Beruflich Dokumente

Kultur Dokumente

Ut 88-94

Hochgeladen von

bhavin178Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ut 88-94

Hochgeladen von

bhavin178Copyright:

Verfügbare Formate

Special Metal Casting and Forming Processes

CAFP - 2008

MODERN ULTRASONIC TECHNIQUES FOR DEFECT DETECTION

IN CAST MATERIALS

S. Palit Sagar

National Metallurgical Laboratory, Jamshedpur 831007

e-mail : sarmi@nmlindia.org

INTRODUCTION

In casting flaw detection is exclusively concerned with manufacturing defects. The typical cast

defects are (i) shrinkage cavities which form during solidification as a result of the reduction in

volume when metal changes from the liquid to the solid state. Shrinkage cavities occur in situations

where molten metal is not available to compensate for the volume decrease during solidification,

(ii) porosity and gas holes; porosity is small smooth-faced cavities, generally smaller than 1.5 mm

diameter, usually caused by the release of gas from the molten metal as it cools. Gas holes are also

smooth-faced cavities but greater than 1.5 mm diameter. Typical causes of gas holes are evolution

of gas from molten metal during solidifications, gas trapped as the molten metal enters the mould

etc. (iii) hot tears; these are jagged crack type defects resulting from stresses imposed on the cast

metal when it is just below the solidification temperature and so is in a weak condition. The stresses

usually arise when the casting is restrained during contraction by the mould, or by an already solid

thinner section. The defect occurs mainly at or near a change of section and may or may not extend

to the surface, (iv) cracks; these are discontinuities due to the fracture of the metal during or after

solidification, (v) inclusions; these are foreign non-metallic materials such as sand or slag trapped

within the cast metal, (vi) cold shuts; these are basically 'lack of fusion' defect caused by the failure

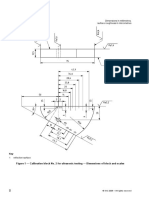

Fig. 1 : Typical casting defects and their detection methods by UT

88

Special Metal Casting and Forming Processes

CAFP - 2008

ofa stream of molten metal to form a continuous bond with a second stream, or solid metal such as

an internal chill or splash. They are most prevalent in thin-walled castings. Various casting defects

as described above are shown in Fig. 1[i].

At present liquid penetrant (LPI), magnetic particle inspection (MPI), x-ray radiography (RT)

and ultrasonic (UT) testing are used in different areas of the casting industries. All these techniques

are briefly described below[31.

VARIOUS NDT TECHNIQUES FOR DEFECT DETECTION IN CAST MATERIALS

Liquid Penetrant Inspection (LPI)

Liquid (or dye) penetrant inspection is an extension of visual inspection and is used for detecting

surface-breaking flaws, such as cracks, laps and folds, on any non-absorbent material's surface.

The various stages of LPI are shown in Fig. 2. In this technique, the surface to be inspected is

cleaned thoroughly to remove dirt and grease. A brightly coloured or fluorescent liquid is then

UV lamp

visible

Fig. 2 : Various stages of Penetrant testing: (A) Sample before testing;

(B) Liquid penetrant applied; (C) Surplus wiped off leaving penetrant in crack;

(D) Developer powder applied, dye soaks into powder; (E) View coloured indications, or

UV lamp shows up fluorescent indications

applied liberally to the component surface and allowed to penetrate any surface-breaking cracks

or cavities. The time the liquid is allowed to soak into the material's surface is normally about 20

minutes. After soaking, the excess liquid penetrant is wiped from the surface and a developer

applied. The developer is usually a dry white powder, which draws penetrant out of any cracks

by reverse capillary action to produce indications on the surface. These (coloured) indications

are broader than the actual flaw and are therefore more easily visible.

A number of different liquid penetrant systems are used in industry. Fluorescent penetrants are

normally used when the maximum flaw sensitivity is required. In cast materials LPI is used to

detect defects like hot tears, stress cracks, cold shuts etc.

