Beruflich Dokumente

Kultur Dokumente

Method Statement - Structural Excavations

Hochgeladen von

Nikolay DrumevCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement - Structural Excavations

Hochgeladen von

Nikolay DrumevCopyright:

Verfügbare Formate

YOUR COMPANY HEAD HERE

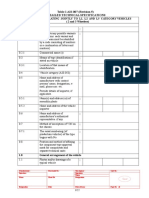

METHOD STATEMENT FOR STRUCTURAL EXCAVATIONS

Project Number:

Project name:

Work Activity: Structural Excavation

Work Location: All locations

Date:

Reference number: MS-001-SE

Prepared by:

Checked by:

Objective:

To complete the required excavations to the lines, levels and profiles as

per Drawings and Engineers instructions.

Timescale:

The works should be completed in 30 days.

Stages:

Reducing Risks:

-

Use of mechanical means where possible

Use and continual use of personal protective equipment (PPE)

Continual inspection of plant and tools

Providing proper shoring if needed

Health, Safety and Environmental (HSE) Assessment

-

According to the HSE plan page.

Means of egress from excavations will be decided and made. A stairway,

ladder, ramp or other safe means of egress will be located in the

excavations.

The works will be executed during daylight or with sufficient artificial

lighting.

Supervision:

-

The works will be supervised by a Structural Engineer, HSE officer and a

Surveyor.

Plant/Equipment:

-

Excavators

Wheel Barrows

Pay loaders

Hand Tools

Trucks

Total station

YOUR COMPANY HEAD HERE

Work method:

General:

1. All drawings and plan will be studied and understood before works

commence.

2. Lines and levels will be set by a competent person.

3. Lines and levels profiles will be continually checked during the works.

Underground utilities:

4. There are no underground utilities passing through the worksite.

Extent of the excavation works:

5. To the lines and levels shown in the excavation plans (DWG)

Excavation:

6. The excavations will be carried out in dry conditions. There is no danger of

water entering or disturbing the excavations other than due to weather

conditions.

7. Machine excavation until reaching the levels shown on the drawings:

The excavation will continue manually until reaching the founding level.

Disposal of the excavated materials:

8. The material which is suitable for backfill will be stored on site, in a

designated place which doesnt hinder the works. Due to the expected

large amount of suitable fill material two or more places might be used if

needed.

9. The material which is not suitable for backfill will be disposed at a depot.

No documents or permits are required from the Municipality and local

authorities.

Treatment of subgrade prior to filling or subsequent construction:

10.Cleaning, grubbing and removal of unsuitable material, leveling the face to

receive fill, moisture conditioning and compacting as required in section

02210-3, Table 3-1 from the civil specifications.

11.Free of standing or running water.

Placing and compaction of fill material:

12.Backfill and fill materials will be placed in layers not greater than 200mm

loose depth when compacted by heavy machinery and 100mm loose

depth when compacted by hand-operated tampers as per the

requirements in section 02220-7, 8 from the civil specifications.

Proposal for dust and noise control:

13.Continuous moisturizing of the surfaces to lower dust forming.

14.The noise level should be within reasonable levels. If needed one or more

of the following actions may be taken: providing earplugs, rotating workers

YOUR COMPANY HEAD HERE

performing noisy tasks, shutting down noisy equipment when not needed,

substituting existing equipment with quieter equipment, retro-fitting

existing equipment with damping materials, mufflers, or enclosures or

other methods proposed by the HSE officer or the Engineer.

Emergencies:

-

The supervisor and HSE officer will have mobile phones available to

summon assistance.

Hospital directions and map placed on site office wall.

Name and position:

Approved by:

..

..

