Beruflich Dokumente

Kultur Dokumente

Methods For Chemical Analysis of Steels: Indian Standard

Hochgeladen von

GopalMahantaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Methods For Chemical Analysis of Steels: Indian Standard

Hochgeladen von

GopalMahantaCopyright:

Verfügbare Formate

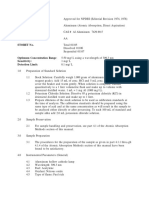

IS 228 ( Part 15 ) : 1992

Indian Standard

METHODS

PART 15

IODIDE

FOR CHEMICAL ANALYSIS

OF STEELS

DETERMINATION

OF COPPER BY THIOSULPHATE

METHOD

( FOR COPPER 005 TO 5 PERCENT)

(Second Revision )

First Reprint SEPTEMBER 19%

UDC

669.14 : 543[ 546.56-226]

Q BIS 1992

BUREAU

OF

MMANAK BHAVAN,

November 1992

INDIAN

STANDARDS

9 BAHADUR SHAH

NEW DELHI 110002

ZAFAR

MARG

Price Group 1

Methods

of Chemical Analysis of Ferrous Metals Sectional

Committee,

MTD 2

FOREWORD

This Indian Standard ( Part 15 ) ( Second Revision ) was adopted by the Bureau of Indian

Standards,

after the draft finalized by the Methods of Chemical Analysis of Ferrous Metals

Sectional Committee had been approved by the Metallurgical Engineering Division Council.

IS 228, which was first published in 1952 and subsequently revised in 1959, covered the chemical

analysis of plain carbon and low alloy steels. along with pig iron and cast iron. It was revised

again to make it comprehensive in respect of stee1 analysis and to exclude pig iron and cast

iron which were being covered in separate standards. During its second revision the standard has

been split up in several parts.

This part covers the method for determination

other parts of this series are:

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

Part

of copper

by thiosulphate-iodide

method.

The

1 Determination

of carbon by volumetric method ( for carbon 0.05 to 2.50 percent )

2 Determination

of manganese in plain carbon and low alloy steels by arsenite

method

3 Determination

of phosphorus by alkalimetric method

of total carbon by gravimetric method ( for carbon > 0.1 percent )

4 Determination

of nickel by dimethyl glyoxime ( gravimetric ) method ( for nickel >

5 Determination

0.1 percent )

of chromium by persulphate oxidation method ( for chromium > 0.1

6 Determination

percent )

of molybdenum by a-benzoinoxime

method ( for molybdenum > O-1

7 Determination

percent )

of silicon by the gravimetric method ( for silicon > 0.1 percent )

8 Determination

of sulphur in plain carbon steels by evolution method

9 Determination

of molybdenum by thiocyanate

( photometric ) method in low and

10 Determination

high alloy steels ( for molybdenum up to 0.1 percent )

of silicon by photometric

method in carbon steels and low alloy

11 Determination

steels ( for silicon 0.01 to 0.05 percent )

of manganese by periodate spectrophotometric

method in low and

12 Determination

high alloy steels ( for manganese 0.01 to 2.0 percent )

of arsenic

13 Determination

of carbon by thermal conductrvity method ( for carbon 0.005 to 2.000

14 Determination

percent)

of tungsten by spectrophotometric

method ( for tungsten O-1 to 2

16 Determination

percent )

In this revision The Gravimetric Method for determination

by The Thiosulphate Iodide Method.

of copper in steel has been replaced

In reporting the result of a test or analysis made in accordance with this standard,

if the final

value observed or calculated is to be rounded off it shall be done in accordance with IS 2 : 1960

Rules for rounding off numerical values ( revised ).

IS228(Part15):1992

Indian Standard

METHODS FOR CHEMICAL ANALYSIS

OF STEELS

PART 15

IODIDE

DETERMINATION

OF COPPER BY THIOSULPHATE

METHOD

( FOR COPPER O-05 TO 5 PERCENT )

Second Revision)

1 SCOPE

5.2.3 Wash Solution

This standard ( Part 15 ) describes the thiosulphate-iodide method for determination

of

copper in steel in range from 0.05 to 5 percent.

