Beruflich Dokumente

Kultur Dokumente

Design of Hvac With VRF System For A Space House in Ahmedabad

Hochgeladen von

IJSTEOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Hvac With VRF System For A Space House in Ahmedabad

Hochgeladen von

IJSTECopyright:

Verfügbare Formate

IJSTE - International Journal of Science Technology & Engineering | Volume 1 | Issue 10 | April 2015

ISSN (online): 2349-784X

Design of HVAC with VRF System for a Space

House in Ahmedabad

Kartik M. Patel

PG Student

Department of Mechanical Engineering

SIRT, RGPV University Bhopal MP. India

Prof. Pushpendra K. Jain

Head of Department

Department of Mechanical Engineering

SIRT, RGPV University Bhopal MP. India

Prof. Dinesh K. Koli

Associate Professor

Department of Mechanical Engineering

SIRT, RGPV University Bhopal MP. India

Abstract

Energy is a big variation of a different site and different system. So Design is the one of the tool of a calculation and smart

integrated system So energy efficiency has been prime importance in HVAC system. I want to design of a HVAC with VRF

technology of a space house in Ahmedabad and calculate instantaneous gain, Space Load, all electrical element load, Primary

energy demand, Ventilation Load, Energy Efficiency ratio (EER) and cost.

Keywords: HVAC, VRF, EER

________________________________________________________________________________________________________

I.

INTRODUCTION

A. What Is Variable Refrigerant Flow (VRF) Systems?

Variable

: Not fixed i.e. changing

Refrigerant : The gas being used in the system

Flow

: The quantity/amount of refrigerant

Therefore in VRF, The volume of refrigerant flowing in the system is variable

Variable refrigerant flow (VRF) is an air-condition system configuration where there is one outdoor condensing unit and

multiple indoor units. The term variable refrigerant flow refers to the ability of the system to control the amount of refrigerant

flowing to the multiple evaporators (indoor units), enabling the use of many evaporators of differing capacities and

configurations connected to a single condensing unit. The arrangement provides an individualized comfort control, and

simultaneous heating and cooling in different zones.

II.

PROPOSED METHODOLOGY OF VRF SYSTEM

These are the following step for proposed Methodology of VRF system and design step.

Primary layout of the system,4 or more zone required ,Occupants can escape refrigerant leak and determine amount of

refrigerant, Suitable for climate (air cooled system most efficient which can handle outdoor temp.) Suitable of VRF

initial Cost. Room space favor of VRF limitations.

Selection of design basic(manufacture, heat pump and heat recovery), Determine heating/cooling load, Determine

ventilation load, Selection of outdoor/indoor unit, Selection of route piping and size with manufacture data,Select

control system, Write specification, Project completion according to manufacture recommendation

III.

DESIGN CONDITION, DESIGN DETAIL AND EER CALCULATION.

A. Design condition :

Location

: 42 B, Space house, Opp. Crossword, Mithakahali six Road, Ahmedabad, Gujarat.

Latitude

: 230. North.

All rights reserved by www.ijste.org

29

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

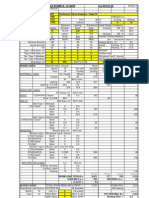

Table -3.1:

Outside design condition to various reference.

In Ahmedabad design condition (Summer)

Used by

Outside condition ASHRAE

IS

Industry

Dry bulb 0C

42.8

42.8

43.33

Wet bulb 0C

26.7

27.6

25.6

(source from Refrigeration and airconditioning by p.s.desai.)

Table -3.2:

Selection of Design Condition

In Ahmedabad as per design condition (Summer)

Condition Dry bulb 0C Wet bulb 0C %RH

Out door 43.33(1100F) 25.6(780F)

33

Indoor

23.88(750F) 17.77(640F)

55

Temp diff.

350F

B. Total Heat Load Calculation:

Table -3.3:

Total Heat Load Calculation

Component

Q (Btu/hr)

Sensible

16878.32

4409.82

68144.8

26655.05

15300

23390.64

72276

46116

273170.63

Q (Btu/hr)

Latent

Walls

Glass

Partition, Ceilings And Floors

Infiltration

27303.8

People

12300

Light

Appliances

Outside air

47238.4

Total heat

86842.2

Total Heat (sensible+latent)

360012.83

Safety factor at 10%

36001.28

Grand Total heat

396014.11 (33.00 TR) (115.5KW) (40HP)

(1 TR (tons) = 12000 BTU/HR, 200 BTU/MIN, 1.21HP, 3.5 KW..)