89

Special Metal Casting and Forming Processes

CAFP - 2008

Magnetic Particle Inspection (MPI)

Magnetic particle inspection (MPI) is used for the detection of surface and near-surface flaws in

ferromagnetic materials. A magnetic field is applied to the specimen, either locally or overall,

using a permanent magnet or electromagnet. If the material is flawless, most of the magnetic

flux is concentrated below the material's surface. However, ifa flaw is present, such that it interacts

with the magnetic field, the flux is distorted locally and 'leaks' from the surface of the specimen

in the region of the flaw. Fine magnetic particles, applied to the surface of the specimen, are

attracted to the area of flux leakage, creating a visible indication of the flaw. The materials

commonly used for this purpose are black iron particles and red or yellow iron oxides. In some

cases, the iron particles are coated with a fluorescent material enabling them to be viewed under

a UV lamp in darkened conditions (Fig. 3). MPI is used to detect defects like hot tears, stress

cracks, cold shuts etc. in ferromagnetic cast materials.

Black light

Crack

Visual

1'.1

Ferromagnetic

materials

Crack disrupts

magnetic field

Magnetic particles held by

disrupted magnetic field

Visual crack detection by

color contrast or 4uorescenco

in *black light"

Fig 3 : Principle of Magnetic Particle Inspection (MPI)

Radiography Testing (RT)

Radiography is the technique of obtaining a shadow image ofa solid using penetrating radiation

such as X-rays or gamma rays. This technique involves the use of penetrating gamma or XN,Radiation

source

Test piece

(object)

Medium Far

converting

the radiation

Fig. 4 : Principle of producing shadowgraph of objects using RT

90

Special Metal Casting and Forming Processes

CAFP - 2008

radiation to examine parts and products for imperfections. An X-ray machine or radioactive

isotope is used as a source of radiation. Radiation is directed through a part and onto film or

other media. The resulting shadowgraph shows the internal soundness ofthe part (Fig. 4). Possible

imperfections are indicated as density changes in the film in the same manner as X-ray shows

broken bonest41.

Radiographic applications fall into two distinct categories: (i) evaluation of material properties

and (ii) evaluation of manufacturing and assembly properties. Material property evaluation

includes the determination of composition, density, uniformity, and cell or particle size.

Manufacturing and assembly property evaluation is normally concerned with dimensions, flaws

(voids, inclusions, and cracks), bond integrity (welds, brazes, etc.), and verification of proper

assembly of component pieces.

Radiography is the preferred NDT technique for the detection of porosity, gas holes, shrinkage

cavities, air locks and inclusions in cast materials.

Computed Tomography (CT)

Computed Tomography (CT) is a powerful non-destructive evaluation (NDE) technique for

producing 2 - D and 3 - D cross-sectional images of an object from flat X-ray images.

Characteristics ofthe internal structure of an object such as dimensions, shape, internal defects,

and density are readily available from CT images.

Ultrasonic Testing (UT)

Ultrasonic technique utilizes frequency of sound waves beyond human hearing (>20kHz) as a

beam of illumination and measures the reflected beams from defects, inhomogeneities or the

back wall ofthe test material. UT is the most widely used NDT technique in industries for product

quality control compared to any other NDT methods. Basically, ultrasonic waves are emitted

from a transducer into an object and the returning waves are analyzed. If an impurity or a crack

is present, the sound will bounce off of them and be seen in the returned signal. A transducer

made of a crystalline material with piezoelectric properties, such as quartz is used to generate

ultrasonic waves. When electricity is applied to piezoelectric materials, they begin to vibrate,

using the electrical energy to create movement. The waves travel in every direction from the

source. To keep the waves from going backwards into the transducer and interfering with its

reception of returning waves, an absorptive material is layered behind the crystal. Thus, the

ultrasound waves only travel outward. Ultrasonic measurements can be used to determine the

thickness of materials and determine the location of a discontinuity within apart or structure by

accurately measuring the time required for an ultrasonic pulse to travel through the material and

reflect from the back surface or the discontinuity. When the mechanical sound energy comes

91

CAFP - 2008

Special Metal Casting and Forming Processes

back to the transducer, it is converted into electrical energy. Just as the piezoelectric crystal

converted electrical energy into sound energy, it can also do reverse. The mechanical vibration

in the material couple to the piezoelectric crystal, which is in turn, generates electrical current.

