Beruflich Dokumente

Kultur Dokumente

Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDF

Hochgeladen von

Marcelo VeronezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDF

Hochgeladen von

Marcelo VeronezCopyright:

Verfügbare Formate

A Parker Company

Tubular Specification Sheet

Operations

New Iberia, LA

Ph. (337) 365-8154

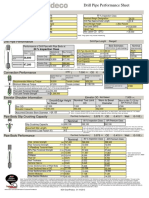

6-5/8" 56.95# .938" V-150 6-5/8"FH Slip Proof Landing String R2

Victoria, TX

Ph. (361) 579-0244

Odessa, TX

Ph. (432) 366-1491

Evanston, WY

Ph. (307) 789-5860

Texarkana, TX

Ph. (903) 838-1620

Williston, ND

Ph. (701) 774-2280

Morgantown, WV

Ph. (304) 212-5191

Enid, OK

Ph. (580) 237-1039

Sales Offices:

Houston, TX

Ph. (281) 445-1777

Tube / Pipe Body

Tube OD:

6.625"

Tube ID:

4.750

Inches

Nominal Weight Designation:

56.95

lbs/ft

Adjusted Weight (Includes TJs):

76.79

lbs/ft

Grade

V150

Slip Proof Section = 135,000 SMYS

Tube Wall (nominal):

0.938"

Slip Proof Section = 1.703"

Inspection Class:

95% RBW

.891" RBW

Tube Tensile:

2,367,300

lbs

Tube Torsional:

284,200

Tube Collapse:

35,347

psi

Tube Internal Yield/Burst:

40,352

psi

Displacement Est. (Includes TJs): 0.0279

bbls/ft

Capacity Est. (Includes TJs):

bbls/ft

New Orleans. LA

Ph. (985) 871-0182

Denver, CO

Ph. (303) 534-1873

Dallas, TX

Ph. (972) 774-4480

San Antonio, TX

Ph. (210) 822-4800

Pittsburgh, PA

Ph. (724) 916-4643

JD 2/26/14

Slip Proof Section: 6.906"

ft-lbs

0.0183 with ID Coating

**This landing string should not be rotated while below the BOPs**

Connection

Connection Type:

6-5/8"FH

Connection OD:

8.688

Inches

Connection ID

3.500

Inches

Drift:

3.375

Inches

Recommended MUT (T4):

71,200 ft-lbs

Tensile: 2,625,600

lbs

The (T4) MUT is recommended to optimize connection operational tensile, See attached for Max MUT.

Minimum MUT:

69,200 ft-lbs

Connection Torsional:

138,500

lbs

Tensile: 2,551,900

ft-lbs

Providing Quality Rental Tools and Service Since 1978

The technical information herein is for reference only & should not be construed as a recommendation. The user should consider all field conditions along with

other combined factors which may affect the final string design used in the field. Combined loads are not considered in most figures. Above figures do not take

into account effects of wear, stress relief features, hard band, or spiral features. All dimensions are nominal. Figures are subject to change without notice.

Please refer to our website for updates: www.quailtools.com

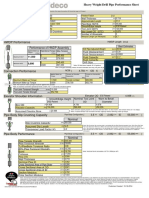

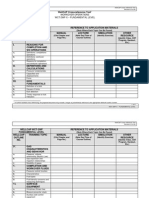

SlipProof Landing String Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Warning: At Maximum make-up torque, the primary shoulder contact stress is too high. Note: Connection operational tension at Maximum MUT is less than

95% inspection class pipe body in tension, a lower MUT should be considered. Connection torsional strength is less than 80% pipe body torsional strength.

Drill Pipe Configuration

Pipe Body OD

(in)

Pipe Body Wall Thickness

(in)

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

6.625

0.938

V-150

Controlled Length

6-5/8 FH

8.688

3.500

12

17

(in)

(in)

(in)

(in)

95 % Inspection Class

(in)

SlipProof Section Length

Nominal Weight Designation

Drill Pipe Approximate Length

SmoothEdge Height

Tool Joint SMYS

Upset Type

Max Upset OD (DTE)

Friction Factor

Note: Tong space may

include hardfacing.