Signature:

Das könnte Ihnen auch gefallen

- Electrical Encasement Method StatementDokument2 SeitenElectrical Encasement Method Statementsujith s pNoch keine Bewertungen

- MOS FOR Plaster MetitoDokument7 SeitenMOS FOR Plaster Metitoeng mohamad husamNoch keine Bewertungen

- Rev-2 Method Statement For Building Construction Works Puma Energy Daulatpur ProjectDokument12 SeitenRev-2 Method Statement For Building Construction Works Puma Energy Daulatpur ProjectM Waqas HabibNoch keine Bewertungen

- Method Statement SandingDokument1 SeiteMethod Statement SandingShah AlamNoch keine Bewertungen

- Example Method Statement For The Installation of Concrete Floor SlabsDokument8 SeitenExample Method Statement For The Installation of Concrete Floor SlabsLombe Paul OkparaNoch keine Bewertungen

- Method Statement Excavation Works ScribdDokument8 SeitenMethod Statement Excavation Works ScribdMoshotle InnocentNoch keine Bewertungen

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDokument5 SeitenRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNoch keine Bewertungen

- GRP Method StatementDokument33 SeitenGRP Method StatementManiNoch keine Bewertungen

- Method Statement For Excavation and Back Filling WorksDokument4 SeitenMethod Statement For Excavation and Back Filling WorksLAM CONoch keine Bewertungen

- Method Statement For Demolition of Building Structures 1Dokument2 SeitenMethod Statement For Demolition of Building Structures 1Bernz OdranNoch keine Bewertungen

- Paving Method StatementDokument7 SeitenPaving Method StatementOfentse LedwabaNoch keine Bewertungen

- Method Statement For Brickworks: Pembinaan Infra E&J SDN BHDDokument5 SeitenMethod Statement For Brickworks: Pembinaan Infra E&J SDN BHDChezy6290% (1)

- Lps 01 Hti MST Me 007 GRP Water TankDokument12 SeitenLps 01 Hti MST Me 007 GRP Water TankJomy JohnyNoch keine Bewertungen

- METHOD - STATEMENTf New ForDokument48 SeitenMETHOD - STATEMENTf New Forhysh89Noch keine Bewertungen

- Confined Space EntryDokument8 SeitenConfined Space EntryJoy WilsonNoch keine Bewertungen

- MOS 2x15T EOTC Robotic ShopDokument17 SeitenMOS 2x15T EOTC Robotic ShopJohn Rey PerlasNoch keine Bewertungen

- Demountable Partition Installation - Method StatementDokument8 SeitenDemountable Partition Installation - Method StatementÖmer Faruk TaşdemirNoch keine Bewertungen

- METHOD OF STATEMENT - ALKHOMRA PROJECT - MarbleDokument9 SeitenMETHOD OF STATEMENT - ALKHOMRA PROJECT - Marbleahmed samirNoch keine Bewertungen

- Anti Termite Method StatementDokument5 SeitenAnti Termite Method StatementTijjani BelloNoch keine Bewertungen

- Method of Statement For Core Drilling WorksDokument7 SeitenMethod of Statement For Core Drilling WorksUgurNoch keine Bewertungen

- Methodology For Storm WaterDokument25 SeitenMethodology For Storm WaterTheodore Teddy KahiNoch keine Bewertungen

- Method Statement Concrete Works 2019Dokument8 SeitenMethod Statement Concrete Works 2019محمد فتحىNoch keine Bewertungen

- Safety Signs On Construction SiteDokument1 SeiteSafety Signs On Construction SiteBëBå Wossen AssefaNoch keine Bewertungen

- Safety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁDokument12 SeitenSafety Method Statement: U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - Á U (tÜÜ - ÁnabillyusofNoch keine Bewertungen

- Method Statement of Brick Masonary WorkDokument6 SeitenMethod Statement of Brick Masonary WorkMihirduttaNoch keine Bewertungen

- Method Statement For ExcavationDokument2 SeitenMethod Statement For ExcavationGkou Dojku100% (1)

- Method Statement TempDokument3 SeitenMethod Statement TempridminjNoch keine Bewertungen

- Block Work MS (Sample)Dokument18 SeitenBlock Work MS (Sample)jones100% (1)

- Attachment 3 - Detailed Scope of Work Construction of The New Franklin Park Storage BuildingDokument13 SeitenAttachment 3 - Detailed Scope of Work Construction of The New Franklin Park Storage BuildingdpkNoch keine Bewertungen

