Beruflich Dokumente

Kultur Dokumente

Welding QC 9 - MMA

Hochgeladen von

Exsan OthmanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding QC 9 - MMA

Hochgeladen von

Exsan OthmanCopyright:

Verfügbare Formate

T.

wI

wot

THE w5151516nJsT:trrTE

S EC T IO N9

T\^/I

TtiE l!LD I NC I\STm_.it:

EQUIPMENT

Weldinginspectton

necessarily

involvescheckrngtharrne correct

welding/cutting

processis beingused,that tne equipmentis

in workable

conorltonand that ihe weldjngparametersof amperes

and voltsare Deing

adheredto.- Tn_efollowingpagesouflinethe constanr

currentprocessand list

the types of defectswhichare associatedwith them.

You will noticethat the arc processesare djvjded

into fwo (2) types (,drooping,

and 'flat'). Thrsrefersto theirvolt_ampoutput

characrerrstrcs.

The conventionar

machineis knownas the constantcurrentmachine

(drooping

characteristic)and has for many years been

used for manuarmetal arc and

tungsten inert gas werding. ey uiing drooping

an aiterationin ur. L"ng1h-g;uu.

a very small changein current.

--,,,._-]-,, ,,,.^_.

F

l

--i

l-; . r

D-r,

7 ) ?r'.c'-:

ril, .-

A. i,.,., ',

\ _-.

.1.

WELDING TECHNOLOGY

I s s u e0 1 9 1

C(. 1

T\vI

7nT

ThE \rLDINc NsTm,TE

A 'D RO O P I NGA RC' P R OC ES S(C ON ST A N T

C U R R E N T)

MANUAL METAL-ABC (MMA)

S h i e l d e dm e t a l - a r c( U S ) ;S t i c k ;

Electric

arc welding

Typicaldefectsassociated

with this

process:

Overlap.

Soudlfl.d tl.g

llfC

'Porosity.

t Slag inclusions.

. Excessivespafter.

Type of Operation

Manual.

Modeof Operation

Arc meits parentplateand

electrode

rorm a weld pool which is protectedto

by

llux cover.

Operatoradjustselectrodefeed

rate,i.e.

to

keep

arc tength

l:19^-ou:-"nt,

constant.

slag must be removedafter

depositingeachbead.Normally

a small

penetration,requirinsptate

edse

:::::._:l

p^reparation.

Bun welds in thickplateor

I a r g et t l l e t sa r e d e p o s i t e di n

a n u m b e ro f

passes.The process

can alsobe usedto

oepositmetal to form a surface

with

arlernat|vep roperties.

q.a

Strayflash.

Incompletepenetration.

Excesspenetration.

. Undercut.

Cratercracks.

Lackof fusion.

WELDING TECHNOLOGY

lssue Olgl

rI

TWI

wcf

Ti{E WEI.DING INSTM-I"IE

WELDINGEQUTPMENT

MANUALMETAL ARC

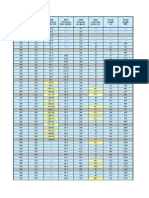

Welding sets

l-t

3s/

= ' \

lQLOarse

Curreaf

Fine

MMA welding set

Manual metal arc ".t "r:j5:-rfactured

in a rangeof sizes, usually

distinguished

by current:notethe dutycycreat wilrr the

currentis quoted

sets. EnginepowereO

g"n"rtors-altowoperationaway from

:T:TTp3ring

marnssupplies.

Electricarinputis singre-phase

at 240 vortsfor smarr

-- sets,and 415 vorts(2 rive

pnasesof a three-phasesupply)

for largerone;.

Outputis AC or DC. AC onlysets needan open

circuitvoltageof gOVto run

all erectrodes;

50V is safer.and arows,nor" "r""ni'to be drawn,

but is rimited

to generalpurposerutileelectrodes

only.

the set ad,lusts

current;the cunentis showneitheron a simpte

1::]|,1,

:n

scaJe,or for

accurateworkon a meter.

WELDINGTECHNOLOGY

lssue 0191

Q . 1

TWI

-ts

17 7.

'/!J1JE

llJE wELDI\c

I\STfn.T:

MANUALMETALARC WELDING

INTRODUCTION

rn manuaimetalarc weldingthe heat

sourceis an erectricarc whichis

iorrnec

betweena consumabte":*:a...