(ft)

72

56.95

31.5

3/32 Raised

(in)

(psi)

(in)

120,000

IEU

6.906

1.0

This

landing string

shouldString

not beRating

rotated while below

BOPs

(lbs)the

SlipProof

Landing

2,055,200

Based on:

90 % Inspection Class SlipProof,

95 % Inspection Class Pipe Body, tool joint operational tensile, elevator OD, no applied drilling torque.

Drill Pipe Length Controlled Length

Drill Pipe Performance

Performance for Drill-Pipe with Pipe Body at

Best Estimates

(without Coating)

95 % Inspection Class

Applied Make-up

Operational

Max Tension

(ft-lbs) Torque

(ft-lbs)

(lbs)

Torque

Recommended

MUT (T4)

71,200

0

70,900

2,367,300

2,292,300

Minimum MUT

69,200

0

68,900

2,367,300

2,296,500

6-5/8 FH

Maximum Make-up Torque

Minimum Make-up Torque

(ft-lbs)

83,100

69,200

8.688

Tension at Shoulder

Separation

(in)

3.500

Tensile Limited

2,551,900

(ft-lbs)

(lbs)

(in)

120,000

(psi)

Tool Joint Dimensions

Tension at Connection

Yield

(lbs)

(lbs)

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

2,161,100

2,625,600

Minimum Tool Joint OD for

Counterbore

Note: To maximize connection operational tensile, a MUT (T4) = 71,200 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

0.77

0.0183

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Applied Make-up

Torque

(with Coating)

76.79

(gal/ft) 1.18

(Bbls/ft) 0.0279

(gal/ft) 0.77

(Bbls/ft) 0.0185

(in) 3.375

(lbs/ft)

Drill-Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

(in)

8.593

Not Applicable

Not Applicable

138,500

2,625,600

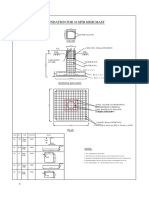

SlipProof Section Slip Crushing Capacity

SlipProof Configuration

6.906

OD

3.5 ID

(in)

135,000 Min Yield

(in)

(psi)

Slip Crushing is to be addressed once slip type, transverse LoadNominal

Factor (K), and

slip

contactClass

length80%

is known.

Inspection

Inspection Class

90 %

(lbs)

SlipProof Section Slip Crushing Capacity

SlipProof Section Tensile Strength

(lbs)

(in)

Assumed Slip Length

Transverse Load Factor (K)

SlipProof Section Specified Minimum Yield Strength

(psi)

2,307,800

3,757,900

2,055,200

3,271,400

16.5

4.2

135,000

1,806,000

2,809,500

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe Fail in

the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference only. Slip

crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in slips, drill pipe

OD and wall variation, and other factors. Consult with the slip manufacturer for additional information.

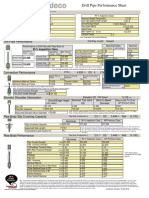

Pipe Body Configuration

(

6.625 OD (in)

0.938 Wall (in)

Slip Crushing is to be addressed once slip type, transverse Load Factor (K), and

slip contact length is API

known.

Premium Class

95 % Inspection Class

Pipe Body Slip Crushing Capacity

V-150 )

Nominal

(lbs)

Pipe Body Slip Crushing Capacity

(in)

Assumed Slip Length

Transverse Load Factor (K)

1,572,200

SmoothEdge OD

3/32 Raised

8.875

2,536,200

(in)

