Beruflich Dokumente

Kultur Dokumente

Basics of Ship Hull Design

Hochgeladen von

alp_alpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Basics of Ship Hull Design

Hochgeladen von

alp_alpCopyright:

Verfügbare Formate

Ship building technology involves business-process technologies, system technologies, shipyard productionprocess technologies, and technologies for new

materials and products. Advanced Shipbuilding Technology is

used to make state-of the art vessels and includes numerically controlled machine tools, robots, automated

process control equipment, computerized flexible manufacturing systems, associated computer software, and

other technology for improving shipbuilding and related industrial production. Advance technology incorporates

novel techniques and processes designed to improve shipbuilding quality, productivity, and practice. The

technology is environmentally sensitive so as to promote sustainable development through quality assurance,

continuous process production technology, energy efficiency, waste minimization and design for recyclability or

parts reuse. Advanced ship building technology also uses inventory management, upgraded worker skills, and

concurrent engineering along with other elements contributing to a shipyard's efficiency or productivity

assisting it to more effectively operates in the shipbuilding industry.

Leave a comment

Basics of Ship Hull Design

written by: Raunekk edited by: Lamar Stonecypher updated: 4/16/2009

Hull is known as the foundation of the ship. It withstands extremely harsh climatic and weather conditions. Hull should be

designed in such a way that it is not affected by the different forces that acts on it while the ship is sailing. In this article we will

have a look at different hull designs.

Introduction

The hull is one part of the ship that requires extra concern during design and construction. In the history of naval architecture,

hull designs has evolved over a period of time, from cylindrical wooden shanks to steel columns. Engineers have been

continuously innovating hull designs to provide greater structural strength. As hull is continuously in contact with water, it is

under the effect of different types of forces acting at the same time. Not only that, a hull requires high durability and resistance to

prevent structural damage in case of collision or grounding.

Naval architects use different methods for hull construction keeping in mind the purpose and type of ship. In this article we will

have a look at the basic ship hull designs which are commonly used.

Terms in ship hull design

For understanding a hull structure, it is important to know the basic terms. We will quickly go through the basic terms that are

required to understand a design.

Frame- It is a steel plate that runs longitudinally or transversely throughout the hull structure. Frames are welded to the sides of

the hull as shown in the figure. They form the basis of any design and all hull designs consist of frames.

Plate Floor or Floor plate - A steel plate which is welded to the floor of the hull. Plate floors run longitudinally throughout the

hull floor as shown in the figure.

Flanged Bracket -Triangular shaped Iron brackets that are welded where the two frames meet. They are attached to the margin

plates to resist excessive bending stress.

Side Girders - Inter coastal plates that are used to join two floor plates.

Keel plate - They are used to join floor plates to the keel of the ship.

The two main methods that are used for hull construction are :

Transverse framing

Longitudinal framing.

Transversally Stiffened

Though this hull design is outdated, it is still used for smaller ships of length less than 120 meters. In

this design there is a plate floor every 3.05 meters and a frame every 1 meter. The frames run tranversally to the hull structure.

The frames are joined together with the help of floor angle iron transverse. In this design every floor plate will have 3 frames.

The frames are attached to the margin plates with the help of flanged bracket as shown in the figure.

Iron transverse is attached between two floor plates to provide additional support and increase structural strength. Refer the

diagram for a better understanding of the design.

Longitudinally framed hull- For Tankers

In longitudinal framing the frames are attached longitudinally to the floor plates instead of transverse.

This helps to resist the bucking force in a much effective way. Frames( Vertical and horizontal frames) are joined at the

intersection of two sides is the same way as in transverse design but with the help of web as shown in figure. Sealing plates are

used wherever the floors are to be made water tight(Generally in tankers). They are welded to the longitudinal frames as shown

in the figure.

Longitudinally framed hull-For Dry cargo

In Longitudinal framed hull for dry cargo, brackets are used to provide strength to the frame. The size of the brackets keeps on

increasing as the height of the deck increases. Brackets are used to provide additional structural strength to the bulkhead as

there are high number of inter-decks in ships used for dry cargo.