- Draft Method Statement Decorative Tile Installation - RemovedDokument17 SeitenDraft Method Statement Decorative Tile Installation - Removedyusuf anwerNoch keine Bewertungen

- SWP 03 - Hacking WorksDokument3 SeitenSWP 03 - Hacking WorksGerald Wong NttNoch keine Bewertungen

- Asbestos Management (Removal, Handling and Disposal)Dokument8 SeitenAsbestos Management (Removal, Handling and Disposal)Okhwa WangilaNoch keine Bewertungen

- SDS - Acrylic Emulsion Primer - English (Uk) - DubaiDokument4 SeitenSDS - Acrylic Emulsion Primer - English (Uk) - DubaiBalasubramanian AnanthNoch keine Bewertungen

- Method Statements 01 - Demolition WorksDokument8 SeitenMethod Statements 01 - Demolition WorksMathewNoch keine Bewertungen

- 15 02 16 Scope of WorksDokument3 Seiten15 02 16 Scope of WorksRicarte Pillos IIINoch keine Bewertungen

- Summary of Quantities: Item D E S C R I P T I O N Unit Quantity As Plan Quantity Remarks As TakeDokument1 SeiteSummary of Quantities: Item D E S C R I P T I O N Unit Quantity As Plan Quantity Remarks As TakeLuigi MontederamosNoch keine Bewertungen

- MS - Raft PouringDokument14 SeitenMS - Raft PouringAby ThykkodathuNoch keine Bewertungen

- Method Statement SampleDokument16 SeitenMethod Statement Sampleuebdennis100% (1)

- Trenching and Excavation SafetyDokument6 SeitenTrenching and Excavation SafetySn AhsanNoch keine Bewertungen

- ExcavationDokument24 SeitenExcavationAhmed ImranNoch keine Bewertungen

- Method Statement For Leakage Testing of Gravity Sewer LineDokument3 SeitenMethod Statement For Leakage Testing of Gravity Sewer LineGerlie DimayugaNoch keine Bewertungen

- Ms - Ele - 01 - PVC Conduit & Gi BoxDokument17 SeitenMs - Ele - 01 - PVC Conduit & Gi BoxromeyleenjosephNoch keine Bewertungen

- Personal Protective EquipmentDokument4 SeitenPersonal Protective EquipmentNajiha Izzati100% (1)

- Method StatementDokument4 SeitenMethod StatementtayitbatovNoch keine Bewertungen

- Work Method Statements For Reed SelectDokument53 SeitenWork Method Statements For Reed SelectInoe InaeNoch keine Bewertungen

- JMS 36 - Roofing WorkDokument9 SeitenJMS 36 - Roofing WorkNaditek BinaNoch keine Bewertungen

- Al Masaood Bergum: ExcavationDokument4 SeitenAl Masaood Bergum: ExcavationAnonymous 3eHGEDbxNoch keine Bewertungen

- EMP - Environmental Risk RegisterDokument23 SeitenEMP - Environmental Risk RegisterNaveen ChaudharyNoch keine Bewertungen

- MS-G-003 - General Method Statement For Horizontal PumpDokument19 SeitenMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNoch keine Bewertungen

- Structured Method Statement For Concrete Repair - 2Dokument10 SeitenStructured Method Statement For Concrete Repair - 2m.umarNoch keine Bewertungen

- MOS Glass Window WorksDokument5 SeitenMOS Glass Window WorksCamlockNoch keine Bewertungen

- WQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers WorksDokument68 SeitenWQIP-D1-ILF-T-0203 V2 METHOD STATEMENT FOR Manholes and Valve Chambers Worksmuhammad.younisNoch keine Bewertungen

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Dokument39 SeitenCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNoch keine Bewertungen

- Roof Renovation Project: Partial Roof Repair by Musanadah Facility MaintenanceDokument9 SeitenRoof Renovation Project: Partial Roof Repair by Musanadah Facility MaintenanceJimmy GutierrezNoch keine Bewertungen