In pulse-echo (P/E) mode of ultrasonic testing, single transducer is used as transmitter as well as

receiver, which is placed on the test material. A good couplant (oil, water, vaseline etc) is required for

proper coupling between the transducer and test material. A pulser is used to send electrical pulse to

the transducer. The priciple of operation of ultrasonic system in PIE mode is shown in Fig. 5.

Pulser/Receiver

Transducer

Initial Pulso

Back Surface

Echo

Crack

Echo

Plate

10 12

Fig. 5 : Principle of ultrasonic testing in Pulse-Echo mode

In cast materials, ultrasonic can be used to detect porosity, gas holes, shrinkage cavities, air locks

and inclusions with proper selection of frequency because ofthe coarser grain size. Coarse grains

give rise to scattering of signals, which in turn highly attenuates the signalE51. Hence, for very

coarse castings conventional ultrasonic testing is not suitable.

Modern approach in ultrasonic

Scattering ofultrasound at grain and phase boundaries in polycrystalline multiphase and/or porous

materials causes attenuation and dispersive sound velocities. High-frequency ultrasonic

backscattering signals are presently being explored for materials characterization and for the

detection and evaluation of defects. Fig. 6 shows a schematic sketch of ultrasonic backscattering

at pores and grain boundaries using a focusing probe. Porosity or single pores can only be detected

when their scattering signals do not vanish within the background signal of the grain noise[6'7].

92

Special Metal Casting and Forming Processes

CAFP - 2008

Fig. 6 : Schematic representation of ultrasonic backscattering at pores and grain boundaries

using a focusing probe (Z = focal length, dsc = focus diameter, D = probe diameter).

It has been found that the detection and evaluation of defects (pores) close to the surface up to about

2 mm depth in die-casting components of complicated shape, only the analysis of ultrasonic

backscattering is promisingE6]. Fig. 7 demonstrates a robot scanning UT system which learns the

geometry ofa component before testing complicated shapes ofthe parts and Fig. 8 depicts the detection

of pores in Al dye casting using the ultrasonic back scattering with the same scanning system.

Robot control unit

PC's for Data Acquisition and

Data analysis

1

US-Transmitter

Digital Oscilloscope

Transducer

IComponent to

be tested

Fig. 7 : Robot controlled high frequency ultrasonic test system

og_.

Position x [mrn]

10 15 29 25

30

35

4p

5-

10 15

Position x [mm]

Fig. 8 : C-Scan of Al dye casting at a depth of (a) 0.5 mm and (b) 1 mm

93

Special Metal Casting and Forming Processes

CAFP - 2008

CONCLUSION

This paper describes various NDT techniques used for defect detection in cast materials. It has

also been shown that the recent approach to apply high frequency ultrasonic backscattering

technique can overcome the limitations of conventional ultrasonic technique for very coarse

casting in detecting small defects.

REFERENCES

1.

Ultrasonic Testing of materials Book; J. Krautkramer & H. Krautkramer, 4th edition,

publisher Springer, 1998

2.

Nondestructive evaluation,Theory, Techniques and Applications,edited by Peter J Shull,

Marcel Dekker, 2002.

3.

Non-destructive testing Book; Louis Cartz, ASM International

4.

C.M. Sayers and R.L. Smith, "The Propagation of Ultrasound in Porous-Media",

Ultrasonics 20, 201-205 (1982).

5.

http://www.engineershandbook.com/MfgMethods/ndtrt.htm

6.

S. Hirsekorn, U. Rabe, D. Bruche, N. Grov, T. Kinzler, W. Arnold," High-frequency

ultrasonic porosity testing of non-ferrous metal die-casting components", Casting

International, 4, 28-33 (2007)

7.