Supply Air Calculations

Supply air flow rate to a space is based only on the total space sensible heat load, thus

1) CFM = 1.08 x [Q sensible / (TR TS)]

2) Air change = CFM x 60/CU.FT

Where,

CFM = air flow in cubic feet per minute

Q sensible = total room sensible heat gain, BTU per hr.

TR = Room dry bulb temperature, F ( 75 )

TS = Room supply air dry bulb temperature, F ( 54 )

Total sensible heat = 273170.63

Total sq.ft = 3440

Total cu.ft = 28206.3

Table -3.4: Supply Air Calculation

C.

Supply air calculation

ERSH/ERTH

CFM

CFM / SQ.FT

TONS

CFM/TR

AIR CHANGE

0.76

14048.78

4.08

33

425.72

29.88

All rights reserved by www.ijste.org

30

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

D. Mechanical Ventilation for Duct System:

Table -3.5:

Ventilation Load Calculation

SR.

NO.

Name Of Area

Area

(Foot2)

Height

(Foot)

Volume

(Foot3)

Min

Air Change

Air Flow

(CFM)

1.0

staff room 1

127.5

1147.5

25

478

2.0

staff room 2

127.5

1147.5

25

478

3.0

Cabin 1

98.44

885.96

25

369

4.0

Cabin 2

43.75

393.75

25

164

5.0

Cabin 3

43.75

393.75

25

164

6.0

staff room 3

221

1989

25

829

7.0

staff room 4

221

1989

25

829

8.0

hub room

39.75

357.75

25

149

9.0

conference 1

70.67

636.03

25

265

10.0

conference 2

108.65

977.85

25

407

11.0

staff room 5

221

1989

25

829

12.0

staff room 6

221

1989

25

829

13.0

admin staff

80.94

728.46

25

304

14.0

meeting room

98.44

885.96

25

369

15.0

Breakout area

117.5

1057.5

25

441

16.0

inspection room

72.5

652.5

25

272

TOTAL

7175

E. Selection of Indoor Unit Capacity:

Table -3.6:

Selection of Indoor Unit Size

SR.

NO.

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

16.0

Name Of Area

staff room 1

staff room 2

Cabin 1

Cabin 2

Cabin 3

staff room 3

staff room 4

hub room

conference 1

conference 2

staff room 5

staff room 6

admin staff

meeting room

Breakout area

inspection room

TOTAL(HP)

Indoor unit size selection (HP)

4.00

4.00

1.25

1.00

1.00

5.00

5.00

1.25

1.25

1.60

5.00

5.00

1.60

1.25

1.60

1.00

40.80

All rights reserved by www.ijste.org

31

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

F. Design Of VRF System In Space House:

Fig. 1: Design of VRF System in a Space House

G. Environmental Friendly Refrigerant - R410A:

Table -3.7:

Comparison of R22and R410

R22

R410

Refrigerant

Single component refrigerant

Non-azeotropic Refrigerant

Refrigerant oil

Mineral oil

Synthetic (ether) oil

Pressure

1.9MPa*

3.0MPa*

Component properties

Contain chlorine (Cl)

Does not Contain chlorine (Cl)

H. Piping Size and Length:

Table -3.8:

Piping Length

Piping length and Ref.joint

14HP OUTDOOR

Total extension length between indoor and outdoor

180foot

Total joint no.

6

18HP OUTDOOR

212foot

8

I. Energy Efficiency of Air Conditioner:

Efficiency of a room air conditioner is normally measured as Energy Efficiency Ratio (EER), which is the ratio of the cooling

output, measured in British thermal units (Btu) per hour, to the power input (in Watts, and includes all inputs to compressor, fan

motors and controls) to operate AC at standard rating conditions. This means a higher the EER, the more efficient the air

conditioner is. At times, EER is defined a little differently. The cooling capacity instead of being denoted in Btu/hr is also

denoted in Watts (1Btu/ hr = 0.293 Watts). Thus EER is represented as Watts/ Watts or as a number without any units.