;l tn" p.r"ripf",e. The arc is

formedby

momentarrytouchingthe.tipof the

erectrodeonto-th"plateand then

liftinathe

erectrode

to sivea s"o "f^1^?Tl_1y:_.60m;

)

o.w".n

fz.;)

the

tipanolhe

plate. When the electrodetouches

the plate,.rrrun, aorr"nces

to

flow and

as it is withdrawnthe currentcontinues

to frowin the form of a sma, spark

acrossthe gap, whichwi, causethe

air in il" g; i; becomeionized,

or made

conoucttve.As a resultof this the

currentcontj-nrie.,otto* evenwhen

ihe qao

Theheatg.enerated

is sufiicient

to ,.rt ti.'ru

l:jr!"_l."ig.

parentptateand

arso

mertthe endof theerectrode;

the moltenr"tui ." formedis transferred

as small globules

acrossthe arc into the m;lte;

;;1.

EQUIPMENT

1 . P o w e rS o u r c e

j::,[:S

consisrs

of a powersourcewithweldinsreadand

an

H ft?chine

The functjonof the power.source

is to provide

malntainan arc belweenthe electrode'anO the voltagenecessaryto

tfre-*lr*p,"." and the end of

the electrode.The amount cufrent

prorO"J Oy",a"po*", source

,of

can be

attered by a conti.olto suit differenf

;"i;;;;;it."".

Power source may sueeJl_ldrlect

cuj-rent(DC) or akernarrngcurrent (AC)

to

tne electrode.AC transformers

and DC generati supplyonly one

type of

current,but transformer

_ rectifiers..n O-",*it"n"o

oetween

AC

or

DC

output.

Welding cables

The weldingcurrentis conducted

from the powersourceto tne

work by

multi-strand'

rnsurated

frexible

copperol.ur,;ini*i' caores.A returncabre

is required

to completethe weldingcircuitOetween

the work and power

;"J;:r'|i"ff:,"J"tf,"":"0't

'uit b" "m'itnt io' tnemaximunioutput

or

The earth lead is a third <labte and

acts as a safety device in the event

of

an electrjcal fault.

q.4

WELDING TECHNOLOGY

lssue Olgl

rr

T\vI

v1[s

TI'JEITELDI\C tN jin-l-

3 . E l e c t r o d eh o l d e r

The hordefshourdbe relativery

right,fu,y insurated

and ratedfor at Ieas:

maximumpowersourceoutout.

4 . R e t u r nc l a m p

This is fastenedto the work or benchon

whjchthe worKrs placedand

completesthe weldingcircuit.The surface

climpeOshouldbe clean

enough to allow good metal to metal contact.

5. Welding shield or helmet

A welding shieldor helm_et.is

necessaryfor protectionfrom arc ray and

heat, and the spatterfrom the motten metat.'-n" ur" is viewedthrough a

filter which reducesthe intensityof tne

riOiation,ir, n,orr" a safe amount

of light to pass for viewingthe weld pool

and end of the electrode.

WELDING TECHNOLOGY

I s s u e0 1 9 1

T\VI

700s

THE \T'ELDI\C

]\ \TTTIJ-

EFFECTOF VARIATIONIN PROCEDURE

1. Too shon an arc lengthwill cause

irregularpilingof the weld metal_

2. Too long an arc lengthwill cause

the depositto be coarserippled

and flatterthan normaj.

3. A slow rate of travel gives a wider

thicker deposit, shoder than normal

tength;too slow a rate of travel may

altow the slag to flood the weld pool

causrngdifficultyin controllingdeposition.

4. A fast rate of travel gives a narrower,

thinner deposit,longer than normal

tength;too fast a rate of travel mav

prevent adequate interfusionwith

ihe

parentmetal.

5. A low welding currentrenos to cause

the weld metal to pile up without

adequate penetrationinto the parent

metal;too low a weldingcurrentmakes

the

slag difficultto control.

6. A high

-weldingcurrentgivesa deposit

that is flatter and wider rnan normaj with

excessivepenetrationinto the parent

metal;too hjgh a wejdjngcurrentcauses

considerablespatter.

7.

correct arc length,cofrect rate

rylh

or lravel,correctweldingconditions

and technique,the run depositedmelal

will be regular in thicknessand width.

with a neat finelyrippledsurface,free

rrom porosityor any slag entrapment.

A r cl o or h o r l

C o a r sr r i p p l 3 3

a v a n I ti p a c c d

C.rter /lrt

A r c l o o l on g

rnd_blrstefcd

q'@

T r a v e lt o o s l o w

JraY?lloo

lasI

lrl?0slar frpplCi

t'rlh r16gtrappedin

vall?yt

C u r r en l l o o l o w

Q r a t e ri r r c A u 1 5 i

C o a r5 q 1 1 p1r .t

tvenly spoccd

C ur rc n l t o o h i g h

S m o ot h r , p g t e r

C o r r c c lr u n

WELDING TECHNOLOGY

Issue 0191

T\)t/I

w[t

THE \IELDING

L\STITI.J'TE

The shielded arc. Manualarc weld on steel base plate

with a covered

elecirode.

