Beruflich Dokumente

Kultur Dokumente

DC Machines

Hochgeladen von

Glen Howell Panes0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten3 SeitenConstruction of DC gen

Originaltitel

Dc Machines

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenConstruction of DC gen

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

37 Ansichten3 SeitenDC Machines

Hochgeladen von

Glen Howell PanesConstruction of DC gen

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

ELECTRICAL MACHINES

Rotating Electrical Machines are widely used for converting

energy from one form to another.

Types of Electrical Machines:

1. Rotary Converter- electrical energy of one form is

changed into electrical energy of another.

Ex. Converting AC to DC

The input is first converted into mechanical

energy, so that the rotating part functions as an electric

motor; the resulting rotation then causes the machine to

become a generator, thereby converting mechanical

energy into DC electrical energy.

2. Frequency Converter- it changes AC electrical energy at

one frequency into AC electrical energy at another

frequency.

3. Generator- converts mechanical energy to electrical

energy.

Generator is driven by mechanical machine usually

called a prime mover. Prime mover may be a steam

turbine, a gasoline engine or an electric motor.

NOTE: Generator action can take place when and only

when there is a relative motion between the conducting

wires and magnetic lines of force.

4. Motor converts electrical energy to mechanical

energy. ( To be discussed further after DC Generator)

GENERATOR

All rotating electric motors consist essential of

two important parts.

1. An even set of electromagnets or permanent

magnets.

2. Laminated steel core containing currentcarrying copper wires or so-called the

armature winding.

In the DC generator, the armature winding is

mechanically rotated through the stationary magnetic

fields created by electromagnets or the permanent

magnets.

( In the AC generator, the electromagnets or the

permanent magnets and their magnetic fields are rotated

with respect to the stationary armature winding.)

ARMATURE WINDING

Armature winding of all types of motors and

generators, whether of direct or alternating

current, are always wound on laminated steel

cores of good magnetic permeability.

Current in the armature windings of all motors

and generators whether of direct or alternating

current is always alternating.

Explanation: Alternating voltages are always

generated in the windings of ac and dc generators.

In AC generator, the generated alternating emf is

transmitted directly to the load; In DC generator, the

generated alternating emf is first rectified by a

commutator and its brushes, that is changed to

direct current, before it is transmitted to its load.

FIELD POLES

The electromagnets ( called field poled ) used in

all DC generators and motors are very simple in

construction.

generator. If the excitation is produced by a single

winding connected to the positive and negative bus

bars fed by another dc generator it is called a

separately excited shunt generator.

NOTE: There are always an even number of field

poles in a given machine and each one consists of a

laminated steel core, of rectangular cross-section,

surrounded by one or more copper coils.

COMPOUND GENERATORS- It has two complete

sets of field windings for excitation purposes.

1.) Shunt Field

2.) Series Field

The spread-out portion of the pole core or shoe

permits the magnetic flux to enter the armature core

over a wider area than would be possible with a

core having straight sides.

Both windings are placed over one set of pole cores

and act together to create a common set of magnetic

fluxes.

When the field structure is assembled for a

stationary-field type of machine, the electromagnets

are bolted to a yoke ring so that they project radially

inward toward the rotating armature.

TYPES OF DC GENERATOR

There are only two types of DC generator. They

are distinguished by the way in which the flux is

produced by the electromagnets. The type of

generator is however, absolutely independent of the

manner in which the armature winding is placed on

the armature core and connected to the commutator.

SHUNT GENERATOR if the excitation is

produced by a single winding connected to its own

positive and negative brushes, the machine is called

a self-excited shunt generator or simply shunt

Its shunt field is, in every respect, exactly like that

used in the shunt generator.

Its series field winding, however, differs greatly

from the shunt-field wingding because it contains

very few turns of heavy wire, has an extremely low

resistance, and is excited by the comparatively large

load current.

