Beruflich Dokumente

Kultur Dokumente

BOMBA PVK Bulletin 47025e

Hochgeladen von

Rolando RodriguezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BOMBA PVK Bulletin 47025e

Hochgeladen von

Rolando RodriguezCopyright:

Verfügbare Formate

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 2

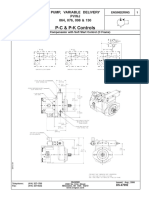

PVK OPEN LOOP PUMPS

Bulletin 47025-E

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 3

Table of Contents

Performance Assurance

Table of Contents

Features and Benefits

page

page

4-5

Specifications

page

Pump Controls

page

Performance

page

Sound

page

Curves

Inlet Suction/Supercharge

How To Order

Copyright 2004 The Oilgear Company All Rights Reserved

page

10

page

11

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 4

PERFORMANCE ASSURANCE

STANDARD WITH EVERY OILGEAR PUMP

As a customer, you also benefit from access to

with our Performance Assurance a corporate

Oilgears impressive technical support network.

commitment to stay with your installation until

Youll find factory trained and field-experienced

our equipment performs as specified.

application engineers on staff at every Oilgear

facility. They are backed by headquarters staff

Hydraulic equipment and systems have been

who can access the records and knowledge learned

Oilgears primary business since 1921. For

from decades of solving the most difficult

decades, we have developed hydraulic techniques

hydraulic challenges.

to meet the unique needs and unusual fluid power

problems of machinery builders and users

When your design or purchase is complete, our

worldwide, matching fluid power systems to a

service is just beginning. If you ever need us, our

tremendous range of applications and industries.

Oilgear engineers will be there, ready to help you

Our exclusive Performance Assurance program is

with the education, field service, parts and repairs

built upon that strong foundation.

to assure that your installation runs smoothly

Performance Assurance

Every Oilgear product is shipped to you

and keeps right on running.

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 5

PVK Open Loop Pumps

Control interchangeability.

Facilitates changes, from stock, on the

machine in the field.

1

Cylinder mounted polymerous journal bearings.

Enables operation with low viscosity or

other special fluids.

Provides infinite bearing life.

Permits compact design.

2

Optional minimum volume stop.

Features and Benefits

Quiet valve plate design.

Minimizes noise at typical

electric motor speeds. 5

Thru-shaft availability.

6

100% thru-shaft capability.

(PVK 140 only; PVK 270/370 is 50%)

Enables multiple pump installation

from a single shaft.

Permits pump to drive auxiliary

devices.

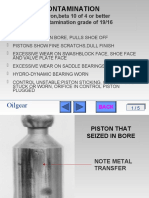

Hardened cylinder surface running on hardened

valve plate (hard-on-hard).

Provides greater resistance to contamination.

Facilitates long life.

Allows operation with low viscosity or

other special fluids.

8

Steel shoes running on hardened

swashblock surface.

Facilitates a higher degree of

contaminate resistance.

Permits higher pressure operation

with long life.

Allows operation with low viscosity

or other special fluids.

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 6

Swashblock and saddle with special polymerous

bearings.

Allows running on low viscosity or other

special fluids.

Permits consistent control reaction.

Eliminates troublesome yoke bearings.

Provides long life.

9

12

Sealed front shaft bearings.

Allows operation with low viscosity or

other special fluids.

Permits side loading.

SAE keyed or SAE splined shaft.

Features and Benefits

11

Maximum volume stop (standard).

10

Patented pressure lubricated swashblock design.

Provides high performance for high pressure

cycling operation.

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 7

SPECIFICATIONS

NOMINAL DIMENSIONS

UNIT SIZE

in.

LENGTH

mm.

in.

WIDTH

mm.

in.

HEIGHT

mm.

lbs.

WEIGHT

kg.