- Site OrgnizationDokument38 SeitenSite Orgnizationaugustine samuelNoch keine Bewertungen

- Favor SOP 3 - Routine Housekeeping and Deep CleaningDokument9 SeitenFavor SOP 3 - Routine Housekeeping and Deep CleaningEric-Michael Wilson, IINoch keine Bewertungen

- Epoxy Grouting Application Work ProcedureDokument14 SeitenEpoxy Grouting Application Work Proceduremanoj thakkarNoch keine Bewertungen

- 171461ot Demolition Method Statement - Units 27-28 Rev 11-06-17Dokument27 Seiten171461ot Demolition Method Statement - Units 27-28 Rev 11-06-17mohamedamine.zemouriNoch keine Bewertungen

- Lab Report No 8Dokument4 SeitenLab Report No 8Kamran AliNoch keine Bewertungen

- Work Methodology, Road WorksDokument14 SeitenWork Methodology, Road WorksFRANCIS KAGUANYUNoch keine Bewertungen

- Aashto GSH-2008Dokument466 SeitenAashto GSH-2008Nikolay DrumevNoch keine Bewertungen

- Aashto T 87-1986 R2004Dokument4 SeitenAashto T 87-1986 R2004Nikolay Drumev0% (1)

- ACI 207 1R 05 Guide To Mass ConcreteDokument30 SeitenACI 207 1R 05 Guide To Mass Concretejua666nNoch keine Bewertungen

- Astm C33 PDFDokument8 SeitenAstm C33 PDFJorge R. Vega C100% (4)

- Astm C131 - 2006Dokument4 SeitenAstm C131 - 2006Jessica FarrugiaNoch keine Bewertungen

- Astm C 127 PDFDokument7 SeitenAstm C 127 PDFNikolay DrumevNoch keine Bewertungen

- Astm C 882Dokument4 SeitenAstm C 882Nikolay Drumev33% (3)

- Astm C 150 2007Dokument8 SeitenAstm C 150 2007Nikolay Drumev100% (1)

- Astm C 144-2004Dokument2 SeitenAstm C 144-2004Nikolay DrumevNoch keine Bewertungen

- Astm C 150 2007Dokument8 SeitenAstm C 150 2007Nikolay Drumev100% (1)

- Astm C 936-2007Dokument2 SeitenAstm C 936-2007Nikolay DrumevNoch keine Bewertungen

- Astm D 6690Dokument4 SeitenAstm D 6690Nikolay Drumev0% (1)

- ASTM А 497Dokument8 SeitenASTM А 497Nikolay DrumevNoch keine Bewertungen

- ASTM А 496Dokument7 SeitenASTM А 496Nikolay DrumevNoch keine Bewertungen

- Astm C33 PDFDokument8 SeitenAstm C33 PDFJorge R. Vega C100% (4)

- Astm D 4220Dokument11 SeitenAstm D 4220Nikolay Drumev100% (1)

- Astm C117-1995Dokument3 SeitenAstm C117-1995Yiu Fai WongNoch keine Bewertungen

- Astm C 150 2007Dokument8 SeitenAstm C 150 2007Nikolay Drumev100% (1)

- Astm D 3282Dokument6 SeitenAstm D 3282Nikolay DrumevNoch keine Bewertungen

- Classification of Soil and Soil-Aggregate AASHTO M-145Dokument4 SeitenClassification of Soil and Soil-Aggregate AASHTO M-145caballerolang0% (1)

- Pooja CVDokument3 SeitenPooja CVEl Cajon de AmeliaNoch keine Bewertungen

- Kinematic Analysis of 5 Dof Lynx ArmDokument6 SeitenKinematic Analysis of 5 Dof Lynx ArmsathyaNoch keine Bewertungen

- Type of Ac StatementDokument3 SeitenType of Ac StatementRoberto SmithNoch keine Bewertungen

- Chapter 6 Tutorial PDFDokument4 SeitenChapter 6 Tutorial PDFAhmad NAz RaInNoch keine Bewertungen