8.688

2,251,500

Pipe Body Configuration

Pipe Tensile Strength

(lbs) 2,512,700

(ft-lbs) 303,100

TJ/PipeBody Torsional Ratio

0.46

80% Pipe Torsional Strength (ft-lbs) 242,400

Pipe Torsional Strength

Burst

Collapse

(psi) 37,166

(psi) 36,462

95

% Inspection Class

2,367,300

284,200

0.49

227,300

40,352

35,347

7.703

856,100

Not Applicable

0

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

7.031

Pipe Body Performance

Nominal

1,247,200

(in)

Box OD at Elevator (no wear)

8.875

Nominal Tool Joint

Worn to Bevel

Worn to Min TJ OD for

API Premium Class

OD

Diameter

Elevator Shoulder Information

(in)

Box OD

(lbs)

Elevator Capacity

Assumed Elevator Bore Diameter

1,490,500

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe Fail in

the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference only. Slip

crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in slips, drill pipe

OD and wall variation, and other factors. Consult with the slip manufacturer for additional information.

16.5

4.2

6.625 OD

Nominal

API Premium Class

1,943,600

230,400

0.60

184,300

33,980

31,695

Note: Nominal Burst calculated at 87.5% RBW per API.

Pipe OD

Wall Thickness

Nominal Pipe ID

(in) 6.625

(in) 0.938

(in) 4.750

Cross Sectional Area of Pipe Body (in^2)

16.751

Section Modulus

(in^2) 34.472

(in^2) 17.721

(in^3) 21.003

Polar Section Modulus

(in^3) 42.006

Cross Sectional Area of OD

Cross Sectional Area of ID

(in)

0.938 Wall

95

% Inspection Class

6.531

0.891

4.750

15.782

33.502

17.721

19.699

39.398

(in)

V-150 )

API Premium Class

6.250

0.750

4.750

12.957

30.678

17.721

15.969

31.939

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and suitability of use of the

technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No

safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end

user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the

www.NOV.com/GrantPrideco/CustomerFeedback

NOV GrantPrideco 09-18-2013

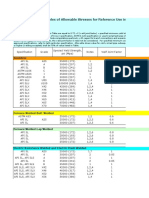

Operational Limits of Drill Pipe

Connection

Pipe Body

6-5/8 FH

95 % Inspection Class

Tool Joint OD

(in)

8.688

Tool Joint ID

Pipe Body OD

(in)

6.625

Wall Thickness (in) 0.938

Combined Loading for Drill Pipe at

(ft-lbs)

0

4,400

8,700

13,100

17,400

21,800

26,200

30,500

34,900

39,300

43,600

48,000

52,300

56,700

61,100

65,400

69,800

74,100

78,500

82,900

(lbs)

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

2,161,100

Pipe Body Grade

V-150

Minimum Make-up Torque = 69,200

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

3.500

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 83,100

Operational Assembly

Torque

Max Tension

(in)

Operational Assembly

Torque

Max Tension

(ft-lbs)

(lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

2,367,300 2,161,100

2,367,300

2,367,300

2,551,900

2,367,000 2,161,100

3,600

2,367,100

2,367,100

2,551,900

2,366,200 2,161,100

7,300

2,366,500

2,366,500

2,551,900

2,364,800 2,161,100

10,900

2,365,500

2,365,500

2,551,900

2,362,800 2,161,100

14,500

2,364,200

2,364,200

2,551,900

2,551,900

2,360,300 2,161,100

18,100

2,362,500

2,362,500

2,357,200 2,161,100

21,800

2,360,300

2,360,300

2,551,900

2,353,600 2,161,100

25,400

2,357,800

2,357,800

2,551,900

2,349,400 2,161,100

29,000

2,354,900

2,354,900

2,551,900

2,344,500 2,161,100

32,700

2,351,600

2,351,600

2,551,900

2,339,200 2,161,100

36,300

2,347,900

2,347,900

2,551,900

2,333,300 2,161,100

39,900

2,343,800

2,343,800

2,551,900

2,551,900

2,326,800 2,161,100

43,500

2,339,400

2,339,400

2,319,700 2,161,100

47,200

2,334,400

2,334,400

2,551,900

2,311,900 2,161,100

50,800

2,329,100

2,329,100

2,551,900

2,303,700 2,161,100

54,400

2,323,500

2,323,500

2,551,900

2,294,800 2,161,100

58,100

2,317,300

2,317,300

2,551,900

2,285,400 2,161,100

61,700

2,310,800

2,310,800

2,551,900

2,303,900

2,303,900

2,551,900

2,296,500

2,296,500

2,551,900

65,300

2,275,200 2,161,100

68,900

2,264,400 2,161,100

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

69,200

70,700

72,300

73,800

75,400

76,900

78,500

80,000

81,600

83,100

Connection Max

Tension

(lbs)

2,551,900

2,607,200

2,582,600

2,524,100

2,461,600

2,403,100

2,340,600

2,282,000

2,219,600

2,161,000

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

NOV GrantPrideco

09-18-2013

Connection Wear Table

Connection

6-5/8 FH

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

8.688

8.619

8.551

8.483

8.415

8.347

8.278

8.21

8.142

8.074

8.006

7.938

Worn OD

(in)

8.688

Tool Joint ID

(in)

3.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

138,500

138,500

134,700

128,700

122,700

116,800

110,900

105,200

99,500

93,900

88,300

82,800

83,100

83,100

80,800

77,200

73,600

70,100

66,500

63,100

59,700

56,300

53,000

49,700

(ft-lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Min MUT

(lbs)

2,161,000

2,116,400

2,128,900

2,176,400

2,229,700

2,284,900

2,350,900

2,416,300

2,490,700

2,575,800

2,599,100

2,506,800

Connection Max

Tension

(lbs)

(ft-lbs)

69,200

2,551,900

69,200

2,603,800

67,300

2,589,800

64,300

2,535,700

61,400

2,484,700

58,400

2,428,700

55,500

2,376,800

52,600

2,322,800

49,700

2,267,600

46,900

2,215,800

44,200

2,167,600

41,400

2,088,200

Note for API Connections: Tension at shoulder separation and Tension at connection failure may fluctuate as OD

decreases due to Recommended make-up toqure exceeding T4.

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

95 % Inspection Class

Pipe Body Torque

25,800

51,700

(in)

6.625

77,500

103,300

Wall Thickness (in) 0.938

129,200

155,000

180,800

Pipe Body Grade

206,700

232,500

258,300

V-150

284,100

(ft-lbs)

Pipe Body Max

2,367,300 2,357,500 2,327,800 2,277,500 2,205,300 2,108,400 1,984,100 1,826,300 1,624,500 1,361,000 986,700

Tension

(lbs)

49,700

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

NOV GrantPrideco

09-18-2013

Das könnte Ihnen auch gefallen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Xt39 Spec SheetDokument3 SeitenXt39 Spec SheetjdcomptonNoch keine Bewertungen

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDokument3 Seiten5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDokument3 Seiten4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNoch keine Bewertungen

- 5 7/8" 23.4 PPF S135 Pipe SpecsDokument2 Seiten5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Dokument3 SeitenLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- Drill Pipe Performance Sheet 5.875 XT57 G105Dokument3 SeitenDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNoch keine Bewertungen

- T3802-Z-DS-001 - Rev. 3 - Technical DocumentDokument5 SeitenT3802-Z-DS-001 - Rev. 3 - Technical DocumentpetricamafteiNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNoch keine Bewertungen

- HeavyWeight 3.5 25.58lbs NC-38Dokument3 SeitenHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNoch keine Bewertungen

- 5 7/8" VM-165 R2 Pipe SpecsDokument2 Seiten5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNoch keine Bewertungen

- Brochure 3Dokument12 SeitenBrochure 3Gohilakrishnan ThiagarajanNoch keine Bewertungen

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Dokument3 SeitenDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNoch keine Bewertungen

