Beruflich Dokumente

Kultur Dokumente

SAIC-A-2015 Rev 7

Hochgeladen von

Bebin MathewCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAIC-A-2015 Rev 7

Hochgeladen von

Bebin MathewCopyright:

Verfügbare Formate

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

Rev 7

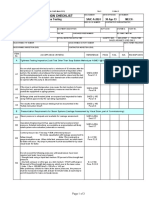

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

SAIC NUMBER

PROJECT TITLE

WBS / BI / JO NUMBER

31-Mar-13

DATE APPROVED

SAIC-A-2015

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

QR NUMBER

30-Apr-13

PIPE-

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

WORK PERMIT REQUIRED?

REFERENCE

General Requirements ... Use SATR-A-2001 with this checklist

A1

After the test pressure is reached and before commencement of inspection

of the system, the isolation valve between the temporary test

manifold/piping and the piping/equipment under pressure test shall be

closed and the test pump disconnected. See Attachments 1 & 2.

SAES-A-004,

Para. 9.1.2

A2

All joints including welded shall be left exposed for visual leak detection

during the strength test. External coating & priming of such joints is not

allowed unless approved by the Manager of Inspection Department and the

proponent Organization representative. The pipe itself can be externally

primed and coated to a final coat.

See

Attachment 3 (Walkdown Inspection Technique).

SAES-L-150,

Para. 7.3

A3

The test pressure shall be maintained for a sufficient time, but shall not be

less than 30* minutes, to determine that there are no leaks.

*Large systems (Plant Piping) can take longer to complete.

PASS

FAIL

N/A

RE-INSP DATE

SAES-L-150,

Para. 7.2

A4

SAES-L-150,

Exceptions to Item A3 above, Plant Piping Pressure Testing & Visual

Section 7

Inspection Requirements. See Attachment 4.

Visual

Inspection & Testing meets SAES-L-150 reqmts.

Plant Piping

A5

SAES-L-150,

Exceptions to Item A3 above, Pipeline Pressure Testing & Visual Inspection

Section 8

Requirements. See Attachment 4.

Visual Inspection

& Testing meets SAES-L-150 reqmts.

Pipelines

A6

Test procedures, pressures, durations, & leakage acceptance criteria shall

be equal to those that the valves were originally purchased to.

All resilient (soft) seated isolation valves shall have zero leakage.

Valve Testing details are included in separate

Procedure

SAES- L-108,

Para. 4.7.5

A7

Test Records for each test are entered on a Pressure Test Report Form

2642-ENG. Test duration & Acceptance is shown in Comment section of

report. (Tape has test pressure & test start/finish time)

Remove tape from gage & press into Test

Report. Attachment 2.

SAES-A-004,

Para. 9.3

REMARKS:

ATTACHMENTS: Attachment 1 - Pressure Testing Details --------- Attachment 2 - Efficient Practice For Acceptance of Pressure Tests

Attachment 3 - Walkdown Inspection Techniques ----------- Attachment 4 - SAES-L-150 Pressure Testing Application & Insp

REFERENCE DOCUMENTS: 1. SAES-A-004, General Requirements for Pressure Testing, (30-Jan-2011)

2. SAES-L-150, Pressure Testing of Plant Piping and Pipelines, (25-April-2010)

3. SAES-L-108, Selection of Valves, (11-Oct-2010)

Contractor / Third-Party

Construction Representative*

Saudi Aramco

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

QC Inspector

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

PID Representative

Performed Inspection

Name, Initials and Date:

T&I Witnessed

Name, Initials and Date:

Work / Rework May Proceed

Name, Initials and Date:

Page 1 of 8

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

T&I Witnessed

QC Record Reviewed

Y = YES

Page 2 of 8

Work Verified

N = NO F = FAILED

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

SAIC-A-2015

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

PIPE-

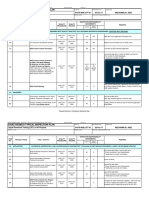

Attachment 1 - Pressure Testing Details

Plant Piping Pressure Tests with fluids (Strength & Service tests) are staged with inspection as follows:

A) Preliminary leak check at 50% of test pressure = complete visual to check for leaks. (Contractor)

B) Twenty per cent stage increase thereafter = visual inspection for leaks as evidenced by no noticeable

pressure drop at test gage. Note Filling & Venting Practices & Efficiency

C) Final at 100% of test pressure with test pump disconnected = Complete visual inspection during full

system walkdown for leaks by all Inspectors & Witnesses. (SA Inspector Witnesses & Accepts/Rejects test)

See Attachment 2 for Efficiency related to testing and inspection of small systems.