EER = cooling capacity / Power consumption (both in Watt)

EER of 33 TR (about 114400 W) capacity air conditioner consuming power 52000 W = 114400/52000 = 2.2

Star Rating System based on EER No star:2.2,1-Star: 2.3, 2-Star: 2.5, 3-Star: 2.7, 4-Star: 2.9 and 5-Star: 3.1

EER of 33 TR For VRF system in a space house maximum cooling capacity 114400W as per outdoor unit and air

conditioner consuming power 21300W = 114400/21300= 5.37

We can use following steps to calculate power consumption of your air conditioner on basis of power input required by

it.

All rights reserved by www.ijste.org

32

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

J.

I am assuming 8 hours normal working hours of air conditioner in a day.

Actually working hours of compressor in cut-in& cut-out condition is 70%.That means 70% of 8 hours=5.6

hours/day.

Electricity consumption of a 33 Ton VRF air conditioning system is 22.51KW

Actual Units of electricity consumed per day = (5.6 x 22.51) =126.06 units

Assuming electricity rate per unit (In Ahmedabad) = Rs. 4.40

Electricity consumed per day in price = (126.06 x 4.40) = Rs. 544.66

Electricity consumed per year = (Rs. 544.66 x 365) = Rs. 202452.4

Energy and Cost Saving For 33tons Split ACS At Different Star Ratings And VRF System:

Table 3.9:

Energy and Cost Saving For 33Tons Split ACS At Different Star Ratings And VRF System

Star

rating

No star

1

2

3

4

5

VRF

system

Minimum energy

efficiency Ratio (EER)

2.2

2.3

2.5

2.7

2.9

3.1

Maximum cooling

capacity (watts)

114400

114400

114400

114400

114400

114400

Input power

(watts)

52000

49739.13

45760

42370.37

39448.28

36903.23

Unit consumption per

day (KWH)

207.9

198.88

183.04

169.4

157.74

147.62

Electricity

cost/year

333887.4

319401.3

293962.2

272056.4

253330.4

237077.7

5.37

114400

21300

126.06

202452.4

IV.

APPLICATIONS FOR VRF SYSTEMS

VRF systems may be a particularly good option for buildings with multiple zones or wide variance heating/cooling loads across

many different internal zones. These systems provide individual control and are the most versatile of the multi-split systems.

Hotels, schools, hospitals, cinema hall courthouses, residential, central plant, multi-storied buildings, Commercial buildings,

office buildings, and industrial unit are good examples.

V.

ADVANTAGES, LIMITATION AND APPLICATION

A. Advantages of VRF Technology:

1) Comfort:

VRF systems are capable of simultaneous cooling and heating. Each individual indoor unit can be controlled by a programmable

thermostat. Most VRF manufacturers offer a centralized control option, which enables the user to monitor and control the entire

system from a single location or via the internet.

2) Flexible Installation:

When compared to the single split system, a VRF system reduces installation cost by about 30%. A VRF system provides

reduction in copper tubing and wiring costs.

3) VRF:

Systems are lightweight; require less outdoor plant space and offer space - saving features

4) Reliability:

Continuous operation is possible even in the event of compressor failure. There is no immediate system shutdown if trouble

occurs in any compressor. The other compressors can continue to operate on an emergency basis.

5) Aesthetics:

Indoor units are available in different capacities and multiple configurations such as wall-mounted, ceiling-mounted cassette

suspended, and concealed ducted types

All rights reserved by www.ijste.org

33

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

6) Design Flexibility:

A single condensing unit can be connected to wide range of indoor units of varying capacity (e.g., 0.5 to 6 tons ducted or

ductless configurations such as ceiling recessed, wall-mounted and floor console).

7) Energy:

VRF systems benefits from the advantages of linear step control in conjunction with inverter and constant speed compressor

combination, which allows more precise control of the necessary refrigerant circulation amount required according to the system

load.

B. Limitation of VRF Technology:

1) Refrigerant Piping:

Concerns have been raised about health, expense, and environmental impacts from refrigerant leaks. It is important that the

designer/building owner is aware of these limitations.

2) Oil Management:

As the system has a larger spread, the refrigerant pipes traverse long lengths; hence their pressure testing and protection becomes

critical. Long refrigerant piping loops also raise concerns about oil return. Typically, each compressor has its own oil separator

which is optimized for the VRF system.