Das könnte Ihnen auch gefallen

- TM 55 1520 236 23P 1Dokument843 SeitenTM 55 1520 236 23P 1Tod A. Wulff100% (1)

- Analyses of Ship ElementDokument21 SeitenAnalyses of Ship Elementsaassaassaas100% (1)

- CDR Jeffrey W. Stettler, Usn, PHD: Assistant Professor, Permanent Military ProfessorDokument14 SeitenCDR Jeffrey W. Stettler, Usn, PHD: Assistant Professor, Permanent Military Professormarquiname50% (4)

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Broadway CafeDokument13 SeitenBroadway CafeIoana Taon100% (1)

- Answer To Question-1: Agricultural ApplicationsDokument7 SeitenAnswer To Question-1: Agricultural ApplicationsSoham ChaudhuriNoch keine Bewertungen

- Ship Basic Hull DesignDokument2 SeitenShip Basic Hull DesignrajishrrrNoch keine Bewertungen

- Ship History of Naval Architecture EngineersDokument3 SeitenShip History of Naval Architecture EngineerspothirajkalyanNoch keine Bewertungen

- Ship History of Naval Architecture EngineersDokument3 SeitenShip History of Naval Architecture EngineerssnvijayanNoch keine Bewertungen

- Ship History of Naval Architecture EngineersDokument3 SeitenShip History of Naval Architecture EngineerssnvijayanNoch keine Bewertungen

- Ship History of Naval Architecture EngineersDokument3 SeitenShip History of Naval Architecture EngineerspothirajkalyanNoch keine Bewertungen

- Ship Framing SystemDokument10 SeitenShip Framing SystemgksahaNoch keine Bewertungen

- What Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentDokument7 SeitenWhat Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentJoel MathewNoch keine Bewertungen

- Hull Structure - HandoutDokument15 SeitenHull Structure - HandoutSamNoch keine Bewertungen

- Steel Intensive Terminal Building 311007Dokument7 SeitenSteel Intensive Terminal Building 311007Goutam ChakrabortyNoch keine Bewertungen

- Production of Precast ConcreteDokument7 SeitenProduction of Precast ConcreteDragosPatrascuNoch keine Bewertungen

- Flat Slab Design - Engineering DissertationsDokument34 SeitenFlat Slab Design - Engineering DissertationsBobby LupangoNoch keine Bewertungen

- Pre Cast ConstructionDokument55 SeitenPre Cast ConstructionAmalaNoch keine Bewertungen

- Belt Conveyor DesignDokument21 SeitenBelt Conveyor DesignRajesh RanjanNoch keine Bewertungen

- Ship Production and Management AbhinavDokument7 SeitenShip Production and Management AbhinavASPIN RAJNoch keine Bewertungen

- Belt Conveyor DesignDokument21 SeitenBelt Conveyor DesignAjith100% (1)

- Production of Precast ConcreteDokument7 SeitenProduction of Precast ConcreteDragosPatrascuNoch keine Bewertungen

- Applications of Sandwich Plate System For Ship StructuresDokument8 SeitenApplications of Sandwich Plate System For Ship StructuresHusen ShahabNoch keine Bewertungen

- CRSI The Designer's ResponsibilityDokument16 SeitenCRSI The Designer's ResponsibilityAdam Jones100% (1)

- Week 2Dokument6 SeitenWeek 2Roger TerminatorNoch keine Bewertungen

- Research Paper On Truss BridgeDokument6 SeitenResearch Paper On Truss Bridgeafnkwbmnmccchy100% (1)

- FormworkDokument9 SeitenFormworkAmol D PawarNoch keine Bewertungen

- An Industrial PresentationDokument28 SeitenAn Industrial PresentationRahul Kumar DabotraNoch keine Bewertungen

- Precast Construction: Prepared By: Parth S. Patel SD1510Dokument55 SeitenPrecast Construction: Prepared By: Parth S. Patel SD1510Gireesh Gowda GiriNoch keine Bewertungen

- Hangar DesignDokument5 SeitenHangar DesignZoran100% (1)

- Longitudinal Vs Transversal Frame in Ship ConstructionDokument17 SeitenLongitudinal Vs Transversal Frame in Ship Constructionistinpoli100% (4)