PRESSURE DROPS (GAUGE READINGS) - SURVEILLANCE OF TESTING REPAIR MEETHODS

On return to test manifold & taped gage after preliminary walkdowns, any drop (noticeable) in pressure must be

accounted for by the Inspector. The test does not proceed to a higher pressure until all leaks are repaired

and repaired by approved methods in procedures as follows:

Flanged connections can be retorqued to maximum torque value

Valve stem packings are tightened to stop leaks (Caution: Watch for uneven Packing Gland flange adjustment)

Note: Often Valves arrive from manufacturer with uneven packing gland flanges. Adjustment/repair may be needed.

Threaded joint leaks are repaired (seal welded or reworked)

Weld joint leaks are repaired (approved welding repair procedure)

Weld joint leaks are repaired (approved welding repair procedure)

After repairs, pressurize system & repeat the entire walkdown, never assume all leaks are repaired.

SEE ATTACHMENT 3 FOR WALKDOWN TECHNIQUES DURING FINAL PRESSURE TESTING (ACCEPTANCE)

Hydrotest Filling & Venting Practices (Efficiency)

1. PRESSURE TESTING IS ALWAYS CRITICAL PATH ON MAJOR PROJECTS

2. COMPANY HAS IDENTIFIED PRESSURE TESTING INEFFICIENCY AS A MAJOR OBSTACLE TO SUCCESS.

3. ROOT CAUSE OF THE INEFFICIENCY IS PRIMARILY POORLY TRAINED TEST CREWS AND INSPECTORS.

4. QUALITY MANAGERS & THEIR INSPECTORS ARE TASKED TO ASSURE BEST & EFFICIENT PRACTICES.

5. WHEN POSSIBLE, MULTIPLE TEST PACKAGES ARE COMBINED INTO ONE TEST. DOCUMENT SET-UP.

6. TEST CREWS SHALL ALLOW ADDITIONAL TIME (EFFECTIVELY VERIFIED) FOR TRAPPED AIR TO VENT.

7. TEST CREWS SHALL PERFORM FINAL FILL SLOWLY AFTER FLUID LEVELS DROP AT OPEN VENTS.

Filling may be done by hand or pump as experience dictates. See Criteria below. Task crews for safety & efficiency.

Trapped air is usually adequately displaced when a solid flow or stream of water is observed coming out of the vent.

8. INSPECTION SHALL EVALUATE EFFICIENCY & ASSURE BEST PRACTICES TO MINIMIZE RETESTS.

BACKGROUND INFORMATION: Thousands of Manhours are lost due to test failures (retest required) when poorly

trained test crews rush during filling. Assure proper venting of air & a slow final fill technique. Efficiency is critical.

Recommendation: Test crews dedicated solely to set-up, filling and other preparation should be utilized.

Training regarding proper filling and venting techniques shall be identified for inefficient test crews who

waste the valuable time of others (Ops, Inspection, SAPMT, PID, etc) when tests fail to hold pressure.

CRITERIA: On initial pressurization, pressure holds AFTER equalization at 50% test pressure. Gauge drops

indicate a leak (acceptable for efficiency) or "inefficient" test crews leaving air in lines (unacceptable).

Note: Gauges that hold pressure at 50% of test pressure almost always pass. Contact SA after lines show

a successful result at 50% initial pressurization stage for efficiency. Communication issue (cell, radio, etc)

Page 3 of 8

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

SAIC-A-2015

31-Mar-13

DATE APPROVED

30-Apr-13

QR NUMBER

PIPE-

Attachment 2 - Efficient Practice For Acceptance of Pressure Tests

EFFICIENT TEST PRACTICE (USE TAPE ON GAUGES)

THIS IS FOR ROUTINE PLANT PIPING PRESSURE TESTS (30-MINUTE TESTS) ON SMALL SYSTEMS.