NOTE: Since the two types of generator differ only

by the addition or omission of a series field, it is

quite possible to operate a compound generator as a

shunt generator by completely disconnecting the

series field from the machine or to change a shunt

generator into a compound generator by properly

winding a series field directly over the shunt field.

VOLTAGE CHARACTERISTICS OF DC

GENERATORS

The most important characteristic of a generator is

its voltage behavior with respect to loading.

When the armature of a machine is delivering no

current to a consuming device, it is said operating at

no load. ( It will of course, be sending a

comparatively low value of current into its own

shunt if it is a self-excited shunt generator.

If the armature is delivering rated ( name-plate )

current to one or more electrical consuming device,

the machine is said to be operating at full load.

Now then, if a shunt generator is operating at full

load at a given voltage and the load is suddenly

removed so that the machine is performing at no

load, the voltage will always rise above the full-load

value.

SPEED OF DC GENERATORS

It is customary for a DC generator, whether shunt or

compound, to operate at a speed that remains

substantially constant at all times.

Obviously, the speed of a generator is determined

and controlled by the machine that drives it, that is

the prime mover. Therefore, if the prime mover is a

constant-speed machine such as a turbine, a steam

engine, a gas engine, a water wheel, or a

synchronous motor, the generator speed will be

constant.

If, for some reason, a DC generator is operated at a

speed much higher or lower than that intended by

the manufacturer, it will usually not perform with

complete satisfaction unless corrective measures are

taken to forestall faulty operation.

For example, a lower speed will cause a generator

to overheat, while a higher speed will give rise to

poorer commutation that is, sparking at the

commutator, and wider voltage changes with

variations in load. Furthermore, the fields of DC

generators operating at speeds other than those

recommended by the manufacturer would have to

be modified to accommodate such changes; for

example, if the speed of a generator were to be

increased without a change in voltage, it would be

necessary to weaken the field.

COMMUTATING POLES FOR DC MACHINES

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Jacobs GuideDokument16 SeitenJacobs GuideRodolfo Alberto Muñoz CarcamoNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hack Mechanic Guide To European Automotive Electrical Systems by Rob Siegel - Table of ContentsDokument2 SeitenThe Hack Mechanic Guide To European Automotive Electrical Systems by Rob Siegel - Table of ContentsBentley Publishers31% (13)

- SB 1803 R2 Operating TBO & HSI FrequencyDokument22 SeitenSB 1803 R2 Operating TBO & HSI FrequencyDade Sobarna100% (4)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Air Leak TestingDokument5 SeitenAir Leak TestingsarikaNoch keine Bewertungen

- DRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARDokument30 SeitenDRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARADITYA SRIKAR KOTANoch keine Bewertungen

- Webasto Heavy Duty Air Conditioning Accessories CatalogDokument93 SeitenWebasto Heavy Duty Air Conditioning Accessories CatalogCarlos Alexandre MendelskiNoch keine Bewertungen

- 6L45 6L90 Vac LocationsDokument4 Seiten6L45 6L90 Vac LocationsPedroMecanico100% (1)

- HKT Glow Plugs 2015Dokument37 SeitenHKT Glow Plugs 2015Andru Sulima100% (2)

- Poster 20090222aDokument1 SeitePoster 20090222aKyle Martin BrunnerNoch keine Bewertungen

- Technology Development, Design and Safety Features of PHWR and Their Operating PerformanceDokument57 SeitenTechnology Development, Design and Safety Features of PHWR and Their Operating PerformanceLuptonga100% (2)

- Bosch CP1 Pump Instruction (En)Dokument6 SeitenBosch CP1 Pump Instruction (En)Miguel Chacon100% (1)

- List of Device Numbers and AcronymsDokument3 SeitenList of Device Numbers and AcronymsRegata Restu RespatiNoch keine Bewertungen

- DC Generator: Construction and WorkingDokument7 SeitenDC Generator: Construction and WorkingGlen Howell PanesNoch keine Bewertungen

