Beruflich Dokumente

Kultur Dokumente

SteelWise Anchor Rods

Hochgeladen von

vCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SteelWise Anchor Rods

Hochgeladen von

vCopyright:

Verfügbare Formate

SteelWise

Anchor Rods

Can’t live with ‘em, can’t live without ‘em.

By Dan Swiatek and Emily Whitbeck with contributions from Victor Shneur, P.E.

Many common anchor rod problems are easier to avoid than you think!

n life there are a few things that are some guidelines on how you can prevent common challenges and easy solutions

I necessary evils, and anchor rods and

column base plate connections seem to

be one of them. These connections

have caused problems on many build-

ing projects, but by looking at the chal-

lenges that others have faced and show-

ing how these challenge have been

common problems in the design of

anchor rods and base plate connections,

and will help the designer to avoid

expensive field repairs and schedule

delays. Specifications and design guides

are already in place to aid in the design of

these connections for strength, but issues

for how to improve everyday anchor rod

and column base plate connection appli-

cations.

Dan Swiatek is a senior civil engineering

student at University of Illinois-Urbana-

Champaign and a former AISC intern. Emily

Whitbeck is a senior architectural engineering

successfully overcome, perhaps we can of constructability should be considered student at Penn State University and a for-

make the use of these important connec- on every project, to ease the construction mer AISC intern. Victor Shneur is chief engi-

tions more bearable. This article will give process. The following chart offers some neer with LeJeune Steel Co., Minneapolis.

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas

Common Mistakes Easy Solutions

Specifying ASTM A325 or A490 anchor rods

Standard ASTM A325 and A490 bolts include Specify ASTM F1554 anchor rods

defined threaded length and heading require- This standard covers anchor rods with yield

1 ments and must be special ordered when strengths of 36, 55, and 105-ksi, in hooked,

their lengths exceed 9½ in. This can take up headed, and threaded/nutted options.

to four months.

Contact a local fabricator for availability

Even though most fabricators don’t make

Assuming that all material are available their own anchor rods, they will still know

It is possible that materials of different types about material availability or possible substi-

2 and sizes will not be readily available for your tutions. It will save money and time on your

project. project. If it is impossible to contact your fab-

ricator, ASTM F1554 grade 36 anchor rods

may be specified as a fail-safe option.

Reduce the variety of anchor rod settings

Specifying many different anchor rod set-

Specify one anchor rod setting and base plate

tings

for all exterior columns, and one for all inte-

Specifying a different anchor rod setting pat-

3 tern and base plate for every column size will

rior columns, based on the largest size. This

will be conservative for lighter columns, but it

end up leading to complications.

will greatly simplify detailing and installation.

Limit anchor rod sizes to one or two

Specifying many different anchor rod sizes This will be conservative in some cases but

Similarly to specifying settings, specifying will reduce installation mistakes. Try to make

4 many different sizes can lead to complica- sure the two sizes differ enough to avoid con-

tions. fusion and mistakes (at least 1/2-in. difference

in diameter).

December 2004 • Modern Steel Construction

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas (cont’d.)

Common Mistakes Easy Solutions

Specify doubly symmetric settings

Specifying odd anchor rod settings Keep it simple by making anchor rod settings

Don’t specify settings that are seldom used if and base plates doubly symmetric about col-

5 you don’t have to. umn centerlines. Simplicity prevents prob-

lems.

Provide sufficient plan dimensions

Specifying base plates that are too small

This will allow for oversized holes and clear-

This provides no room for errors that are

6 likely to occur.

ances. Field fixes to enlarge holes or to add

plate washers will also be possible.

Use AISC anchor rod and base plate hole

Specifying standard oversized holes for

recommendations

anchor rods

Use the recommended hole sizes for base

Foundation inaccuracies are common. Often,

plates shown in AISC Design Guide 1, or in

7 the standard oversized hole dimensions used

Table 14-2 of the 3rd Edition Manual. This will

for bolts are not sufficient because there is

allow for even more tolerance in the founda-

not enough tolerance available.

tion for anchor rod placement. Make sure to

use a heavy plate washer over the hole.

Only provide grout holes with large plates

Specifying grout holes in small base plates If more than one hole is required, grout holes

If the smaller dimension is less than 24 in., need to be spaced approximately 18 in. apart.

8 do not specify grout holes. Grout holes should be 2 in. to 3 in. in diame-

ter.