3) Fresh Air Requirements:

All split systems, VRF systems do not provide ventilation of their own, so a separate ventilation system is necessary

4) Maintenance:

Regular maintenance of VRF systems consists of changing filters and cleaning coils for the fan coil units.

C. Application of VRF Technology:

Hotels, schools, hospitals, cinema hall, courthouses, residential, central plant, multi-storied buildings, Commercial buildings,

office buildings, and industrial unit are good examples.

VI.

CONCLUSIONS

The variable refrigerant flow system is considered to be one of the most promising energy saving technologies gaining its

momentum in recent years. That is a big variation of a different star rating split air conditioner and VRF system for a cost saving.

However, a viable energy efficient technology is needed to conserve energy as well as to achieve better human comfort. So this

is been relatively new and efficient way to design HVAC system with VRF technology.

ACKNOWLEDGMENT

It is indeed a pleasure for me to express my sincere gratitude to those who have always helped me for this research work. I wish

to express my gratitude to my parents, whose love and Encouragement have supported me throughout my education.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Roth, kurt, et al. energy consumption characteristics of commercial building HVAC system volume III: energy saving potential TIAX LLC FOR

DOE,2002 www.eere.gov/building/info/documents/pdfs/hvacvolume2finalreport.pdf

Hai, Xiaohong; Tao, Zhang; Yun, Fanhua; and Jun, Shen, "Design and Research of the Commercial Digital VRV Multi-Connected Units With Sub-Cooled

Ice Storage System" (2006). International Refrigeration and Air Conditioning Conference. Paper 759. http://docs.lib.purdue.edu/iracc/759

William Goetzler, Member ASHRAE, ASHRAE Journal, April 2007

Johnson

Spellman

ASHRAE

headquarters

building

renovation,

mechanicals

narrative

June26,2007.http;//images.ashrae.biz/renovation/documents/o6js22_mech_design_narrative_permit%20set_2.pdf.

Ammi Amarnath, Variable Refrigerant Flow: An Emerging Air Conditioner and Heat Pump Technology Electric Power Research Institute. Morton Blatt,

Energy Utilization Consultant 2008, ACEEE Summer Study on Energy Efficiency in Buildings.

John rogers, RESIDENTIAL CONSUMPTION OF ELECTRICITY IN INDIA Background Paper

India: Strategies for Low Carbon Growth, July 2008 The World Bank.

Qiu Tua,b, Ziping Fenga,b, Shoubo Maoc, Kaijun Donga,b, Rui Xiaoa,b, Wenji Songa Heating control strategy for variable refrigerant flow air

conditioning system with multi-module outdoor units Guangzhou Institute of Energy Conversion, Chinese Academy of Science, Guangzhou 510640,

All rights reserved by www.ijste.org

34

Design of HVAC with VRF System for a Space House in Ahmedabad

(IJSTE/ Volume 1 / Issue 10 / 006)

[8]

[9]

China b Key Laboratory of Renewable Energy and Gas Hydrate, Chinese Academy of Science, Guangzhou 510640, China c Haier Air-Conditioning

Electronic Co. LTD., Qingdao 266510, China

Li, Y.M., Wu, J.Y., and Shiochi, S., Experimental validation of the simulation

module of the water-cooled variable refrigerant flow system under cooling operation, Applied Energy, vol. 87, pp. 1513-1521, 2010.

Tolga N. Aynur Variable refrigerant flow systems: A review, Center for Environmental Energy Engineering, Department of Mechanical Engineering,

University of Maryland, 3157 Glenn Martin Hall Building, College Park, MD 20742, USA.

[10] Brian Thornton ,Senior Researcher, Pacific Northwest National Laboratory, Green Proving Ground Program www.gsa.gov/gpg or Variable Refrigerant

Flow Systems which is available from the GPG program website, www.gsa.gov/gpg. December 2012.

[11] Daikin AC. www.daikinac.com.

[12] Goetzler, W. (2007). Variable refrigerant flow systems. ASHRAE Journal.

[13] VARIABLE REFRIGERANT FLOW SYSTEMS Technology Overview ASHRAE NB/PEI,SEPTEMBER 2011 Roger Nasrallah, ing. Enertrak inc.