- How Is Saleable Area CalculatedDokument5 SeitenHow Is Saleable Area CalculatedkailashNoch keine Bewertungen

- Rukovodstvo Atlas Copco Xahs 447 CDDokument99 SeitenRukovodstvo Atlas Copco Xahs 447 CDradamantus100% (1)

- Philips Accent LightingDokument37 SeitenPhilips Accent LightingCecila Torrez BenitezNoch keine Bewertungen

- 243 RegulatorDokument24 Seiten243 RegulatorDavid Somogyi DovalNoch keine Bewertungen

- Criterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareDokument6 SeitenCriterion 6 Facilities and Technical Support 80: With Computer Systems GCC and JDK SoftwareVinaya Babu MNoch keine Bewertungen

- Commodity Market (A Project Report)Dokument6 SeitenCommodity Market (A Project Report)Manish GargNoch keine Bewertungen

- Palmtop Computer (Report of Early Usage)Dokument8 SeitenPalmtop Computer (Report of Early Usage)rodrigur8036100% (2)

- AIS - 007 - Rev 5 - Table - 1Dokument21 SeitenAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseNoch keine Bewertungen

- IEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionDokument5 SeitenIEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionkaruldeepaNoch keine Bewertungen

- Quick Operation Guide of DS-7200-ST DVR (V1.2.0)Dokument40 SeitenQuick Operation Guide of DS-7200-ST DVR (V1.2.0)Roman MayurNoch keine Bewertungen

- NCHRP Report 507Dokument87 SeitenNCHRP Report 507Yoshua YangNoch keine Bewertungen

- Novell Course 3076 SUSE Upgrading To Certified Linux Engineer 10Dokument362 SeitenNovell Course 3076 SUSE Upgrading To Certified Linux Engineer 10Legioner LegionerovNoch keine Bewertungen

- Organic PoolsDokument163 SeitenOrganic PoolsEdu Socolovsky100% (3)

- Schlafhorst Texlab: Catalogue of ServicesDokument27 SeitenSchlafhorst Texlab: Catalogue of ServicesvenkatspinnerNoch keine Bewertungen

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFDokument5 SeitenLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerNoch keine Bewertungen

- Oracle - Fusion - Middleware - 11g ADF I Volume IDokument374 SeitenOracle - Fusion - Middleware - 11g ADF I Volume IMaged AliNoch keine Bewertungen

- OZONE 70W Programmable LED Drivers :: ROAL Living EnergyDokument12 SeitenOZONE 70W Programmable LED Drivers :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- Pre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumDokument13 SeitenPre-Disciplinary and Post-Disciplinary Perspectives: Bob Jessop & Ngai-Ling SumMc_RivNoch keine Bewertungen

- SimonKucher Ebook A Practical Guide To PricingDokument23 SeitenSimonKucher Ebook A Practical Guide To PricingHari Krishnan100% (1)

- Behringer FX2000-Product InfoDokument10 SeitenBehringer FX2000-Product Infogotti45Noch keine Bewertungen

- 002 SM MP4054Dokument2.009 Seiten002 SM MP4054tranquangthuanNoch keine Bewertungen

- Ms For Demin Water Tank Modification Rev 1 Feb. 28 2011lastDokument9 SeitenMs For Demin Water Tank Modification Rev 1 Feb. 28 2011lastsharif339100% (1)

- Eletrical Motor OffshoreDokument38 SeitenEletrical Motor OffshoreandreisraelNoch keine Bewertungen

- Final Exam Review Questions Funds of SecurityDokument65 SeitenFinal Exam Review Questions Funds of Securityidk80% (5)

- Appendix A.ivankova, Et Al.2006Dokument34 SeitenAppendix A.ivankova, Et Al.2006Ismet EliskalNoch keine Bewertungen

- Educational Design Research: Introduction and Illustrative CasesDokument24 SeitenEducational Design Research: Introduction and Illustrative Casespatterson nji mbakwaNoch keine Bewertungen