1. PRESSURE TESTING IS ALWAYS CRITICAL PATH ON MAJOR PROJECTS

2. COMPANY HAS IDENTIFIED PRESSURE TESTING INEFFICIENCY AS A MAJOR OBSTACLE TO SUCCESS.

3. ROOT CAUSE OF THE INEFFICIENCY IS PRIMARILY POORLY TRAINED TEST CREWS AND INSPECTORS.

4. QUALITY MANAGERS & THEIR INSPECTORS ARE TASKED TO ASSURE BEST & EFFICIENT PRACTICES.

5. WHEN POSSIBLE, SAVE TIME DURING PRESSURE TESTING SET-UP & PRODUCTION AS FOLLOWS:

a) Ensure Efficient Test Crew Practices as outlined in Attachment 1. Retrain any crews who are inefficient.

b) Minimize time required for Outside Parties (SAPMT, PID, Proponent, etc) to attend Pressure Testing.

c) Implement an easy to perform and easy to document practice of "tape" application on test gauges.

d) Mimimize time waiting on Project Inspection/SAPMT to ABSOLUTE ZERO as follows for 30-minute tests:

END RESULT WILL BE IMPROVED EFFICIENCY AND LESS TIME ACHIEVING PASSING PRESSURE TESTS.

FOLLOW THESE GENERAL GUIDELINES (DETAILS AS AGREED UPON IN PROJECTS)

1) Notify SA that day (at agreed upon intervals) of the test packages likely to be ready for testing.

2) Notify SA Witness (PMT, PID) exactly when 50% test pressure holds "after equalization". (Cell, Radio)

Technique: QC Inspector has applied a strip of tape (to be later affixed into the test report) on test gauge.

This can be the plain vanilla colored tape approximately 25 mm wide by 50 mm long that allows marking.

The QC Inspector or test crew supervisor match marks the test pressure (on equalization at 50%) and

Verifies the test is ready to proceed to the next stage. Company is informed that their witness is needed.

Note: Any pressure drop indicates liklihood of trapped air or leakage as per Attachment 1 (identify the

cause of the pressure drop BEFORE proceeding, checking valve stems, fittings, valve seat leakby, etc ).

Test reaches 100% of test pressure. Allow adequate equalization time. Note exact start time & notify SA*.

At this time, SA (SAPMT, PID, etc) is notified that the test is ready to begin if they are not already present.

*QC Inspector match marks the pressure gauge needle & writes the start time on the tape (30 minute test).

Note: Usually, only a few minutes are required for most walkdowns. At the test conclusion, the time the

test ended is written down on the tape & the Inspector Initials/Dates/Accepts & affixes tape into test report.

COMPANY WITNESS ALSO INITIALS/DATES/ACCEPTS TEST ON THE TAPE AFFIXED INTO TEST REPORT.

PACKAGE CONTROL IS CRITICAL FOR EFFICIENCY. LATER, SIGNATURES ARE OBTAINED EASILY LATER

WHEN HARD TAPE EVIDENCE IS AFFIXED INTO TEST REPORTS. IT ELIMINATES THE NEED FOR 100% SA

PRESENCE AT ALL TEST SITES FOR THE ENTIRE TEST DURATION. ALSO, ON VERBAL APPROVAL, AFTER

CONFIDENCE IS OBTAINED THAT TECHNIQUE IS EFFICIENT, START TIMES DO NOT WAIT ON COMPANY.

IN ALL CASES, THE TEST IS TERMINATED WHEN INSPECTORS COMPLETE THEIR EXAMINATIONS.

LARGER SYSTEMS, ESP. WHERE CLIMBING IS REQUIRED, REQUIRED COORDINATED INSP EFFORTS.

PRACTICE IS RECOMMENDED FOR PRESSURE TESTING PROCEDURES & IMMEDIATE IMPLEMENTATION.

Page 4 of 8

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

SAIC-A-2015

31-Mar-13

DATE APPROVED

QR NUMBER

30-Apr-13

PIPE-

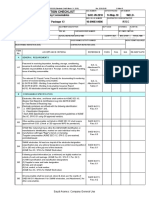

Attachment 3 - Walkdown Inspection Techniques

Hot Weather Effect & Test Interpretations (Inspector to Note):

1. Test pressures rise steadily and very noticeably due to rise in pipe surface temps during Summer.

2. Test pressure at gage can remain the same and even rise slightly with very small leaks*

* Ensure good walkdown practice. Check valve stems, threads, flanges & low points very closely.

