Beruflich Dokumente

Kultur Dokumente

Solvent Extraction in Production and Processing of Uranium and Thorium

Hochgeladen von

Rubaiyat IshtiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Solvent Extraction in Production and Processing of Uranium and Thorium

Hochgeladen von

Rubaiyat IshtiCopyright:

Verfügbare Formate

This article was downloaded by: [ABM Utvikling STM / SSH packages]

On: 4 January 2009

Access details: Access Details: [subscription number 788608356]

Publisher Taylor & Francis

Informa Ltd Registered in England and Wales Registered Number: 1072954 Registered office: Mortimer House,

37-41 Mortimer Street, London W1T 3JH, UK

Mineral Processing and Extractive Metallurgy Review

Publication details, including instructions for authors and subscription information:

http://www.informaworld.com/smpp/title~content=t713644625

Solvent Extraction in Production and Processing of Uranium and Thorium

Harvinderpal Singh a; C. K. Gupta a

a

Materials Group, Bhabha Atomic Research Centre, Mumbai, India

Online Publication Date: 01 September 2000

To cite this Article Singh, Harvinderpal and Gupta, C. K.(2000)'Solvent Extraction in Production and Processing of Uranium and

Thorium',Mineral Processing and Extractive Metallurgy Review,21:1,307 349

To link to this Article: DOI: 10.1080/08827500008914172

URL: http://dx.doi.org/10.1080/08827500008914172

PLEASE SCROLL DOWN FOR ARTICLE

Full terms and conditions of use: http://www.informaworld.com/terms-and-conditions-of-access.pdf

This article may be used for research, teaching and private study purposes. Any substantial or

systematic reproduction, re-distribution, re-selling, loan or sub-licensing, systematic supply or

distribution in any form to anyone is expressly forbidden.

The publisher does not give any warranty express or implied or make any representation that the contents

will be complete or accurate or up to date. The accuracy of any instructions, formulae and drug doses

should be independently verified with primary sources. The publisher shall not be liable for any loss,

actions, claims, proceedings, demand or costs or damages whatsoever or howsoever caused arising directly

or indirectly in connection with or arising out of the use of this material.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Min. Pro. Ex,. Ma. Rev.. Vol.21. pp.307-349

Reprints available directly tram the pubhrhcr

Photcapying permitled by license only

Q 2OOO OPA (Over-

Publishers Alsociation) N.V.

Publrhed by license under

the Gordon and Breach Scicnac

Publishers imprint.

Prinld in Malaysia.

Solvent Extraction in Production

and Processing of Uranium

and Thorium

HARVINDERPAL SlNGH and C. K. GUPTA

Materials Group, Bhabha Atomic Research Centre, Mumbai 400085,

India

Solvent extraction plays a vital role in the production and processing of uranium and

thorium for use as fuels in the front-end of the nuclear fuel cycle. The development of

solvent extraction technology in the nuclear field in the last five decades has contributed

to advances in the non-nuclear hydrometallurgy. In turn the large scale applications in

the field of base metals such as copper have led to development of new equipment and

techniques as well as better understanding of the process chemistry and hydrodynamics.

Advances in the field of solvent extraction of relevance to the nuclear fuels, are reviewed

in this paper. The significant results from the research and development work in India

are also included. Various aspects discussed include chemistry of process flowsheets for

uranium and thorium recovery and refining including recent improvements, diluents for

use in the processes, thermal effects in extraction, process instrumentation including

on-line measurements, solvent loss by entrainment, purification of feed streams prior to

extraction, solvent-in-pulp processing, separation of uranium and thorium, binary extractants and application of solvent extraction in uranium enrichment.

Keyu'ords: Uranium; thorium; solvent extraction; nuclear fuel; processes; chemistry;

instrumentation; loss; diluent; enrichment

INTRODUCTION

The high purity required for production and processing of uranium and

thorium for use as fuels in the nuclear reactors, with concentration of

some of the specific elements (called as nuclear poisons) limited to less

than a fraction of ppm, can only be achieved by use of highly selective

extracting agents used in the liquid or immobilised forms such as

membranes o r impregnated resins. Developments in the nuclear field

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

308

H. SlNGH AND C. K. GUPTA

have led to maturing of solvent extraction technology which finds

application today in diverse fields such as hydrometallurgy for recovery of base metals, environmental engineering for removal of pollutants, analytical chemistry for separation and determination of metals

in trace concentrations and organic industry, among others. There has

been an inter-dependent growth among these areas in last few decades, whereby advances made in one field find application in others. In

particular there has been a better understanding of process chemistry,

hydrodynamics of processes operated in large scale equipment and the

interface of solvent extraction with related fields. Some of the recent

developments in these areas, of interest to the nuclear hydrometallurgy, are discussed in this paper. The data from the Indian research

investigations has been highlighted. The discussion essentially pertains

to the 'front-end' of the nuclear fuel cycle, but it is also recognised that

there are related developments in the 'back-end' of the cycle which are

equally relevant.

Uranium and thorium processing by solvent extraction essentially

involves two steps. In the first step processing of leach solutions obtained by acid o r alkali leaching of lean ore/crude concentrate is

carried out with the objective of produing a chemically pure concentrate that is free of gross impurities such as silica and iron. In the

second step, referred to as refining, purification is carried out by separation of elements that are regarded as nuclear poisons. There is a

related area where uranium and thorium are separated from the solutions where they occur simultaneously. The separation processes for

the two steps are discussed first in this paper, and then specific fundamental phenomenon, common to all solvent extraction processes are

discussed with reference to uranium and thorium.

URANIUM EXTRACTION AND REFINING PROCESSES

Extraction of uranium from ore leach solutions is carried out by

solvent extraction, o r by ion exchange or by a combination of the

two processes. The leach 'solutions are generally acidic in nature.

Amine extraction has replaced the extraction by di-2-ethyl hexyl

phosphoric acid (DZEHPA) which has poor selectivity with reference

to iron.

URANIUM AND THORIUM SOLVENT EXTRACTION

309

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Amine Extraction from Ore Leach ~olutions

High molecular weight amines are widely used for uranium recovery

from sulphuric acid ore leach solutions on industrial scale [I]. Tertiary amines are known to be efficient extractants [2], as are branched

aliphatic amines. The mechanism of extraction has been a matter of

study by several investigators [3-51. Reactions between sulphuric acid

and amine, equilibria between amine sulphate/bisulphate and uranium

complexes has been difficult to explain. In particular the observed

exponential dependence of the uranium-VI distribution ratio on the

amine sulphate concentration is difficult to correlate with the apparent ratio of amine to U-Vl in the extracted species [4]. Mechanism

based on parallel competing reactions and the law of mass action

yields results consistent with the observations [5]. The sulphuric acid

extraction can be described by the reactions

The reactions involving uranyl sulphate extraction are:

UO, SO4 = uo;+ + so:-

(6)

Parallel reactions (3) and (4) occur in the stoichiometric ratio, x, while

(7) and (8) are described by the ratio, y. By mass balance the distribution ratio D can be expressed in terms of x and y. A t high initial amine

310

H . SlNGH AND C. K.GUPTA

and free amine concentrations x 1, while a t lower values x is lower

and a proportion of amine bisulphate is formed. The D value for acid

shows a maxima in the pH range 1.25-2.25, with the peak shifting to

higher value as the initial amine concentration increases. The extraction of uranium shows similar trends, except that initial uranium

concentration is too small to saturate the organic phase. Hence D falls

only a t the lowest conditions, at pH 1.25.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

P r o c e s s I m p r o v e m e n t s in t h e Amine Solvent

Extraction P r o c e s s

Improvements in amine process flowsheets include the use of strong

acid for stripping of uranium, and precipitation from the strip solution

by hydrogen peroxide, thereby completely eliminating the use of ammonia [6,7]. The conventional ammonium sulphate stripping of uranium can lead to crud problem and loss of solvent. Besides ammonia

limits for effluent disposal are stringent and difficult to achieve continuously on plant scale. The chloride strip is free of the crud problem,

but again there are environmental discharge limits on chloride ion.