[14] HVAC Variable Refrigerant Flow Systems BY A BHATIA. Continuing Education and Development, Inc. 9 Greyridge Farm Court Stony Point, NY 10980

[15] Bonneville Power Administration Prepared by: 570 Kirkland Way, Suite 200 Kirkland, Washington 98033

[16] Refrigeration and Air-Conditioning BY P.S.DESAI

[17] Refrigeration and Air-Conditioning BY R.S.KHURMI

WEBSITE:

http://www.daikinac.com

http://www.ashrae.in

http://www.daikinindia.com

http://www.energy.gov.on.ca/index.cfm?fuseaction=conservation.tips

http://www.energystar.gov

http://www1.eere.energy.gov/buildings/appliance_standards/residential/central_ac_hp.html

http://www.digit.in/forum/consumerelectronicseverythingelse/171373reviewsharpahxp18mv15tonecoinverterairconditioner.

All rights reserved by www.ijste.org

35

Das könnte Ihnen auch gefallen

- Canadair Regional Jet 100/200 - Automatic Flight Control SystemDokument28 SeitenCanadair Regional Jet 100/200 - Automatic Flight Control Systemmamon113Noch keine Bewertungen

- Ca Va de SoiDokument15 SeitenCa Va de SoiManideep SrirangamNoch keine Bewertungen

- Descon FormatDokument15 SeitenDescon FormatKhuda BukshNoch keine Bewertungen

- Heat TransferDokument1 SeiteHeat TransferhuangjlNoch keine Bewertungen

- Well Control: BOP Accumulator Unit (Koomey Unit)Dokument12 SeitenWell Control: BOP Accumulator Unit (Koomey Unit)faraj100% (1)

- MRI Formulas ConversionsDokument1 SeiteMRI Formulas ConversionsJoey ManlangitNoch keine Bewertungen

- R&AC Lecture 30Dokument17 SeitenR&AC Lecture 30Denise Koh Chin HuiNoch keine Bewertungen

- C.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFDokument10 SeitenC.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFErGiteshAroraNoch keine Bewertungen

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDokument5 SeitenSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuNoch keine Bewertungen

- Calculation of Induction Motor Starting Parameters Using MatlabDokument6 SeitenCalculation of Induction Motor Starting Parameters Using MatlabДејан ПејовскиNoch keine Bewertungen

- Steel Design DocumentDokument198 SeitenSteel Design Documentpudumai100% (5)

- Cooling Towers Design and Operation ConsiderationsDokument8 SeitenCooling Towers Design and Operation ConsiderationsThieuhuyen Ky100% (1)

- BSE 3712 HVAC System Design for Commercial BuildingDokument19 SeitenBSE 3712 HVAC System Design for Commercial BuildingChan Tsz HimNoch keine Bewertungen

- Cooling and dehumidifying heat load estimateDokument149 SeitenCooling and dehumidifying heat load estimateHenry San PedroNoch keine Bewertungen

- Bell-Coleman Refrigeration Cycle ProblemsDokument10 SeitenBell-Coleman Refrigeration Cycle ProblemsBalvinderNoch keine Bewertungen

- Key HVAC Design ConceptsDokument45 SeitenKey HVAC Design ConceptsSatyam BhardwajNoch keine Bewertungen

- ACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDFDokument5 SeitenACMV DESIGN: Sample Heat Load Calculation For General Office Meeting Room PDFVenkates AdhinarayananNoch keine Bewertungen

- Compressed Air Supply: Training NotesDokument22 SeitenCompressed Air Supply: Training NotesardianalimNoch keine Bewertungen

- 1Dokument3 Seiten1ntt_121987Noch keine Bewertungen

- HVAC Designing Course Presentation S-1,2 PDFDokument106 SeitenHVAC Designing Course Presentation S-1,2 PDFNaqqash SajidNoch keine Bewertungen

- Double Pipe Heat Exchanger - Excel CalculationsDokument4 SeitenDouble Pipe Heat Exchanger - Excel CalculationsMmmmohNoch keine Bewertungen

- Designing Dedicated Outdoor Air SystemsDokument4 SeitenDesigning Dedicated Outdoor Air Systemsrogel_ganaNoch keine Bewertungen

- L P - The Dear Departed-Drama-10thDokument5 SeitenL P - The Dear Departed-Drama-10thVritika Shorie100% (2)