Using anchor rods to transfer substantial Consider a shear key or an embedded plate

shear A shear key or embedded plate with welded

Anchor rods cannot be expected to transfer side plates can be used to transfer a large

9 shear forces due to their larger holes and the horizontal shear force from the column base

use of grout. to the foundation.

Welding all around the column and base Use one-sided fillet welds for gravity

plate columns

Column web-to-flange fillets provide very little A typical gravity column only requires a fillet

strength and may cause fabrication problems. weld at the flange. Columns in framing sys-

10 Welding that wraps around the flange toes for tems that experience uplift and shear will

a column and base plate connection creates require fillet welds on both sides of the flange

unwanted stress concentrations. and web.

Specifying a CJP groove weld

Specify a fillet weld if possible

If a simple fillet weld can resist uplift or shear,

Use a fillet weld on both sides of a joint than

then using a complete-joint-penetration

a CJP groove weld, if possible. Remember

11 groove weld for the connection between the that the fillet weld will benefit from the direc-

column and base plate is unnecessary and

tional strength increase factor.

expensive.

Modern Steel Construction • December 2004

Solutions to 17 Common Anchor Rod and Base Plate Dilemmas (cont’d.)

Common Mistakes Easy Solutions

Always using brackets at base plates

If the column is subjected to uplift, specifying Use thicker base plates

brackets or stiffener plates are not always This can eliminate the need for brackets or

12 necessary. These measures are not only stiffeners at base plates and will result in

expensive but also make field corrections much less labor to fabricate the columns.

impossible.

Specifying hooked anchor rods for axial

Use anchor rods that are headed or

loads

threaded at the end for axial loads

Because a hook can straighten and pull out,

Use rods that are headed or threaded at the

hooked rods should not be used for axial

13 loads. Exceptions include using them to pre- end with a nut for anchorage. Because of the

bigger shear cone, these have a greater pull-

vent overturning caused by erection loads or

out strength.

collisions during erection.

Tack weld this nut at the bottom

Welding the anchorage nut all around Since the only purpose of this weld is to keep

This includes both sides and the top. Welding the rod from turning while the top nut is tight-

14 the top can reduce the assembly strength. ened, a tack weld is more than sufficient. You

can also use a jamb nut.

Know the tolerances for anchor rod place-

Assuming precise placement per design

ment

The placement of both the concrete and the

ACI tolerances for anchorage are very liberal.

anchor rods cannot guarantee perfect eleva-

15 tion according to the design or erection Consider specifying the more stringent AISC

Code of Standard Practice tolerances for use

details.

by the concrete contractor.

Assuming anchor rods were installed per-

fectly Consider hiring a surveyor

It is very common for an anchor rod to be It might be a good idea to hire someone to

16 installed incorrectly. It is even more common inspect anchor rod installation, especially in a

for them to be damaged after installation by complicated or tightly-scheduled job.

other construction work.

Construction sequence should be specified

Assuming that walls will not be constructed

If there is a chance that the columns might be

It is very possible that walls or other con-

installed after a wall, make sure the correct

17 straints will be built before the column is order is specified before you design the

installed.

anchor rods and base plates.

December 2004 • Modern Steel Construction

Das könnte Ihnen auch gefallen

- AutoCAD Beginners Guide To 2D & 3D Drawings PDFDokument13 SeitenAutoCAD Beginners Guide To 2D & 3D Drawings PDFChandra RashaNoch keine Bewertungen

- Vicwest DiaphragmsDokument62 SeitenVicwest Diaphragmsrmsa17Noch keine Bewertungen

- Awc Wood Connection Design Des330 1 Slide Per PageDokument112 SeitenAwc Wood Connection Design Des330 1 Slide Per Pagecerratosys100% (1)

- Detailing StairsDokument7 SeitenDetailing StairsSelbi CeylanNoch keine Bewertungen

- Flange Bending in Single CurvatureDokument21 SeitenFlange Bending in Single CurvaturePeterNoch keine Bewertungen

- Designing HSS Connections PDFDokument4 SeitenDesigning HSS Connections PDF112160rbcNoch keine Bewertungen

- AISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFDokument2 SeitenAISC - Design Guide 12 - Errata - Modification of Existing Welded Steel Moment Frame Connections For Seismic Resistance PDFapuhapuh_153349Noch keine Bewertungen

- AISC Design GuidesDokument3 SeitenAISC Design GuidesDharmendu00780% (5)