Saturate dilute sulphuric acid

( v/v ) with hydrogen sulphide.

solution

1 : 99

5.2.4 Dilute Nitric Acid, 60 percent.

2 REFERENCES

The following Indian Standards

adjuncts to this standard:

are

to IS 264 : 1976

5.2.5 Sodium Fluoride, solid.

Title

IS Na.

NdTE - Nitric acid conforming

contains 70 percent of nitric acid.

necessary

264 : 1976

Nitric acid ( second revision )

5.2.6 Dilute Ammonium Hydroxide,

1070 : 1992

Reagent grade water - Specification ( third revision )

5.2.7 Acetic Acid, 80 percent.

1 : 1 ( v/v ).

5.2.8 Potassium Iodide, solid.

3 SAMPLING

5.2.9 Starch Solution, O-5 percent.

The sample shall be drawn and prepared

prescribed in the relevant Indian Standard.

as

4 QUALITY OF REAGENTS

Unless specified otherwise,

analytical grade reagents and distilled water ( see IS 1070 : 1992 )

shall be employed for the test.

5 DETERMINATION

Make a suspension of 0.5 g of starch in 10 ml

of water. Add to it 90 ml of boiling water,

cool and mix.

5.2.10 Standard

( N/50 )

Solution

Dissolve 5 g of sodium thiosulphate

( Nas!&O,.

5Hz0 ) in 500 ml of water, add 0.1 g of sodium

carbonate and dilute to 1 litre. Standardize

against pure copper.

OF COPPER

5.1 Outline of the Method

The sample is dissolved in dilute sulphuric

acid and copper is precipitated

with sodiumthiosulphate.

Precipitate

is ignited, dissolved

in acid and determined iodometrically.

5.2.10.1 Standardization

Transfer 0.05 g of pure copper to 150 ml beaker,

cover and dissolve in 4-5 ml of dilute nitric

acid ( 3 : 5 ),. Boil gently to expel oxides of

nitrogen. Cool and add ammonium

hydroxide

( 1 : 1 ) until the solution just turns blue. Add

5 ml of acetic acid and then 1 ml in excess.

Complete the titration

as described in 5.3.2

to 5.3.4. Find out the copper equivalent

for

1 ml of thiosulphate

solution.

5.2 Reagents

5.2.1 Dilute Sulphuric Acid, 1 : 9 ( v/v )*

5.2.2 Sodium Thiosulphate Solution

Dissolve 100 g of sodium thiosulphate

5H,O ) in 100 ml of water and filter

solution is obtained.

Sodium Thiosulphate

( Na,S,O,

if a hazy

5.2.11 Ammonium BiJuoride Solution, 200 g/l.

1

Is228(Part

15):B92

until the solution

the blue colour.

temperature.

5.3 Procedure

5.3.1 Test Portion

Weigh

a sample neatest

to 1 mg as follows:

Copper, Percent

Mass in g of Sample

Up to 0.25

0.25 to 1

1 to 1.5

1.5 to 5

5

2

1

0.5

5.3.2 Weigh the quantity

of sample as per

copper content mentioned above and transfer

to 500 ml beaker. Add 100 ml of dilute sulphuric acid (see Note ).

Heat

gently until

reaction ceases, dilute to 250 ml. Heat to

boil, add 10 ml of sodium thiosulphate

solution in small portions and continue to boil for

5-10 minutes or until the precipitate

settle

rapidly.

Filter, and wash the precipitate

with wash solution.

Place the paper and

precipitate

in a porcelain

or silica crucible,

dry and ignite at a low temperature

( 520 to

550C) until all carbon is destroyed.

Cool,

and transfer the contents

of the crucible to

250 ml beaker. Add 5-6 ml of dilute nitric acid

to the crucible,

warm gently and pour upon

the contents in the beaker. Rinse the crucible

with water and warm the beaker and the

contents until the copper oxide has dissolved.

is just alkaline as noticed by

Cool the solution to room

5.3.4 Acidify the solution with acetic acid and

add 1 ml in excess. Add 3-4 g of potassium

Immediately

titrate

iodide and stir well.

with standard

sodium thiosulphate

solution.

