA Number

6 or 7 should be substituted for a 5 or 6 respectively, under this

ambient condition.

OIL PUMPS When selecting a lubricant for a gear drive

equipped with an oil pump, cold temperature oil viscosity is

important. Lubricant viscosity at start-up generally should not

exceed 1725 cSt (8,000 SSU). When exceeding this viscosity,

pump cavitation is possible, preventing oil circulation. A sump

heater may be required or it may be possible to use a lower

viscosity oil to minimize pump cavitation, refer to Factory.

EXTREME PRESSURE (EP) LUBRICANTS (Table 2, Page 2)

For highly loaded gear drives or drives loaded in excess of original

estimates, industrial type petroleum extreme pressure lubricants

are preferred. The EP lubricants currently recommended are of

the sulfur-phosphorus type.

WARNING: EP LUBRICANTS IN FOOD PROCESSING

INDUSTRY EP lubricants may contain toxic substances and

should not be used in the food processing industry without the

lubricant manufacturers approval. Lubricants which meet USDA

H1 classification are suitable for food processing applications.

CAUTION: EP LUBRICANTS & INTERNAL BACKSTOPS Do

not use EP lubricants or lubricants with anti-wear additives or

lubricant formulations including sulfur, phosphorus, chlorine, lead

derivatives, graphite or molybdenum disulfides in drives equipped

with internal cartridge type backstops. Some lubricants in Table

1 below, may contain anti-wear additives. Lubricants in Table 2,

Page 2, do contain several of these additives.

Synthetic Lubricants

Synthetic lubricants of the polyalphaolefin type are recommended

for cold climate operation, high temperature applications,

extended temperature range (all season) operation and/or

extended lubricant change intervals. The proper viscosity grade

of synthetic lubricant is given in Table 4, Page 2.

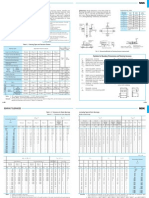

TABLE 1 Petroleum Based R&O Gear Oils (Maximum operating temperature of lubricants 200F (93C)

AGMA Viscosity Grade

ISO Viscosity Grade

46

68

100

150

220

320

460

cSt @ 40C

41.4-50.6

61.2-74.8

90-110

135-165

198-242

288-352

414-506

SSU @ 100F

193-235

284-347

417-510

626-765

918-1122

1335-1632

1919-2346

Viscosity

Lubricant

Lubricant

Lubricant

Lubricant

Lubricant

Amoco Oil Co.

BP Oil Co.

Chevron U.S.A., Inc.

Citgo Petroleum Corp.

Manufacturer

Amer. Ind. Oil 46

Turbinol T-46

Hydraulic Oil AW 46

Citgo Pacemaker 46

Lubricant

Amer. Ind. Oil 68

Turbinol T-68

Hydraulic Oil AW 68

Citgo Pacemaker 68

Amer. Ind. Oil 100

Turbinol T-100

Machine Oil AW 100

Citgo Pacemaker 100

Amer. Ind. Oil 150

....

Machine Oil AW 150

Citgo Pacemaker 150

Amer. Ind. Oil 220

Energol HLP-HD 220

Machine Oil AW 220

Citgo Pacemaker 220

Amer. Ind. Oil 320

....

Machine Oil AW 320

Citgo Pacemaker 320

Amer. Ind. Oil 460

....

....

Citgo Pacemaker 460

Conoco Inc.

Exxon Co., U.S.A.

Houghton International Inc.

Imperial Oil Ltd.

Dectol R&O Oil 46

Teresstic 46

Hydro-Drive HP-200

Teresso 46

Dectol R&O Oil 68

Teresstic 68

Hydro-Drive HP-300

Teresso 68

Dectol R&O Oil 100

Teresstic 100

Hydro-Drive HP-500

Teresso 100

Dectol R&O Oil 150

Teresstic 150

Hydro-Drive HP-750

Teresso 150

Dectol R&O Oil 220

Teresstic 220

Hydro-Drive HP-1000

Teresso 220

Dectol R&O Oil 320

Teresstic 320

....

Teresso 320

DectolR&OOil460

Teresstic 460

....

....

Kendall Refining Co.

Keystone Lubricants

Lyondell Petrochemical (ARCO)

Mobil Oil Corp.