- Steel DetailerDokument3 SeitenSteel DetailerKooroshNoch keine Bewertungen

- Constructability of Embedded Steel Plates in CIP ConcreteDokument7 SeitenConstructability of Embedded Steel Plates in CIP ConcreteimranNoch keine Bewertungen

- Steel Design Guide 11 - Vibrations of Steel-Framed Structural Systems Due To Human Activity - 2nd. EditionDokument138 SeitenSteel Design Guide 11 - Vibrations of Steel-Framed Structural Systems Due To Human Activity - 2nd. EditionIvan Alejandro Miramontes MunguiaNoch keine Bewertungen

- High Strength Bolting PDFDokument68 SeitenHigh Strength Bolting PDFmovila100% (2)

- Icbo Es Report-Er2078pDokument65 SeitenIcbo Es Report-Er2078peltorro-tNoch keine Bewertungen

- PILE Foundation Analysis - ASCE William Saul-1980 - SearchableDokument22 SeitenPILE Foundation Analysis - ASCE William Saul-1980 - Searchablev100% (1)

- 2.1 Symbaroum-Tomb-of-Dying-DreamsDokument44 Seiten2.1 Symbaroum-Tomb-of-Dying-DreamsTar50% (2)

- Connections: Best Tips of The 21st CenturyDokument4 SeitenConnections: Best Tips of The 21st Centurysymon ellimac100% (1)

- Structural Defects Reference Manual For Low Rise BuildingsDokument295 SeitenStructural Defects Reference Manual For Low Rise BuildingsvNoch keine Bewertungen

- Designing HSS ConnectionsDokument8 SeitenDesigning HSS ConnectionsjarnebergNoch keine Bewertungen

- EM 1110-1-1904 - Settlement AnalysisDokument205 SeitenEM 1110-1-1904 - Settlement AnalysisPDHLibrary100% (1)

- Cable Supported Bridges: Concept and DesignVon EverandCable Supported Bridges: Concept and DesignBewertung: 5 von 5 Sternen5/5 (1)

- DPWH 2015 DGCS Vol 6Dokument359 SeitenDPWH 2015 DGCS Vol 6Shara Mae de Mesa100% (1)

- Design of Lifting and Tailing LugsNetsc001Dokument30 SeitenDesign of Lifting and Tailing LugsNetsc001Tshilidzi Irene Netselo100% (1)

- FE Structural Analysis On An ExcelDokument27 SeitenFE Structural Analysis On An Excelchuckhsu124867% (3)

- Substation Structures, Valmont NewmarkDokument111 SeitenSubstation Structures, Valmont Newmarkdavidfc26Noch keine Bewertungen

- Guía de Fallas en Conexiones HSSDokument57 SeitenGuía de Fallas en Conexiones HSSlcorao100% (3)

- Standard Details Public Works ConstructionDokument207 SeitenStandard Details Public Works Constructionnido77Noch keine Bewertungen

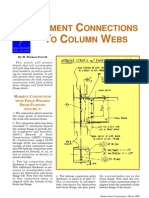

- Moment Connections To Column WebsDokument3 SeitenMoment Connections To Column WebsAmro Ahmad AliNoch keine Bewertungen

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDokument13 SeitenPrinciples and Practices of Stud Welding: State-Of-The-Art Paperalbert limantonoNoch keine Bewertungen

- Rfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure StripsDokument6 SeitenRfis On Circular Ties, Rotating Hooks, Staggered Lap Splices, and Closure Stripsvelmurug_bala100% (1)

- Moody's ChartDokument100 SeitenMoody's Chartbsk109100% (3)

- Cold-formed Tubular Members and Connections: Structural Behaviour and DesignVon EverandCold-formed Tubular Members and Connections: Structural Behaviour and DesignBewertung: 5 von 5 Sternen5/5 (2)

- Base Plates and Anchor Rods - Steel Design AISCDokument3 SeitenBase Plates and Anchor Rods - Steel Design AISCpenneng0% (2)

- Connections in Steel 6 PDFDokument624 SeitenConnections in Steel 6 PDFKosnendi Putropranoto50% (2)

- FAQs About Headed Reinf Bars - ETN-M-3-14Dokument8 SeitenFAQs About Headed Reinf Bars - ETN-M-3-14MukarramuddinNoch keine Bewertungen