FACE MOUNTING

FLANGE

140

14.81

376,2

8.25

209,6

10.78

273,8

200

91

SAE D 4 Bolt

270 & 370

21.25

539,8

11.75

298,5

15.69

398,5

550

250

SAE F 4 Bolt

Specifications

NOMINAL PERFORMANCE SPECIFICATIONS

MAXIMUM

PRESSURE

10% of duty cycle

POWER INPUT

FLOW RATE

UNIT

SIZE

THEORETICAL

MAXIMUM

DISPLACEMENT

RATED

CONTINUOUS

PRESSURE

in 3 /rev

ml/rev

psi

bar

psi

bar

rpm

gpm

l/min

hp

kw

140

8.61

141

5000

345

5800

400

1800

63.0

238,7

207.2

154,6

270

16.3

267

5000

345

5800

400

1500

100.0

379,0

326.9

244,0

370

22.4

367

3500

241

4100

283

1500

135.1

512,0

324.5

242,2

MAXIMUM

RATED SPEED*

at max. rated rpm, rated

cont. pressure & 14.7 psia

(1 bar abs) inlet conditions

at rated cont.

pressure &

max. rated rpm

*Higher operating speeds may be approved. Consult the Oilgear application engineering department.

PORT CONFIGURATION

Shaft

Rotation

Left Hand

(CCW)

Right Hand

(CW)

Port A

left side

facing shaft

Pressure

Suction

Port B

right side

facing shaft

Suction

Pressure

H

Port B

W

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 8

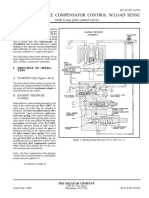

PUMP CONTROLS

MECHANICAL

Electronic Servo Control

A precision servo control designed to minimize hysteresis

is available with several electro-hydraulic servo valve

sizes to provide slow or very fast response rates.

Pressure Proportional Displacement Control

The control is designed with a spring feedback so that the

pump will go to a stroke setting in response to a separate

pressure signal. A pressure unloading option is available.

RU

Solenoid Operated Dual Position

CAM

One, two or there pressure adjusting operators can be

added to the basic P Control. The operator can be

selected by integral solenoid valves and will provide

independent pressure adjustment.

SOL. A

CONN.

TO PILOT

PRESSURE

INTERNAL

DRAIN

Basic Pressure Compensating Control

The use of a four-way valve spool in the signal circuit allows this

Oilgear Control to be adjusted to lower minimum operating

pressures than other manufacturers. The Control is developed in a

modular configuration facilitating the addition of multiple

operators. An auxiliary port for remote pressure signal is included.

A pressure compensating function is included with any of the

following operators.

Electronically Modulated Pressure Operator

A proportional valve can be added to the basic P Control

to regulate the compensating pressure. This operator can

be used singularly or in conjunction with a pressure

operator.

Flow Compensating Operator

Controls

Two adjustable deliveries as selected by an integral

solenoid operated valve.

Multiple Pressure Operators

RU

A module can be added to allow the pressure compensator to operate in response to the differential pressure

across an orifice changing the operator to a flow

compensator control.

Horsepower Limiting Operator

A module can be added to all of the previously mentioned

pressure sensing options to provide a control that limits

horsepower as related to pump delivery.

Note: Numerous P control/operator combinations are listed under How-to-Order.

Please consult the factory if you have a specific requirement.

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 9

PERFORMANCE CURVES

Performance Curves

PVK-140

PVK-270

PVK-370

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 10

SOUND CURVES

PVK-140 NOISE @ 3 ft.

Sound Curves

PVK-270 NOISE @ 3 ft.

PVK-370 NOISE @ 3 ft.

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 11

PERFORMANCE CURVES

Inlet Suction Curves

PVK-140 SUCTION TEST

10

PVK-370 SUCTION TEST

PVK-270 SUCTION TEST

5204002_Bulletin_47025-E_6

3/26/04

1:30 PM

Page 12

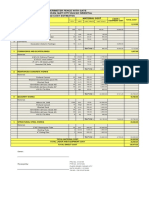

HOW TO ORDER

BLOCK NUMBER

EXPLANATION

VARIABLE PUMP

EXAMPLE

FIXED PUMPS

EXAMPLE

3 4 5

7 8

9 10 11 12 13 14 15 / 16

K 270 B1 U

V L

Y E RNN SN GS /

P

P

V

F

K 140 A1 U

K 140 A1 U

V L

V L

D

D

F

F

S F 100 SB CP

S N NN

CP

N

0

1

2

3

N

R

W

S

L

F = Load Sense Option

G = Load Sense w/Horsepower

Limiting Option

H = Horsepower Limiting Option

=

=

=

=

=

13 5 = Input Horsepower:

100 = 100 HP Input

@ 1800 rpm

None Required

.500 NPT w/o Light

.500 NPT w/Light

PG-11 w/o Light

PG-11 w/Light

12 =

R = Solenoid Operated Volume Control

F = Fixed Control

13

R

None Required

115/60 - 110/50 VAC

230/60 - 220/50 VAC

12 VDC

24 VDC

12 =

6 = DESIGN SERIES MODIFIER

U = SAE Mounting and Ports

B = Metric Threads w/BSPP

Ports (PVK-140)

7 = SEALS

V = Viton (Std.)

B = Buna - N

E = Butyl

P = EPR

8 = ROTATION

L = Left hand (CCW)

R = Right hand (CW)

9 = VALVE PLATE TYPE

D = One-Way Service

T = Two-Way Service

10 = CONNECTION TYPE

F = Flange

(Flanges are customer supplied)

11 = SHAFT END

Y = Keyed

S = Splined

12 = CONTROL TYPE

& 13 = MODIFIER

12 =

E = Proportional Pilot Signal

Displacement Control

=

=

=

=

=

13 3 = Connector:

A1 = (PVK - 140)

B1 = (PVK - 270 & 370)

(Subject to change)

12

(Omit if not required)

13 4 = Control Modifier:

13 2 = Solenoid Voltage:

12

13

100

A = Normally Open Proportional Device

B = Normally Closed Proportional Device

R = Remote (Customer Supplied

Proportional Device)

1 = Solenoid Operated, One Volume

2 = Solenoid Operated, Two Volume

3 = Solenoid Operated, Three Volume

4 = Solenoid Operated, Four Volume

13

U

13 1 = Type:

U = Two Volume Control

13 2 = Solenoid Voltage:

13 1 = Stroke Type:

0

1

2

3

075 = 75% Stroke

100 = Full Stroke

12 =

12

13

NNN

R=

W=

S=

L =

B=

13 1 = Type:

P = Pressure Compensating Control

13

1

H 100

13 1 = Pressure Compensator

Options:

1 =

2 =

3 =

A=

B=

C=

D=

E=

R=

N=

0 =

1 =

2 =

3 =

Single

Dual

Triple

Normally Open Proportional Device

Normally Closed Proportional Device

Single Pressure w/No Load Starting

Dual Pressure w/No Load Starting

Triple Pressure w/No Load Starting

Remote

Non Required

115/60 - 110/50 VAC

230/60-220/50 VAC

12 VDC

24 VDC

13 3 = Connector:

N=

R=

W=

S=

L =

.500 NPT w/o Light

.500 NPT w/Light

PG-11 w/o Light

PG-11 w/Light

.500 NPT Conduit Box

V = Electrohydraulic (w/feedback) Control

12 =

115/60 100/50 VAC

230/60 220/50 VAC

12 VDC

24 VDC

12 =

NNN = No Control

12

=

=

=

=

13 3 = Connector:

N = No Control

13 2 = Solenoid Voltage:

13 1 = Type:

12

Non Required

.500 NPT w/o Light

.500 NPT w/Light

PG-11 w/o Light

PG-11 w/Light

12

13

S25

How to Order

1 = UNIT

P = Pump

2 = TYPE

V = Variable

F = Fixed

3 = DESIGN TYPE

K = Type

4 = UNIT SIZE

140 = 140 ml/revolution

270 = 270 ml/revolution

370 = 370 ml/revolution

5 = DESIGN SERIES

51

13 1 = Type:

M20 =

M40 =

S25 =

S50 =

RNN =

Servo Valve Size 20

Servo Valve Size 40 (PVK-270/370 only)

Servo Valve Size 25

Servo Valve Size 50 (PVK-270/370 only)

Remote Valve Control

14 = VOLUME STOPS

SN = Maximum Volume Stop (Standard)

SB = Minimum & Maximum Volume Stop

15 = COVER PLATE OR ADAPTERS

CP = Cover Plate, (Standard without Auxiliary Pump)