Strong sulphuric acid strip, 400 g/l, yields a pregnant solution containing upto 125 g/l uranium. After peroxide precipitation, the solution can be recycled o r safely sent to the effluent treatment plant.

Reactions involved are:

Free acid level of 275 g/l was found necessary for efficient stripping,

with barren organic containing less than 0.1 g/l uranium. Degradation

of the organic by strong acid becomes high a t high temperatures, and

stripping must be done below 35C. At this temperature the degradation is significantly lower than the entrainment loss rate. The acid

concentration also needs to be kept lower than 450g/I. High oxidation

potential of the leach solution and the presence of molybdenum in the

feed are other causative factors for crud formation.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

311

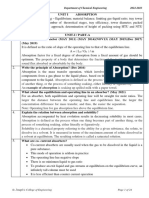

In India we have carried out batch and pilot plant solvent extraction tests on leach solution of Domiasiat uranium ore [8-131. The

feed was obtained by two stage counter-current leaching. It was purified by activated carbon. The feed analysis is given in Table 1. Batch

kinetics were studied for extraction with 3.5% AIamine 336 and

1.75% iso-decanol in refined kerosene at 29C. Results on kinetics

show complete extraction in 10 seconds. A continuous mixer however

requires more time, 30-60 seconds. Pilot plant flowsheet is shown in

Figure I. Four stage counter-current extraction showed a loading of

1.7g/l in the extract with raffinate analysing 0.005g/l, showing over

99% extraction. Distribution ratio of 24 and saturation loading of the

organic phase of 2.241 were determined. The mixer-settler used for

test runs were operated at a feed rate of 1000-1500l/h. The mixer

hydrodynamic data is given in Table 11. Stripping with ammoniacal

ammonium sulphate as well as strong acid was equally effective. Acid

strip results are given Table 111. During operation, slight crud formation was observed. The average rate of crud of generation was 39 g/m3

of feed processed. The crud accumulated in the settler solvent, which

was processed periodically in a solid bowl centrifuge a t a feed rate of

1200 l/h. Crud recovered was 145 g/m3 or solvent. The amine entrainment losses were measured a t various points in the process. The raffinate was passed through a parallel plate separator and then through

a flotation cell. Results are given in Table IV. The solvent recovered in

the parallel plate separator was measured and found to be 40 rnl/rn3

of feed solution processed. Similarly the recovery from the flotation

TABLE1 Analysis of the Domiasiat uranium leach solution

used as reed lor solvent extraction by alamine

Species

U38

Fe-Ill

Fe-I1

P A

Ca

dl

0.93

0.85

0.1

0.13

0.27

H. SINGH AND C. K. GUPTA

pregnant

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

feed

1 : AQUEOUS FEED TANK

4 : EXTRACTION UNIT

7 : AIR FLOTATION CELL

9 : SOLVENT

REGENERATOR

raffiate

2: SAND FILTER

%CARBONCOLUMN

5: STRIPPING UNTI 6 : PARALLEL PLATE

8 : SOLVENT TANX

10 : mm FILTER

11:CARBON COLUMN

12 : STRIP FEED TANK

FIGURE 1 Schematic flowsheet for uranium extraction.

cell was 0.2 ml/m3. A final effluent sample was treated with carbon

and it was round that complete removal was achieved. In a parallel

test, the final effluent was neutralised with lime and filtered and in the

filtrate the amine level was found to be 2 ppm, which is much below

the toxicity limits. Air-borne hydrocarbon levels in the working environment were measured with Kitgawa gas detector tubes. It was

URANIUM AND THORIUM SOLVENT EXTRACTION

313

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

TABLE 11 Mixer-settler for solvent extraction

I. MIXER

1.1 SlZE

1.2 VOLUME

1.3 IMPELLER (D)

1.4 NO. O F BLADES

1.5 WIDTH (W)

1.6 TYPE

1.7 SPEED (N)

1.8 N3D2

1.9 INFLOW ORIFICE

1.10 CLEARANCE

2. SEITLER

2.1 SlZE

2.2 INLET

2.3 RECYCLE

500 x 500 x 410 (mm)

100 Litres

240 mm, D,T = 0.48

6

40(W/D= 116, WIT= 1/12)

T O P SHROUDED TURBlNE

250 RPM = 4.17RPS

45 (it2 rps3)

100 mm

15 mm

500 mm x 1200mm (0.6 m2)

PICKET FENCE BAFFLES

ORGANIC 1:4

TABLE 111 Strong acid stripping ofamine extract of uranium

S. no.

CffPOJ

M

Strip U30,

(910

% Stripping

TABLE IV Entrainment levels in pilot plant (ppm)

S. no.

I

2

3

4

Raffinare

P P S efluent

Floated

efluent

13

26

22

21

3

II

13

12

3

6

6

6

PPS = Parallel Plate Separator. Levels given in ppm.

found that the concentrations were in the range 50-100 ppm near the

unit and below detection limit at three metres distance. The concentration inside the vapour space below the mixer cover and above

liquid level was about 200 ppm. All these are below the T.L.V. limits

for hydrocarbon vapours.

314

H . SlNGH AND C. K. GUPTA

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Recent developments, which are a matter of intense study, include

the use of hollow fibre type liquid membranes for uranium extraction

[14-161. A pilot plant plant was operated for extraction of uranyl

nitrate Tri-n-octyl phosphate (TOP). T O P was preferred over T B P to

cnsure low solubility in the water and increase its retention in the

membrane pores. A counter-current flow of the feed and strip phases

was maintained. Reactions at the feed-membrane interface are:

UO, (NO,),

HNO,

+ 211T O P = UO, (NO,),

(n TOP),

+ n T O P = HNO, (n TOP)

( I 1)

(12)

The extracted complex diffuses across and at the membrane-strip interface are:

= Na,U02(C0,)

+ 4 n T O P + H,O + CO, + 4 N a N 0 ,

(13)

2 HNO, (n TOP) + N a z C 0 3 = 2n T O P

+ H 2 0 + CO, + 2 N a N 0 ,

(14)

Operating flux of 100 miro-gram U/mz.sec was observed. Studies

have been reported [17] on uranium extraction from ground water

using phosphinic acid carrier in a polypropylene membrane [16]. The

process was found to be very erective in separating uranium at

pH = 2. Pilot plant uranium recovery on extraction by tertiary amine

in kerosene with a polysulfone membrane has shown [17] operational

costs lower than the conventional extraction or ion exchange. Studies

in BARC have shown uranium Rux value of 4.8 micro-moles/m2.s for

T B P in silicone membranes, while the value for DZEHPA is lower to

a third the value [18, 191. The separation based on hollow fibre type

units, which provide large surface area, and can hence be economical

for use with expensive agents, can be expected to play an important

role in future [20].