- Pan Humidifier CalculaitonDokument1 SeitePan Humidifier CalculaitonAshok KrishnamurthyNoch keine Bewertungen

- Vietnam ProjosDokument271 SeitenVietnam Projosjbart252Noch keine Bewertungen

- SAFID Acoustics: Source Sound Power LevelDokument1 SeiteSAFID Acoustics: Source Sound Power LevelRama Lakshmi SaradhiNoch keine Bewertungen

- Machinery Room Ventilation Analysis ToolDokument48 SeitenMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNoch keine Bewertungen

- Design of Ventilation SystemsDokument5 SeitenDesign of Ventilation SystemsSimon LaurentNoch keine Bewertungen

- Air-Conditioning Load EstimationDokument23 SeitenAir-Conditioning Load Estimationtkm2004Noch keine Bewertungen

- Energy Management Tutorial SolutionsDokument9 SeitenEnergy Management Tutorial SolutionsLucas LentzNoch keine Bewertungen

- Cooling Load Calculations: Sample Project Date: Cabin 150 (SQFT) 10 (FT) 1500Dokument3 SeitenCooling Load Calculations: Sample Project Date: Cabin 150 (SQFT) 10 (FT) 1500HARISH VERMANoch keine Bewertungen

- HPT Optimizing Outside Air With HPTDokument11 SeitenHPT Optimizing Outside Air With HPTNGUYEN QUANGNoch keine Bewertungen

- AC V For Fast Food RestaurantsDokument4 SeitenAC V For Fast Food Restaurantselijah namomoNoch keine Bewertungen

- Technical Handbook Air CurtainsDokument13 SeitenTechnical Handbook Air Curtainsaca111111Noch keine Bewertungen

- Boiler Pumps Fans Sizing CalculationsDokument4 SeitenBoiler Pumps Fans Sizing CalculationsFarrahxviiiNoch keine Bewertungen

- Air ConditioningDokument72 SeitenAir ConditioningNIKNoch keine Bewertungen

- Guide To Build Steam RoomDokument2 SeitenGuide To Build Steam RoomsidNoch keine Bewertungen

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDokument5 SeitenGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaNoch keine Bewertungen

- Geothermal HVAC - : Exceeding ASHRAE Standards at Lowest Life Cycle CostDokument11 SeitenGeothermal HVAC - : Exceeding ASHRAE Standards at Lowest Life Cycle CostKagitha TirumalaNoch keine Bewertungen

- Building Heat Loss Building Heat Gain: 1000Xbtu/H 1000Xbtu/H 1000Xbtu/HDokument69 SeitenBuilding Heat Loss Building Heat Gain: 1000Xbtu/H 1000Xbtu/H 1000Xbtu/HFarid FarjadNoch keine Bewertungen

- امثلةعلى الدورة الشتويةDokument7 Seitenامثلةعلى الدورة الشتويةkarrar AilNoch keine Bewertungen

- ORC Working Fluids Comparison ECOS PresentationDokument16 SeitenORC Working Fluids Comparison ECOS Presentationoverlord5555Noch keine Bewertungen

- RAC Data BookDokument130 SeitenRAC Data BookFaisal Ahmmed FahimNoch keine Bewertungen

- Mech3005 Lab1112 Fancoil PDFDokument5 SeitenMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- Waste Heat Recovery (Mech-31)Dokument18 SeitenWaste Heat Recovery (Mech-31)shammiNoch keine Bewertungen

- Ref Pipe Sizing Ver 02 21 11Dokument12 SeitenRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- IRR Calculation Sheet For Auto LoansDokument8 SeitenIRR Calculation Sheet For Auto LoansmskharadeNoch keine Bewertungen

- 5.6 Schedule of Electrical RequirementsDokument7 Seiten5.6 Schedule of Electrical RequirementsFaquruddin AliNoch keine Bewertungen

- 02 Cooling Load Calculation - HAPDokument2 Seiten02 Cooling Load Calculation - HAPU DEEPAKNoch keine Bewertungen

- HRW SelectionDokument2 SeitenHRW SelectionGohdsNoch keine Bewertungen

- HVAC Cooling Load Estimate SheetDokument1 SeiteHVAC Cooling Load Estimate SheetideepujNoch keine Bewertungen