*AS = Short Adapter for Mounting PVWH-04, 06, 10

(SAE A 2-Bolt)

*BS = Short Adapter for Mounting PVWH-11, 15, 20

(SAE B 2-Bolt)

*CS = Short Adapter for Mounting PVWH-25, 34, 45, 60

(SAE C 2-Bolt)

AL = Long Adapter for Mounting PVWH-04, 06, 10

(SAE A 2-Bolt)

BL = Long Adapter for Mounting PVWH-11, 15, 20

(SAE B 2-Bolt)

CL = Long Adapter for Mounting PVWH-25, 34, 45, 60

(SAE C 2-Bolt)

*GS = Short Adapter for Mounting 51 Gear Pump

(SAE B 2-Bolt)

GL = Long Adapter for Mounting 51 Gear Pump

(SAE B 2-Bolt)

* See DS-47927 for Adapter Mounting Limitations

16 = OPTIONAL AUXILIARY PUMPS

51 = Gear Pump 5.10 cipr (85 ml/revolution) (2000 psi)

31 = Gear Pump 3.10 cipr (51 ml/revolution) (2000 psi)

11

World Headquarters

The Oilgear Company

2300 South 51st Street Milwaukee, WI USA 53219

phone: 414/327-1700 fax: 414/327-0532

www.oilgear.com

For more information about your application or the products

in this brochure, please contact your nearest Oilgear facility.

AUSTRALIA

Oilgear Towler Australia Pty. Ltd.

BRAZIL

Oilgeardo Brazil Hydraulica Ltd.

CANADA

The Oilgear Company

FRANCE

Oilgear Towler S.A.

GERMANY

Oilgear Towler GmbH

INDIA

Oilgear Towler Polyhydron Pvt. Ltd.

Towler Automation Pvt. Ltd.

ITALY

Oilgear Towler S.r.l.

JAPAN

The Oilgear Japan Company

KOREA

Oilgear Towler Korea Co. Ltd.

MEXICO

Oilgear Mexicana S.A. de C.V.

SPAIN

Oilgear Towler S.A.

TAIWAN

Oilgear Towler Taiwan Co. Ltd.

UNITED KINGDOM

Oilgear Towler Ltd.

UNITED STATES OF AMERICA

The Oilgear Company

Bulletin 47025-E

Revised March, 2004

Printed in USA

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Sae Ams 4027 SheetmetalDokument7 SeitenSae Ams 4027 Sheetmetaljuan100% (5)

- Case Study-Temperature & Humidity Mapping Study & Qualification of A Cold Room in QatarDokument3 SeitenCase Study-Temperature & Humidity Mapping Study & Qualification of A Cold Room in QatarVacker Group UAE100% (1)

- BAGHOUSEDokument210 SeitenBAGHOUSEAllan Roelen Bacaron100% (5)

- TALAT Lecture 3501: Alloys and PropertiesDokument8 SeitenTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsNoch keine Bewertungen

- Balancing Chemical Equations Worksheet PDFDokument4 SeitenBalancing Chemical Equations Worksheet PDFTiffany Ayala100% (1)

- Nalco Cooling Tower Presentation PDFDokument115 SeitenNalco Cooling Tower Presentation PDFAttyub100% (2)

- Alfa Laval Sanitary Fittings and Basic ValvesDokument91 SeitenAlfa Laval Sanitary Fittings and Basic ValvesDobrovolschi ConstantinNoch keine Bewertungen

- Flexpipe PDS FlexCord EnglishDokument2 SeitenFlexpipe PDS FlexCord EnglishpsycopaulNoch keine Bewertungen

- Four-Way Pilot Operated Control: OilgearDokument5 SeitenFour-Way Pilot Operated Control: OilgearRolando RodriguezNoch keine Bewertungen

- 3 OverpressureDokument4 Seiten3 OverpressureRolando RodriguezNoch keine Bewertungen

- Pump, Variable Delivery PVWJ 025, 034 & 046 P-1NN/F, P-LNN/F, P-1NNN/J, P-LNN/J P-1NN/K and P-LNN/K ControlsDokument2 SeitenPump, Variable Delivery PVWJ 025, 034 & 046 P-1NN/F, P-LNN/F, P-1NNN/J, P-LNN/J P-1NN/K and P-LNN/K ControlsRolando RodriguezNoch keine Bewertungen