URANIUM AND THORIUM SOLVENT EXTRACTION

315

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

P r o c e s s Improvements in t h e TBP Refining P r o c e s s

The crude concentrates produced from the ores, by-products of phosphate industry and from the monazite processing are refined by separation of nuclear impurities using TBP. Fundamental studies [21] of

the extraction of U and HNO, by T B P have been carried out. The

extraction is found to be stepwise in nature and initially involves the

extraction of HNO, alone. Subsequently, U enters the organic phase

by displacing extracted HNO, molecules until the equilibrium is

reached. Similarly the fundamentals of hydrodynamics in a mixersettler have been examined [22]. The Sauter mean diameters and

droplet distributions were measured using photographs of the dispersions. Overall extraction efficiencies were measured. Settler behavior

was determined by measurement of dispersion band heights. It was

characterized by a normalized band height corresponding to a specific

throughput of 0.144 cm3/cm2/s. Normalized band heights depend on

solution composition and stirrer speed. Crud formation was studied,

but solid characteristics were such that dispersion band heights were

reduced, i.e., coalescence in the settler was enhanced.

In the refining of uranium by TBP, ammonium uranyl tricarbonate

(AUC), (NH,),UO,(CO,),

can be produced directly by contacting the

loaded organic with strong solution of ammonium carbonate [23].

The solubility limit of AUC, 200g/l, can be exceeded by optimising

the process parameters. Reactions involved are:

4 NH:

+ [UO,

(CO3),I4- = (NH,), UO, (CO,), (solid)

(16)

AUC is a crystalline product and has excellent physical properties for

subsequent processing to the nuclear fuel grade oxide.

T B P has also been used for purification of recycled material, particularly those containing fluoride [24-271. In the Canadian plant,

digested slurry containing 18% solids by weight, with 150 g/l uranium

and 20 g/l fluoride at 2N free acidity was processed in 15 nos. of

MlXCO columns at 50C by 22% T B P in Isopar M with solvent/feed

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

316

H . S l N G H A N D C . K . GUPTA

ratio of 3:l. Raffinate analysed <0.5 g/l uranium. Stripping of the

loaded organic in 2 columns with water at 70C in 1:l ratio gave a

pregnant liquor containing 35 g/l uranium and 0.1 g/l fluoride. In the

Indian plant, high fluoride in the plant feed was found to lead to

stress-corrosion cracking a t weld joints of steel impeller to the shaft. A

separate circuit was built to handle fluoride solutions in a polypropylene mixer settler. Fluoride solutions result from leaching of uranium

slag in nitric acid. Typical leach solution analyses (g/l): U = 10-15,

F = 1-3; Mg = 7 and Fe = 0.5-1. The free acidity is 2-2.5 N. A five

stage mixer-settler battery operating a t a n overall phase ratio of

O/A = 114 yields an extract containing 40-60gU/l. The unit has an

internal recycle from settler to same mixer stage to maintain a ratio of

O / A = 1.5/1. Loading of extract is below saturation to ensure raffinates are below 0.5 g u l l . This does not affect the purity since the feed

solution is already pure with regard to nuclear poisons and the only

separation required is for F. The extract contains only 0.05-0.1 gF/I

and free adidity is 0.1 -0.2 N.

Other advances in the field of refining in India [25,28] include: (a)

improvement in settling rate by use of 0.05 N acid for stripping instead of dimineralised water. Tests also showed coalescence rate doubled by an increase of temperature from 30C to 50C, (b) Entrainment

loss in alkaline processing of solvent was 9-15 ml/l, into the raffinate

was 0.7-2 ml/l and the pure strip solution was 0.5-3 ml/l. A dual

knit mesh packing of steel/polypropylene installed in the settler reduced the losses by a factor of five and reduced the dispersion band width

by a factor of 2, (c) solvent degradation over a period of two years

reduced the settling rate 15 times. Regular processing was found

necessary. Used solvent could be subjected to vacuum distillation in

the range 40C-130C and a residue separated for discarding as

waste, (d) slurry extraction as described subsequently in this paper.

Uranium from Phosphates

In India by-product uranium from indigenous phosphorites is estimated at 1695 tonnes [29]. As India imports bulk of its 2.5 million

tonnes of P,O, requirements of phosphates from Morocco, Florida

Jordan, Senegal etc. - all of which are uraniferous, the potential for

recovery is much greater. Research has been carried out in India o n

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

317

various aspects of uranium recovery from phosphoric acid [30-411.

Initial studies were carried out on the pyrophosphates as extractants.

However since the pyrophosphates were found to be unstable, further

studies were carried out on phenyl phosphoric acids. These had been

earlier considered as inefficient extractants by the researchers at

O R N L in USA. Based on systematic work with octyl phenyl acid

phosphates (OPAP), a process was finalised in India, which was later

developed in ORNL and used in Canada. A highly sensitive dye

method was developed for solvent loss determination. In 1987, a n

on-site pilot plant was operated to demonstrate the process feasibility

and study the requirements for feed purification. Subsequently, a large

scale pilot plant was operated on-site for technology demonstration.

Currently processes have been developed for simultaneous separation

of rare earth elements and cadmium. Industrial operation a t a large

fertiliser plant is under consideration. The environmental aspects of

radioactivity have been also investigated [42].

The pre-treatment to remove 'humic' matter has been studied. It has

been shown by IR spectroscopy that the humic matter present in the

acid can be separated by (a) clariflocculation with appropriate flocculant, (b) contacting the acid with a viscous D2EHPA solution to

precipitate the impurities as 'gunk', which can be subsequently separated in a centrifuge or a filter, and (c) adsorption on activated carbon.

The efficiency of separation as measured by the optical density (OD)

a t 408 nm, was found to be good. In a typical plant trial a t 1000 I/h,

the feed acid had a O D 1 1 . 5 , the O D of flocculated and aged acid

was 0.4, and after gunk generation it was < 0.35. N o carbon treatment

was necessary. About 440 gram of gunk was generated from a cubic

metre of acid. The uranium concentration in the gunk was low,

-0.0045%. Solvent loss with gunk was about 2/3rd weight of the

gunk. The acid oxidation study in 10 m3 reaction vessel showed that

the hot acid could be oxidised to an e m f . of above 450 mV by sparging of air. Oxygen sparging was needed for oxidation to > 550 mV. In

either case, heating of the acid was essential for effective oxidation.