Never assume a test result based on the test gauge. Visually examine the entire pressure boundary methodically.

3. Relief valves (set 5% above test pressure) can pop and lower test pressures (nullify test results)

*Efficiency is needed to complete exams as quickly as possible without rushing through inspection.

4. In hot weather, ensure careful bleedoff in inspection presence. Maintain minimum test pressure.

5. Always account for noticeable drops in test pressures. See Potential Leak Sources.

Potential Leak Sources (Inspector to Note):

a) Valve leakby and test connection threaded fitting leaks (worn) are the # 1 cause of failed tests*.

* Closed valves used as a test limit are never assumed to be "passing" water. Verify no other leaks

* Closed valves in the test manifold are checked and replaced if they "pass", verify no other leaks

* Threaded pressure hose connections wear out & need frequent replacement. Most common leak.

b) Valve packing leaks are very often found with NO* noticeable test pressure drop (in hot weather)

*The normal test pressure rise due to sun-heated piping is not seen, but negated by packing leak.

c) Flanges with small leaks are hard to find. Check low points by hand*patting & use mirror/light.

*A sheet of dry paper can be patted against lowest periphery of the flange. Watch for sharp edges!

d) Threaded joints* are checked closely (leaks are common with inadequate thread engagement).

*Seal welded threaded joints often leak. Best technique is close visual checks with mirror & hand.

e) Socket welds (GTAW & SMAW process) can leak through tiny pores caused by oil contamination.

f) Butt weld leaks are rare & 100% through-wall porosity is often the culprit.

g) Telltale hole leakage (stanchion legs, dummy legs, repads) is thru attachment welds*

* Attachment welds to pressure boundary can burn through & create thru-wall defects that leak

h) Pipe/Fitting manufacturing defects cause thru-wall leaks. There is a variety of common defects*

* Seams, laps, slugs, delaminations, pinholes, tears, shuts and thread defects (torn, flat, etc)

6. Leakage Evidence or questionable leakage (also check gage pressure) is always investigated

Investigate Leakage Evidence (Inspector to Note):

1) Visually attempt to determine the exact source* of leakage evidence (except for obvious leaks)

* Never Assume Leakage Evidence is local. The source may be another line (Know the Effects of Gravity).

* Never Assume water present means a test system leak. (Filling Leak Repaired, another source)

* Assess leakage evidence carefully by a detailed visual inspection/observation method:

* Check test gage or have a test crew member return & check the gage for obvious pressure drop

* Never assume because pressure hasn't dropped that a leak does not exist (hot weather effect)

2) Approach the area with caution. Assess the evidence. Is the leak ACTIVE? (Obviously wet or dripping)

3) If yes, wipe the area dry & wait a few seconds (on further leaks, mark the location & move on)

4) If not obvious, but a leak is suspected, wipe area dry & wait 60* seconds. Use Hand/dry paper!

* Ascertain a leakage rate (in drops/minute). Move on and complete the remainder of test.

PROBLEM

5) Test crews often struggle with small leaks & use a pressure gage as their acceptance criteria*.

REASON = INSPECTOR IS LIKELY ACCEPTING TESTS BASED ON GAUGE RESULTS ALONE

SOLUTION = AWARENESS

6) Any Leakage found (rate) on unsuccessful tests is entered in Test Report "Remarks/Comment" Section

Example: Retest OK (no leaks at test pressure) after minor valve packing leaks (2 drops/minute) repaired

NEVER ASSUME A TEST RESULT BASED

ON THE TEST GAUGE ALONE

Page 5 of 8

NEVER ASSUME A TEST RESULT BASED

ON THE TEST GAUGE ALONE

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

SAIC-A-2015

Page 6 of 8

31-Mar-13

DATE APPROVED

30-Apr-13

QR NUMBER

PIPE-

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

31-Mar-13

DATE APPROVED

SAIC-A-2015

QR NUMBER

30-Apr-13

PIPE-

Attachment 4 - SAES-L-150 Pressure Testing Application & Insp

7 Plant Piping Applications

7.1 Unless limited by flanges, valves or other component in the line or specified in paragraph 7.4 below, the

hydrostatic strength test pressure for every section of new constructed line shall produce a hoop stress in the pipe

of 90% of the specified minimum yield strength (SMYS) at the test temperature. The test pressure shall be

calculated based on the pipe nominal wall thickness less the mill tolerance (manufacturer's minus tolerance). The

test pressure shall not be less than the minimum test pressure per ASME B31.3 paragraph 345.4.2.

