Beruflich Dokumente

Kultur Dokumente

Methods PCB Fabrication

Hochgeladen von

Luiz Carlos TilhaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Methods PCB Fabrication

Hochgeladen von

Luiz Carlos TilhaCopyright:

Verfügbare Formate

Methods PCB fabrication

In this article we will discuss that take shape essential copper circuits via that are realized the electric

connections between the elements. We will be reported extensively in the stages that it should follow

the amateur but also professional electronic, in order that beginning from the theoretical diagram that

has drawn in a paper it leads to what is known as printed circuit. You will still learn how it is

manufactured anyone of pcb abbey or double aspect with simple and easy way. And all these following

the directives that you we give below.

In order to is materialised a any printed circuit it will be supposed we begin from the designing of lines

of interconnection of elements, we advance in their transport in films and we finish with the etching

and the piercing of pcb. Firstly we will speak concisely for the stages of manufacture plake'tas. Then

we will analyze the each one from them more extensive using photographs and drawings.

The artwork

The designing of printed circuit can become with one from the following

ways:

1. With special thin felt-tip on rise paper or simple white

paper.

2. With specifically designing tools (stencils) that contain

islands and lines on rise paper from white paper.

3. With specifically design auto transferable stickers

(letraset, magictype etc) in rise paper, white paper, and in

special transparent gelatin.

4. With the help of designing programs that runs in

computer, the known programs CAD, which offer

facilities and crowd of possibilities.

This programs apart from the possibility simple (off-hand) transport in printer of spikes, have the

possibility of printing out perfect in printers inject and laser. Certain of them have the possibility of

transformation printed in form PostScript. With use of form PostScript exists the possibility of sending

your drawing in special machines of photosynthesis that it is possible him they print in very high

analysis in special film. In this way the final result does not have envy in nothing from a professional

work. The method that has prevailed today because it has simplified all the stages is the last one. In

case where the drawing of printed circuit is already ready (f.e has been published in certain periodical)

then obviously we omit the stage of designing and simply we prepare the drawing for the final transport

in pcb. Thus we can photocopy the drawing in rise paper or him repeat in films in some shop that has

the possibility of production of special photocopies. Himself it will be supposed we make also in the

other cases where the drawing has been made in paper.

The TRANSPORT of DRAWING

The transport of drawing of printed circuit above in pcb can become with a lot of ways mainest than

which they are:

1.

2.

3.

4.

5.

With direct designing of lines with special

felt-tip indelible ink above in the copper

surface pcb. This way is judged ideal for

simple and small dimensions pcb or off-hand

essays that should be printed out immediately.

With specifically auto transferable selfadhesive elements as films and islands that are

stuck above in the copper surface.

With special self-adhesive artworks printed

that is offered by certain magazines.

With the method that forecasts use of

photosensitive special spray covering pcb (as

the known Positive of 20 German company

Kodakt Chemie or the Photosensitive of

English company Electrolube) and film.

With special ready photosensitive pcb as f.e of

German company Bungard. The pcb these

even if they are more expensive than simple

pcb have the advantage the perfect and

uniform covering pcb with photosensitive

material, thing that guarantees the perfect

transport of drawing.

The two last methods in combination with the designing in computer give pcb high technical

specifications.

EXPOSURE OF PCB IN THE UV LIGHT

The report pcb in UV light becomes in order to are burned that points that constitute the final drawing

of printed circuit and will be supposed they are impressed in pcb. It is a process similar with that of

appearance of photographic film. The report PCB in the UV light becomes in the interior of specifically

shaped box where a special lamp of steams of mercury of force 125 W undertakes it transports the

drawing printed in the surface pcb. In order to becomes possible what it will be supposed the

photosensitive pcb on her adjoin film with the help of piece of pane it is placed in distance 30

hundredth from lamp UV.

Then it will be supposed it is exposed for 4 until 10 thinly depending

on the type of film (gelatin, rise paper or other transparent paper) and

proportionally photosensitive surface pcb. We stress that the lamp this

in order to it functions needs in line with her catering a special

inductor (tsok) similar with what we use in the pipes of fluorescence. If

him you forget exists danger to be burned. Mark that the UV radiation

is VERY DAMAGING for the eyes and should not never him you look

at.