The extraction tests showed that as the e.m.f. increased from 453 mV

to 571 mV, the distribution ratio increased from 9 to 29. The entrainment loss was found to be uniformly low, < 30ppm. The operation of

equipment such as clarifier, oxidation reactor, carbon column, phase

separation settler, froth flotation was found to be highly sensitive to

318

H. SlNGH AND C. K . GUPTA

the specific characteristics of the acid, attributed to the rock source

e.g., Florida, Morocco, Jordan or Senegal. In all cases however, the

plant could be tuned for optimal performance.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

SELECTION OF DILUENT

Selection of a diluent for solvent extraction is important in the process

technology. Diluent selection depends on physical properties such as

flash point, viscosity, density, boiling range, evaporation rate and

solubility; on chemical properties such as influence on the distribution

ratio, selectivity, reaction with the extractant; hydrodynamic factors

such as third phase formation, crud formation, entrainment loss; and

safety factors such as the flammability hazard, toxicity rating and

effluent control limits; besides the economic factors. Diluent selected

to dissolve the extractant(s) may be aromatic, aliphatic or a mixture of

the two types of hydrocarbons. The nature of diluent has a significant

effect on the kinetics of process, including extraction and phase separation. A diluent which strongly solvates the extractant (for example a

diluent high.'in aromatics) will not allow it to be present at interface

for equilibration, while a diluent with low solvation (such as a mixture

of aliphatic hydrocarbons) may .not dissolve adequate concentration

of extractant for efficient extraction [43]. Hence it is necessary to have

a compromise. Often a mixture of the two types of hydrocarbons is

used, or a third component such as a phase modifier is added to

prevent formation of a third insoluble phase.

The effect of raw and sulfonated kerosene-type diluent has been

investigated in detail with reference to solvent extraction of uranium

and co-extractable impurities from both nitric acid solutions and wet

process phosphoric acid [44,45]. Kerosene as obtained from the

petroleum distillation contains a mixture of paraffinic aromatic and

napthenic hydrocarbons. Stability of the diluent to chemical attack

depends on the presence of double bonds which are the sites for

oxidation reaction and irreversible extraction of metals. In the study

reported, the effect of chemical treatment involving several washings

with 98% H,SO,, neutralisation with 5% Na,CO, and final washing

with water was studied by IR spectroscopy and experimental measurement of extraction performance. A comparison of treated kerosene

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND

THORIUM SOLVENT EXTRACTION

319

(TK) and untreated kerosene (NK) showed that the treatment procedure decreased the unsaturated compounds, especially the

aromatics, from 16% to 6%, reduced the density and viscosity,

reduced the phase disengagement times by a bctor of two, and increased the distribution ratio. In the case of TBP extraction from

nitrate media, the saturation loading increased by 13%, and for a

six-stage extraction followed by eight stage stripping it was found that

there was reduction in raffinate level from 670 mg/l to 90 mg/l and

improvement in pregnant concentration from 64 g/l to 97.4 g/l. The

barren organic concentration also decreased from 2.75 g/l to 0.03 g/l.

There was greater inhibition of extraction of impurities. Similarly the

results on extraction from wet process phosphoric acid showed that

the treatment procedure improved the recovery of uranium by 30%

while reducing the co-extraction of Fe and Al by about 25% and 15%

respectively. Co-extraction of thorium and rare earths was also reported.

In a similar study [46,47] on the inter-phase transfer of U-VI from

phosphoric acid to kerosene solutions of D2EHPA-TOPO, it was

found that a sample with aromatic hydrocarbon content of 0.5%

(Ker.-A) gave higher distribution ratio and faster transfer rate than

sample with aromatic content of 18.3% (Ker.-B), particularly at lower

temperatures. The activation energy was also higher, at around 12.23

kJ/mol for transfer from aqueous to organic for Ker.A as against 9.04

kJ/mol for Ker-B, indicating the role of diffusional processes. The

activation energy for transfer in reverse direction was higher at 46.1

kJ/mol, indicating that the rate was chemically controlled. The effect

on the distribution ratio was correlated by log D = - AHl(2.303RT).

The value of AH was found to be -42.49 kJ/mol for Ker.-A and

-39.86 kJ/mol for Ker.-B. The behaviour of distribution ratios is

different for the two kerosenes. A plot of A log D vs T shows a

negative trend. The values of D rapidly decrease with acidity, nonaromatic kerosene always giving higher values. The results are consistent with the fact that the dominant species is UO;' at low acidity and

UO,(H,PO:-")n

a t higher acidity [48]. Performance of diluents for

uranium extraction from a n Australian ore leach solution has been

reported [49]. It was found that for uranium extraction with Adogen

364, an aromatic diluent, led to an interfacial crud formation, while a

purely aliphatic diluent gave a lower distribution ratio. Optimum

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

320

H. SlNGH AND C. K. GUPTA

results were obtained with a solvent having 16% aromatics, density of

0.808 g/l, viscosity of 1.97 cst @ 2 5 T , boiling range of 200-240C and

a flash point of 80C. An excellent study on the selection of diluent for

practical application in treatment of wet process phosphoric acid is

presented with regard to cadmium extraction [50]. Wet process phosphoric acid (WPA) is a complex solution containing a large number of

inorganic impurities present both in solution and in suspension. The

large number of ions present lead to numerous chemical equilibria. The

formation of complexes between anions (F, C1, SO,) and cations (Fe, Al,

My) results in a complex system. The source of phosphate rock

(Morocco or Florida) leads to additional complications. WPA acid

made from Morocco rock has Cd level of 16 ppm, while that from

Florida it is 7 ppm. The purification level of 1 ppm is desired. In-depth

investigations showed that only an aromatic diluent Shellsol-A (flash

point 5WC, i.e., 15C above operating temperature) could be used. Its

main component is I,2,4-tri-methylbenzene and water solubi-lity is

59ppm [51] as against the solubility of 0.85 ppm for n-octane [52]. The

Florida acid gives a C1- level of 0.022 M but has high organic content

while that from Morocco gives 0.035 M CI but organic content is much

lower. Both CI- and organic level influence the extraction. The diluent

with high aromatic content has higher toxic rating.

In India over the years kerosene, purified kerosene, normal heavy

paraffin (NHP)-also called as Petrofin and n-dodecane have been

used as diluent for T B P in liquid-liquid extraction of uranium. N H P

of required quality is now produced indigenously by a process developed jointly by the Indian industry and BARC. The properties of

locally produced N H P for re-processing are: n-paraffin content

> 99%; aromatic and water < 100ppm; specific gravity: 0.75 a t 2WC;

flash point > 70C. Use of N H P has the advantage of greater stability

due to presence of > 99% normal chain compounds, and avoidance of

viscous red oil formation. While the products of T B P degradation are

removed readily by carbonate treatment, degradation products of the

diluent are not easily removed and get accumulated in the solvent

rendering it ultimately unusable, as also observed during refining.

Refined kerosene has the advantages of high flash point and higher

fire safety, lower evaporation loss, low vapour concentration in air,

permitting safer working environment without undue ventilation costs

and improved phase separation.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTlON

32 1

The specifications of N H P have been modified for economical use

in uranlum recovery from phosphoric acid, Table V. Based on the

experience gained, N H P is now in use for uranium separation from

ore leach liquors, separation of rare earths and for uranium refining. It

may be noted that as per the hazardous substance notification of

Government of India [53], three classes are defined: 1) Flammable

gases with boiling point below 20C, 2) Highly flammable liquids with

flash point below 21C and boiling point above 2WC, 3) Flammable

liquids with flash point below 55C. The paraffin does not fall in

above classes. Similarly as per IATA regulations only liquids with

flash point upto 60.5"C classify as flammable.