- Tank WeightsDokument48 SeitenTank WeightsHamzaHashimNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDokument3 SeitenDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- Drill Pipe Configuration: 95 % Inspection ClassDokument3 SeitenDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNoch keine Bewertungen

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Dokument3 SeitenDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNoch keine Bewertungen

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Dokument3 SeitenDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNoch keine Bewertungen

- Asme PQR DemoDokument3 SeitenAsme PQR DemoMuthusamy AyyanapillaiNoch keine Bewertungen

- Tablas Tuberia XTDokument35 SeitenTablas Tuberia XTArcadio Bahena100% (1)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument2 SeitenPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNoch keine Bewertungen

- TopCorbelco - WPS FCAW Sa 516 GR 70Dokument6 SeitenTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisNoch keine Bewertungen

- A 716 - 99 Qtcxni1sruqDokument7 SeitenA 716 - 99 Qtcxni1sruqwahyudiNoch keine Bewertungen

- Casing DesignDokument49 SeitenCasing DesignAmar BenAmar100% (1)

- Sa 516 GR 70 WPSDokument5 SeitenSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Series 805YD Specification SheetDokument2 SeitenSeries 805YD Specification SheetFEBCONoch keine Bewertungen

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance Sheetjinyuan74Noch keine Bewertungen

- 1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetDokument2 Seiten1038 TDD GD 100t Continuous Duty Pump Brochure Data SheetYeins Edson OrdoñezNoch keine Bewertungen

- Casing DesignDokument48 SeitenCasing Designdrillinganaco60% (5)

- Double Block Bleed TOSVDokument8 SeitenDouble Block Bleed TOSVplanet123Noch keine Bewertungen

- Trispiral XT39Dokument1 SeiteTrispiral XT39Cerón Niño SantiagoNoch keine Bewertungen

- Bottom Hole Assembly Design and Usage: Jar Triggering LoadDokument8 SeitenBottom Hole Assembly Design and Usage: Jar Triggering LoadHeris SitompulNoch keine Bewertungen

- A085hydraulicactuators PDFDokument2 SeitenA085hydraulicactuators PDFCesar PomposoNoch keine Bewertungen

- Ficha Tecnica TDS - US - 77 Continental BlowerDokument1 SeiteFicha Tecnica TDS - US - 77 Continental BlowerfranciscopulgarNoch keine Bewertungen

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDokument1 SeitePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNoch keine Bewertungen

- Bending Machine CRC Evans Centurion 06 20Dokument4 SeitenBending Machine CRC Evans Centurion 06 20bharathaninNoch keine Bewertungen

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDokument32 SeitenI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- Louver WeightDokument2 SeitenLouver WeightAbhay Sisodia0% (1)

- Drill Pipe Performance SheetDokument3 SeitenDrill Pipe Performance SheetGarcia C L AlbertoNoch keine Bewertungen

- MIL Control Valve Specification and Sizing CalculationDokument34 SeitenMIL Control Valve Specification and Sizing CalculationRahulTewari67% (3)

- 15hp 4p 254tpa Au Bf31Dokument13 Seiten15hp 4p 254tpa Au Bf31rhusseinpos4765Noch keine Bewertungen

- Excess Flow Valves Bleed Valves and Purge ValvesDokument6 SeitenExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryNoch keine Bewertungen

- Control Choke Valve 9000Dokument8 SeitenControl Choke Valve 9000sabi_shi100% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerVon EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerBewertung: 5 von 5 Sternen5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Lifting Tongs Below The Hook PDFDokument5 SeitenLifting Tongs Below The Hook PDFMarcelo VeronezNoch keine Bewertungen

- Jayanti Vagdoda 001Dokument1 SeiteJayanti Vagdoda 001Marcelo VeronezNoch keine Bewertungen