When the brown tint has nearly disappeared,

add 5 ml of starch solution and continue titration until with one drop it changes the colour

from biue to yellowish

white and remains

permanent for 15 to 20 seconds ( see Notes ).

NOTES

1

Add 5 ml of potassium

thiosulphate

solution

( 10 percent ) to get a better end point detection.

2 If caper is present in small amount, estimate

copper by diethyldithio-carbamate

spectrophotometric method.

5.3.5 Blank

Carry out a blank determination

following the

procedure specified in 5.3.2 to 5.3.4 using same

amount of all reagents but without the sample.

5.3.6 Calculation

Copper, percent

by mass =

where

A=

B=

NOTE -

For samples not dissolving in dilute sulph.

uric acid, use mixture of hydrochloric acid, nitric

acid and 10 ml of sulphuric acid. Heat to fumes,

cool and repeat the operation once more.

C!=

D=

5.3.3 Carefully,

evaporate

the solution to 2-3

ml. Cool, add 30 ml of water and either 5 ml

of ammonium

bifluoride solution or 1 g of

sodium fluoride.

Add ammonium

hydroxide

(A-B)

x C x 100

D

volume in ml, of Na,S,O, solution

required for the sample;

volume

in ml, of Na,S,O, solution

required for the blank;

copper equivalent

( in g/ml ) of

Na$,O, solution; and

mass in g, of sample taken.

5.4 Reproducibility

&O-O1percent

at 0.1 nercent cooper level.

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods and

attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course of

implementing the standard, of necessary details, such as symbols and sizes, type or grade designations.

Enquiries relating to copyright be addressed to the Director (Publication), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed

periodically; a standard along with amendments is reaffirmed when such review indicates that no changes are

needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards

should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue

of BIS Handbook and Standards Monthly Additions.

This Indian Standard has been developed from Dot: No. MTD 2 ( 3606 )

Amendments

Amend No.

Issued Since Publication

Text Affected

Date of Issue

BUREAU OF INDIAN STANDARDS

Headquarters:

Telegrams: Manaksanstha

(Common to all offices)

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones: 323 0131,323 83 75,323 94 02

Telephone

Regional Offices:

Central

Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern

l/14 C.I.T. Scheme VII M, V.I.P. Road, Maniktola

CALCUTTA 700054

323 76 17,323 38 41

337 84 99,337 85 61

{ 337 86 26,337 9120

60 38 43

{ 60 20 25

Northern : SC0 335-336, Sector 34-A, CHANDIGARH 160022

Southern

C.I.T. Campus, IV Cross Road, MADRAS 600113

235 02 16,235 04 42

{ 235 15 19,235 23 15

Western

Manakalaya, E9 MIDC, Marol, Andheri (East)

MUMBAI 400093

832 92 95,832 78 58

{ 832 78 91,832 78 92

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR.

COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHATI.

HYDERABAD. JAIPUR. KANPUR. LUCKNOW. PATNA.

THIRUVANANTHAPURAM.

Reprography Unit, BIS, New Delhi, India

Das könnte Ihnen auch gefallen

- Practical Manual of Analytical ChemistryVon EverandPractical Manual of Analytical ChemistryBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Methods For Chemical Analysis of Steels: Indian StandardDokument5 SeitenMethods For Chemical Analysis of Steels: Indian StandardUmar MohammadNoch keine Bewertungen

- Advanced Pharmaceutical analysisVon EverandAdvanced Pharmaceutical analysisBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Is 228 Part 9Dokument5 SeitenIs 228 Part 9np27031990100% (1)

- Hydrogen Production TechnologiesVon EverandHydrogen Production TechnologiesMehmet SankirNoch keine Bewertungen

- Methods For Chemical Analysis of Steels: Indian StandardDokument5 SeitenMethods For Chemical Analysis of Steels: Indian StandardAryansh Rocky RanaNoch keine Bewertungen