HEAT EFFECTS IN SOLVENT EXTRACTION

Enthalpy changes accompanying solvent extraction have been a subject of interest from fundamental as well as applied considerations.

Thus, for example, in the extraction of uranium by tri-n-butyl phosphate diluted with an aliphatic diluent, it has been found that the

transfer of solute (both uranium and nitric acid) between the two

liquid phases is accompanied by significant change in temperature. Several published data for heat of reaction involving TBP under standard

TABLE V Characteristics of the Indian heavy normal paraffin for extraction

ITEM

TESTMETHOD

TYPICAL

SPECIFIC GRAVITY (15/4"C)

COLOUR (SAYBOLT)

VISCOSITY (cst)

FLASH POINT ("C)

REFRACTIVE INDEX

DISTILLATION ("C, at 760 mm Hg)

IBP

BP

TOTAL AROMATICS (%)

TOTAL NON-NORMAL (%)

C-I0

C-l l

C-12

C-13

C-14

ASTM D-1298

ASTM D-156

ASTM D-445

ASTM D-93

ASTM D-I216

ASTM D-1160

0.74-0.76

430

1.62 1

> 65

1.4358

> 175

UOP-495

Capillary GC

< 245

<I

> 98

18-30

20-35

20-35

10-25

<I5

322

conditions are available [54-581. The enthalpy change for uranium

extraction by TBP, which involves a solvation mechanism, is -54.5

kJ/mol. The heat effect for acidic extractant D2EHPA is lower,

- 30 kJ/mol. This may be because in the reaction with acidic extractant no major amount of electrostatic energy is gained when

U O i C exchanges for 2 H + , in contrast to the solvation mechanism

with TBP which involves association or UO;' with 2NO;. Additional differences arise due to bonding with four P - 0 groups in the

case of DZEHPA, compared to the two P - 0 groups and two nitrate

groups for TBP. Differences of the heat of hydration of UO;+, 2H'

and 2NO; are also significant. The data obtained under standard

conditions can be extended to cover the variations observed in practice [59,60].

The temperature profile across a cascade can be correlated with

concentration profile by mathematical modeling of the heat and

mass balance processes. Since the temperature profile is easier t o

measure on-stream in practice, it provides an inexpensive technique

for automatic process control [54-571. A computer program based

on these principles [60] has shown that, in the case of a reprocessing

flowsheet, temperatures can vary by over 10C at various stages and

these correlate with concentration successfully. The transient processes can be successfully simulated. A sensitivity analysis showed

that rt: 1% error of temperature measurement at each mixer settler

stage (i.e., k0.3"C for 30C) does not lead to any serious errors in

the estimation of concentration profile. The process control strategy

for changes in solvent flow rate, scrub acid concentrations, T B P

concentration, feed uranium concentration, feed flow rate can be

successfully implemented.

Heat effects are equally important when the ambient temperatures

difler significantly from the optimum process conditions. Thus for

example in the case of uranium recovery from Domiasiat ore in India,

the ambient temperatures can go down as low as 3"C, and insulation

of mixer-settlers as well as heaters Tor the start up are essential in the

extraction circuit. In the case of separation from phosphoric acid, the

stripping of uranium from the extract requires temperatures above

50C. In addition the strip acid is very viscous and forms an emulsion

if temperatures fall below 40C. Hence it was found necessary to

install graphite heaters in the mixer itself.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

H.SlNGH AND C. K.GUPTA

URANIUM AND THORIUM SOLVENT EXTRACTION

323

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

PROCESS INSTRUMENTATION AND CONTROL

The efficient operation of solvent extraction plants is very strongly

dependent on the level of process instrumentation and control. While

much of the items are standard in the chemical industry, specific items

of interest to the uranium extraction are discussed.

An important requirement for automatic process control of solvent

extraction is the development of techniques for sensing the concentration levels of the extracted metal in the organic phase. Several

methods, depending on the metal of interest and the accuracy required, have been reported. An interesting method involves laser-induced thermal lensing effect [61] as demonstrated for uranyl nitrate in

30% TBP solution [62]. A pulsed dye laser excites uranyl ions so as

to create a local temperature gradient which changes the refractive

index. A probe beam from He-Ne laser passing through the sample

diverges. A fast Fourier transform spectral analysis helps determine

the absorbance of the sample solution, and detect concentration difference of 0.0001 M of uranyl ion. Normal absorption spectroscopy is

unable to resolve such low differences.

On-line analysis by X-ray fluorescence is becoming important for

automatic control and process optimisation. In India installations

have already been made in the ore concentrators of Hindustan Zinc

Limited, Hindustan Copper Limited and Indian Rare Earth Limited.

Similar application for solvent extraction are under consideration.

The system uses a n energy dispersive solid state detector and

radio-isotope energy source for the X-ray analysis. Each element in

the solution stream emits fluorescent X-rays of a n energy that is

characteristic of the element. The signals are processed for resolution

into concentration measurements. Elements in the range of atomic

numbers 16 to 92 (sulphur to uranium) can be measured besides

measuring p H and temperature. Typical accuracy is 2-8% in the

concentration range 0.001-1 g/l, and 1-2% for > 10 g/l.

ENTRAINMENT

Successful industrial operation of solvent extraction processes requires

that the loss of solvent into the aqueous raffinate should be minimised.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

324

H. SlNGH AND C. K. GUPTA

The solvent loss is due to soluble loss as well as entrainment loss. The

soluble loss, which is generally low, depends on the physico-chemical

characteristics of the system selected for operation and is beyond the

control of an operator. The entrainment loss is due to mechanical

factors and can be significantly high. Experimental investigations have

been conducted world-wide for understanding the mechanism of entrainment loss and development of equipment for its minimisation

[63-711. In a commercial plant operating with large flows, even a

ppm level loss can be unacceptable either in terms of the economics o r

toxicity load on the environment if released as effluents o r lead to

downstream technical problems.

Primary reason for entrainment from mixer-settlers, which are the

preferred equipment for large scale operation of solvent extraction, is

secondary liquid-liquid phase dispersion. The secondary dispersion

consists of extremely fine droplets which do not coalesce in the conventional gravity settlers [64]. Secondary droplets are formed which

are stable and their distribution depends on several factors such as:

droplet-film particle size, curvature of the droplet film interface, density differences between the phases, viscosity ratio of the phases, impedance ratio of the phases, interfacial tension, interfacial potential,

temperature effects, mechanical vibration effects, presence of third

phase, mutual solubility, external electric field, external magnetic field,

internal electrical field.