- Ibape PeDokument7 SeitenIbape PeMarcelo VeronezNoch keine Bewertungen

- Dr. D. K. Tuli Holds Ph.D. in Synthetic Chemistry Followed by OverDokument1 SeiteDr. D. K. Tuli Holds Ph.D. in Synthetic Chemistry Followed by OverMarcelo VeronezNoch keine Bewertungen

- Mr. Dipak Chakravarty, Managing Director NRLDokument1 SeiteMr. Dipak Chakravarty, Managing Director NRLMarcelo VeronezNoch keine Bewertungen

- Ashish Bansal, Senior Manager, B S R & CoDokument1 SeiteAshish Bansal, Senior Manager, B S R & CoMarcelo VeronezNoch keine Bewertungen

- 5 - M Bhattacharya & DR S NarainDokument1 Seite5 - M Bhattacharya & DR S NarainMarcelo VeronezNoch keine Bewertungen

- SCO-06 FeeSched Rev18Dokument1 SeiteSCO-06 FeeSched Rev18Marcelo VeronezNoch keine Bewertungen

- 15 - S Ghosh PDFDokument1 Seite15 - S Ghosh PDFMarcelo VeronezNoch keine Bewertungen

- Wellcap Cross-Reference Tool: Well Servicing Operations-Snubbing Wct-2Sf-X - Fundamental LevelDokument6 SeitenWellcap Cross-Reference Tool: Well Servicing Operations-Snubbing Wct-2Sf-X - Fundamental LevelMarcelo VeronezNoch keine Bewertungen

- Mathcad - Roark's Formulas For Stress and Strain Table 26, Case 2aDokument2 SeitenMathcad - Roark's Formulas For Stress and Strain Table 26, Case 2aKapil Nandwana100% (1)

- Overview Offshore Support Vessels Final 1229875610432380 2 PDFDokument27 SeitenOverview Offshore Support Vessels Final 1229875610432380 2 PDFMarcelo Veronez100% (1)

- Iadc Well Control Accreditation Program (Wellcap) : Missed Portions/Amended Curriculum ReportDokument1 SeiteIadc Well Control Accreditation Program (Wellcap) : Missed Portions/Amended Curriculum ReportMarcelo VeronezNoch keine Bewertungen

- Workover Operations Wct-2Wf-X - Fundamental LevelDokument5 SeitenWorkover Operations Wct-2Wf-X - Fundamental LevelMarcelo VeronezNoch keine Bewertungen

- WCT 33 WellCAP Instructor Evaluation FormDokument2 SeitenWCT 33 WellCAP Instructor Evaluation FormMarcelo VeronezNoch keine Bewertungen

- Bulletin14-03 Instrcard 20may2014Dokument1 SeiteBulletin14-03 Instrcard 20may2014Marcelo VeronezNoch keine Bewertungen

- WCT 15 Appl Review ChecklistDokument6 SeitenWCT 15 Appl Review ChecklistMarcelo VeronezNoch keine Bewertungen

- WCT 2wlf X CrossrefDokument5 SeitenWCT 2wlf X CrossrefMarcelo VeronezNoch keine Bewertungen

- Transocean Driller: Arrivals and Departures ReportDokument1 SeiteTransocean Driller: Arrivals and Departures ReportMarcelo VeronezNoch keine Bewertungen

- ConclusionsAndRecommendationsRecap (01-01) Portuguese PDFDokument1 SeiteConclusionsAndRecommendationsRecap (01-01) Portuguese PDFMarcelo VeronezNoch keine Bewertungen

- Load Tables - Capacity Charts - Selective (VERY GOOD) PDFDokument10 SeitenLoad Tables - Capacity Charts - Selective (VERY GOOD) PDFsarbiniNoch keine Bewertungen

- Tier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)Dokument85 SeitenTier 1 Bridge Heavy Load Assessment Criteria - 2013 (Main Road)yyanan1118Noch keine Bewertungen

- Sikadur 32: Epoxy Resin Bonding AgentDokument3 SeitenSikadur 32: Epoxy Resin Bonding AgentReab SimanthNoch keine Bewertungen