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsDokument151 SeitenDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxNoch keine Bewertungen

- MIVAN SeminarDokument57 SeitenMIVAN Seminarrsandye67% (3)

- Steel Tips 1Dokument40 SeitenSteel Tips 1banbanio4680% (5)

- Design of Unstiffened Extended Single Plate Shear ConnectionsDokument14 SeitenDesign of Unstiffened Extended Single Plate Shear ConnectionsGonzalo ContrerasNoch keine Bewertungen

- Hollow Sections 2nd EdtDokument240 SeitenHollow Sections 2nd Edtksuscribdacct100% (2)

- Axial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsDokument38 SeitenAxial Capacities of Eccentrically Loaded Equal-Leg Single Angles - Comparisons of Various Design MethodsAnonymous 7MdZQn1100% (1)

- Simple Shear Connections SteelwiseDokument4 SeitenSimple Shear Connections SteelwiseAnil K Vishwa100% (1)

- Schwimmbadbau enDokument34 SeitenSchwimmbadbau enBojan Besedić100% (1)

- Design of Guardrail PDFDokument31 SeitenDesign of Guardrail PDFVladimir SimeunovicNoch keine Bewertungen

- National Artists For ArchitectureDokument16 SeitenNational Artists For ArchitecturebbalacyNoch keine Bewertungen

- Detailing Corner 2013Dokument12 SeitenDetailing Corner 2013Abdus Salam100% (1)

- SJI SimpleConnectionsSimplified FINAL 05162018 Handout 1Dokument106 SeitenSJI SimpleConnectionsSimplified FINAL 05162018 Handout 1Nemanja RandelovicNoch keine Bewertungen

- Cavitation in Chutes and SpillwaysDokument164 SeitenCavitation in Chutes and SpillwaysjamesnyamaiNoch keine Bewertungen

- HHS Connection DesignDokument3 SeitenHHS Connection Designwii2001Noch keine Bewertungen

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNoch keine Bewertungen

- Hollow Sections Book WardenierDokument199 SeitenHollow Sections Book WardenierANUSSBAUMER100% (3)

- STI HSS Column Load Tables LRFD PDFDokument123 SeitenSTI HSS Column Load Tables LRFD PDFAhmed Ali MohammedNoch keine Bewertungen

- Pre-Fabricated Punching Shear ReinfDokument4 SeitenPre-Fabricated Punching Shear ReinfJose ManjooranNoch keine Bewertungen

- FRANKFORT. The Art and Architecture of The Ancient Orient PDFDokument228 SeitenFRANKFORT. The Art and Architecture of The Ancient Orient PDFErnesto Castro Cordoba100% (1)

- Rain Water Harvesting (RWH) : Anand DubeyDokument28 SeitenRain Water Harvesting (RWH) : Anand DubeyAnand DubeyNoch keine Bewertungen

- Steelwise PDFDokument3 SeitenSteelwise PDFFourHorsemenNoch keine Bewertungen

- Ej 2020 - q1 Issue PDFDokument94 SeitenEj 2020 - q1 Issue PDFgv Sathishkumar KumarNoch keine Bewertungen

- Steelwise - Moment ConnectionsDokument4 SeitenSteelwise - Moment ConnectionsManoj JaiswalNoch keine Bewertungen

- Base Plate and Anchor Rod Design 2nd PDFDokument8 SeitenBase Plate and Anchor Rod Design 2nd PDFAmol JdvNoch keine Bewertungen

- SteelWise Joists FactsDokument2 SeitenSteelWise Joists FactsvNoch keine Bewertungen

- Fire Protection Basics: A Variety of Good Options Are AvailableDokument3 SeitenFire Protection Basics: A Variety of Good Options Are AvailableMohammad MeqdadNoch keine Bewertungen

- SteelWise Specifying MaterialsDokument6 SeitenSteelWise Specifying Materialsv100% (1)

- Structural Steel BoltsDokument7 SeitenStructural Steel BoltsMark OglesbyNoch keine Bewertungen

- Steelwise: A Quick Look at PryingDokument2 SeitenSteelwise: A Quick Look at Pryingsdutta2591Noch keine Bewertungen

- Bolt Spec ReviewDokument2 SeitenBolt Spec ReviewameensderajNoch keine Bewertungen

- Astm A325 PernosDokument14 SeitenAstm A325 PernosDiego Lever TorresNoch keine Bewertungen