DEVELOPMENT

The appearance is the thinnest process because it

requires experience and patience. It becomes with the help

of special solution of 7-10 gr caustic soda (NaOH) in one

liter of water. In this appears to appearance pcb for 1-2

thinly the hour. After this time becomes visible the drawing

that will constitute the final electronic diagram of

connections. This solution becomes denser if is added

extra caustic soda. Naturally this him you will make

provided that the thickness of photosensitive surface is

bigger than usual. Attention: this work is imposed it

becomes with plastic gloves and big attention. The caustic

soda is dangerous when it comes in contact with the skin.

The ETCHING

The hour of etching is holiest for the amateur that makes this first pcb, after moment it sees his labours

be rewarded. Sure it is not little you see pcb be created front in your eyes. The etching can become with

four ways:

1.

2.

3.

4.

With solution of arid chloride iron in proportion 1:2 in water

With solution of chloride iron in proportion 1:1 in water

With solution of hythio salt of ammonia in proportion 4:10 in water in temperature

40 I C

With solution hydrochloric acid (2 parts) peroxide of hydrogen (perintrol 1 part) and

water (4 parts)

Attention: the solution emit dangerous steams for the eyes but also for the breathing. For this

reason the etching it is essential to become in open space (courtyard etc.) and never in

underground or in space without good ventilation. Sure even if slow method is second. It

presents the disadvantage however that where it falls this solution soils and does not leave

with nothing or rather up to recently did not clean with nothing because henceforth exists in

the market her dust company Bungard that will save your beloved shirt from his

transformation in duster. Independent from this it is good you wear the old clothes and you

avoid is poured the solution in the floor or in your skin. All the above materials you can him

find in any shop of chemical products. Certain perhaps him you find also in shops electronic.

THE DRILLING

It specifically becomes with drills that accept small drills 0, 5 3 mms. In the practice are used drills 0,8 mms for the IC

completed and drivers of elements, drills 1 mm for pins big

elements, 1,2 -1,3 for pins, 1,5 for relay, switches etc and 3

mms for holes of support pcb. For better results, you can use

special base of support in order to centered better the

apertures. Also you can use special power supply that has the

possibility of regulation turn drill but also his her force.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Semiconductor Device Formula SheetDokument2 SeitenSemiconductor Device Formula SheetSRIKAR SAI SYAMA P100% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On The Basic Concept of Nano-TechnologyDokument6 SeitenOn The Basic Concept of Nano-TechnologyfungedoreNoch keine Bewertungen

- Sop Iii-002 R00Dokument38 SeitenSop Iii-002 R00BepdjNoch keine Bewertungen

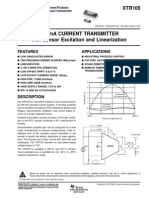

- XTR105 - AmplificadorDokument22 SeitenXTR105 - AmplificadorLuiz Carlos TilhaNoch keine Bewertungen

- APV CU4 ASiDokument47 SeitenAPV CU4 ASiLuiz Carlos TilhaNoch keine Bewertungen

- Instruction Set Reference (By Bradley)Dokument372 SeitenInstruction Set Reference (By Bradley)Carlos IvanNoch keine Bewertungen

- VPNDokument4 SeitenVPNLuiz Carlos TilhaNoch keine Bewertungen

- Correntes Especiais Correntes EspeciaisDokument33 SeitenCorrentes Especiais Correntes EspeciaisLuiz Carlos TilhaNoch keine Bewertungen

- Excise and Tax Stamps Products and VerificationDokument7 SeitenExcise and Tax Stamps Products and VerificationTobacco IndustryNoch keine Bewertungen

- Silicone Encapsulants and GelsDokument12 SeitenSilicone Encapsulants and GelssundarNoch keine Bewertungen

- Spek ESWL DORNIER-dikonversiDokument1 SeiteSpek ESWL DORNIER-dikonversiHelmi AgustianNoch keine Bewertungen