- Is-00228-Part03 - Chemical Analysys of SteelDokument10 SeitenIs-00228-Part03 - Chemical Analysys of Steelnishanth132Noch keine Bewertungen

- Methods For Chemicalanalysisofsteels: Third Revision) W7A'Fs STFTFFDokument6 SeitenMethods For Chemicalanalysisofsteels: Third Revision) W7A'Fs STFTFFsaurabhpathak39Noch keine Bewertungen

- Methods of Chemical Analysis of Steels: Indian StandardDokument5 SeitenMethods of Chemical Analysis of Steels: Indian StandardNav TalukdarNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument8 SeitenDisclosure To Promote The Right To Informationanand.bharadwajNoch keine Bewertungen

- Is-00228-Part05 - Chemical Analysys of SteelDokument7 SeitenIs-00228-Part05 - Chemical Analysys of Steelnishanth132Noch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument8 SeitenDisclosure To Promote The Right To InformationAbhijeet SahuNoch keine Bewertungen

- Is 228 - 12 PDFDokument5 SeitenIs 228 - 12 PDFNav TalukdarNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument9 SeitenDisclosure To Promote The Right To InformationChaitanyaSinghalNoch keine Bewertungen

- Methods For Chemical Analysis of Steels: Indian StandardDokument6 SeitenMethods For Chemical Analysis of Steels: Indian StandardNav TalukdarNoch keine Bewertungen

- 228 10 1989 Reff2019Dokument6 Seiten228 10 1989 Reff2019OMEGA CONSULTANTNoch keine Bewertungen

- Is 12308-3 - 1987 - 1Dokument1 SeiteIs 12308-3 - 1987 - 1Svapnesh ParikhNoch keine Bewertungen

- Methods For Chemicalanalysisofsteels: Third Revision) W7A'Fs STFTFFDokument6 SeitenMethods For Chemicalanalysisofsteels: Third Revision) W7A'Fs STFTFFUppala Krishna ChaitanyaNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument9 SeitenDisclosure To Promote The Right To InformationDiptiNoch keine Bewertungen

- E 316 Â " 95 RTMXNI1SRUQDokument4 SeitenE 316 Â " 95 RTMXNI1SRUQmario valenzuelaNoch keine Bewertungen

- Method For Measurement of Emission From Stationary Sources: Indian StandardDokument8 SeitenMethod For Measurement of Emission From Stationary Sources: Indian StandardDipeshBardoliaNoch keine Bewertungen

- Is:228 9Dokument5 SeitenIs:228 9kaifmdNoch keine Bewertungen

- CookBook 09Dokument73 SeitenCookBook 09Le HuyNoch keine Bewertungen

- Lead in Gasoline by Atomic Absorption Spectroscopy: Standard Test Method ForDokument4 SeitenLead in Gasoline by Atomic Absorption Spectroscopy: Standard Test Method ForKu BonNoch keine Bewertungen

- ASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible PaintsDokument2 SeitenASTM D 2352 - 90 (Reapproved 2005) Test Method Standard For Sulfur Dioxide in White Pigment Separated From Solvent-Reducible Paintshenry rojasNoch keine Bewertungen

- Is 11255 4 2006Dokument8 SeitenIs 11255 4 2006VinodVaghaniNoch keine Bewertungen

- Chemical Analysis of Copper-Nickel and Copper-Nickel-Zinc AlloysDokument7 SeitenChemical Analysis of Copper-Nickel and Copper-Nickel-Zinc AlloyswpwmhatNoch keine Bewertungen

- E 75 - 76 R96 - RTC1Dokument7 SeitenE 75 - 76 R96 - RTC1nasryudiinNoch keine Bewertungen

- TESTING PB, CD, As, HG FOR FRUITY FLV POWDERDokument9 SeitenTESTING PB, CD, As, HG FOR FRUITY FLV POWDERNguyễn Ngọc MaiNoch keine Bewertungen

- Tobacco and Tobacco Products - Determination of Reducing and Total SugarsDokument8 SeitenTobacco and Tobacco Products - Determination of Reducing and Total SugarsmurthalNoch keine Bewertungen