The aqueous raffinate needs to be passed through equipment such

as post-settlers, flotation cells, absorption columns, centrifuges and

electrical settlers for overcoming the limitations of ordinary gravity

settlers in coalescence of secondary droplets. We have carried out

investigations in a 1000 litreslhr pilot plant having a lamellar parallel

plate coalescer as well as a flotation cell. The applications include (a)

uraniferous phosphoric acid contacted with an organophosphorous

synergistic mixture in aliphatic diluent, and (b) sulphate leach solution

containing uranium contacted with 0.5 M tertiary amine in aliphatic

kerosene and an alcohol as phase modifier. The details of the lamellar

settler are shown in Figure 2. The entrainment levels were measured

by a dye technique [33] and also confirmed by infra-red spectrometry.

The efficiency of the lamellar settler was found to be > 90% and that

of the flotation cells to be 80%. The secondary dispersion resulting

from the last settler can be measured by laser size analyser. Droplets

URANIUM AND THORIUM SOLVENT EXTRACTION

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

CLEAN ACID

OUTLET

SLUI

PLATE PA

FIGURE 2 Parallel Plate Separator for recovery of entrained solvent.

of the dispersed phase diffract the incident laser beam due to differences

in the refractive index of the organic phase and the aqueous phase. The

emergent beam is detected by a multi-channel detector and the angle of

dfiaction is correlated to the droplet size. The data is analysed on-line

to obtain the size distribution. Typical results are shown in Figure 3. The

fine droplets in the settler approach the corrugated parallel plate, get

adsorbed on the hydrophobic surface, the intervening film between two

droplets ruptures and coalescence takes place, as shown in Figure 4.

Large coalesced drop rises to the surface where it is skimmed off.

The data obtained on droplet size distribution of the entrained

phase can be used to model the performance of the lamellar settler by

a population balance approach. The desired inclination of the plate

separator has been reported to be 15". At this slope the fouling capacity of the unit is reduced and the load of dispersed phase is acceptable [71]. Solutions with higher solids and scaling tendency need

higher slope, -45".

The performance of the primary settler in the mixer-settler battery

has been the subject to considerable research over the years [65,72-751

H. SlNGH AND C. K. GUPTA

18.00

12.00

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

8.00

VOLUME (%)

4.00

0.00

FIGURE 3

&

5.00

10.00

15.00

DIAMETER (ym)

20.00

25.00

&

Laser size analysis ofentrained solvent drops.

Coalescence

Heavy phase

droplet Heavy phase

continumn

/

Inclined d a c e

FIGURE 4 Coalescence of secondary droplets in a Parallel Plate Separator.

as it is the source of the formation of entrained droplets. It has been

shown that the data on settling can be correlated by a power law:

H = K ( Q , / A ) q ,where H =thickness of the dispersion band, Q, =flowrate of the dispersed phase, A =settling area, K and q =empirical

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

327

constants. The scale-up based on this approach suffers from the limitations that the K and q values are highly variable, depending upon

mixing intensity, phase continuity, temperature, phase ratio, impurities present in the aqueous and organic phase etc.

Hydrodynamic studies have shown that the droplet size is independent of the dispersed phase flow rate, the thickness of the dispersion

band is a function of the specific flow rate of the dispersed phase but

independent of the total flow of the dispersion and there are both

vertical and horizontal zones of coalescence. In the horizontal zone

the dispersion is uniformly spread with little variation in the drop size.

In the vertical direction, the droplet size changes very significantly.

Dramatic reductions of the aqueous entrainment in the organic phase

have been reached by using an externally applied pulsed D C electrical

field across coated electrodes [67,68,75,76]. Field tests in the US have

shown for amine extraction of uranium, the conventional loading rate

can be increased six times by using a n electrostatic coalescer.

Fibre bed coalescers provide another technique to reduce entrainment [76,77]. Modelling studies show how the inertial interception

leads to coalescence as a function of internal pore properties, shape,

area and hydraulic diameter. Fibre coalescer media have high surface

area and rather large pore cross section which help enhance efficiency

without increasing the pressure drop. Polypropylene fibres are

superior media for promoting coalescence.

Structural factors influencing phase separation rates, and consequently the entrainment level, have been systematically investigated

for systems employing tertiary amine extractants [78]. The extraction

of uranium has also been evaluated. It was found that in the case of

organic continuous (OC) mode, increasing the number of carbon

atoms per chain (n) reduced the phase separation rate, whether the

chain was linear or branched. For a constant value of n, the branched

chain amines were found to separate faster than linear chain in the

O C mode. A key structural factor for the O C separation was found to

be the backbone chain length i. e., the longest chain in each alkyl

group. Aqueous continuous (AC) dispersion separated fast, but was

very sensitive to presence of colloidal silica as well as the use of actual

leach solution instead of the synthetic one. Stabilisation of AC dispersion by silica and crud formation was explained by a model. Larger

molecular weight amines with n z 10 were found to give faster settling

328

H. SINGH AND C. K. GUPTA

rate, less emulsion stabilisation and crud formation as well as higher

uranium extraction and lower tendency for formation of a third phase.

Solubility losses can also be expected to be lower. Results showed

that uranium ore processing plants based on the amine process could

improve performances by using branched chain extractants of higher

molecular weight.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

PURIFICATION O F AQUEOUS AND ORGANIC PHASES

Aqueous solution containing the metal value of interest must meet

stringent requirements with regard to impurit& before it is considered

suitable for industrial operation of solvent extraction. Presence of

colloidal silica can lead to deleterious process performance, as discussed earlier with regard to the entrainment levels. Impurities in the

commercial extractants, solvent degradation products, presence of

solids and humic acids in the ore and their build-up over time can

have a marked effect on the process performance [79,80]. Actual

process testing is essential for each specific system. Mere measurement

of physical parameters can lead to misleading conclusions. Higher

interfacial tension can thus be expected to increase the phase separation rate since it can be expected to increase the thermodynamic

instability which favours coalescence. But the opposite trends have

been reported from the plant experience [79] and research studies

[80]. The effect of impurities in the commercial extractants is pronounced on phase separation in the case of aqueous continuous dispersions

when ore leach solutions containing silica are used. Purification can

lead to dramatic improvements. Similarly the effect of recycling water

from a tailings pond back into the solvent extraction circuit in a mill

is known to have caused emulsion problems [78].

Crud formation involving build-up of a film like solid phase at the

interface of the aqueous and organic phases is a serious problem in

the industry [81,82]. The interfacial layer of crud stabilises organic

droplets and prevents their coalescence. A large amount of solvent

gets trapped, leading to high losses and in extreme cases it can cause

expensive shut-down. Crud formation is enhanced not only by Si, but

also by Fe and to lesser extent by alkali metals. lncorporation of a

scrub.stage before the stripping, apart from any benefits in terms of

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

329

purity, helps to improve the system hydrodynamics by isolating the

crud to extraction stages only. Addition of fluoride is one of the

methods of dealing with a siliceous crud problem [83]. Crud formation

is also affected by the nature of diluent, aliphatic diluents like Exsol D

100 (aromatics < 0.9%, flash point 102"C, distillation range 235-262"C,

non-flammable) producing less crud than aromatic diluents when contacted, for example, with wet process phosphoric acid [84].