- KAT-A 1912 DUOJET Edition13 02-01-2017 ENDokument6 SeitenKAT-A 1912 DUOJET Edition13 02-01-2017 ENwinston11Noch keine Bewertungen

- High Mast Foundation Layout - DiagramDokument8 SeitenHigh Mast Foundation Layout - DiagramTanveer Ahmad89% (9)

- CNG 291546Dokument3 SeitenCNG 291546ALEJANDRONoch keine Bewertungen

- CATALOG 4660-Thermoplastic HoseDokument339 SeitenCATALOG 4660-Thermoplastic HoseJose Antonio GomezNoch keine Bewertungen

- Tablas HWDPDokument1 SeiteTablas HWDPdiesarheNoch keine Bewertungen

- 10 IMS - DocumentationDokument4 Seiten10 IMS - DocumentationantivariNoch keine Bewertungen

- BCM-V U2 Part-B 19-07-2021Dokument55 SeitenBCM-V U2 Part-B 19-07-2021hyperloop707 designNoch keine Bewertungen

- Armani Casa Penthouse Floor PlanDokument4 SeitenArmani Casa Penthouse Floor PlanSarah Elles BoggsNoch keine Bewertungen

- PracticalDokument94 SeitenPracticalAshiqueHussainNoch keine Bewertungen

- Armada SamplingDokument2 SeitenArmada SamplingDavid RuizNoch keine Bewertungen

- LIFE CYCLE - Stages of An HospitalDokument10 SeitenLIFE CYCLE - Stages of An HospitalShweta SainiNoch keine Bewertungen

- Inline Slide ValveDokument1 SeiteInline Slide ValveBiswanath LenkaNoch keine Bewertungen

- Section 1720 Data - 2Dokument10 SeitenSection 1720 Data - 2Andri AjaNoch keine Bewertungen

- Pump DesignDokument23 SeitenPump DesignDidi Kurniadi100% (2)

- Attachment Ref Book - Ver1.3Dokument89 SeitenAttachment Ref Book - Ver1.3mikeNoch keine Bewertungen

- 1716,1734,1751,1769 - Highrise and Earthquake Resistant ConstructionDokument34 Seiten1716,1734,1751,1769 - Highrise and Earthquake Resistant ConstructionFAB RAHINoch keine Bewertungen

- Daily Report 05 Sept 2022Dokument2 SeitenDaily Report 05 Sept 2022t_i_f_anoNoch keine Bewertungen

- Engineering Materials PDFDokument24 SeitenEngineering Materials PDFPradeepkumarKatgiNoch keine Bewertungen

- Calex Auto Private LimitedDokument8 SeitenCalex Auto Private LimitedVishalNoch keine Bewertungen

- Space in Urban Design, Urban AestheticsDokument16 SeitenSpace in Urban Design, Urban AestheticsFritz Dela Vega100% (1)

- Ship LaddersDokument5 SeitenShip LaddersPatrick GuoNoch keine Bewertungen

- Braced FrameDokument2 SeitenBraced FrameRicha ShahNoch keine Bewertungen

- The Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesDokument15 SeitenThe Philippines, Occupational Safety and Health Standards: RULE 1140 ExplosivesRuby Arnz PagaranNoch keine Bewertungen

- Allowable Stress in PipingDokument6 SeitenAllowable Stress in PipingpelotoNoch keine Bewertungen

- Vitor Renan Vitor Gama - Dissertação (Ppgeq) 2021Dokument65 SeitenVitor Renan Vitor Gama - Dissertação (Ppgeq) 2021JatousNoch keine Bewertungen

- FP 700 EngineeringDokument8 SeitenFP 700 EngineeringCarlos Alberto VargasNoch keine Bewertungen

- ASCE - 'Astoria Tunnel Profile Under The East River'Dokument109 SeitenASCE - 'Astoria Tunnel Profile Under The East River'Colin PearceNoch keine Bewertungen