- Section 10 - Medicines & Biological AnalysisDokument43 SeitenSection 10 - Medicines & Biological AnalysisNguyễn Mai Thanh LộcNoch keine Bewertungen

- Is 228 9 1989Dokument8 SeitenIs 228 9 1989Andrewz PachuauNoch keine Bewertungen

- D 2348 - 02 PDFDokument4 SeitenD 2348 - 02 PDFAl7amdlellahNoch keine Bewertungen

- GBT 2566-2010 - en PhotopermiabilityDokument11 SeitenGBT 2566-2010 - en PhotopermiabilityYudan TonoNoch keine Bewertungen

- EPA 202.1 - AlDokument2 SeitenEPA 202.1 - AlAristaNoch keine Bewertungen

- IS 11255 - 4 - 2006 - Reff2022 Methods For Measurement of Emissions From Stationary Sources Part 4 Hydrogen Sulphide and Carbon DisulphideDokument8 SeitenIS 11255 - 4 - 2006 - Reff2022 Methods For Measurement of Emissions From Stationary Sources Part 4 Hydrogen Sulphide and Carbon DisulphidePawan SharmaNoch keine Bewertungen

- Chemical Analysis of Steels: Indian Standard " Methods ForDokument5 SeitenChemical Analysis of Steels: Indian Standard " Methods ForMuthusamy ArumugamNoch keine Bewertungen

- C560Dokument8 SeitenC560guadalupegomezperezNoch keine Bewertungen

- EPA 9034 - ReactividadDokument7 SeitenEPA 9034 - ReactividadGuadalupe EspinozaNoch keine Bewertungen

- Methods For Chemicalanalysisofsteels: Indian StandardDokument5 SeitenMethods For Chemicalanalysisofsteels: Indian StandardMuthusamy ArumugamNoch keine Bewertungen

- Feed Analysis Standard Operation (Analysis) Procedure SOPDokument27 SeitenFeed Analysis Standard Operation (Analysis) Procedure SOPZiauddeen Noor100% (1)

- Indian Standard: (Reaffirmed 2012)Dokument12 SeitenIndian Standard: (Reaffirmed 2012)VinodVaghaniNoch keine Bewertungen

- D 3969 - 85 r94 - Rdm5njktukveDokument5 SeitenD 3969 - 85 r94 - Rdm5njktukvejorge armandoNoch keine Bewertungen

- Sodium Acetate, AnhydrousDokument3 SeitenSodium Acetate, AnhydrousjycortesNoch keine Bewertungen

- Lab Report Chem Exp 5Dokument5 SeitenLab Report Chem Exp 5ABDUL HAFIZ ABD GHAFARNoch keine Bewertungen

- Sodium Tartrate Dihydrate 2017Dokument3 SeitenSodium Tartrate Dihydrate 2017sviblaNoch keine Bewertungen

- Heavy MetalsDokument5 SeitenHeavy Metalsiqbalpec8721Noch keine Bewertungen

- Is 228 16 1992Dokument8 SeitenIs 228 16 1992hyper meshNoch keine Bewertungen

- D 1510 PDFDokument9 SeitenD 1510 PDFDark57100% (1)

- CookBook 10Dokument42 SeitenCookBook 10Le HuyNoch keine Bewertungen

- Methods of Sampling and Test (Physical and Chemical) For Water and WastewaterDokument5 SeitenMethods of Sampling and Test (Physical and Chemical) For Water and WastewaterRaghav TiwaryNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument9 SeitenDisclosure To Promote The Right To InformationSantosh KumarNoch keine Bewertungen

- Methods Chemical Analysis of Steels: ThirdDokument6 SeitenMethods Chemical Analysis of Steels: ThirdferozNoch keine Bewertungen

- Is 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsDokument5 SeitenIs 14684 - 1999 Determination of Nitrogen and Nitrogenous Compounds in SoilsPrapa KaranNoch keine Bewertungen

- TiO2 DeterminationDokument9 SeitenTiO2 Determinationdoctuer_pdh100% (1)