Kenoil R&O AW 46

KLC-15 Duro 46

DTE Oil Medium

Kenoil R&O AW 68

KLC-20

Duro 68

DTE Oil Heavy Medium

Kenoil R&O AW 100

KLC-30

Duro 100

DTE Oil Heavy

Four Seasons AW 150

KLC-40

Duro 150

DTE Oil Extra Heavy

....

KLC-50

Duro 220

DTE Oil BB

....

....

Duro 320

DTE Oil AA

....

....

....

DTE Oil HH

Petro-Canada Prod.

Phillips 66 Co.

Shell Oil Co.

Shell Canada Ltd.

Harmony 46

Magnus Oil 46

Turbo T46

Tellus 46

Harmony 68

Magnus Oil 68

Turbo T68

Tellus 68

Harmony 100

Magnus Oil 100

Morlina 100

Tellus 100

Harmony 150 or 150D

Magnus Oil 150

Morlina 150

Tellus 150

Harmony 220

Magnus Oil 220

Morlina 220

Tellus 220

Harmony 320

Magnus Oil 320

Morlina 320

Tellus 320

....

....

Morlina 460

....

Texaco Lubricants

Unocal 76 (East)

Unocal 76 (West)

Valvoline Oil Co.

Regal Oil R&O 46

Unax RX 46

Turbine Oil 46

Valvoline AW ISO 46

Regal Oil R&O 68

Unax RX 68

Turbine Oil 68

Valvoline AW ISO 68

Regal Oil R&O 100 Unax

RX 100

Turbine Oil 100

Valvoline AW ISO 100

Regal Oil R&O 150

Unax RX 150

Turbine Oil 150

Valvoline AW ISO 150

Regal Oil R&O 220

Unax RX 220

Turbine Oil 220

Valvoline AW ISO 220

Regal Oil R&O 320

Unax AW 320

Turbine Oil 320

Valvoline AW ISO 320

Regal Oil R&O 460

Turbine Oil 460

Turbine Oil 460

....

Rexnord

3001 W. Canal St., Milwaukee, WI 53208-4200

Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com

Lubricant

128-010

November 2000

Supersedes 4-94

Lubrication Recommendations Falk Enclosed Gear Drives

All Series C, E, F, G, J, P, Q, S, & Y

(Page 1 of 4)

COLD CLIMATE CONDITIONS The proper viscosity grade

of synthetic lubricant is given in Table 4 below. Usable temperature

ranges can sometimes be widened if specific application conditions are

known.

Synthetic lubricants may be used in gear drives with internal backstops

operating in cold temperatures (30 to +50F or 34 to +10C).

Select proper lubricant grade from Table 4 below. Mobil 624 and SHC

626 provide proper backstop action under these conditions. Other

synthetic lubricants may also be acceptable. DO NOT use synthetic

lubricants in drives with backstops operating above +50F (10C).

NORMAL CLIMATE CONDITIONS For temperatures of 15F

(9C) and above, use viscosity grades as recommended in Table 5,

Page 4. Select a lubricant from Table 1, Page 1. Usable temperature

ranges can sometimes be widened if specific application conditions are

known.

WARNING: SYNTHETIC LUBRICANTS IN FOOD

PROCESSING INDUSTRY Synthetic lubricants may contain

toxic substances and should not be used in the food processing

industry without the lubricant manufacturers approval.

Lubricants which meet USDA H1 classification are suitable for

food processing applications.

CAUTION: SYNTHETIC LUBRICANTS & INTERNAL

BACKSTOPS Synthetic lubricants may be used in

gear drives with internal backstops operating only in cold

temperatures 30 to +50F (34 to +10C). Mobil SHC 624

and SHC 626 provide proper backstop action under these

conditions. Other synthetic lubricants may also be acceptable.

DO NOT use synthetic lubricants in drives with backstops

operating in ambient temperatures above 50F (10C).

TABLE 2 Extreme Pressure Lubricants

Maximum Operating Temperature 200F (93C)

Manufacturer

Lubricant

Amoco Oil Co.

BP Oil Co.

Chevron U.S.A. Inc.

Citgo Petroleum Corp.

Permagear/Amogear EP

Energear EP

Gear Compounds EP

Citgo EP Compound

Conoco Inc.

Exxon Co. U.S.A.

E.F. Houghton & Co.

Imperial Oil Ltd.

Gear Oil

Spartan EP

MP Gear Oil

Spartan EP

TABLE 3 Greases for Grease Lubricated

Bearings & Grease Purged Seals

(0 to 200F (-18 to +93C)

Manufacturer

Amolith Grease No. 2

Energrease LS-EP2

Industrial Grease Medium

Premium Lithium Grease No. 2

Conoco Inc.