7.2 Except where specified in 7.4 of this standard, the test pressure shall be maintained for a sufficient time, but

shall not be less than 30 minutes, to determine that there are no leaks. (Item A3 of this Checklist)

7.3 All joints including welded shall be left exposed for visual leak detection during strength test. External coating

and priming of such joints are not allowed unless approved by Manager of Inspection Department and the proponent\

Organization representative. The pipe itself can be externally primed and coated to a final coat.

7.5 Following are specific cases of exemptions to either or both of 7.1 and 7.2 of this standard (Item A4):

7.5.1 Lube and seal oil piping shall be pressure tested with its own fluid. The test pressure shall be 1.5 times the

design pressure or 690 kPa (ga) (100 psig) whichever is the greater. Test duration shall be in accordance with 7.2.

7.5.2 Underground process piping shall be tested prior to backfilling. The test pressure shall be maintained for a

minimum of 2 hours while the joints are inspected for leakage. If for justifiable safety reasons the line must be backfilled, then the joints shall remain exposed during testing, otherwise the test shall be a 24 hour recorded test. The

test pressure is in accordance with 7.1.

7.5.3 Flare lines 24-inch NPS and larger* with a design pressure of 517 kPa (ga) (75 psig) or lower may be

pneumatically strength tested in accordance with paragraph 345.5 of ASME B31.3.

* Note: Portions of this line may be smaller than 24" and extend to isolation valves downstream of PZVs, etc

7.5.4 Piping in vacuum service shall be pressure tested to 1.5 times the differential external pressure not less

than 100 kPa (ga) (15 psig). Test duration shall be in accordance with 7.2.

7.5.5 Service test is acceptable for the following per L-150, Para. 7.5.5 (Threaded Joints)

a) Plant utility piping in air & inert gas services with designed pressure & equal to less than 035 kPa (ga) (150 psig).

b) Low pressure steam piping designed for 60 psig or less.

INSPECTION SHALL REFER TO SAIC-L-2015 CHECKLIST FOR THREADED JOINTS AS APPLICABLE.

7.6 For revalidation purposes of existing plant piping, test pressure shall be minimum req'd by ASME B31.3.

Actual piping wall thickness and flange rating shall be taken into consideration when calculating the test pressure.

8 Pressure Testing of Pipelines

This section defines specific requirements (such as test pressure, duration, etc.) for pressure testing of pipelines.

8.1 Unless limited by flanges or valves in the line, hydrostatic strength test pressure for every section of newly

constructed pipelines shall be calculated to produce a hoop stress of 90% of the SMYS of the pipe material based

on the nominal wall thickness. The test pressure at the lowest point of the pipeline, considering hydrostatic head,

shall not result in a hoop stress greater than the SMYS. Strength test pressure shall be maintained for 2 hours.

8.2 The strength test temperature shall not result in a combined longitudinal stress (calculated based on 0.7 hoop

stress at the test pressure plus temperature stress plus bending stress) exceeding the SMYS.

8.3 Tightness test shall be conducted at 95% of strength test pressure, immediately after completing strength test.

Tightness test pressure shall be maintained as long as req'd for inspector to examine all exposed joints.

A 24-hour recorded tightness test shall be applied when the pipeline is buried or insulated, or is partially

buried or insulated for more than 300 m (1000 ft) or 10% of its total length whichever is less.

8.4 Existing pipelines if subjected to revalidation pressure testing, the test pressure shall be minimum of 1.25 times

the MAOP for pipelines with 0.6 and 0.72 design factors; and shall be minimum of 1.4 times the MAOP for pipelines

with 0.4 and 0.5 design factors. The actual pipe wall thickness and flange rating shall be taken into consideration

when calculating the test pressure.

For Pipelines, The results of the latest (new) pressure testing shall be documented in the "Safety Instruction Sheet".