Suresh Palanisamy, Ultrasonic Inspection of Sub-Surface Defects In Aluminium DieCastings, www.swin.edu.au/iris/pdf/profiles/SureshPalanisamy.pdf

94

Das könnte Ihnen auch gefallen

- Feeding Systems FosecoDokument12 SeitenFeeding Systems Fosecobhavin178Noch keine Bewertungen

- Steel Grades HandbookDokument6 SeitenSteel Grades Handbookbhavin178Noch keine Bewertungen

- Special Alloy Steel MaterialsDokument8 SeitenSpecial Alloy Steel Materialsbhavin178Noch keine Bewertungen

- BS EN ISO 9934-1 Current CalculationDokument3 SeitenBS EN ISO 9934-1 Current Calculationbhavin178Noch keine Bewertungen

- EN 1369:2012 (E) DIN EN 1369:2013-01: 5.2.1 GeneralDokument1 SeiteEN 1369:2012 (E) DIN EN 1369:2013-01: 5.2.1 Generalbhavin178100% (1)

- Quality Management System (QMS) ManualDokument28 SeitenQuality Management System (QMS) Manualbhavin178100% (8)

- DIN EN 1369-Acceptance TableDokument2 SeitenDIN EN 1369-Acceptance Tablebhavin178Noch keine Bewertungen

- Table A.2 - Image Quality Requirements For Testing Class B: BS EN 12681-1:2017Dokument1 SeiteTable A.2 - Image Quality Requirements For Testing Class B: BS EN 12681-1:2017bhavin178Noch keine Bewertungen

- BS EN ISO 9934-1-Type of MagnetizationDokument3 SeitenBS EN ISO 9934-1-Type of Magnetizationbhavin178Noch keine Bewertungen

- Annex E Severity Levels For Copper Alloy Castings: (Normative)Dokument2 SeitenAnnex E Severity Levels For Copper Alloy Castings: (Normative)bhavin178Noch keine Bewertungen

- Annex D Severity Levels For Aluminium Alloy and Magnesium Alloy CastingsDokument2 SeitenAnnex D Severity Levels For Aluminium Alloy and Magnesium Alloy Castingsbhavin178Noch keine Bewertungen

- BS EN ISO 9934-1 Current RectificationDokument1 SeiteBS EN ISO 9934-1 Current Rectificationbhavin178Noch keine Bewertungen

- BS en 12681-1:2017Dokument2 SeitenBS en 12681-1:2017bhavin178Noch keine Bewertungen

- EN 12681-1-IQI - ClassADokument1 SeiteEN 12681-1-IQI - ClassAbhavin178Noch keine Bewertungen

- Complete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface FinishDokument15 SeitenComplete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface Finishbhavin178Noch keine Bewertungen

- EN ISO 7963 - Calibration Block No.2 PDFDokument1 SeiteEN ISO 7963 - Calibration Block No.2 PDFbhavin178Noch keine Bewertungen

- BS en Iso 16826-2014 PDFDokument26 SeitenBS en Iso 16826-2014 PDFbhavin178Noch keine Bewertungen

- ISO 2400-Calibration Block No.1Dokument1 SeiteISO 2400-Calibration Block No.1bhavin178Noch keine Bewertungen

- Materials and Melt: Batching SmeltingDokument4 SeitenMaterials and Melt: Batching Smeltingbhavin178Noch keine Bewertungen

- FANUC at IMTEX FORMING - 2016 21 26 January, 2016Dokument1 SeiteFANUC at IMTEX FORMING - 2016 21 26 January, 2016bhavin178Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Errors in Chemical Analysis - Lecture 3Dokument20 SeitenErrors in Chemical Analysis - Lecture 3Acidri AbdulkarimNoch keine Bewertungen

- Unstable Formation and Sand ControlDokument17 SeitenUnstable Formation and Sand ControlHafiz AsyrafNoch keine Bewertungen

- Analysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerDokument7 SeitenAnalysis of Biodiesel Combustion in A Boiler With A Pressure Operated Mechanical Pulverisation BurnerSyahriRomadhoniNoch keine Bewertungen

- Ch. 3 Molecules of Life Review-2008Dokument3 SeitenCh. 3 Molecules of Life Review-2008Nopporn SaSaNoch keine Bewertungen