Exxon Company, U.S.A.

E.F. Houghton & Co.

Imperial Oil Ltd.

EP Conolith Grease No. 2 Unirex N2

Cosmolube 2

Unirex N2L

Kendoll Refining Co.

Keystone Div., Penwalt Corp.

Lyondell Petrochemical (ARCO)

Mobil Oil Corp.

Multi-Purpose Lithium Grease L421

Zeniplex 2

Litholine H EP 2 Grease

Mobilith 22

Mobil Oil Corp.

Petro-Canada Products

Phillips 66 Co.

Shell Oil Co.

Mobilith SHC 460

Mulipurpose EP2

Philube Blue EP

Alvania Grease 2

Shell Canada Limited

Sun Oil Co.

Texaco Lubricants

Alvania Grease 2

Ultra Prestige EP2

Premium RB Grease

Unocal 76 (East & West)

Valvoline Oil Co.

Unoba EP2

Multilube Lithium EP Grease

High performance synthetic alternate.

TABLE 4 Polyalphaolefin Type

Synthetic Lubricants

AGMA Viscosity

Grade

...

ISO Viscosity Grade

32

68

150

220

320

cSt @ 40C

28.835.2

61.274.8

135165

198242

288352

SSU @ 100F

135164

284347

626765

9181122

13351632

Viscosity

Ambient

Temperature

RangeF

Kendall NS-MP

Keygear

Pennant NL

Mobilgear

Petro-Canada Products

Phillips 66 Co.

Shell Oil Co.

Shell Canada Limited

Ultima EP

Philgear

Omala Oil

Omala Oil

Sun Oil Co.

Texaco Lubricants

Unocal 76 (East & West)

Valvoline Oil Co.

Sunep

Meropa

Extra Duty NL Gear Lube AGMA EP

Chevron U.S.A., Inc.

CPI Engineering

Services, Inc.

Exxon Co. U.S.A.

128-010

15to+50

0to+80

+10 to+125

+20to+125

Lubricant

...

...

...

Syn. Gear

Lube Tegra

220

...

...

...

...

Syncon 32

Syncon 68

CP4620

32

CP4620

68

CP46201

50

CP4620220

...

CP4630

32

CP4630

68

CP46301

50

CP4630

220

...

Spartan

Synthetic

EP 150

Spartan

Synthetic

EP 220

Spartan

Synthetic

EP 320

SHC 629

SHC 630

SHC 632

Mobilgear

SHC 220

Mobilgear

SHC 320

...

SHC 624

Mobil Oil Corp.

November 2000

Supersedes 4-94

30to+10

Manufacturer

Conoco, Inc.

Kendall Refining Co.

Keystone Div.,

Pennwalt Corp.

Lyondell Petrochemical (ARCO)Mobil

Oil Corp.

Lubricant

Amoco Oil Co.

BP Oil Co.

Chevron U.S.A., Inc.

Citgo Petroleum Corp.

...

...

SHC 626

...

Mobilgear

SHC 150

Minimum viscosity index of 130 (consult lubricant supplier/manufacturer for maximum

operating temperature). Viscosity grade selections are not applicable to semi-high speed

and high speed drives.

With complete application information, temperature range can sometimes be extended,

refer to Factory.

Extreme pressure EP lubricants (contains sulfur phosphorus).

Rexnord

3001 W. Canal St., Milwaukee, WI 53208-4200

Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com

Falk Enclosed Gear Drives Lubrication Recommendations

All Series C, E, F, G, J, P, Q, S, & Y

(Page 3 of 4)

Oil Levels

Bearing & Seal Greases

Prior to filling gear drives, remove the inspection cover

(on drives so equipped) and flood the oil troughs with a

generous flow of oil to the bearings. Fill the drive with oil to

the level indicated on the oil dipstick or appropriate plug.

Some gear drives have one or more grease lubricated

bearings and grease purged seals. Whenever changing oil

in the drive, grease the bearings and purge the seals with

one of the NLGI #2 greases listed in Table 3, Page 2.

Some of these greases are of the EP type and may contain

toxic substances not allowed in the food processing

industry. A grease that meets the USDA H1 classification

is suitable for food processing applications.

GREASE LUBRICATED BEARINGS Remove pressure

relief plug when greasing bearing on vertical shaft drives.