PIPELINE PRESSURE VARIATIONS (TEMPERATURE VARIATIONS)

11.3 Where pressure variations due to test water temperature changes occur, such as in cross-country pipelines,

thermocouples shall be installed to obtain accurate pipe metal temperature measurements to determine the

acceptance of the pressure test. Chairman of the Piping Standards Committee in Consulting Services Department

Page 7 of 8

SAUDI ARAMCO ID/PID - REV - 18-May-05 (Standards Cutoff -March 2013)

SAUDI ARAMCO INSPECTION CHECKLIST

Visual Inspection at Test Pressure

Rev 7

SAIC NUMBER

SAIC-A-2015

shall be consulted for any deviations on the 24 hour pressure chart.

Page 8 of 8

31-Mar-13

DATE APPROVED

30-Apr-13

QR NUMBER

PIPE-

Das könnte Ihnen auch gefallen

- SAIC-A-2009 Rev 2Dokument5 SeitenSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-A-2009 Rev 0Dokument3 SeitenSAIC-A-2009 Rev 0philipyapNoch keine Bewertungen

- Satip A 004 03Dokument3 SeitenSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDokument3 SeitenSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNoch keine Bewertungen

- SAUDI ARAMCO PNEUMATIC TEST CHECKLISTDokument3 SeitenSAUDI ARAMCO PNEUMATIC TEST CHECKLISTரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saic A 2011Dokument8 SeitenSaic A 2011jerinNoch keine Bewertungen

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDokument8 SeitenSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Noch keine Bewertungen

- SATIP-A-004-01 Rev 7Dokument2 SeitenSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- Saic A 2011Dokument5 SeitenSaic A 2011Anonymous 4e7GNjzGWNoch keine Bewertungen

- SAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)Dokument15 SeitenSAIC-A-2001 Rev 3 Review Procedure Pressure Testing (All Applications)imrankhan2250% (2)

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14Dokument10 SeitenSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 31-Dec-14pravinNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1Dokument6 SeitenSaudi Aramco Inspection Checklist: Reqmts Are Listed in Attachment 1sureshNoch keine Bewertungen

- SAIC-L-2014 Flange Joint Insp PDFDokument7 SeitenSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDokument12 SeitenSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNoch keine Bewertungen

- Saic L 2008 PDFDokument4 SeitenSaic L 2008 PDFHesham HelalNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Reinstatement Procedure ChecklistDokument5 SeitenSaudi Aramco Reinstatement Procedure ChecklistpravinNoch keine Bewertungen

- SAUDI ARAMCO LPT INSPECTION PLANDokument3 SeitenSAUDI ARAMCO LPT INSPECTION PLANDurga Jagan PuppalaNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistJoni Carino SuniNoch keine Bewertungen

- Saep 351Dokument24 SeitenSaep 351Raj KumarNoch keine Bewertungen

- SAIC-A-2016 Rev 0Dokument2 SeitenSAIC-A-2016 Rev 0philipyapNoch keine Bewertungen

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Dokument2 SeitenSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNoch keine Bewertungen

- SAIC-A-2008 Rev 0Dokument3 SeitenSAIC-A-2008 Rev 0Kristine Caye DatarioNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistAbdul HannanNoch keine Bewertungen

- 01 Samss 010Dokument11 Seiten01 Samss 010doyenofcastleNoch keine Bewertungen

- Materials System SpecificationDokument7 SeitenMaterials System Specificationaanouar77Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument15 SeitenSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Inspection Procedure EDRDokument8 SeitenInspection Procedure EDRaamirtec301Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDokument3 SeitenSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNoch keine Bewertungen

- Saep 35Dokument6 SeitenSaep 35hendraox3996Noch keine Bewertungen

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDokument2 SeitenSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDokument12 SeitenSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNoch keine Bewertungen

- SAIC-L-2035 Rev 6Dokument2 SeitenSAIC-L-2035 Rev 6biplabpal2009Noch keine Bewertungen

- Saudi Aramco Typical Inspection PlanDokument10 SeitenSaudi Aramco Typical Inspection Plankarthi51289Noch keine Bewertungen

- Saic L 2007 PDFDokument7 SeitenSaic L 2007 PDFHesham HelalNoch keine Bewertungen

