Beruflich Dokumente

Kultur Dokumente

TI Polymer Periodic Table Complete

Hochgeladen von

Kelly PerniaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TI Polymer Periodic Table Complete

Hochgeladen von

Kelly PerniaCopyright:

Verfügbare Formate

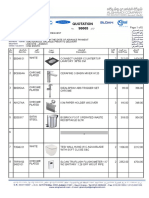

The Periodic Table of the elements by Medvedev was a historic achievement in

chemistry and enabled chemists to see the relationship between structure and

properties of the basic elements.

Polymers also have a strong relationship between structure and properties and this

Periodic Table of Polymers is a first attempt to provide a simple codification of the

basic polymer types and structures.

The diversity of polymer types makes it impossible to include all of the variations in

one simple table and this table only includes the most common polymers.

TANGRAM

TECHNOLOGY

Tangram Technology

Periodic Table of Thermoplastics

Consulting

Engineers

KEY

TS =

EAB =

TM =

LTST =

HDT =

Cost =

Tensile Strength at Yield @ 23oC

Elongation at break

Tensile Modulus @ 23oC

Long Term Service Temperature

Heat Deflection Temperature @ 1.8 MPa

Relative Cost

Increasing performance

All properties are for the natural injection moulding

grade resin only and do not include polymers with

reinforcements or other functional fillers.

Random molecular

orientation in both

molten and solid

phases.

Commodity

PS-HI

High Impact

Polystyrene

TS: 19 - 33 MPa

EAB: 40 - 50%

TM: 1.8 GPa

LTST: 55 - 60oC

HDT = 60 - 80oC

Cost:

Increasing crystallinity

Amorphous

PVC-P

General

Characteristics

Soften gradually.

Generally transparent.

Lower Tensile Strength

and Tensile Modulus.

Lower Density.

Low Creep Resistance.

High Dimensional

Stability.

Low fatigue resistance.

Easy to bond using

adhesives and solvents

(high surface energy).

Plasticised

Polyvinylchloride

TS: 6 - 20 MPa

EAB: 50 - 460%

TM: 0.002 - 0.020 GPa

LTST: 50oC

HDT: 20 oC

Cost:

PVC-U

Unplasticised

Polyvinylchloride

TS: 45 - 55 MPa

EAB: 25 - 60 %

TM: 2.50 - 3.02 GPa

LTST: 60 - 70 oC

HDT: 64 - 70oC

Cost:

PS-GP

Engineering

ABS

General Purpose

Polystyrene

TS: 40 - 50 MPa

EAB: < 3%

TM: 3.2 - 3.5 GPa

LTST: 70 - 85oC

HDT: 72 - 82oC

Cost:

Acrylonitrile Butadiene

Styrene (Copolymer)

TS: 40 - 60 MPa

EAB: 3 - 20%

TM: 2.0 - 2.6 GPa

LTST: 80 - 95oC

HDT = 90 - 100oC

Cost:

SBS

SAN

Styrene Acrylonitrile

(Copolymer)

TS: 47 - 72 MPa

EAB: 2.0 - 10%

TM: 2.3 - 4.1 GPa

LTST: 55 - 60oC

HDT = 84 - 95oC

Cost:

SMA

Styrene-ButadieneStyrene (Copolymer)

TS: 35 - 40 MPa

EAB: 40%

TM: 1.8 - 2.0 GPa

LTST: 60oC

HDT = 67oC

Cost:

Styrene-Maleic

Anhydride (Copolymer)

TS: 40 - 52 MPa

EAB: 1.8%

TM: 2.0 GPa

LTST: 100oC

HDT = 105oC

Cost:

CA

ASA

Acrylonitrile Styrene

Acrylate (Copolymer)

TS: 38 - 70 MPa

EAB: 15 - 45%

TM: 2.3 - 2.9 GPa

LTST: 82 - 120oC

HDT = 82 - 120oC

Cost:

CAB

Cellulose Acetate

TS: 30 - 55 MPa

EAB: 5 - 55%

TM: 1.6 GPa

LTST: 45 - 70oC

HDT: 48 - 65oC

Cost:

Cellulose Acetate

Butyrate

TS: 26 - 50 MPa

EAB: 8 - 80%

TM: 0.7 - 1.5 GPa

LTST: 75 - 100oC

HDT: 62 - 70oC

Cost:

CAP

Cellulose Acetate

Propionate

TS: 26 - 47 MPa

EAB: 30 - 100%

TM: 0.7 - 1.5 GPa

LTST: 75 - 100oC

HDT: 45 - 75oC

Cost:

PPO (Modified)

PC

PAR

PSU

PES

Polyphenylene Oxide

Polycarbonate

Polyarylate

Polysulphone

Polyethersulphone

TS: 56 - 70 MPa

EAB: 3.0 - 3.5%

TM: 3.0 GPa

LTST: 90oC

HDT = 85 - 95oC

Cost:

TS: 40 - 90 MPa

EAB: 10 - 60%

TM: 2.0 - 5.4 GPa

LTST: 80 - 260oC

HDT = 129oC

Cost:

TS: 55 - 75 MPa

EAB: 110 - 120%

TM: 1.6 - 2.4 GPa

LTST: 95 - 154oC

HDT = 135 - 140oC

Cost:

SB

CP

PET-G

Cellulose Propionate

Glycolised Polyethylene

terephthlate

TS: 30 - 45 MPa

EAB: 45 - 65%

TM: 0.8 - 1.5 GPa

LTST: 68 - 100oC

HDT: 61 - 73oC

Cost:

TS: 55 MPa

EAB: 300%

TM: GPa

LTST: 60oC

HDT: 70oC

Cost:

PVC-UX

Crosslinked

Unplasticised PVC

TS: 28 - 40 MPa

EAB: 150 %

TM: 2.5 - 3.0 GPa

LTST: 70 - 95oC

HDT: 120oC

Cost:

PE-LLD

PE-MD

Medium Density

Polyethylene

TS: 14 - 25 MPa

EAB: 50 - 300%

TM: 0.25 - 0.70 GPa

LTST: 38 - 70oC

HDT = 38 - 43oC

Cost:

PMP

EVA

Polymethyl pentene

Ethylene-vinyl Acetate

(12% VA)

TS: 10 - 19 MPa

EAB: 50 - 750%

TM: 0.04 - 0.14 GPa

LTST: 50oC

HDT = 20 - 23oC

Cost:

TS: 25 - 28 MPa

EAB: 15 - 30%

TM: 1.0 - 2.2 GPa

LTST: 55 - 60oC

HDT = 40 - 50oC

Cost:

KEY TO MAJOR POLYMER FAMILIES:

PP

PE-VLD

Very Low Density

Polyethylene

TS: 34 - 400 MPa

EAB: 400 - 700%

TM: 0.10 - 0.20 GPa

LTST: 60oC

HDT = 75 - 95oC

Cost:

EMA

Ethylene-methyl

Acrylate

TS: 9 - 12 MPa

EAB: 750 - 800%

TM: 0.03 GPa

LTST: 55oC

HDT = 59oC

Cost:

PP

Polypropylene

(Homopolymer)

TS: 33 MPa

EAB: 150%

TM: 1.5 GPa

LTST: 100oC

HDT = 65oC

Cost:

PE-X

Crosslinked

Polyethylene

TS: 18 MPa

EAB: 350%

TM: 0.6 GPa

LTST: 90oC

HDT = 60oC

Cost:

PBT

Polybutyleneterephthlate

TS: 30 - 105 Mpa

EAB: 250%

TM: 1.5 - 5.2 GPa

LTST: 65 - 120oC

HDT: 70oC

Cost:

PET

Crystalline Polyethyleneterephthlate

Polypropylene

(Copolymer)

TS: 25 MPa

EAB: 300%

TM: 1.2 GPa

LTST: 90oC

HDT = 60oC

Cost:

TS: 57 - 75Mpa

EAB: 50 - 200%

TM: 2.47 - 3.0 GPa

LTST: 63 - 100oC

HDT: 63 - 100oC

Cost:

PB

Polybutene-1

(Polybutylene)

TS: 12 - 17 MPa

EAB: 300 - 380%

TM: 0.21 - 0.26 GPa

LTST: 110oC

HDT = 54 - 60oC

Cost:

PA 6

Polyamide 6

(Nylon 6)

TS: 40 - 50 MPa

EAB: 150 - 250%

TM: 1.2 - 2.8 GPa

LTST: 80 - 120oC

HDT = 60 - 90oC

Cost:

PA 6/10

Polyamide 6/10

(Nylon 6/10)

TS: 50 - 60 MPa

EAB: 70 - 150%

TM: 1.5 - 2.8 GPa

LTST: 60 - 110oC

HDT = 65 - 85oC

Cost:

PE-UHMW

Ultra-high Molecular

Weight Polyethylene

TS: 35 MPa

EAB: 500%

TM: 0.5 GPa

LTST: 55oC

HDT = 42oC

Cost:

PA 11

Polyamide 11

(Nylon 11)

TS: 20 - 60 MPa

EAB: 30 - 400%

TM: 1.0 - 2.0 GPa

LTST: 74 - 147oC

HDT = 38 - 55oC

Cost:

PA 66

Polyamide 66

(Nylon 66)

TS: 40 - 86 MPa

EAB: 4.8 - 300%

TM: 0.7 - 5.5 GPa

LTST: 60 - 200oC

HDT = 50 - 150oC

Cost:

PA 6/12

Polyamide 6/12

(Nylon 6/12)

TS: 17 - 60 MPa

EAB: 4 - 600%

TM: 0.29 - 5.5 GPa

LTST: 42 - 190oC

HDT = 50 - 90oC

Cost:

PE-HD

PAI

PI

PBI

Polyamideimide

Polyimide

Polybenzimideazole

TS: 90 - 150 MPa

EAB: 2.6 - 12%

TM: 2.5 - 8.8 GPa

LTST: 220 - 280oC

HDT = 275 - 280oC

Cost:

TS: 72 - 90 MPa

EAB: 6 - 8%

TM: 1.3 - 4 GPa

LTST: 260 - 300oC

HDT = 280 - 360oC

Cost:

TS: 120 - 160 MPa

EAB: 2.6 - 3.0%

TM: 4.0 - 6.5 GPa

LTST: 260 - 400oC

HDT = 220oC

Cost:

POM

Polyoxymethylene

(Acetal Copolymer)

TS: 62 - 70 MPa

EAB: 20 - 75%

TM: 2.8 - 3.1 GPa

LTST: 104oC

HDT = 110oC

Cost:

PPA

PARA

Polyphthalamide

(Amorphous)

TS: 85 MPa

EAB: 2.6%

TM: 3.7 GPa

LTST: 140oC

HDT = 138oC

Cost:

PA 12

Polyaryl amide

TS: 60 MPa

EAB: 100%

TM: 24 GPa

LTST: 150oC

HDT = 150oC

Cost:

PPA

Polyamide 12

(Nylon 12)

TS: 50 MPa

EAB: 200%

TM: 1.2 - 1.6 GPa

LTST: 70 - 80oC

HDT = 55oC

Cost:

PA 46

Polyphthalamide

Polyamide 46

(Nylon 46)

TS: 100 MPa

EAB: 40%

TM: 3.3 GPa

LTST: 130oC

HDT = 190oC

Cost:

TS: 85 MPa

EAB: 2.6%

TM: 3.7 GPa

LTST: 140oC

HDT = 138oC

Cost:

LCP

PFA

Liquid Crystal Polymer

(Aromatic copolyester)

TS: 55 - 165 Mpa

EAB: 1.3 - 2.8%

TM: 2 - 20 GPa

LTST: 230oC

HDT: 200oC

Cost:

Perfluoroalkoxy

ECTFE

Ethylenechlorotrifluoroethylene

TS: 42 - 48 MPa

EAB: 200%

TM: 1.4 GPa

LTST: 140 - 166oC

HDT = 63 - 67oC

Cost:

TS: 15 - 30 MPa

EAB: 300%

TM: 0.60 GPa

LTST: 260oC

HDT = 48 - 60oC

Cost:

EVOH

PPS

Ethylene-vinyl Alcohol

Polyphenylene Sulphide

TS: 37 - 205 MPa

EAB: 100 - 330%

TM: 1.9 - 3.5 GPa

LTST: 80 - 100oC

HDT =70 - 90oC

Cost:

TS: 69 - 124 MPa

EAB: 1 - 5%

TM: 2.2 - 5.5 GPa

LTST: 190 - 260oC

HDT = 174oC

Cost:

FEP

Fluorinated

ethylene-propylene

TS: 15 - 21 MPa

EAB: 240 - 350%

TM: 0.35 - 0.50 GPa

LTST: 60 - 204oC

HDT = 48 - 60oC

Cost:

PEK

PEEK

Polyetherketone

Polyetheretherketone

TS: 52 - 214 MPa

EAB: 1.3 - 330%

TM: 1.5 - 18.6 GPa

LTST: 90 - 334oC

HDT = 93 - 334oC

Cost:

PCTFE

Polychlorotrifluoroethylene

TS: 30 - 40 MPa

EAB: 175%

TM: 1.3 GPa

LTST: 140 - 150oC

HDT = 67 - 75oC

Cost:

ETFE

Ethylenetetrafluoroethylene

TS: 35 - 45 MPa

EAB: 200 - 500%

TM: 1.00 GPa

LTST: 160oC

HDT = 90oC

Cost:

TS: 90 - 110 MPa

EAB: 2.5 - 100%

TM: 3.1 - 8.3 GPa

LTST: 154 - 315oC

HDT = 154 - 295oC

Cost:

PTFE

Polytetrafluorethylene

TS: 17 - 21 MPa

EAB: 140 - 400%

TM: 0.35 - 0.75 GPa

LTST: 250 - 260oC

HDT = 50 - 60oC

Cost:

PVDF

Polyvinylidenefluoride

TS: 30 - 55 MPa

EAB: 50%

TM: 1.3 GPa

LTST: 150oC

HDT = 75 - 82oC

Cost:

POM

High Density

Polyethylene

TS: 10 - 50 MPa

EAB: 400 - 800%

TM: 0.18 - 1.6 GPa

LTST: 55oC

HDT = 46oC

Cost:

Styrenes

PEI

Polyetherimide

PVC-C

TS: 60 - 100 MPa

EAB:> 50 %

TM: 1.4 - 2.3 GPa

LTST: 125oC

HDT = 102 - 123oC

Cost:

Linear Low Density

Polyethylene

TS: 8.0 - 20 MPa

EAB: 50 - 500%

TM: 0.2 - 1.0 GPa

LTST: 44 - 50oC

HDT = 37 - 44oC

Cost:

PPSU

Polyethersulphone

(Block copolymer)

TS: 83 MPa

EAB: 40 - 80%

TM: 2.65 GPa

LTST: 180oC

HDT = 204oC

Cost:

Chlorinated

Polyvinylchloride

TS: 53 - 58 MPa

EAB: 25 - 45%

TM: 2.6 - 2.7 GPa

LTST: 90 - 110oC

HDT: 105oC

Cost:

PA 6/3/T

PE-LD

TS: 70 - 95 MPa

EAB: 40 - 80%

TM: 2.4 - 2.6 GPa

LTST: 180 - 220 oC

HDT = 200 - 210oC

Cost:

TS: 100 - 105 MPa

EAB: 40 - 60%

TM: 2.7 - 4.5 GPa

LTST: 170 - 215oC

HDT = 200 - 215oC

Cost:

Amorphous polyamide

Low Density

Polyethylene

TS: 7.0 - 25 MPa

EAB: 50 - 400%

TM: 0.15 - 0.35 GPa

LTST: 40 - 70oC

HDT = 35oC

Cost:

TS: 70 - 76 MPa

EAB: 10 - 80%

TM: 1.5 - 2.7 GPa

LTST: 150 - 180oC

HDT = 160 - 174oC

Cost:

Styrene-Butadiene

(Copolymer)

TS: 26 - 30 MPa

EAB: 20 - 80%

TM: 1.8 GPa

LTST: 65 - 77oC

HDT = 70 - 77oC

Cost:

PVC-U

Chlorinated

Polyethylene

TS: 12.5 MPa

EAB: 700%

TM: 0.002 GPa

LTST: 60oC

HDT = 25oC

Cost:

General

Characteristics

Sharp melting point.

Generally translucent

or opaque.

Higher Tensile

Strength and Tensile

Modulus.

Higher Density.

High Creep Resistance.

Low Dimensional

Stability.

High fatigue

resistance.

Difficult to bond using

adhesives and solvents

(low surface energy).

TS: 68 - 71 MPa

EAB: 50 - 100%

TM: 2.0 - 2.2 GPa

LTST: 130 - 150oC

HDT = 165 - 175oC

Cost:

High-Impact Unplasticised

PVC

PE-Chlorinated

Semicrystalline

PMMA

Polymethylmethacrylate

(Acrylic)

TS: 45 - 55 MPa

EAB: 25 - 60 %

TM: 2.5 - 3.0 GPa

LTST: 60 - 70 oC

HDT: 64 - 70oC

Cost:

Random molecular

orientation in

molten phase,

densely packed

crystallites in solid

phase.

Performance

Polyoxymethylene

(Acetal Homopolymer)

TS: 67 - 85 MPa

EAB: 15 - 70%

TM: 2.9 - 3.6 GPa

LTST: 85 oC

HDT = 124oC

Cost:

Polyolefins

Vinyls

Cellulosics

Polyesters

Polyamides

Acrylics

Polycarbonates

Acetals

Polysulphones

Imides

Fluoropolymers

This table is for comparison only and no responsibility can be taken for the accuracy or the use of the information contained herein. Copyright: Tangram Technology Ltd. (www.tangram.co.uk). The table may be freely reproduced for non-profit purposes provided full acknowledgement of the copyright is given. Comments and suggestions for improvement are welcome.