- 6 1987 Reff2022Dokument2 Seiten6 1987 Reff2022OMEGA CONSULTANTNoch keine Bewertungen

- LCS 77.100 CHEMICAL ANALYSIS OF FERROSILICON-MAGNESIUM ALLOY - BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELH1 110002Dokument9 SeitenLCS 77.100 CHEMICAL ANALYSIS OF FERROSILICON-MAGNESIUM ALLOY - BUREAU OF INDIAN STANDARDS MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG NEW DELH1 110002Рифгат МирзаевNoch keine Bewertungen

- Chemical Analysis of Steels: Indian Standard " Methods ForDokument5 SeitenChemical Analysis of Steels: Indian Standard " Methods ForUppala Krishna ChaitanyaNoch keine Bewertungen

- Opportunities Naturalfiber CompositesDokument35 SeitenOpportunities Naturalfiber CompositesGopalMahantaNoch keine Bewertungen

- Presentations Oil Refinery ProcessesDokument36 SeitenPresentations Oil Refinery ProcessesGururaj SreepatharaoNoch keine Bewertungen

- Asnt Snt-Tc-1a (2016)Dokument5 SeitenAsnt Snt-Tc-1a (2016)Santiago DuranNoch keine Bewertungen

- MCQ m8Dokument3 SeitenMCQ m8Karan BansalNoch keine Bewertungen

- MCQ m8Dokument3 SeitenMCQ m8Karan BansalNoch keine Bewertungen

- Piping PDFDokument46 SeitenPiping PDFGORO43100% (1)

- ASHRAEDokument1 SeiteASHRAECésar MiguéisNoch keine Bewertungen

- Inter Plant Standard - Steel IndustryDokument6 SeitenInter Plant Standard - Steel IndustryGopalMahantaNoch keine Bewertungen

- ASHRAEDokument1 SeiteASHRAECésar MiguéisNoch keine Bewertungen

- List of IS CodesDokument2 SeitenList of IS CodesKashan KhanNoch keine Bewertungen

- Inter Plant Standard - Steel IndustryDokument5 SeitenInter Plant Standard - Steel IndustryGopalMahantaNoch keine Bewertungen

- Specification For Single Motor Control Units For Voltages Not Exceeding 1000 V Ac (First Revision) IPSS:1-04-039-03Dokument9 SeitenSpecification For Single Motor Control Units For Voltages Not Exceeding 1000 V Ac (First Revision) IPSS:1-04-039-03GopalMahanta100% (1)

- Condition Monitoring of Transformers SAILDokument17 SeitenCondition Monitoring of Transformers SAILavadiraja100% (1)

- ISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsDokument222 SeitenISA TR84.00.03 Guidance For Testing of Process Sector Safety Instrumented FunctionsGopalMahanta100% (1)

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Dokument9 SeitenSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNoch keine Bewertungen

- Inter Plant Standard - Steel Industry Specification For Arc Extinguishing Chamber For Ac and DC Contactors IPSS:1-04-028-89Dokument3 SeitenInter Plant Standard - Steel Industry Specification For Arc Extinguishing Chamber For Ac and DC Contactors IPSS:1-04-028-89GopalMahantaNoch keine Bewertungen

- MSS SP-115 (1999)Dokument11 SeitenMSS SP-115 (1999)raobabar21Noch keine Bewertungen

- Inter Plant Standard - Steel IndustryDokument6 SeitenInter Plant Standard - Steel IndustryGopalMahantaNoch keine Bewertungen

- Gen. Insulating GasketsDokument12 SeitenGen. Insulating GasketsGopalMahanta100% (1)

- Inter Plant Standard - Steel IndustryDokument5 SeitenInter Plant Standard - Steel IndustryGopalMahantaNoch keine Bewertungen

- Condition Monitoring of Transformers SAILDokument17 SeitenCondition Monitoring of Transformers SAILavadiraja100% (1)