Pump grease into bearing cage until it appears at the plug.

Replace pressure relief plug.

GREASE LUBRICATED SEALS Most gear drives and

all BIF pawl type backstops are furnished with grease

purged seals which minimize the entry of contaminants

and abrasive dusts into the drive or backstop. Gear drives

and backstops are shipped with NLGI #2 grease in the

seal housing cavities unless otherwise specified. If grease

could contaminate the product, as in the food and drug

industries, it should be removed. A grease that meets

USDA H1 classification is suitable for food processing

applications.

Periodically (at least every six months) depending upon

the frequency and degree of contamination, purge

contaminated grease from seals by slowly pumping fresh

bearing grease thru the seal, WITH A HAND GREASE

GUN, until fresh grease flows out along the shaft. Wipe off

purged grease.

CAUTION: For Y-Type drives only, rapid regreasing with a

power grease gun can force grease inward past the seals

and plug the oil drain back system causing seal leaks.

Lubricant Changes

OIL ANALYSIS REPORT Checking oil condition at

regular intervals is recommended. In the absence of more

specific limits, the guidelines listed below may be used to

indicate when to change oil:

1. Water content is greater than 0.05% (500 ppm).

2. Iron content exceeds 150 ppm.

3. Silicon (dust/dirt) exceeds 25 ppm.

4. Viscosity changes more than 15%.

PETROLEUM LUBRICANTS For normal operating

conditions, change gear oils every six months or 2500 operating

hours, whichever occurs first. If the drive is operated in an area

where temperatures vary with the seasons, change the oil viscosity

grade to suit the temperature, refer to Table 1, Page 1. Lubricant

suppliers can test oil from the drive periodically and recommend

economical change schedules.

SYNTHETIC LUBRICANTS Synthetic lube change

intervals can be extended to 8000-10,000 hours

depending upon operating temperatures and lubricant

contamination. Laboratory analysis is recommended

for optimum lubricant life and gear drive performance.

Change lube with change in ambient temperature, if

required. Refer to Table 4, Page 2.

Lubrication Systems

OIL PUMPS Occasionally gear drives are equipped

with oil pumps, either for special lubrication considerations

or for external cooling. When so equipped, run the

lubrication system for several

minutes to fill the system

components. Verify that the pump is

circulating oil properly then recheck

the oil level. Before starting the

gear drive, rotate the input shaft by

hand to check for any obstruction.

Then start the drive and allow it

to run without a load for several

minutes. Shut down and recheck

oil level. Add oil to compensate for

cooler, filter, etc., oil capacities. If everything is satisfactory,

the drive is ready for operation.

CAUTION: Refer to Factory for drives that use pumps to

distribute lubricants with temperatures below 30F(1C).

Rexnord

3001 W. Canal St., Milwaukee, WI 53208-4200

Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com

128-010

November 2000

Supersedes 4-94

Lubrication Recommendations Falk Enclosed Gear Drives

All Series C, E, F, G, J, P, Q, S, & Y

(Page 4 of 4)

TABLE 5 Viscosity Recommendations

Synthetic Lubricants

Classification

Symbol

(Drive Type)

Drive

Size

Y1

YF1

50-135, 2050-2135

1080-1135

32

32

AGMA

...

...

Parallel Shaft and Horizontal

Right Angle

Y1

YF1

140-195, 2140-2165 11401195

32

32

...

...

Roller Bearings

Fabricated Steel Housings

Y2 & YB2

Y2 & YB2

50-195

2050-2245

32

32

Y3, YB3 & 4

Y3, YB3 & 4

50-135, 2050-2135

140-195, 2140-2245

32

32

YBX2

YBX3

YBX2

YBX3

50-135, 2070-2135

50-135, 2070-2135

140-195, 2140-2195

140-195, 2140-2195

32

32

32

32

56-9

10-13

32

32

32

2050-2120

3-5

6-9

10-12

32

32

32

32

4, 5

6-12

3&5

32

32

32

Drive Description

Vertical Right Angle

Fabricated Steel Housings

Parallel Shaft

Sleeve and Roller Bearings

Cast Iron Housings

Right Angle

Horizontal and Vertical

Cast Iron Housings

GHC, GHF

GDA, GDF

GRA, GRF

2000 GHB1

GHB

GDB

GRB

GDX

GDX, GRX

DTC

YHF1

YH1

YH2

Parallel Shaft Semi-High Speed

Sleeve, Roller and Ball Bearings

GHCH

GHCH

1080-1135

2050-2125

2050-2175

5

6-13

R & O Petroleum Oils

Cold Climates

Normal Climates

30 to +10F

(34 to 12C)