- Steelwise: Designing Welds For Skewed Shear TabsDokument5 SeitenSteelwise: Designing Welds For Skewed Shear TabsAdery Baltodano Monterrey100% (1)

- Lifting Beams: If You've Ever Asked Yourself "Why?"Dokument2 SeitenLifting Beams: If You've Ever Asked Yourself "Why?"sppramNoch keine Bewertungen

- Steelwise PDFDokument4 SeitenSteelwise PDFJagatheesh RadhakrishnanNoch keine Bewertungen

- Design of Unstiffened Extended Single-Plate ShearDokument15 SeitenDesign of Unstiffened Extended Single-Plate ShearM. Murat ErginNoch keine Bewertungen

- Irjet V8i1007Dokument5 SeitenIrjet V8i1007Diwakar Singh RajputNoch keine Bewertungen

- Connections Art, Science, and Information in The Quest For Economy and SafetyDokument13 SeitenConnections Art, Science, and Information in The Quest For Economy and SafetyDoctoreNoch keine Bewertungen

- Tips & More: For Economical DesignDokument4 SeitenTips & More: For Economical DesignLuis Horacio Martínez MartínezNoch keine Bewertungen

- MSC October 2011 PDFDokument8 SeitenMSC October 2011 PDFYan Naung KoNoch keine Bewertungen

- Applications of Pretensioned Anchor Rods in Industrial FacilitiesDokument10 SeitenApplications of Pretensioned Anchor Rods in Industrial FacilitiesAndré Luiz NogueiraNoch keine Bewertungen

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Dokument2 SeitenSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoNoch keine Bewertungen

- Si 5 2014 PDFDokument2 SeitenSi 5 2014 PDFhector diazNoch keine Bewertungen

- Fatigue of Deformed Welded-Wire ReinforcementDokument15 SeitenFatigue of Deformed Welded-Wire ReinforcementMridul HasanNoch keine Bewertungen

- EJ Fisher BracingwithJoistsDokument6 SeitenEJ Fisher BracingwithJoistsGabby KenNoch keine Bewertungen

- RRW 410 FDokument90 SeitenRRW 410 FvNoch keine Bewertungen

- Introduction To Programming Using Fortran 95/2003/2008: Ed JorgensenDokument237 SeitenIntroduction To Programming Using Fortran 95/2003/2008: Ed JorgensenDwight ThothNoch keine Bewertungen

- Singapore. Building and Construction Authority-Structural Precast Concrete Handbook - Building and Construction Authority (2001) PDFDokument174 SeitenSingapore. Building and Construction Authority-Structural Precast Concrete Handbook - Building and Construction Authority (2001) PDFShamim Ahsan ZuberyNoch keine Bewertungen

- OSHA Rigging Tables-FiguresDokument15 SeitenOSHA Rigging Tables-FiguresvNoch keine Bewertungen

- Moving Load EquationsDokument6 SeitenMoving Load EquationsvNoch keine Bewertungen

- Entire Book 2018 PDFDokument597 SeitenEntire Book 2018 PDFArunkumarNoch keine Bewertungen

- WRN Oct08Dokument88 SeitenWRN Oct08vNoch keine Bewertungen

- Doe Standard: Hoisting and Rigging (Formerly Hoisting and Rigging Manual)Dokument403 SeitenDoe Standard: Hoisting and Rigging (Formerly Hoisting and Rigging Manual)vNoch keine Bewertungen

- Emhhhmhhmmhhhl E Hhheeeeon: Bosef: Bean On Shelling Elastic F/G 9/2 NLDokument44 SeitenEmhhhmhhmmhhhl E Hhheeeeon: Bosef: Bean On Shelling Elastic F/G 9/2 NLvNoch keine Bewertungen

- Cálculo Studs PDFDokument19 SeitenCálculo Studs PDFCristiana FurlanNoch keine Bewertungen

- BuoyancyWhite Paper2018Dokument26 SeitenBuoyancyWhite Paper2018nagireddy SudhindraNoch keine Bewertungen

- Standard Hooks Card-ASTMDokument2 SeitenStandard Hooks Card-ASTMvNoch keine Bewertungen

- Stress Analysis of Concrete PipeDokument17 SeitenStress Analysis of Concrete PipeAli ÖztürkNoch keine Bewertungen