Purification of a solvent by contacting with another extractant has

been reported in a novel application [85]. Solvent containing

25%TBP in lsopar M was contaminated with tributuxyethyl phosphate (TBEP) leading to reduced extraction of uranium and higher

phosphorous levels in the uranium product. Conventional sodium

carbonate wash gave an organic containing 100 ppm uranium, higher

than the required limit of 5 ppm. The strong complexing power of

IONQUEST 201 (I-hydroxyethyl-1, 1-diphosphonic acid) and its ability to form metal complexes which are soluble in water was utilised

for purification of the contaminated solvent. The IONQUEST 201

product stream was decomposed by hydrogen peroxide into phosphoric acid and carbon dioxide for subsequent treatment.

Electrodialysis techniques have been investigated [86] for purification of uranium leach solutions to remove anionic impurities such as

molybdates.

In our pilot plant test work, purification of feed solution has been

found essential when organic impurities are present in the form of

dissolved 'humic' matter and insoluble oils, greases, etc. due to leakages

into the process fluid from gear-boxes etc. As solvent is repeatedly

recycled, these impurities can accumulate. Once poisoned, there is little

possibility of solvent purification. The humic matter resulting from dissolution of organic impurities under strong lixiviation conditions has

been recognized as a major problem in many plants. Harmful affects

are (a) poor phase separation in settlers, lowering capacity (b) stable

emulsions leading to solvent loss and plant shut-downs (c) aggravated

problems in stripping, especially with 10% (NH&SO,. A detailed

Chinese study on sandstone-type ores (using IR Spectroscopy, electron

microscopy) used in acid leach and amine extraction has shown [87]

following: (a) Organic continuous dispersion inseparable at humate

level about 39 mg/l. Upto 30 mg/l the separation time increases linearly,

from 30 sec to 300 sec., (b) Nature of crud varied from 100 nm spherical

330

H. SlNGH A N D C. K. GUPTA

particles to fibrous forms. (c) Decrease in uranium loading was to

two-thirds of normal value. (d) Pre-treatment with activated carbon

adsorption o r coagulation with higher molecular weight flocculant,

removed organics. (e) The accumulated humus in organic phase could

be removed by sodium carbonate scrubbing of solvent.

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

SOLVENT-IN-PULP PROCESSING

In the front end of the nuclear fuel cycle, extraction of uranium from

ore leach solutions commonly uses solvent extraction. Mixer-settlers

are the preferred choice of equipment. The mixer-settlers are however

prone to failure if the feed solutions are not adequately clarified. The

clarificati'on of the feed slurry is an expensive operation, accounting

for nearly a third of the capital costs and 10-20% of the operating

costs. Solvent in pulp (SIP) technology is under development for direct extraction from slurries without prior filteration [88-911. It also

increases the overall recovery by reducing the soluble uranium losses.

The equipment to be used for contacting needs to have the capacity to

handle solids. An 'internal mixer-settler' has been tested for extraction

by the DZEHPA solvent from sulphate leach solutions [88]. In this

apparatus mixer and settler are combined in a single tank. Settling

takes place in the bottom and top sections. Internal recycle of organic

phase provides an O/A ratio of over 10 which helps in treating dense

slurries, having solids in the range of 40-55% w/w. From the mixer

tank, the aqueous is pumped from the bottom while the organic overflows by gravity. The losses of organic could be reduced by varying

parameters such as mixer speed, dilution of the effluent with water or

addition of surface active agents such as organic sulfonates to levels of

0.03-0.06 m3/tonne of solids. High levels of entrainment were observed to be due to free standing droplets ranging in size from 15-150

micron. Slurry extraction with amine solvents was considered less feasible since the amines are preferentially adsorbed on the solid surface.

Alternatively pulsed columns have been tested [91,92]. When treating solids, the flow rate, amplitude and frequency need to be decreased

by a factor of two compared to operations with clarified solutions.

Under these conditions, uranium extraction from 20% solids by

Alamine 336 could be achieved at a solvent loss of < 50 ppm. However

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

331

the throughput was low and the inventory of solvent high [92]. The

ralfinate from uranium was processed for recovery of copper and

nickel and by slurry extraction using LIX63 and D2EHPA. Feasibility

of slurry extraction was demonstrated in a 250mm column at a

throughput of 13.5 T P D solids in a slurry containing 35% solids with

amine loss limited to 35 gmltonne [90]. The loaded organic was

filtered through a plate and frame filter and the solids were repulped

for solvent recovery and recycle. Acidification of the solvent after

stripping was carried out to pH of 0.5 to prevent crud formation,

which occurred at higher pH. The amine loss was of the order of 15

gmltonne of solvent for each settler [93]. A more extensive investigation [94] showed that aqueous continuous phase gave much lower

solvent losses, even though the operation in organic continuous mode

was easier. Effect of the plate material was also reported. In a recent

study [91] it was found that the presence of solids reduces the dispersed phase hold-up, increases drop sizes and leads to loss of the organic

phase by formation of stable emulsions or adsorption of the solvent

on the solid surface. The erosion of the pulsing stator can be expected

to be high. The occluded solvent needs to be recovered by an additional

step. A recent study on hydrodynamics of Rotating Disc Contactor has

shown [95] that it can handle solids of the order of 20% by weight.

Solvent in pulp is a potential technology for economical uranium

extraction and is a logical extension to proven technologies of resinin-pulp and carbon-in-pulp [96].

In India, air-mixed slurry extraction units have been developed [97]

and have been in operation in three plants in the country. It has

helped to eliminate three stages of filtration and cake-repulping when

conventional units based on clarified feed were in use. The unit is

schematically shown in Figure 5. It has no moving parts and is without control valves. Air lift pump is used for inter-stage transfer of the

aqueous phase and for mixing the two phases. Organic flows by gravity from stage to stage, with an overall level difference of 300 mm for

seven stages..A large recycle of the organic, controlled by flow regulation of air used for air lift, is maintained to ensure operation in the

aqueous dispersed mode and minimise the loss of solvent. Slurries

containing 15% solids could be handled. The air is separated from the

liquid-solid phases at the end of air lift in a disengagement chamber. It

passes through mist eliminators and is exhausted through a header. At

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

332

H . SlNGH A N D C. K. GUPTA

FIGURE 5 Solvent in Pulp(S1P) for uranium refining.

the raffinate end, the aqueous phase is drawn by air metering. Mixing efficiency of the order of 85-90% has been achieved during the

contacting in the air lift zone with a residence time of the order of

seconds. The organic flow to subsequent stages is through the settler

downcomer, which is s o sized that there is upward flow of organic

and downward flow of the aqueous. The recycle rate of organic at

each stage is very important and an automatic control system has

been developed.

EXTRACTION OF URANIUM AND THORIUM

Solvent extraction plays a vital role in the recovery and separation of

uranium and thorium from monazite mineral concentrate of monazite

URANIUM AND THORIUM SOLVENT EXTRACTION

333

produced from beach sand minerals. It is also important when mined

ores containing both uranium and thorium minerals are processed

[98,99].