- SAIC-H-2010 Rev 7Dokument1 SeiteSAIC-H-2010 Rev 7Satheesh Rama SamyNoch keine Bewertungen

- SAIC-L-2136 Rev 0Dokument3 SeitenSAIC-L-2136 Rev 0philipyapNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDokument2 SeitenSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNoch keine Bewertungen

- Materials System SpecificationDokument21 SeitenMaterials System Specificationnadeem shaikhNoch keine Bewertungen

- Saudi Aramco Storage ChecklistDokument4 SeitenSaudi Aramco Storage Checklistரமேஷ் பாலக்காடுNoch keine Bewertungen

- 04 Samss 035Dokument28 Seiten04 Samss 035SamiNoch keine Bewertungen

- 04 Samss 055Dokument42 Seiten04 Samss 055nadeem shaikh100% (1)

- Satr-W-2010Dokument1 SeiteSatr-W-2010Joni Carino SuniNoch keine Bewertungen

- Saep 351Dokument19 SeitenSaep 351QA QC100% (1)

- Receiving Inspection of Pressure VesselsDokument5 SeitenReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-L-2014 Rev. 5Dokument10 SeitenSAIC-L-2014 Rev. 5Jagadeesh PuppalaNoch keine Bewertungen

- Saic A 2013Dokument6 SeitenSaic A 2013jerinNoch keine Bewertungen

- 32 Samss 020Dokument18 Seiten32 Samss 020naruto256Noch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Satip - S-050-01Dokument4 SeitenSatip - S-050-01LIJINNoch keine Bewertungen

- SAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageDokument8 SeitenSAEP-35-N - Valves Handling, Hauling, Receipt Tests and StorageMuhammad Farukh Manzoor0% (1)

- Saudi Aramco Test ReportDokument7 SeitenSaudi Aramco Test ReportziaNoch keine Bewertungen

- Saep-352, 01.01.2018 PDFDokument15 SeitenSaep-352, 01.01.2018 PDFRami ELLOUMI100% (2)

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Dokument2 Seiten1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNoch keine Bewertungen

- SAIC-A-2015 Rev 2Dokument9 SeitenSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SATR-J-6512 - Rev 0 PDFDokument5 SeitenSATR-J-6512 - Rev 0 PDFAdel KlkNoch keine Bewertungen

- SAIC-A-2023 Rev 0Dokument2 SeitenSAIC-A-2023 Rev 0philipyapNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005Dokument3 SeitenSaudi Aramco Inspection Checklist: 1-Dec-06 Mech. Review of Leak Test Procedure (Bubble Test) SAIC-A-2005ரமேஷ் பாலக்காடுNoch keine Bewertungen

- SAIC-A-2013 Rev 0Dokument2 SeitenSAIC-A-2013 Rev 0philipyapNoch keine Bewertungen

- SAIC-A-2024 Rev 2Dokument2 SeitenSAIC-A-2024 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Saep 31Dokument5 SeitenSaep 31brecht1980100% (1)

- Gi 2 .102 Pressure Testing SafelyDokument17 SeitenGi 2 .102 Pressure Testing SafelyBebin MathewNoch keine Bewertungen

- SATIP-A-004-01 Rev 7Dokument2 SeitenSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- 0188e CHB OxygenDokument2 Seiten0188e CHB OxygenBebin Mathew83% (6)

- 0049e CHB AcetyleneDokument1 Seite0049e CHB AcetyleneBebin Mathew50% (2)

- Gom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Dokument5 SeitenGom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Bebin Mathew100% (2)

- SAEP-351 Bolted Flange Joint AssemblyDokument12 SeitenSAEP-351 Bolted Flange Joint AssemblyBebin Mathew75% (8)

- Gom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Dokument5 SeitenGom Region Hot Bolting Safe Work Practice (SWP) : Document Number: CD # Ups-Us-Sw-Gom-Hse-Doc-00112-2Bebin Mathew100% (2)

- BA TSF2 V.04.00 EN 30aug2022 WebDokument316 SeitenBA TSF2 V.04.00 EN 30aug2022 WebAlejo CastroNoch keine Bewertungen

- Gearbox Technical Data OverviewDokument504 SeitenGearbox Technical Data Overviewюрий ерёменко100% (1)