- Duct Metal Take-Off SheetDokument2 SeitenDuct Metal Take-Off SheetpratheeshNoch keine Bewertungen

- Fans Static Head Calculation SheetDokument1 SeiteFans Static Head Calculation SheetraifaisalNoch keine Bewertungen

- RTS Example Montreal ASHRAE Chapter 6oct2003Dokument26 SeitenRTS Example Montreal ASHRAE Chapter 6oct2003Sid KherNoch keine Bewertungen

- Tube Wire Vs Wall Condenser PDFDokument15 SeitenTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- CO2 Sensor RoomDokument8 SeitenCO2 Sensor RoomTrần Khắc ĐộNoch keine Bewertungen

- Fan Fundamentals - Greenheck (May2005)Dokument24 SeitenFan Fundamentals - Greenheck (May2005)jagdishgharoteNoch keine Bewertungen

- Air Leakage Through Automatic DoorsDokument5 SeitenAir Leakage Through Automatic DoorsstranfirNoch keine Bewertungen

- Sealant - 1st Acrylic A-700 MSDSDokument6 SeitenSealant - 1st Acrylic A-700 MSDSBozow BongNoch keine Bewertungen

- PRICE - Air Distribution GuideDokument5 SeitenPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Dokument1 SeiteRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNoch keine Bewertungen

- Water-Cooled Series R (TM) RTHD Product ReportDokument2 SeitenWater-Cooled Series R (TM) RTHD Product ReporttrangocvuNoch keine Bewertungen

- Aircraft Flying Project (PRINT OUT)Dokument24 SeitenAircraft Flying Project (PRINT OUT)Priyanka KumariNoch keine Bewertungen

- Free Cooling Types and ControlsDokument2 SeitenFree Cooling Types and ControlsHnin PwintNoch keine Bewertungen

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Von EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Noch keine Bewertungen

- HVAC VRF DesignDokument7 SeitenHVAC VRF DesignrkibNoch keine Bewertungen

- PPPTS777774 222worddDokument28 SeitenPPPTS777774 222worddsuman chandNoch keine Bewertungen

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDokument4 SeitenFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTENoch keine Bewertungen

- Design and Analysis of Magneto Repulsive Wind TurbineDokument7 SeitenDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENoch keine Bewertungen

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Dokument8 SeitenAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTENoch keine Bewertungen

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDokument8 SeitenOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTENoch keine Bewertungen

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDokument9 SeitenMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTENoch keine Bewertungen

- A Mixture of Experts Model For ExtubationDokument4 SeitenA Mixture of Experts Model For ExtubationIJSTENoch keine Bewertungen

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDokument9 SeitenOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTENoch keine Bewertungen

- RFID Based Toll Gate AccessDokument5 SeitenRFID Based Toll Gate AccessIJSTENoch keine Bewertungen

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDokument6 SeitenA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTENoch keine Bewertungen

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDokument7 SeitenPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENoch keine Bewertungen

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDokument6 SeitenDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENoch keine Bewertungen

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDokument9 SeitenEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENoch keine Bewertungen

- A Cloud Based Healthcare Services For Remote PlacesDokument4 SeitenA Cloud Based Healthcare Services For Remote PlacesIJSTENoch keine Bewertungen

- A Radar Target Generator For Airborne TargetsDokument8 SeitenA Radar Target Generator For Airborne TargetsIJSTENoch keine Bewertungen

- Enriching Gum Disease Prediction Using Machine LearningDokument6 SeitenEnriching Gum Disease Prediction Using Machine LearningIJSTENoch keine Bewertungen

- Optimum Placement of DG Units Using CPF MethodDokument6 SeitenOptimum Placement of DG Units Using CPF MethodIJSTENoch keine Bewertungen

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDokument4 SeitenOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTENoch keine Bewertungen

- The Bicycle As A Mode Choice - A Gendered ApproachDokument4 SeitenThe Bicycle As A Mode Choice - A Gendered ApproachIJSTENoch keine Bewertungen

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDokument6 SeitenApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTENoch keine Bewertungen

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDokument7 SeitenComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTENoch keine Bewertungen

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDokument5 SeitenAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENoch keine Bewertungen

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDokument6 SeitenUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENoch keine Bewertungen