- Paper - Integral BridgesDokument10 SeitenPaper - Integral BridgesviralisursNoch keine Bewertungen

- Longitudinal and Transverse Framing PDFDokument62 SeitenLongitudinal and Transverse Framing PDFShivam Kumar100% (2)

- Btech 1 M1Dokument12 SeitenBtech 1 M1corbitecoNoch keine Bewertungen

- Design of Long Span Exhibition Hall of Steel StructureDokument5 SeitenDesign of Long Span Exhibition Hall of Steel StructureInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Advanced Construction TechnologyDokument41 SeitenAdvanced Construction TechnologyBCAS HND QS Assignment100% (1)

- NASC TheoryDokument20 SeitenNASC Theoryannie rawatNoch keine Bewertungen

- CTE-6 FormworkDokument37 SeitenCTE-6 FormworkM. H MahiNoch keine Bewertungen

- Finite Element Method Sizing Beam Members Using Symmetry and Using Modern Fe ToolDokument12 SeitenFinite Element Method Sizing Beam Members Using Symmetry and Using Modern Fe ToolFaizan SamdaniNoch keine Bewertungen

- Framing System (Written Report)Dokument14 SeitenFraming System (Written Report)Wincy Sta AnaNoch keine Bewertungen

- Framing System: Frames, Deck Beams EtcDokument2 SeitenFraming System: Frames, Deck Beams EtcMir Tareque AliNoch keine Bewertungen

- Flat Slab: Framing System: Initial Framing System Formulation Provides A Detailed Geometric Description ofDokument3 SeitenFlat Slab: Framing System: Initial Framing System Formulation Provides A Detailed Geometric Description ofmariyam khanNoch keine Bewertungen

- Lec3 ColumnsDokument24 SeitenLec3 ColumnsAminah KamranNoch keine Bewertungen

- The International Journal of Science & Technoledge: Optimization of Water TankDokument10 SeitenThe International Journal of Science & Technoledge: Optimization of Water Tanktvpavan666Noch keine Bewertungen

- Segmental Bridge Construction ProcessDokument14 SeitenSegmental Bridge Construction Processbadam zadran100% (1)

- Common Fabrication ProblemsDokument10 SeitenCommon Fabrication Problemsshivu khatriNoch keine Bewertungen

- Mivan TechnologyDokument24 SeitenMivan TechnologyArjun MNoch keine Bewertungen

- Transfer SlabDokument13 SeitenTransfer Slabdarsu Naik100% (1)

- Teja's Presentation NewDokument22 SeitenTeja's Presentation Newkorada gayatriNoch keine Bewertungen

- Recent Trends in Design and Construction of FlyoversDokument5 SeitenRecent Trends in Design and Construction of FlyoversCIVILNoch keine Bewertungen

- Long Span StructuresDokument13 SeitenLong Span StructuresVinay KatariyaNoch keine Bewertungen

- Winter 2010 PCI Journal RosignoliDokument22 SeitenWinter 2010 PCI Journal RosignolipvmoorthiNoch keine Bewertungen

- 1.1 Background of StudyDokument7 Seiten1.1 Background of StudyMuhamad Arief AmienNoch keine Bewertungen

- Topic3 - Hull Structure PDFDokument11 SeitenTopic3 - Hull Structure PDFAnonymous qHl3lFIkRNoch keine Bewertungen

- Design Challenges and Construction Benefits of Precast Segmental Rail BridgesDokument32 SeitenDesign Challenges and Construction Benefits of Precast Segmental Rail Bridgessk1875Noch keine Bewertungen

- Temporary WorksDokument8 SeitenTemporary WorksMirara SimonNoch keine Bewertungen

- Long Span Structures: TOS - Assignment 2Dokument12 SeitenLong Span Structures: TOS - Assignment 2harish guptaNoch keine Bewertungen

- Discontinuous Columns 2016Dokument34 SeitenDiscontinuous Columns 2016AbhiNoch keine Bewertungen

- Section 3 Notes On Structural Design and Design RequirementsDokument6 SeitenSection 3 Notes On Structural Design and Design Requirementsel_hasbiNoch keine Bewertungen