\\

;,

E

t r r. l-c- c, .r.r.o, ,u-erL,( ) v c n n g

t-l

E r c c rr o u c L o r e w t r c

I

Weld Pool

-l)

Slae

Weld ivlctal

WELDING TECHNOLOGY

lssue 0191

I

TWI

v70f

THE WELDING D,'ST|n,ryE

QUESTIONS:

MANUAL METAL ARC

l;: -

tt- - ,-:r

Explaintwo typesof electricalsupply

and an

-

l"t

r,-,

-,' ):a

T .

nQ

advantageof each type.

1"1..._-.

,.

\ ,'ytl.-i. , ,- -.

of powersourcecharacteristics

is considered

essentiat

for

HflXr""O"

a)

b)

Constantcurrent? Constantvoltage? -.--_

Give six functionsof an electrodecoatino.

i)

ii)

ii0

iv)

v)

vi)

Providesa gas shield

_,)

"

,^ra-. r- ',

wnar ts tne usualcomposition

oi the corewiie of an MMAelectrode?

as9

Das könnte Ihnen auch gefallen

- A-Health Advance - Application Form With InstructionsDokument14 SeitenA-Health Advance - Application Form With InstructionsExsan OthmanNoch keine Bewertungen

- Engineering Your Future PDFDokument605 SeitenEngineering Your Future PDFExsan OthmanNoch keine Bewertungen

- Remote Field Eddy CurrentDokument4 SeitenRemote Field Eddy CurrentExsan OthmanNoch keine Bewertungen

- A-Health Advance-I Premium RatesDokument2 SeitenA-Health Advance-I Premium RatesExsan OthmanNoch keine Bewertungen

- Astm C 871Dokument5 SeitenAstm C 871Exsan Othman100% (2)

- Asmt C 795Dokument4 SeitenAsmt C 795Exsan OthmanNoch keine Bewertungen

- Astm C 692 PDFDokument7 SeitenAstm C 692 PDFExsan Othman100% (1)

- Pipeline DataDokument4 SeitenPipeline DataExsan OthmanNoch keine Bewertungen

- AWS Weld Symbol ChartDokument1 SeiteAWS Weld Symbol ChartExsan OthmanNoch keine Bewertungen

- AWS Specifications For Filler MaterialDokument9 SeitenAWS Specifications For Filler MaterialExsan OthmanNoch keine Bewertungen

- Chat For Organization of CodeDokument1 SeiteChat For Organization of CodeExsan OthmanNoch keine Bewertungen

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Dokument6 SeitenCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNoch keine Bewertungen

- Calculation Minimum Required Thickness For Bending Pipe r2Dokument11 SeitenCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNoch keine Bewertungen

- MaterialsDokument181 SeitenMaterialsExsan OthmanNoch keine Bewertungen

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDokument1 SeiteHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNoch keine Bewertungen

- 300 - F&D Head Design Tool Ver E4.01Dokument1 Seite300 - F&D Head Design Tool Ver E4.01Honey TiwariNoch keine Bewertungen

- Hardness Conversion For Ferrous AlloysDokument2 SeitenHardness Conversion For Ferrous AlloysExsan OthmanNoch keine Bewertungen

- Piping TableDokument59 SeitenPiping TableExsan Othman100% (1)

- I) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerDokument1 SeiteI) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerExsan OthmanNoch keine Bewertungen

- Actvities On Boiler Maintenance: I. FurnaceDokument5 SeitenActvities On Boiler Maintenance: I. FurnaceExsan OthmanNoch keine Bewertungen

- Boiler Feedwater ControlDokument6 SeitenBoiler Feedwater ControlExsan OthmanNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- GENERAL5 Answer-1Dokument4 SeitenGENERAL5 Answer-1JlkKumarNoch keine Bewertungen

- AIGA 021 - 05 Oxygen Pipeline SystemsDokument74 SeitenAIGA 021 - 05 Oxygen Pipeline SystemsRamesh RameshvdNoch keine Bewertungen

- Effect of Variation in LPG Composition On Heating Value Using Aspen HYSYSDokument7 SeitenEffect of Variation in LPG Composition On Heating Value Using Aspen HYSYSIstiak HussainNoch keine Bewertungen