- The Complete Guide To Team Bid Evaluation: A Bentley White PaperDokument9 SeitenThe Complete Guide To Team Bid Evaluation: A Bentley White PaperPalanas A. VinceNoch keine Bewertungen

- Floor Vibrations: Design For Walking ExcitationDokument18 SeitenFloor Vibrations: Design For Walking ExcitationHattori HanzoNoch keine Bewertungen

- ACB Design Manual Third EditionDokument112 SeitenACB Design Manual Third EditionvNoch keine Bewertungen

- Engineering Monograph 10Dokument156 SeitenEngineering Monograph 10vNoch keine Bewertungen

- Strut and Tie Part 1Dokument14 SeitenStrut and Tie Part 1Turcu Catalin NicolaeNoch keine Bewertungen

- Chapter 13Dokument44 SeitenChapter 13V.m. RajanNoch keine Bewertungen

- MOJAVE Single 2016 - OptimizedDokument20 SeitenMOJAVE Single 2016 - OptimizedDonnarose DiBenedettoNoch keine Bewertungen

- 04 HSPA ProtocolsDokument19 Seiten04 HSPA ProtocolsUsman WaseemNoch keine Bewertungen

- Fatigue-Resistant Detail Design Guide For Ship StructuresDokument6 SeitenFatigue-Resistant Detail Design Guide For Ship Structuresy_596688032Noch keine Bewertungen

- Introduction To Aircom OptimaDokument66 SeitenIntroduction To Aircom OptimaHarsh KalraNoch keine Bewertungen

- Urban AtriumDokument10 SeitenUrban AtriumrashmigodhaNoch keine Bewertungen

- FDSFSDDokument35 SeitenFDSFSDAndreaNoch keine Bewertungen

- DSL-G225 User ManualDokument128 SeitenDSL-G225 User ManualGeoff BudgeNoch keine Bewertungen

- 1987 08 UPD77C25 DSP Adv Prod Data SheetDokument36 Seiten1987 08 UPD77C25 DSP Adv Prod Data SheetAli GachkarNoch keine Bewertungen

- Making Custom Modifications On IERP MS Access Forms and ReportsDokument3 SeitenMaking Custom Modifications On IERP MS Access Forms and ReportsrakhinethuNoch keine Bewertungen

- Rate Analysis For M-25 Concrete: A Material Unit Qty Rate AmountDokument3 SeitenRate Analysis For M-25 Concrete: A Material Unit Qty Rate AmountSyamala BaiNoch keine Bewertungen

- Crown StandardTCP IPPortDokument5 SeitenCrown StandardTCP IPPortDavid Alejandro Quijada GilNoch keine Bewertungen

- Java EE TutorialDokument10 SeitenJava EE TutorialbilldigmanNoch keine Bewertungen

- Resume Indrajeet SinghDokument5 SeitenResume Indrajeet SinghNismi Narayanan KjNoch keine Bewertungen

- 2015ebook Nuage PDFDokument90 Seiten2015ebook Nuage PDFalfagemeoNoch keine Bewertungen

- JSP Standard Tag Library (JSTL) TutorialDokument8 SeitenJSP Standard Tag Library (JSTL) Tutoriallahari chepuriNoch keine Bewertungen

- Apache Internals and Debugging: Ryan MattesonDokument41 SeitenApache Internals and Debugging: Ryan MattesonGleb LegasovNoch keine Bewertungen

- Standard/Specification For Standard/Specification For Windows, Doors, and Windows, Doors, and Unit Skylights Unit SkylightsDokument8 SeitenStandard/Specification For Standard/Specification For Windows, Doors, and Windows, Doors, and Unit Skylights Unit SkylightsSibi SamNoch keine Bewertungen

- 5992-2035EN Nemo Outdoor Qualcomm Chipset Based Terminals DSDokument34 Seiten5992-2035EN Nemo Outdoor Qualcomm Chipset Based Terminals DSHajiAkbarBabarNoch keine Bewertungen

- Error Detected by Export DLL Crystal Reports PDFDokument2 SeitenError Detected by Export DLL Crystal Reports PDFSarahNoch keine Bewertungen

- KX Mb2025cxDokument124 SeitenKX Mb2025cxZahid NaqviNoch keine Bewertungen

- Mietskaserne 1Dokument26 SeitenMietskaserne 1Luiza Sassi100% (1)

- Opertaing System Lecture NoteDokument90 SeitenOpertaing System Lecture NoteSajendra KumarNoch keine Bewertungen