- Technology Advancement For Abled PersonDokument9 SeitenTechnology Advancement For Abled PersonIJSTENoch keine Bewertungen

- Onerider The Bike TaxiDokument3 SeitenOnerider The Bike TaxiIJSTENoch keine Bewertungen

- Interstage Construction Techniques For Mass Gain: An OverviewDokument5 SeitenInterstage Construction Techniques For Mass Gain: An OverviewIJSTENoch keine Bewertungen

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDokument6 SeitenWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENoch keine Bewertungen

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDokument6 SeitenResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENoch keine Bewertungen

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDokument5 SeitenAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENoch keine Bewertungen

- Duplicate Detection Using AlgorithmsDokument3 SeitenDuplicate Detection Using AlgorithmsIJSTENoch keine Bewertungen

- Evadeee ReadmeDokument11 SeitenEvadeee Readmecostelmarian2Noch keine Bewertungen

- API 620 Vs API 650 Steel Oil Storage TanksDokument2 SeitenAPI 620 Vs API 650 Steel Oil Storage TanksBogdan ChivulescuNoch keine Bewertungen

- Chapter 8-Stringing and Miscellaneous WorksDokument3 SeitenChapter 8-Stringing and Miscellaneous Workschintan pandyaNoch keine Bewertungen

- Preliminary Hazard Identification: Session 3Dokument19 SeitenPreliminary Hazard Identification: Session 3Isabela AlvesNoch keine Bewertungen

- Blaze Magazine VOL 04 ISSUE 09Dokument28 SeitenBlaze Magazine VOL 04 ISSUE 09Sunway UniversityNoch keine Bewertungen

- 2012 Price Schedule Fiberfrax Durablanket 2600 - UnifraxDokument2 Seiten2012 Price Schedule Fiberfrax Durablanket 2600 - UnifraxMagin Idelfonso TorreblancaNoch keine Bewertungen

- Covey Stephen RDokument90 SeitenCovey Stephen RcemgallNoch keine Bewertungen

- Machine Design ME 314 Shaft DesignDokument14 SeitenMachine Design ME 314 Shaft DesignMohammed AlryaniNoch keine Bewertungen

- ATAL FDP On The Role of Materials in Electric Vehicles Workshop - ReportDokument12 SeitenATAL FDP On The Role of Materials in Electric Vehicles Workshop - ReportPuneet Mohan SharmaNoch keine Bewertungen

- Bhatia CPD 20001Dokument1 SeiteBhatia CPD 20001bilalaimsNoch keine Bewertungen

- Items List ProcessorDokument4 SeitenItems List ProcessorDiego Escobar MoncadaNoch keine Bewertungen

- Sony MP3 NWZ B143F ManualDokument82 SeitenSony MP3 NWZ B143F ManualdummihaiNoch keine Bewertungen

- Anshul BhelDokument96 SeitenAnshul BhelMessieurs Avinash PurohitNoch keine Bewertungen

- Modules Test ReportDokument4 SeitenModules Test ReportprojectsNoch keine Bewertungen

- Underground Cable Ampacity With Neher McGrathDokument7 SeitenUnderground Cable Ampacity With Neher McGrathJesus RodriguezNoch keine Bewertungen

- TNEB vacancy cut-off datesDokument7 SeitenTNEB vacancy cut-off dateswinvenuNoch keine Bewertungen

- Personal PositioningDokument4 SeitenPersonal PositioningJaveria MasoodNoch keine Bewertungen

- Executive Synopsis Internet BankingDokument8 SeitenExecutive Synopsis Internet BankingSweta PandeyNoch keine Bewertungen

- AUC-Knowledge QuestionsDokument68 SeitenAUC-Knowledge QuestionsFarhan SethNoch keine Bewertungen

- Noise Barriers Standards FrameworkDokument50 SeitenNoise Barriers Standards FrameworkanandalaharNoch keine Bewertungen

- Seah 1998Dokument299 SeitenSeah 1998Wallison MedeirosNoch keine Bewertungen

- Aiou Code 1423 Solved Assignment 1 Autumn 2017, Code 1423 PDFDokument4 SeitenAiou Code 1423 Solved Assignment 1 Autumn 2017, Code 1423 PDFtelecom_numl82330% (2)