- Maritime Engineering Exam EthiopiaDokument7 SeitenMaritime Engineering Exam EthiopiaLemi Chala Beyene95% (37)

- Brief Survey of Wood Adhesives: Classification and DescriptionDokument10 SeitenBrief Survey of Wood Adhesives: Classification and DescriptionHari BudiartoNoch keine Bewertungen

- Handbook On Textile Auxiliaries With FormulationsDokument6 SeitenHandbook On Textile Auxiliaries With FormulationsSarweshwaranand Pandey100% (2)

- Aerospace MaterialsDokument21 SeitenAerospace MaterialsrkneyveliNoch keine Bewertungen

- BP Guide Pharma ComplianceByDesign en Nov15Dokument12 SeitenBP Guide Pharma ComplianceByDesign en Nov15Jessicalba LouNoch keine Bewertungen

- Acids and Bases Used Natural Indicators (Hibiscus Flowers)Dokument5 SeitenAcids and Bases Used Natural Indicators (Hibiscus Flowers)Winda SglgNoch keine Bewertungen

- Oxidation Reduction Potential (Orp) :redox and Free ChlorineDokument2 SeitenOxidation Reduction Potential (Orp) :redox and Free ChlorinePraneeth SrivanthNoch keine Bewertungen

- Corrosion Protection SystemsDokument9 SeitenCorrosion Protection SystemsDan PascaruNoch keine Bewertungen

- Control of Retained Delta Ferrite in Type 410 Stainless SteelDokument7 SeitenControl of Retained Delta Ferrite in Type 410 Stainless SteelEnp JgcNoch keine Bewertungen

- Catalytic Activity of Transition ElementsDokument47 SeitenCatalytic Activity of Transition ElementsNeen Naaz100% (1)

- Plasma W&S CatalogueDokument124 SeitenPlasma W&S CataloguePramod AthiyarathuNoch keine Bewertungen

- Monalite® - Technical Data Sheet - EnglishDokument2 SeitenMonalite® - Technical Data Sheet - EnglishLorena CCNoch keine Bewertungen

- Equivalência Materiais - OTIMO PDFDokument40 SeitenEquivalência Materiais - OTIMO PDFTúlio Barata FrançaNoch keine Bewertungen

- Camphor WaterDokument19 SeitenCamphor WaterChristine Ranoa100% (1)

- Outokumpu - Wallchart Product RangesDokument5 SeitenOutokumpu - Wallchart Product RangesXavierNoch keine Bewertungen

- 1-s2.0-S0950061816308364-Kunal Kupwade Patil Fly Ash 2016Dokument25 Seiten1-s2.0-S0950061816308364-Kunal Kupwade Patil Fly Ash 2016Israel VenkatNoch keine Bewertungen

- Recent Advances in Dental MaterialsDokument11 SeitenRecent Advances in Dental MaterialsAjith KumarNoch keine Bewertungen

- Submerged Arc TechnologyDokument11 SeitenSubmerged Arc TechnologymerlonicolaNoch keine Bewertungen

- Aggregation of Charged Colloidal Particles SPRINGERLINK ChpterDokument41 SeitenAggregation of Charged Colloidal Particles SPRINGERLINK ChpterAnonymous GYl4dpXoNoch keine Bewertungen

- Msts Study Guide Asme Pcc-2Dokument40 SeitenMsts Study Guide Asme Pcc-2jpwhyteincNoch keine Bewertungen

- Sulfate Soundness TestDokument2 SeitenSulfate Soundness TestdevendrapadhiyarNoch keine Bewertungen

- Coconut Oil - WikipediaDokument11 SeitenCoconut Oil - WikipediaYusuf Aliyu UNoch keine Bewertungen

- MFDokument29 SeitenMFRayhan AdhaNoch keine Bewertungen

- Experiment #1Dokument7 SeitenExperiment #1Lakani Tindiwi YangalaNoch keine Bewertungen

- Refractory EngineeringDokument3 SeitenRefractory EngineeringaauppalNoch keine Bewertungen

- Carbon Fibres: Production, Properties and Potential Use: Pooja Bhatt and Alka GoelDokument6 SeitenCarbon Fibres: Production, Properties and Potential Use: Pooja Bhatt and Alka GoelResego PhiriNoch keine Bewertungen

- Alloy 59 - Alfa Laval Olmi Aprile 2018 PDFDokument12 SeitenAlloy 59 - Alfa Laval Olmi Aprile 2018 PDFfabianoNoch keine Bewertungen