15 to +50F

(26 to +10C)

15 to 60F

(9 to +16C)

ISO-VG

ISO-VG

AGMA

ISO-VG

AGMA

ISO-VG

68

68

2

2

100

100

3

3

220

220

5

5

68

68

2

2

150

150

4

4

220

220

5

5

68

68

2

2

150

150

4

4

220

220

5

5

68

68

2

2

150

220

4

5

220

320

5

6

...

...

...

...

68

68

68

68

2

2

2

2

100

150

150

220

3

4

4

5

220

220

220

320

5

5

5

6

...

......

68

68

68

2

2

2

100

150

150

3

4

4

220

220

220

5

5

5

2

2

2

2

100

100

150

150

3

3

4

4

220

220

220

220

5

5

5

5

32

32

32

32

32

...

...

...

...

50 to 125F

(10 to 52C)

...

...

...

...

...

...

...

68

68

68

68

68

68 68

2

2

2

100

150

150

3

4

4

220

220

220

5

5

5

...

...

...

68

68

68

2

2

2

100

100

150

3

3

4

220

220

220

5

5

5

68

68

2

2

68

100

2

3

100

150

3

4

68

68

2

2

46

100

1

3

68

150

2

4

...

...

...

...

S Press Lube

S Splash Lube

All Sizes

32

32

Q, P, YQA, YPA

All Sizes

32

...

68

46

68

AllF&ETypes

All FC & C Types

All J Types

All Sizes

32

...

68

150

220

Parallel Shaft High Speed

Sleeve Bearings

Motoreducers

Concentric Shaft Speed Reducers

Shaft and Flange Mounted Drives

Refer to Factory for viscosity recommendations when ambient temperatures are higher than 125F(52C), or when drives are operating in extremely humid, chemical, or

dust laden atmospheres.

Lubricant inlet temperature to gear drive must not exceed 100F(38C) when using an AGMA No. 1 oil (193 to 235 SSU at 104F; 41.5-50.6 cSt at 40C) in a pressure

lubrication system.

Refer to Factory before substituting higher viscosity grades from those indicated in Table 5 above.

128-010

November 2000

Supersedes 4-94

Rexnord

3001 W. Canal St., Milwaukee, WI 53208-4200

Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com

Das könnte Ihnen auch gefallen

- Falk Installation Manuel, Ring Gear, Pages 17 24Dokument8 SeitenFalk Installation Manuel, Ring Gear, Pages 17 24Yerko NavarroNoch keine Bewertungen

- Y Drive MaintananceDokument8 SeitenY Drive MaintananceezeladalNoch keine Bewertungen

- Astm A307Dokument1 SeiteAstm A307SAlman Khan100% (1)

- ISO Standards Vibration MachineryDokument2 SeitenISO Standards Vibration MachineryAdrian Rodrigo Jofre AlvarezNoch keine Bewertungen

- 163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualDokument4 Seiten163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualLazzarus Az Gunawan100% (1)

- Materialcomprison GHISADokument3 SeitenMaterialcomprison GHISAlavius_mNoch keine Bewertungen

- PBL Series K CatalougeDokument117 SeitenPBL Series K CatalougeankitkanujiyaNoch keine Bewertungen

- End Truck DataDokument1 SeiteEnd Truck DataErc Nunez VNoch keine Bewertungen

- 163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualDokument4 Seiten163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNoch keine Bewertungen

- Bombas EngrenagensDokument76 SeitenBombas EngrenagensjairmorettoNoch keine Bewertungen

- Section Q: Splined Hubs, Drive KitsDokument8 SeitenSection Q: Splined Hubs, Drive KitshaggNoch keine Bewertungen

- Pistons Catalogue 2009 (V2.2 Compact)Dokument28 SeitenPistons Catalogue 2009 (V2.2 Compact)Mr.JohnNoch keine Bewertungen

- FalkDokument4 SeitenFalknoviyanthyNoch keine Bewertungen

- Synchronous Belt Drives - Automotive PulleysDokument14 SeitenSynchronous Belt Drives - Automotive Pulleystv-locNoch keine Bewertungen