- Ds 47992Dokument1 SeiteDs 47992Rolando RodriguezNoch keine Bewertungen

- Improper Inlet Conditions Suction Strainer Not RecommendedDokument2 SeitenImproper Inlet Conditions Suction Strainer Not RecommendedRolando RodriguezNoch keine Bewertungen

- Heat Where It Comes From: OilgearDokument2 SeitenHeat Where It Comes From: OilgearRolando RodriguezNoch keine Bewertungen

- Service Instructions "PVWJ" A-FRAME PUMPS - 011/-014/-022 For Type "P-1Nn" and "P-LNN" Pressure Compensating ControlsDokument16 SeitenService Instructions "PVWJ" A-FRAME PUMPS - 011/-014/-022 For Type "P-1Nn" and "P-LNN" Pressure Compensating ControlsRolando RodriguezNoch keine Bewertungen

- 5 Case DrainDokument9 Seiten5 Case DrainRolando RodriguezNoch keine Bewertungen

- PVG ApplicationDokument9 SeitenPVG ApplicationRolando RodriguezNoch keine Bewertungen

- 1 ContaminationDokument5 Seiten1 ContaminationRolando RodriguezNoch keine Bewertungen

- 1 NoiseDokument2 Seiten1 NoiseRolando RodriguezNoch keine Bewertungen

- 2 Fluid ProblemDokument4 Seiten2 Fluid ProblemRolando RodriguezNoch keine Bewertungen

- "V-M Control: Pump, Variable Delivery PVV-440 "A2"Dokument1 Seite"V-M Control: Pump, Variable Delivery PVV-440 "A2"Rolando RodriguezNoch keine Bewertungen

- "V-M" Control: Pump, Variable Delivery PVV-540 "B1" WithDokument1 Seite"V-M" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNoch keine Bewertungen

- PVV Pumps: Technical BulletinDokument3 SeitenPVV Pumps: Technical BulletinRolando RodriguezNoch keine Bewertungen

- Service Instructions Pvv-440 - A2 Series PumpDokument28 SeitenService Instructions Pvv-440 - A2 Series PumpRolando RodriguezNoch keine Bewertungen

- Ds m47683 PDFDokument1 SeiteDs m47683 PDFRolando RodriguezNoch keine Bewertungen

- "V-R" Control: Pump, Variable Delivery PVV-540 "B1" WithDokument1 Seite"V-R" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNoch keine Bewertungen

- "R-U" Control: Pump, Variable Delivery PVV-540 "B1" WithDokument1 Seite"R-U" Control: Pump, Variable Delivery PVV-540 "B1" WithRolando RodriguezNoch keine Bewertungen

- Pump, Variable Delivery PVV-200 or 250 "Ru" Control: Engineering 1Dokument1 SeitePump, Variable Delivery PVV-200 or 250 "Ru" Control: Engineering 1Rolando RodriguezNoch keine Bewertungen

- "P-2Nn" Dual Pressure Compensator Control: (With 4-Way Pilot Control Valve)Dokument4 Seiten"P-2Nn" Dual Pressure Compensator Control: (With 4-Way Pilot Control Valve)Rolando RodriguezNoch keine Bewertungen

- Ds 47168 PDFDokument1 SeiteDs 47168 PDFRolando RodriguezNoch keine Bewertungen

- Pump, Variable Delivery PVV-540 "B1" With "F" Control: Engineering 1Dokument1 SeitePump, Variable Delivery PVV-540 "B1" With "F" Control: Engineering 1Rolando RodriguezNoch keine Bewertungen

- P-1Nnf" Pressure Compensator Control W/Load Sense: (With 4-Way Pilot Control Valve)Dokument4 SeitenP-1Nnf" Pressure Compensator Control W/Load Sense: (With 4-Way Pilot Control Valve)Rolando RodriguezNoch keine Bewertungen

- "C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Dokument5 Seiten"C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Rolando RodriguezNoch keine Bewertungen