- Form Scaffolding and StagingDokument27 SeitenForm Scaffolding and Stagingincrediblesmile1234Noch keine Bewertungen

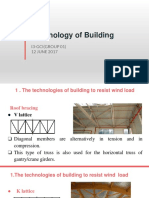

- Technology of Building: I3-GCI (GROUP 01) 12 JUNE 2017Dokument43 SeitenTechnology of Building: I3-GCI (GROUP 01) 12 JUNE 2017ChhengnguonNoch keine Bewertungen

- RoofDokument31 SeitenRoofsamNoch keine Bewertungen

- Hydraulic Robotic Arm: Bachelor of Technology IN Mechanical EngineeringDokument3 SeitenHydraulic Robotic Arm: Bachelor of Technology IN Mechanical Engineeringalp_alpNoch keine Bewertungen

- A Good Paper For Applied Thermal EngineeringDokument29 SeitenA Good Paper For Applied Thermal Engineeringalp_alpNoch keine Bewertungen

- Four Quadrant DC Motor Control Without Microcontroller: Department of Electrical and Electronics EngineeringDokument3 SeitenFour Quadrant DC Motor Control Without Microcontroller: Department of Electrical and Electronics Engineeringalp_alpNoch keine Bewertungen

- Performance Amelioration of Adaptive Detection of Moderately-Fluctuating Radar Targets in Severe InterferenceDokument24 SeitenPerformance Amelioration of Adaptive Detection of Moderately-Fluctuating Radar Targets in Severe Interferencealp_alpNoch keine Bewertungen

- Case Study of Viability of Bioenergy Production From Landfill Gas (LFG)Dokument12 SeitenCase Study of Viability of Bioenergy Production From Landfill Gas (LFG)alp_alpNoch keine Bewertungen

- Basic Electronics and Devices - Dec - 2015Dokument5 SeitenBasic Electronics and Devices - Dec - 2015alp_alpNoch keine Bewertungen

- Dynamic Restoration of Periodic Noisy Image Using: Upper-Half SpectrumDokument4 SeitenDynamic Restoration of Periodic Noisy Image Using: Upper-Half Spectrumalp_alpNoch keine Bewertungen

- Ratified Principals & FacultyDokument30 SeitenRatified Principals & Facultyalp_alpNoch keine Bewertungen

- Guide To Unix - Commands - File System Utilities - Wikibooks, Open Books For An Open WorldDokument12 SeitenGuide To Unix - Commands - File System Utilities - Wikibooks, Open Books For An Open Worldalp_alpNoch keine Bewertungen

- Advance Data Structure qp-16Dokument4 SeitenAdvance Data Structure qp-16Christina RobinsonNoch keine Bewertungen

- Work-Energy For Particle Systems: ME 231: DynamicsDokument12 SeitenWork-Energy For Particle Systems: ME 231: Dynamicsalp_alpNoch keine Bewertungen

- ME 230 Kinematics and Dynamics: Wei-Chih WangDokument84 SeitenME 230 Kinematics and Dynamics: Wei-Chih Wangalp_alpNoch keine Bewertungen

- Solutions To Chapter 7 ProblemsDokument12 SeitenSolutions To Chapter 7 Problemsalp_alpNoch keine Bewertungen

- Scantling Is A Measurement of Prescribed Size, Dimensions, or Cross Sectional Areas. ForDokument1 SeiteScantling Is A Measurement of Prescribed Size, Dimensions, or Cross Sectional Areas. Foralp_alpNoch keine Bewertungen

- Potential Energy: ME 231: DynamicsDokument13 SeitenPotential Energy: ME 231: Dynamicsalp_alpNoch keine Bewertungen

- Ground EffectDokument59 SeitenGround Effecteafz111Noch keine Bewertungen

- Constructing 30deg AngleDokument4 SeitenConstructing 30deg AngleArthur ChewNoch keine Bewertungen

- Rog Strix Z390-E Gaming: DDR4 4266 Qualified Vendors List (QVL)Dokument13 SeitenRog Strix Z390-E Gaming: DDR4 4266 Qualified Vendors List (QVL)ALAN ANDRES ZAVALA LLANOSNoch keine Bewertungen