- SCX MotoresDokument27 SeitenSCX MotoresRalpho Carlos da Silva100% (1)

- 00 FRASLE CintaFreno 01 16Dokument95 Seiten00 FRASLE CintaFreno 01 16Gabriel100% (1)

- ILJINDokument72 SeitenILJINСергей ВодяницкийNoch keine Bewertungen

- Steel AsiaDokument109 SeitenSteel AsiaHieu Do TatNoch keine Bewertungen

- Sae J200-Epdm-Ts5 - Google SearchDokument2 SeitenSae J200-Epdm-Ts5 - Google SearchJessica ApalinNoch keine Bewertungen

- 2010 Catalogue AndertonDokument47 Seiten2010 Catalogue Andertonaiyubi2100% (1)

- Riken Europe Rew01Dokument160 SeitenRiken Europe Rew01Dario Antonio Manjarrés Ariza100% (1)

- EN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionDokument1 SeiteEN-GJL-200 - EN-JL1030 - Cast Iron Equivalent, Mechanical Properties, Chemical CompositionBao Duy NguyenNoch keine Bewertungen

- Bac Cau Din Iso 12240.1Dokument67 SeitenBac Cau Din Iso 12240.1Nguyen hanhNoch keine Bewertungen

- Development of UNS S 32760Dokument8 SeitenDevelopment of UNS S 32760TasmanijskaNemaNoch keine Bewertungen

- Standard Torque List Loesche-425101E0Dokument1 SeiteStandard Torque List Loesche-425101E0Yhane Hermann BackNoch keine Bewertungen

- 1570 (Part II)Dokument20 Seiten1570 (Part II)Kaushik SenguptaNoch keine Bewertungen

- Download435 PDFDokument28 SeitenDownload435 PDFAlamarumNoch keine Bewertungen

- CATAE902Dokument1.246 SeitenCATAE902Desmond OeiNoch keine Bewertungen

- Aisi 4340 Alloy Steel (Uns g43400)Dokument4 SeitenAisi 4340 Alloy Steel (Uns g43400)Muhamad Ikbal TrismanaNoch keine Bewertungen

- 318 100 - Falk UltraMax Type FC, FZ, Sizes 2040 2130 Gear Drives - Installation ManualDokument14 Seiten318 100 - Falk UltraMax Type FC, FZ, Sizes 2040 2130 Gear Drives - Installation Manualbasavaraj patil100% (1)

- ELBE Programm E PDFDokument124 SeitenELBE Programm E PDFMidhunNoch keine Bewertungen

- Drive Belts and Kits From Bosch 2014Dokument160 SeitenDrive Belts and Kits From Bosch 2014Fix It0% (1)

- Newman-Cams Pricedata Catalogue2016-1Dokument72 SeitenNewman-Cams Pricedata Catalogue2016-1stalinNoch keine Bewertungen

- Shell Tellus Oils: High Performance Hydraulic OilDokument2 SeitenShell Tellus Oils: High Performance Hydraulic Oilsamar209Noch keine Bewertungen

- Testing agricultural trailersDokument9 SeitenTesting agricultural trailersEdsel Jay RaperNoch keine Bewertungen

- Big Bolt Nut Brochure PDFDokument4 SeitenBig Bolt Nut Brochure PDFanon_932866951Noch keine Bewertungen

- SAE J306 Transmission OilDokument1 SeiteSAE J306 Transmission OilEin100% (1)

- Aurora Bearing 610 CatalogDokument84 SeitenAurora Bearing 610 CatalogWellington S. FrançaNoch keine Bewertungen

- BEARING TOLERANCES TABLEDokument12 SeitenBEARING TOLERANCES TABLESandeep MatetiNoch keine Bewertungen

- NGT Thread Series: Total Solution For Thread GaugingDokument2 SeitenNGT Thread Series: Total Solution For Thread Gaugingrenebb100% (1)

- Hardened steel pins and weightsDokument1 SeiteHardened steel pins and weightsSachin JawaleNoch keine Bewertungen

- Approximate Leeb Type D Hardness Conversion Charts For Non Austenitic Steels Rckwell C Hardness Range PDFDokument1 SeiteApproximate Leeb Type D Hardness Conversion Charts For Non Austenitic Steels Rckwell C Hardness Range PDFNookang SeaSunNoch keine Bewertungen

- Metric DIN 939 Double End Studs (1.25xD) : Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 939 Double End Studs (1.25xD) : Visit Our For Product Availabilitysudarshan pugaliaNoch keine Bewertungen