- DC Hysteresis/Remanence ExperimentDokument5 SeitenDC Hysteresis/Remanence ExperimentGlen Howell PanesNoch keine Bewertungen

- Pwet Ni WensieDokument1 SeitePwet Ni WensieGlen Howell PanesNoch keine Bewertungen

- DC Hysteresis/Remanence ExperimentDokument5 SeitenDC Hysteresis/Remanence ExperimentGlen Howell PanesNoch keine Bewertungen

- Characteristic Impedance of Free SpaceDokument1 SeiteCharacteristic Impedance of Free SpaceGlen Howell PanesNoch keine Bewertungen

- Desulfurization of Oils Produced From Pyrolysis of Scrap TiresDokument6 SeitenDesulfurization of Oils Produced From Pyrolysis of Scrap TiresjishnuNoch keine Bewertungen

- Removing and Installing Unit InjectorsDokument9 SeitenRemoving and Installing Unit InjectorsDiana SilvaNoch keine Bewertungen

- ReaktorDokument10 SeitenReaktoralmiraNoch keine Bewertungen

- Subject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerDokument19 SeitenSubject Code: 17529 SUMMER - 15 EXAMINATION Model AnswerSuraj KambleNoch keine Bewertungen

- MEA101 - Fundamental of Automotive SystemDokument3 SeitenMEA101 - Fundamental of Automotive SystemShubham JhaNoch keine Bewertungen

- Top MonthlyPresentation 201905Dokument83 SeitenTop MonthlyPresentation 201905Aniket SharmaNoch keine Bewertungen

- CEE Guide to LNG in North AmericaDokument2 SeitenCEE Guide to LNG in North AmericaNatalia Magaia CambaNoch keine Bewertungen

- St. Petersburg to Receive 23 New Metelitsa Tram Wagons From StadlerDokument2 SeitenSt. Petersburg to Receive 23 New Metelitsa Tram Wagons From StadlerLuca Marius CristianNoch keine Bewertungen

- Ethylene Cracking Furnace PDFDokument2 SeitenEthylene Cracking Furnace PDFNicole0% (1)

- Modern Leak Detection Modern Leak Detection Technologies TechnologiesDokument45 SeitenModern Leak Detection Modern Leak Detection Technologies TechnologiesCarlos TarquinoNoch keine Bewertungen

- Jpa, JPC, JPD PT: Installation and Operating InstructionsDokument16 SeitenJpa, JPC, JPD PT: Installation and Operating InstructionsI Made Candra IrawanNoch keine Bewertungen

- 2015 Directory of China's GasfieldsDokument2 Seiten2015 Directory of China's GasfieldsarapublicationNoch keine Bewertungen

- Vectra RecDokument30 SeitenVectra Recstevie19721Noch keine Bewertungen

- Overview of Bikaner Railway DivisionDokument6 SeitenOverview of Bikaner Railway Divisionneeraj0309Noch keine Bewertungen

- Shared Research Flammable Mist PDFDokument2 SeitenShared Research Flammable Mist PDFJay JayNoch keine Bewertungen

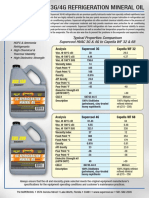

- Typical Properties Comparison Supercool HVAC 3G & 4G To Capella WF 32 & 68Dokument1 SeiteTypical Properties Comparison Supercool HVAC 3G & 4G To Capella WF 32 & 68Arlex Ricardo Guillen PetitNoch keine Bewertungen

- European Emission StandardsDokument15 SeitenEuropean Emission StandardsksbbsNoch keine Bewertungen

- Boiler Combustion & EmissionDokument15 SeitenBoiler Combustion & EmissionMustafa HusainNoch keine Bewertungen

- Halliburton Membrane Nitrogen Equipment Presentation April 10, 2014Dokument14 SeitenHalliburton Membrane Nitrogen Equipment Presentation April 10, 2014Beatriz Velásquez LeónNoch keine Bewertungen