Issue 7: February 2008

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- d9 VolvoDokument57 Seitend9 Volvofranklin972100% (2)

- MS3XV30 Hardware 1.3Dokument229 SeitenMS3XV30 Hardware 1.3Colton CarmichaelNoch keine Bewertungen

- RTE Online Application Form For Admission Year 2018 19Dokument6 SeitenRTE Online Application Form For Admission Year 2018 19sudheer singhNoch keine Bewertungen

- Is 15707 2006Dokument23 SeitenIs 15707 2006anupam789Noch keine Bewertungen

- Steering Gear TestingDokument9 SeitenSteering Gear TestingArun GK100% (1)

- VX-1700 Owners ManualDokument32 SeitenVX-1700 Owners ManualVan ThaoNoch keine Bewertungen

- Constraints in DBMS - Types of Constraints in DBMS - Gate VidyalayDokument5 SeitenConstraints in DBMS - Types of Constraints in DBMS - Gate VidyalayBivek Man SinghNoch keine Bewertungen

- Electrical SubstationsDokument16 SeitenElectrical SubstationsEngr Syed Numan ShahNoch keine Bewertungen

- Quotation 98665Dokument5 SeitenQuotation 98665Reda IsmailNoch keine Bewertungen

- Economics BasisDokument14 SeitenEconomics BasiskumarNoch keine Bewertungen

- Project of InternshipDokument2 SeitenProject of InternshipSurendra PatelNoch keine Bewertungen

- Health Safety StatementDokument22 SeitenHealth Safety StatementShafiqul IslamNoch keine Bewertungen

- Uses of The Components of Crude Oil As FuelsDokument6 SeitenUses of The Components of Crude Oil As FuelsPearl LawrenceNoch keine Bewertungen

- 2011 TH 18205 Awad Nassib PdfaDokument95 Seiten2011 TH 18205 Awad Nassib PdfahafosaamrNoch keine Bewertungen

- p2714 Opel 6t45Dokument5 Seitenp2714 Opel 6t45Валентин ДNoch keine Bewertungen

- Electrochemical Technologies in Wastewater Treatment PDFDokument31 SeitenElectrochemical Technologies in Wastewater Treatment PDFvahid100% (1)

- CT2000 Manual EN 20151202 PDFDokument634 SeitenCT2000 Manual EN 20151202 PDFKhang NguyenNoch keine Bewertungen

- cjv30 Maintenance V10a PDFDokument101 Seitencjv30 Maintenance V10a PDFEdu100% (1)

- Phys114 Ps 1Dokument11 SeitenPhys114 Ps 1Reine Amabel JarudaNoch keine Bewertungen

- Lifting Plan For CranesDokument9 SeitenLifting Plan For CranesBibin JohnNoch keine Bewertungen

- A Mesh-Free Solid-Mechanics ApproachDokument26 SeitenA Mesh-Free Solid-Mechanics ApproachMustafa YildizNoch keine Bewertungen

- 2 Strokes 4 Strokes: 1 CylinderDokument2 Seiten2 Strokes 4 Strokes: 1 CylinderariffNoch keine Bewertungen

- Us06-106 850 01 01 02 PDFDokument6 SeitenUs06-106 850 01 01 02 PDFF2CANALESNoch keine Bewertungen

- Rev2 Service Manual Apollo PDFDokument370 SeitenRev2 Service Manual Apollo PDFJordi Vaquero RamirezNoch keine Bewertungen

- VarPlus Can - BLRCH104A125B48Dokument2 SeitenVarPlus Can - BLRCH104A125B48Achira DasanayakeNoch keine Bewertungen

- Seismic Design & Installation Guide: Suspended Ceiling SystemDokument28 SeitenSeismic Design & Installation Guide: Suspended Ceiling SystemhersonNoch keine Bewertungen

- MC9S12XD128 ProcessadorDokument1.350 SeitenMC9S12XD128 ProcessadorMarcelo OemNoch keine Bewertungen

- Cadence Short CommandsDokument1 SeiteCadence Short Commandsgetme_samNoch keine Bewertungen

- AVR Interrupt Programming in Assembly and CDokument38 SeitenAVR Interrupt Programming in Assembly and CK142526 AlishanNoch keine Bewertungen

- An Overview of Subspace Identification: S. Joe QinDokument12 SeitenAn Overview of Subspace Identification: S. Joe QinGodofredoNoch keine Bewertungen