- ASTM F593 stainless steel fastener specificationDokument1 SeiteASTM F593 stainless steel fastener specificationBilly DNoch keine Bewertungen

- 2017 CN CatalogDokument84 Seiten2017 CN Catalog1costin1Noch keine Bewertungen

- Yec 2009-2010Dokument7 SeitenYec 2009-2010Alex LopezNoch keine Bewertungen

- Design - Ring Gear MaterialsDokument4 SeitenDesign - Ring Gear Materialstushar11singhNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument17 SeitenDisclosure To Promote The Right To InformationCanan DönmezNoch keine Bewertungen

- Steel grade 1.2312 propertiesDokument4 SeitenSteel grade 1.2312 propertiesFrancisco CarrascoNoch keine Bewertungen

- WL 00200 6 de enDokument200 SeitenWL 00200 6 de enaNoch keine Bewertungen

- RBL Ball and Roller Bearing Brb2008Dokument94 SeitenRBL Ball and Roller Bearing Brb2008Ringball_GusNoch keine Bewertungen

- 6885 1Dokument1 Seite6885 1ajeshNoch keine Bewertungen

- Approved Lubrication DDokument2 SeitenApproved Lubrication DMostafa MohamedNoch keine Bewertungen

- Gear oils guideDokument3 SeitenGear oils guideSong Meng KimNoch keine Bewertungen

- Marley LubricantDokument2 SeitenMarley LubricantMohammed SayeeduddinNoch keine Bewertungen

- G06Dokument6 SeitenG06Oscar CruzNoch keine Bewertungen

- Operating Instructions for Lubricants in FLENDER Gear UnitsDokument26 SeitenOperating Instructions for Lubricants in FLENDER Gear UnitshoseinNoch keine Bewertungen

- Gear Oils: Gear Oil Is A Fluid Lubricant Used in Gears (Gearboxes) For Reduction of Friction and Wear of The Gear ToothDokument4 SeitenGear Oils: Gear Oil Is A Fluid Lubricant Used in Gears (Gearboxes) For Reduction of Friction and Wear of The Gear Toothspyros_peiraiasNoch keine Bewertungen

- Lubrication Selection For Enclosed Gear DrivesDokument16 SeitenLubrication Selection For Enclosed Gear DrivesGian TeryNoch keine Bewertungen

- Sensors PDFDokument53 SeitenSensors PDFteknikpembakaran2013Noch keine Bewertungen

- Divinol Industrial Oils: Gear Oils and Hydraulic Fluids - Guide and Slideway OilsDokument12 SeitenDivinol Industrial Oils: Gear Oils and Hydraulic Fluids - Guide and Slideway OilsJorge Iván CarbajalNoch keine Bewertungen

- Viscosity ChartDokument3 SeitenViscosity ChartJorge Iván CarbajalNoch keine Bewertungen

- Ajebu 2010. Coffe PulpDokument10 SeitenAjebu 2010. Coffe PulpJorge Iván CarbajalNoch keine Bewertungen

- Study of Free Vibration Characteristics of Cantilever Beams Through Modal Testing and Analysis 2017-18Dokument70 SeitenStudy of Free Vibration Characteristics of Cantilever Beams Through Modal Testing and Analysis 2017-18ranjithkrajNoch keine Bewertungen

- Expedation DemoDokument94 SeitenExpedation DemoMahmoud OmaraNoch keine Bewertungen

- John B WatsonDokument12 SeitenJohn B Watsonsanika kadamNoch keine Bewertungen

- Adnan's Pharmaceutical Quality Management by Adnan Sarwar Chaudhary - 3rd EditionDokument152 SeitenAdnan's Pharmaceutical Quality Management by Adnan Sarwar Chaudhary - 3rd EditionWeb Of PharmaNoch keine Bewertungen

- Orthogonal Deformation in Ecuador's Eastern AndesDokument4 SeitenOrthogonal Deformation in Ecuador's Eastern AndesAna Chiluisa GuamanNoch keine Bewertungen

- Database Practice QPDokument5 SeitenDatabase Practice QPnelsgeorgealtNoch keine Bewertungen

- Wands & Wizards - A Harry Potter 5e Adaptation v1.0 - GM Binder PDFDokument77 SeitenWands & Wizards - A Harry Potter 5e Adaptation v1.0 - GM Binder PDFtmartel_99Noch keine Bewertungen