- Art 2Dokument15 SeitenArt 2Solams CastilloNoch keine Bewertungen

- AS May 2024Dokument1 SeiteAS May 2024tonimatanjimevaNoch keine Bewertungen

- Biology Paper 1Dokument32 SeitenBiology Paper 1Cameron DaviesNoch keine Bewertungen

- TorsionDokument30 SeitenTorsionVedasheershBoorla67% (3)

- Liver Metabolism: Liver Is The Chief Metabolic Organ of Our BodyDokument123 SeitenLiver Metabolism: Liver Is The Chief Metabolic Organ of Our Bodymex Gbrekorkos100% (1)

- Solar Flat Plate CollectorDokument6 SeitenSolar Flat Plate CollectorVenkataramanLakshminarayananNoch keine Bewertungen

- Name: Grade 12 - AMETHYST Date: April 23, 2021 1 Summative Exam - Physical Science (Quarter 3)Dokument1 SeiteName: Grade 12 - AMETHYST Date: April 23, 2021 1 Summative Exam - Physical Science (Quarter 3)Jeff Tristan CaliganNoch keine Bewertungen

- Safety-Sup E 02 PDFDokument69 SeitenSafety-Sup E 02 PDFEliseo GonzalezNoch keine Bewertungen

- Clinical Nutrition KatalogDokument37 SeitenClinical Nutrition KatalogGab ParagasNoch keine Bewertungen

- Systems Our Know HowDokument24 SeitenSystems Our Know HowRizky Bagas PermanaNoch keine Bewertungen

- Mil DTL 244BDokument29 SeitenMil DTL 244BTri DoNoch keine Bewertungen

- Aci 318-02Dokument3 SeitenAci 318-02Fiorella CondorNoch keine Bewertungen

- Vulcanization of Rubber (Autosaved) .pptx234Dokument14 SeitenVulcanization of Rubber (Autosaved) .pptx234Koundinya ManchiNoch keine Bewertungen

- FIITJEE AITS PAPER2 MDokument23 SeitenFIITJEE AITS PAPER2 MshreyashNoch keine Bewertungen

- Flux 5000 Manual PDFDokument39 SeitenFlux 5000 Manual PDFDuban Mihai86% (7)

- For GATE and Computer General Knowledge Questions AnswersDokument10 SeitenFor GATE and Computer General Knowledge Questions Answersseeralan balakrishnanNoch keine Bewertungen

- Norton Lubricating OilDokument5 SeitenNorton Lubricating OilRajesh BNoch keine Bewertungen

- Performance Evaluation of Solar Stills: January 2018Dokument5 SeitenPerformance Evaluation of Solar Stills: January 2018Siva RajNoch keine Bewertungen

- BMMV1013 Lab 2 20212022 2Dokument17 SeitenBMMV1013 Lab 2 20212022 2Blue BeatleNoch keine Bewertungen

- Customs and Border Protection: Keeping The Public Safe-And Commerce Moving - With Handheld Checkpoint SolutionsDokument2 SeitenCustoms and Border Protection: Keeping The Public Safe-And Commerce Moving - With Handheld Checkpoint SolutionsWacel HamaniNoch keine Bewertungen

- Heavy MetalsDokument841 SeitenHeavy MetalsAnonymous EzNMLt0K4CNoch keine Bewertungen

- Effluent ToxicityDokument7 SeitenEffluent ToxicityKrishnakumar P KadinjappalliNoch keine Bewertungen

- Shaft WorkDokument20 SeitenShaft WorkEdward MorganNoch keine Bewertungen

- Lurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMDokument14 SeitenLurgi 2001 Methanol Casale Experience With A Russian Methanol Project FIMFer MugrabiNoch keine Bewertungen

- HGE-PyramidSeries BrochureDokument4 SeitenHGE-PyramidSeries BrochureCesar HernandezNoch keine Bewertungen

- FLOWTEK - Ficha Tecnica-ComprimidoDokument8 SeitenFLOWTEK - Ficha Tecnica-ComprimidoJosé BrionesNoch keine Bewertungen