- 1 04 035 08Dokument27 Seiten1 04 035 08Bhupinder SinghNoch keine Bewertungen

- 1 03 037 09Dokument5 Seiten1 03 037 09GopalMahantaNoch keine Bewertungen

- Specification For Fuse Combination Units For Voltages Not Exceeding 1000 V Ac IPSS:1-04-019-02Dokument6 SeitenSpecification For Fuse Combination Units For Voltages Not Exceeding 1000 V Ac IPSS:1-04-019-02GopalMahantaNoch keine Bewertungen

- Specification For Belt Speed Relays and Transducers (First Revision) IPSS:1-04-018-06Dokument5 SeitenSpecification For Belt Speed Relays and Transducers (First Revision) IPSS:1-04-018-06GopalMahantaNoch keine Bewertungen

- Interplant Standard - Steel Industry: Specification For Control Transformers (First Revision) IPSS:1-04-013-02Dokument6 SeitenInterplant Standard - Steel Industry: Specification For Control Transformers (First Revision) IPSS:1-04-013-02GopalMahantaNoch keine Bewertungen

- 191 1t10Dokument40 Seiten191 1t10REUBEN74Noch keine Bewertungen

- Code of Practice For Overhauling of DC Motors With Antifriction / Sliding Bearings IPSS: 1-03-033-03Dokument9 SeitenCode of Practice For Overhauling of DC Motors With Antifriction / Sliding Bearings IPSS: 1-03-033-03GopalMahantaNoch keine Bewertungen

- 1 03 038 09Dokument5 Seiten1 03 038 09GopalMahantaNoch keine Bewertungen

- Chemistry Practicals 2023-2024Dokument30 SeitenChemistry Practicals 2023-2024prashant10thbNoch keine Bewertungen

- Astm D1439 03 PDFDokument9 SeitenAstm D1439 03 PDFLOGISTICA AGROAVILABNoch keine Bewertungen

- Tips & Techniques, SK-15, Rev02Dokument12 SeitenTips & Techniques, SK-15, Rev02AntWonxxxNoch keine Bewertungen

- 1020am - 3.sunil Jayant Kulkarni - FINDokument4 Seiten1020am - 3.sunil Jayant Kulkarni - FINRuben Aldi WicaksonoNoch keine Bewertungen

- Review of DemetallisationDokument12 SeitenReview of DemetallisationLohit MataniNoch keine Bewertungen

- United States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, HerDokument7 SeitenUnited States Patent (19) : Attorney-Harry M. Saragovitz, Edward J. Kelly, Herwilly dwinovNoch keine Bewertungen

- Chemistry: Pearson EdexcelDokument16 SeitenChemistry: Pearson EdexcelHosni ShowikeNoch keine Bewertungen

- BS en 480-10-2010Dokument12 SeitenBS en 480-10-2010Abey VettoorNoch keine Bewertungen

- Detection of Carbon and HydrogenDokument9 SeitenDetection of Carbon and HydrogenIvanne IdorotNoch keine Bewertungen

- WP 1408 FRDokument128 SeitenWP 1408 FRBernard ShamNoch keine Bewertungen

- Full Download Solution Manual For Strategic Management A Competitive Advantage Approach Concepts and Cases 17th Edition Fred R David PDF Full ChapterDokument36 SeitenFull Download Solution Manual For Strategic Management A Competitive Advantage Approach Concepts and Cases 17th Edition Fred R David PDF Full Chapterhurriesscavenge9z16a100% (15)

- Abnormal Psychology An Integrative Approach Barlow 7th Edition Test BankDokument36 SeitenAbnormal Psychology An Integrative Approach Barlow 7th Edition Test Bankwydcirri.818y4100% (43)

- Reactions of CopperDokument20 SeitenReactions of CopperChaimaaElborki100% (2)

- Salt 2 - Lead NitrateDokument2 SeitenSalt 2 - Lead NitrateaaravNoch keine Bewertungen

- JHM V165, 1-3, 751-758 AN - PyriteDokument8 SeitenJHM V165, 1-3, 751-758 AN - PyriteGonzalo O'ortiz Araneda's IIINoch keine Bewertungen

- History of Sulphuric AcidDokument59 SeitenHistory of Sulphuric Acid圈圈100% (1)