- ISO 13920 - Tolerâncias para Juntas SoldadasDokument7 SeitenISO 13920 - Tolerâncias para Juntas SoldadasRicardo RicardoNoch keine Bewertungen

- Practice 4Dokument11 SeitenPractice 4Justine Rs Dela TorreNoch keine Bewertungen

- BR18S-7 Manual CracteristicasDokument10 SeitenBR18S-7 Manual Cracteristicasrendimax insumos agricolasNoch keine Bewertungen

- Faculty Profile: Dr. Injam Siva ParvathiDokument9 SeitenFaculty Profile: Dr. Injam Siva ParvathiMr. Y. RajeshNoch keine Bewertungen

- Capsicums - Innovative Uses of An Ancient CropDokument11 SeitenCapsicums - Innovative Uses of An Ancient CropMaarioNoch keine Bewertungen

- Plugs, Fuses and Household ElectricityDokument4 SeitenPlugs, Fuses and Household ElectricityRonald HuynhNoch keine Bewertungen

- Thru Tubing Catalog PDFDokument43 SeitenThru Tubing Catalog PDFchubby_hippoNoch keine Bewertungen

- Pedia 2017 Case ProtocolDokument14 SeitenPedia 2017 Case ProtocolArjay Amba0% (1)

- MR - Samaksh Jhalani Machinery-FinalDokument45 SeitenMR - Samaksh Jhalani Machinery-FinalSamaksh JhalaniNoch keine Bewertungen

- CMC 2023 Senior Category Question BankDokument5 SeitenCMC 2023 Senior Category Question BankNikita AgrawalNoch keine Bewertungen

- CBSE Sample Paper Class 9 Science SA2 Set 7Dokument13 SeitenCBSE Sample Paper Class 9 Science SA2 Set 7PALAK SHARMANoch keine Bewertungen

- Interpretation of Results ReportingDokument7 SeitenInterpretation of Results ReportingMerill Harrelson LibanNoch keine Bewertungen

- Edc Contractors Basic Safety Training: "New Normal" EditionDokument8 SeitenEdc Contractors Basic Safety Training: "New Normal" EditionCharles Rommel TadoNoch keine Bewertungen

- VIC Routing Model PreprocessingDokument11 SeitenVIC Routing Model PreprocessingpchrisrlNoch keine Bewertungen

- List Lagu EnglishDokument7 SeitenList Lagu EnglishRyn ZulfanNoch keine Bewertungen

- Atomic Structure RevisionDokument4 SeitenAtomic Structure RevisioncvNoch keine Bewertungen

- Selulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusDokument8 SeitenSelulitis Orbita Pada Laki-Laki Usia 64 Tahun: Laporan KasusLuh Dita YuliandinaNoch keine Bewertungen

- 03-CircO2 Previous Control Nitric OxideDokument17 Seiten03-CircO2 Previous Control Nitric OxideVic SpeaksNoch keine Bewertungen

- 02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingDokument47 Seiten02-779 Requirements For 90-10 Copper - Nickel - Alloy Part-3 TubingHattar MNoch keine Bewertungen

- Features and Highlights - : CapableDokument2 SeitenFeatures and Highlights - : CapableaarianNoch keine Bewertungen

- Geometry CheatsheetDokument5 SeitenGeometry CheatsheetMarilyn CitadelNoch keine Bewertungen

- International SubcontractingDokument2 SeitenInternational SubcontractingCatherine JohnsonNoch keine Bewertungen

- 4.5.redistrribution - PBR Quiz AnswersDokument4 Seiten4.5.redistrribution - PBR Quiz AnswersffbugbuggerNoch keine Bewertungen

- 06-Soil Fert Nutr MGTDokument8 Seiten06-Soil Fert Nutr MGTAndres LuqueNoch keine Bewertungen

- ENDOCRINE-BOARD REVIEW Dr. SchearDokument57 SeitenENDOCRINE-BOARD REVIEW Dr. SchearNayara PataroNoch keine Bewertungen