- Gamas SP y Spa 60hz PDFDokument100 SeitenGamas SP y Spa 60hz PDFDaniel Alejandro GuerreroNoch keine Bewertungen

- Question Bank MechanicalDokument16 SeitenQuestion Bank MechanicalPiyush GururaniNoch keine Bewertungen

- Conery Catalog 2016Dokument28 SeitenConery Catalog 2016Aqua Technology GroupNoch keine Bewertungen

- BS 6364-1984Dokument11 SeitenBS 6364-1984harshithreemaNoch keine Bewertungen

- E-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsDokument4 SeitenE-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsAdrian MacayaNoch keine Bewertungen

- Runxin Multiport Control ValvesDokument23 SeitenRunxin Multiport Control ValvesEdsonNoch keine Bewertungen

- Champion Dual Disc Wafer Check ValvesDokument8 SeitenChampion Dual Disc Wafer Check ValvesShanghai koko ValvesNoch keine Bewertungen

- Machine Component Locations: 446D Hydraulic System Backhoe LoaderDokument2 SeitenMachine Component Locations: 446D Hydraulic System Backhoe LoaderCarlos Irabedra100% (2)

- DS Datasheet ERHARD Needle Valves enDokument8 SeitenDS Datasheet ERHARD Needle Valves enEnrike GutierrezNoch keine Bewertungen

- Preliminary - MITTEN HPU Only Rev DDokument120 SeitenPreliminary - MITTEN HPU Only Rev DFabyano BrittoNoch keine Bewertungen

- 330C Excavator Hydraulic System: Fluid Power SymbolsDokument2 Seiten330C Excavator Hydraulic System: Fluid Power SymbolsVictor Nunez100% (1)

- Time Fullcat en - 132Dokument2 SeitenTime Fullcat en - 132FernandoNoch keine Bewertungen

- Dog ClutchDokument7 SeitenDog ClutchSajoud MohsinNoch keine Bewertungen

- New Hydrastep Electronic 202MP ManualDokument69 SeitenNew Hydrastep Electronic 202MP ManualSrinivasarao YenigallaNoch keine Bewertungen

- 170i ULTRA PDFDokument51 Seiten170i ULTRA PDFLuis Alfonso Contreras SantosNoch keine Bewertungen

- Cf34-8 CMM Index PDFDokument12 SeitenCf34-8 CMM Index PDFHaithem BrebishNoch keine Bewertungen

- HB UCM 2018-10 enDokument44 SeitenHB UCM 2018-10 enNaeem HussainNoch keine Bewertungen

- Series LF210-5 Specification SheetDokument2 SeitenSeries LF210-5 Specification SheetWattsNoch keine Bewertungen

- Chapter 2 - Safe Work Procedure / Risk Assessment: Service ManualDokument70 SeitenChapter 2 - Safe Work Procedure / Risk Assessment: Service Manualjacklyn ade putra100% (1)

- c25 33 Propulsion Engines 06 01 2017Dokument143 Seitenc25 33 Propulsion Engines 06 01 2017chao wangNoch keine Bewertungen

- Diesel Engine Fuel Injection Pump and Governor Removal and InstallationDokument39 SeitenDiesel Engine Fuel Injection Pump and Governor Removal and InstallationGallego Carlos100% (1)

- Instructions and Manual for JOWA 3SEP OWSDokument154 SeitenInstructions and Manual for JOWA 3SEP OWSПетко Петков100% (1)

- Fan Coil Unit: YPHBC 200 1600 OptionalDokument1 SeiteFan Coil Unit: YPHBC 200 1600 Optionalcm08909Noch keine Bewertungen

- Standard Drawings CurrentDokument111 SeitenStandard Drawings CurrentHuynh Thanh TamNoch keine Bewertungen

- Pump System CalculationsDokument31 SeitenPump System CalculationsMandarNoch keine Bewertungen

- Bomba de Alta Presion Denso HP2 PDFDokument4 SeitenBomba de Alta Presion Denso HP2 PDFDiegoD'AmbrosioNoch keine Bewertungen

- Cat CSVDokument36 SeitenCat CSVaqhammamNoch keine Bewertungen

- 27-09-22 Valve Block 787A0000 SeriesDokument152 Seiten27-09-22 Valve Block 787A0000 SeriesEdson CarvalhoNoch keine Bewertungen