- A. Acid Rain: 1. HistoryDokument2 SeitenA. Acid Rain: 1. HistoryLaurensia RainieNoch keine Bewertungen

- Optimass: Corrosion & Abrasion Guidelines For Coriolis MetersDokument18 SeitenOptimass: Corrosion & Abrasion Guidelines For Coriolis Metersyrdna nawaiteosNoch keine Bewertungen

- A+ Blog-Class-9-First Bell-Chemistry-Chapter-5-Science Diary-Class-30-EmDokument2 SeitenA+ Blog-Class-9-First Bell-Chemistry-Chapter-5-Science Diary-Class-30-EmRiya Maria SijuNoch keine Bewertungen

- Stoichiometry 1Dokument8 SeitenStoichiometry 1Raju SinghNoch keine Bewertungen

- Qualitative Analysis Wired ChemistDokument18 SeitenQualitative Analysis Wired ChemistFrances GanotisiNoch keine Bewertungen

- Uranium Pakistan Report PDFDokument278 SeitenUranium Pakistan Report PDFZia KhanNoch keine Bewertungen

- 1.3 Mine Gases - Gases in Mine Air IIDokument9 Seiten1.3 Mine Gases - Gases in Mine Air IIDeepakKattimaniNoch keine Bewertungen

- What Happens When You Breath Niric Acid FumesDokument4 SeitenWhat Happens When You Breath Niric Acid FumesAFLAC ............Noch keine Bewertungen

- 200 Best Questions (P-Block Elements)Dokument31 Seiten200 Best Questions (P-Block Elements)Tanishq KumarNoch keine Bewertungen

- Automatic Product Identification During Unloading: Relevant For: Chemical-, Petro-And Beverage IndustryDokument3 SeitenAutomatic Product Identification During Unloading: Relevant For: Chemical-, Petro-And Beverage Industryping dengNoch keine Bewertungen

- Is 12308-3 - 1987 - 1Dokument1 SeiteIs 12308-3 - 1987 - 1Svapnesh ParikhNoch keine Bewertungen

- P - Block PDFDokument60 SeitenP - Block PDFSubham roushanNoch keine Bewertungen

- CHEM 238 Experiment #4: Formal Lab Report: Electrophilic Aromatic Substitution-The Nitration of Methyl BenzoateDokument18 SeitenCHEM 238 Experiment #4: Formal Lab Report: Electrophilic Aromatic Substitution-The Nitration of Methyl Benzoateapi-592105594Noch keine Bewertungen

- Model T201 Ammonia Analyzer: Manual AddendumDokument42 SeitenModel T201 Ammonia Analyzer: Manual AddendumTruong HungNoch keine Bewertungen

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsVon EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsBewertung: 4 von 5 Sternen4/5 (146)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolVon EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNoch keine Bewertungen

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNoch keine Bewertungen

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilVon EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilBewertung: 5 von 5 Sternen5/5 (1)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableVon EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- Chemistry: a QuickStudy Laminated Reference GuideVon EverandChemistry: a QuickStudy Laminated Reference GuideBewertung: 5 von 5 Sternen5/5 (1)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeVon EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeBewertung: 5 von 5 Sternen5/5 (1)

- Bioplastics: A Home Inventors HandbookVon EverandBioplastics: A Home Inventors HandbookBewertung: 4 von 5 Sternen4/5 (2)

- Taste: Surprising Stories and Science About Why Food Tastes GoodVon EverandTaste: Surprising Stories and Science About Why Food Tastes GoodBewertung: 3 von 5 Sternen3/5 (20)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsVon EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNoch keine Bewertungen

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireVon EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireBewertung: 4 von 5 Sternen4/5 (129)

- Meltdown: Nuclear disaster and the human cost of going criticalVon EverandMeltdown: Nuclear disaster and the human cost of going criticalBewertung: 5 von 5 Sternen5/5 (5)

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)

- Tribology: Friction and Wear of Engineering MaterialsVon EverandTribology: Friction and Wear of Engineering MaterialsBewertung: 5 von 5 Sternen5/5 (1)