- Outokumpu Product Range WallchartDokument4 SeitenOutokumpu Product Range WallchartKevin YewNoch keine Bewertungen

- TRAPATT and BARITT DiodesDokument14 SeitenTRAPATT and BARITT DiodesgokuldarojiNoch keine Bewertungen

- B KW Power ToolDokument16 SeitenB KW Power TooldumbledoreaaaaNoch keine Bewertungen

- Jjap Express Letter: P-Gan Contact Pd/Au ZroDokument3 SeitenJjap Express Letter: P-Gan Contact Pd/Au ZroBillieNoch keine Bewertungen

- Travelling Wave Antenna GuideDokument13 SeitenTravelling Wave Antenna Guidemohan inumarthiNoch keine Bewertungen

- DLC Coating On Food Packaging Film Using PIII-D TechniqueDokument27 SeitenDLC Coating On Food Packaging Film Using PIII-D Techniqueiwpda2009Noch keine Bewertungen

- IPM vs PPM printing speeds for Canon photo printersDokument2 SeitenIPM vs PPM printing speeds for Canon photo printersmircroNoch keine Bewertungen

- Cyberdoom Tower - RegrasDokument6 SeitenCyberdoom Tower - RegrasRodrigo CamposNoch keine Bewertungen

- Exact Theory of OTR and COTRDokument8 SeitenExact Theory of OTR and COTR甘逸凱Noch keine Bewertungen

- Transparent Corrugated Sheets Product OverviewDokument13 SeitenTransparent Corrugated Sheets Product OverviewBharathVenkatachalamNoch keine Bewertungen

- Manufacturing Technologies: A History of Synthetic Diamond ProductionDokument8 SeitenManufacturing Technologies: A History of Synthetic Diamond ProductionKema Technowaka0% (1)

- GATE Metrology QuestionsDokument14 SeitenGATE Metrology QuestionsWilson Kumar33% (3)

- Impact PrintersDokument25 SeitenImpact PrintersreghunathevNoch keine Bewertungen

- Catalog Samyang 2013Dokument24 SeitenCatalog Samyang 2013mariosapereiraNoch keine Bewertungen

- High Strength Aluminium Alloys in Laser-Based Powder Bed Fusion - A ReviewDokument6 SeitenHigh Strength Aluminium Alloys in Laser-Based Powder Bed Fusion - A ReviewAndrés PacompíaNoch keine Bewertungen

- Ec8701 Optical CommunicationDokument2 SeitenEc8701 Optical CommunicationSaranya GunasekarNoch keine Bewertungen

- Detailed Damage Reference for Adeptus Titanicus BattlesDokument2 SeitenDetailed Damage Reference for Adeptus Titanicus BattlesPsyKo TineNoch keine Bewertungen

- EXPERIMENT 2: Fractorgraphy Using SEM: Name: Date: - Unsim Adm No: ClassDokument4 SeitenEXPERIMENT 2: Fractorgraphy Using SEM: Name: Date: - Unsim Adm No: ClassYeow Chong TohNoch keine Bewertungen

- Technological Advances in Fine Abrasive ProcessesDokument52 SeitenTechnological Advances in Fine Abrasive ProcessesLucas HarimNoch keine Bewertungen

- Smallpt: Global Illumination in 99 Lines of C++ A Ray Tracer by Kevin BeasonDokument77 SeitenSmallpt: Global Illumination in 99 Lines of C++ A Ray Tracer by Kevin BeasonShubham JalanNoch keine Bewertungen

- Light HeadsDokument60 SeitenLight HeadsJosé NNoch keine Bewertungen

- VL53L0X Ranging Module Cover Window GuidelinesDokument20 SeitenVL53L0X Ranging Module Cover Window GuidelinespepenitoNoch keine Bewertungen

- Atomic Physics Using Short-Wavelength Coherent RadiationDokument10 SeitenAtomic Physics Using Short-Wavelength Coherent RadiationmukphyzicsNoch keine Bewertungen