- III Design of Steel Structures Unit 2Dokument72 SeitenIII Design of Steel Structures Unit 2VikrantNoch keine Bewertungen

- Adams Falk Dierking - Things Change1Dokument21 SeitenAdams Falk Dierking - Things Change1JhonWilliamNoch keine Bewertungen

- FATE - Atomic Robo - Majestic 12Dokument82 SeitenFATE - Atomic Robo - Majestic 12jonjay100% (1)

- IR-2100 - 2101 - Infrared Systems DevelopmentDokument1 SeiteIR-2100 - 2101 - Infrared Systems DevelopmentFraser CastleNoch keine Bewertungen

- Duranti2009LinguisticAnthropology AReader2ndedDokument535 SeitenDuranti2009LinguisticAnthropology AReader2ndedAngel Zidomi EB20100% (2)

- Azzam Athallah Parlaungan Siregar - Individual Assignment 1Dokument3 SeitenAzzam Athallah Parlaungan Siregar - Individual Assignment 1azzamNoch keine Bewertungen

- Thesis Statement For StereotypesDokument8 SeitenThesis Statement For Stereotypesalejandrarodriguezlasvegas100% (2)

- Zundorf 2015 Dual Pathway Auditory SystemDokument10 SeitenZundorf 2015 Dual Pathway Auditory SystemRicardo Jose De LeonNoch keine Bewertungen

- Career Technology Curriculum b7 b10 Draft ZeroDokument209 SeitenCareer Technology Curriculum b7 b10 Draft ZeroPatricia MintahNoch keine Bewertungen

- Science7 - Wheeldon, Stuber, Dierking - April7Dokument9 SeitenScience7 - Wheeldon, Stuber, Dierking - April7Lea Bondoc LimNoch keine Bewertungen

- Trichoderma Biofertilizers Boost Mustard and Tomato YieldsDokument11 SeitenTrichoderma Biofertilizers Boost Mustard and Tomato YieldsKinjal BambhaniyaNoch keine Bewertungen

- 5 6246970811807171560Dokument190 Seiten5 6246970811807171560Viena TantyoNoch keine Bewertungen

- K To 12 Curriculum OrientationDokument69 SeitenK To 12 Curriculum Orientationelizabeth olarveNoch keine Bewertungen

- EP2268594A2 - Fertilizer Suspension and Method of Preparation - Google PatentsDokument1 SeiteEP2268594A2 - Fertilizer Suspension and Method of Preparation - Google PatentsMostafa FawzyNoch keine Bewertungen

- Students Problems QuestionnaireDokument3 SeitenStudents Problems Questionnaireapi-546569844Noch keine Bewertungen

- Perencanaan Pembangunan Sektor Pariwisata Di Kabupaten Minahasa TenggaraDokument11 SeitenPerencanaan Pembangunan Sektor Pariwisata Di Kabupaten Minahasa TenggaracriszthaNoch keine Bewertungen

- Checkpoint - A2-B1 - WB - TE-U1-2 (1) - 210912 - 204737Dokument16 SeitenCheckpoint - A2-B1 - WB - TE-U1-2 (1) - 210912 - 204737Lamija AjanovicNoch keine Bewertungen

- Bsoa Loja Et Al Prelim DoneDokument10 SeitenBsoa Loja Et Al Prelim DoneZainahl Danica DangcatanNoch keine Bewertungen

- Gallego LESSON PLAN IN MATHEMATICS IVDokument11 SeitenGallego LESSON PLAN IN MATHEMATICS IVLapis FoundationNoch keine Bewertungen

- Slides Linear RegressionDokument70 SeitenSlides Linear Regressionvalavala durgapoojithaNoch keine Bewertungen

- Combined Differential and Common-Mode Scattering Parameters - Theory and Simulation PDFDokument10 SeitenCombined Differential and Common-Mode Scattering Parameters - Theory and Simulation PDFJustin WalkerNoch keine Bewertungen

- Calculate Sales Tax in SAPDokument4 SeitenCalculate Sales Tax in SAPAmit BakshiNoch keine Bewertungen

- An Investigation Into The Relationship Between Teaching Methods and Academic Performance of Secondary School Students in NigeriaDokument61 SeitenAn Investigation Into The Relationship Between Teaching Methods and Academic Performance of Secondary School Students in NigeriaUsman Ahmad TijjaniNoch keine Bewertungen