- "F" Control: Pump, Variable Delivery PVV-200 or 250Dokument1 Seite"F" Control: Pump, Variable Delivery PVV-200 or 250Rolando RodriguezNoch keine Bewertungen

- "B" Frame: Pump, Variable Delivery PVM 065/075Dokument7 Seiten"B" Frame: Pump, Variable Delivery PVM 065/075Rolando RodriguezNoch keine Bewertungen

- Bulletin 947541 PDFDokument2 SeitenBulletin 947541 PDFRolando RodriguezNoch keine Bewertungen

- "B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Dokument7 Seiten"B" Frame: Pump, Variable Delivery PVM 025, 034 & 046Rolando RodriguezNoch keine Bewertungen

- Pump, Variable Delivery PVM 011, 014 & 022 A-Frame: Engineering 1Dokument4 SeitenPump, Variable Delivery PVM 011, 014 & 022 A-Frame: Engineering 1Rolando RodriguezNoch keine Bewertungen

- Av en Valves PDFDokument246 SeitenAv en Valves PDFWahyuNoch keine Bewertungen

- CMT Lab ReportDokument3 SeitenCMT Lab ReportJohn Emerald GoloNoch keine Bewertungen

- EstimateDokument1 SeiteEstimateAlemar Soriano MalintadNoch keine Bewertungen

- Hydro Test ProcedureDokument17 SeitenHydro Test Procedureyaser elgoharyNoch keine Bewertungen

- HeaterDokument12 SeitenHeaterErwin Paulian SihombingNoch keine Bewertungen

- S 1300 Pene Krete Product Data 347250Dokument3 SeitenS 1300 Pene Krete Product Data 347250uocmogiandi_aNoch keine Bewertungen

- Thermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsDokument96 SeitenThermal and Mechanical Analysis of Nylon 6 and Nylon 66 BlendsHung VuNoch keine Bewertungen

- MasterSeal Traffic 1330Dokument3 SeitenMasterSeal Traffic 1330Jonathan Wardrop100% (1)

- Catalogue Centrifugal Pumps 2Dokument54 SeitenCatalogue Centrifugal Pumps 2Velez SantanderNoch keine Bewertungen

- Takara MicroMist OPDokument20 SeitenTakara MicroMist OPNazihCosmeticsNoch keine Bewertungen

- Ratliperl: The Modern Solution For Energy Efficient BuildingDokument18 SeitenRatliperl: The Modern Solution For Energy Efficient BuildingAdhil Ramsurup100% (1)

- Productivity Improvement Through Lean ManufacturingDokument30 SeitenProductivity Improvement Through Lean ManufacturingmanikandaprabuNoch keine Bewertungen

- Polymer Engineering FundamentalsDokument20 SeitenPolymer Engineering FundamentalsNoor FatimaNoch keine Bewertungen

- Scientific American Supplement, No. 455, September 20, 1884 by VariousDokument83 SeitenScientific American Supplement, No. 455, September 20, 1884 by VariousGutenberg.orgNoch keine Bewertungen

- Is 3589Dokument19 SeitenIs 3589kishor.kokate60% (5)

- Materials 16 01374 v2Dokument11 SeitenMaterials 16 01374 v2Feyisa GuyeNoch keine Bewertungen

- Instructions For Use Tau Clave 3000 Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)Dokument14 SeitenInstructions For Use Tau Clave 3000 Vacuum: Tau Steril S.N.C Via Gorizia, 6/a Fino Mornasco (CO)soufianeNoch keine Bewertungen

- 742 222Dokument2 Seiten742 222slymnNoch keine Bewertungen

- Iglidur X - The High-Tech Problem SolverDokument12 SeitenIglidur X - The High-Tech Problem Solvergoooga299Noch keine Bewertungen

- Reverse Osmosis SystemsDokument1 SeiteReverse Osmosis SystemsNaresh KhubaniNoch keine Bewertungen

- Codigos Falla Motor Detriot PLC RTGDokument3 SeitenCodigos Falla Motor Detriot PLC RTGHERNANDO A BECERRANoch keine Bewertungen

- TalbrosDokument26 SeitenTalbrossk9568270% (1)