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Extraction by TBP

Selective extraction of uranium, in the hexavalent form, from the tetravalent thorium from nitrate leach solutions by neutral organophosphorus compounds such as T B P has been practiced on commercial

scale world-wide [loo-1021. The separation by TBP generally uses a

low concentration of TBP, say 5-lo%, for selective extraction of

uranium over thorium. From the raffinate, free of uranium, thorium

extraction requires a higher T B P concentration, about 40%. Here

care has to be taken to avoid formation of a third phase due to lower

solubility of the extracted Th(NO,),. T B P in the non-polar diluents

used. The selectivity of TBP is rather low. It can be improved by use

of other phosphates and phosphonates, particularly by incorporating

branched alkyl groups [102-1031. Fundamental studies on the TBPnitrate system have been carried out for better understanding of the

process [104-1061. The extraction rates of uranium and thorium increase with increasing nitric acid concentration and with saturation

appearing a t nitric acid concentration higher than about 2.0 M. The

rates increase linearly with NO; ion concentration, but decrease with

H' ion concentration. Apparent activation energy of 16 kJ/mol for

uranium and 43 kJ/mol for thorium was obtained from the temperature

data. It suggests that the extraction rate of uranium and thorium is

controlled by chemical reaction at lower temperature and by diffusion

process at higher temperature. The thorium nitrate extraction by trialkyl phosphates is by solvation with 3 number of molecules as well as

by 2 numbers. Uranium forms only di-solvates with TBP.

Separation by Carboxylic Acid Amides

Extractants of the carboxylic acid amides, N-alkyl type (R.CO.NHR'),

developed as alternatives to organophosphorus extractants in the

back-end of the nuclear fuel cycle, are of interest in the front end as

well [107]. The effect of extractant structure on the selectivity of

separation and stoichiometry of the extracted species has been studied

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

334

H. SlNGH AND C. K. GUPTA

by varying the alkyl groups R and R'. Also studied are the N,Ndialkyl amides (R.CO.NR,') and non-substituted amides (R.CO.NH,).

Studies were carried out by solutions of the amides in toluene.

Increasing steric bulk of the alkyl groups R and R', for N-alkyl

amides, was found to cause a marked decrease in the extraction of

thorium with the effect on uranium being lower. This significantly

increases the selectivity between the two metals. The effect of group R'

becomes strongly evident for tert-alkyl groups, or if both R and R' are

branched. The alkyl group R has greater steric effect than R'. The

structure of U-VI complex [lo81 can explain these differences as the

amide ligands are coordinated to the metal ion by the carbonyl oxygen

atoms. The significantly greater steric effect observed in the extraction

of Th-IV are apparently due to the difficulty of assembling four nitrate

ions and the required number of amide ligands around the central

cation. Comparison with the separation factor for neutral organophosphorous compounds shows amides are capable of superior separation

to both 1M TBP, having a factor of 1.89, and 0.15M di-n-butyl

n-butylphosphonate, having a factor of 1.51.

The separation factors for the extraction from 2M sodium nitrate

by O.SM N,N-Dialkyl Amides R.CO.NR, have been evaluated and

results show that the separation factor for branched chain compounds

are much higher. Thorium is appreciably extracted only by a compound containing R=CH,.

Extraction by amides is generally by solvation type mechanism

[lO8-1 lo].

Where M n f denotes Th4+ or U O i f . The relation for the distribution

ratio D follows:

log D = log Kex + n log[NO;]

+ plog[Amide]

(18)

Experimental data [lo71 showed that values of p were in the range

i.98-2.09 for uranium and to 2.75-3.37 for thorium, with the n values

being 2 and 4 respectively. At lower amide concentrations, the value of

p for thorium has been reported to be two [108].

URANIUM AND THORIUM SOLVENT EXTRACTION

335

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Separation by Tri-sec-Butyl Phosphate

The steric effect on the differential extraction by phosphate or phosphonate is the basis for using extractants with the introduction of

branching at the first carbon atom of the alkyl group attached to the

oxygen atom. The extraction of uranium is not affected but that of

thorium is reduced due to the higher number of extractant molecules

(3-4) in the thorium solvate.

Experimental studies have been reported on extraction by tri-secbutyl phosphate (TsBP) [ l l 1-1 121 and tri-iso-butyl phosphate (TiBP)

[113]. Results on uranium show that for low acidity, say upto 3 M,

the differences in the three cases of TBP, TsBP, and TiBP are not very

significant. The extraction of thorium decreases very significantly at

high loading and high acidity when T B P is replaced by TsBP. Thus at

5M HNO,, from a feed containing 1 g/l U-VI and 50g/l Th-IV, the

separation factor using 1.1 M for T B P is 6.8 while that for TsBP is six

times better at 41.2. The selectivity can be further improved by lower

loading and by using lower extractant concentration. An additional

advantage of TsBP is the significantly higher, by a factor of 1.3 to 1.5,

the limiting organic concentration for third phase formation in comparison with TBP. The higher solubility of the thorium solvate with

TsBP also makes it a better choice for extraction of macro levels of

thorium in the second cycle.

Separation by DZEHPA in a Carboxylic Acid Diluent

DZEHPA is generally used in a diluent in which the extractant is

generally aggregated as a dimer. Extraction of uranium and thorium

from an aqueous mineral acid using D2EHPA in a dimerising diluent

yields very high distribution ratios [I 14-1151. An alcohol can be used

as a monomerising diluent [I161 but it yields very low distribution

ratios. An alternative is to use carboxylic acid as a monomerising

diluent [117]. Extraction behaviour for U-VI and Th-IV using 2-ethyl

hexanoic acid as a diluent for DZEHPA has been reported for an

aqueous chloride phase [118]. It is found that the extraction reactions

correspond to

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

H. SINGH A N D C. K . GUPTA

where HY represents the monomer of D2EHPA. With H Z representing the monomer of 2-ethylhexanoic acid, the extracted species are

postulated to be Th(HY),(HYZ), and UO,(HY,)(HYZ). The distributions ratio K in terms of formality F (defined as the number of formula weights of solute per litre of solution), acidity [HC], and a

constant K , is K = K,, F 3 / [ H f I 4 for thorium and K = K,, F Z / [ H + I z

for uranium.

The value for K , are 70000 for thorium and 200 for uranium. Selectivity with respect to trivalent rare earths which have K , values

0.01-7, is excellent. The extracted metals can be stripped into an

aqueous phase by 6 F HCI. I n fact the extractant scheme has been

proposed for extraction of thorium from low-grade resources while

purifying from rare earth contaminants. During the extraction by

D2EHPA, regeneration of organic solvent can be achieved completely

by contacting with aqueous solution of oxalic acid [I 191.

Similarly extraction with bis para-octylphenyl phosphoric acid, denoted as HDO+P, has been investigated from chloride medium [I201

and it is found that the K, ratio T h 4 + / U O i + is nearly 2.0 x lo5, and

the selectivity w.r.t. Eu is over a million. O n the other hand if the

extractant is bis-diisobutyl methyl phosphoric acid (HD(DIBM)P),

then the K, ratio is reversed to 2 x lo-' and uranium extraction is

favoured. The latter extractant has adequate selectivity in the nitrate

medium also to be useful [121]. Thus the liquid-liquid extraction

system can be selected to extract the minor component selectively,

whether uranium or thorium.

Selectivity of uranium extraction over thorium from hydrochloric

acid solutions using diphenyl sulphoxide (DPSO) has been investigated with respect to parameters such as concentration, temperature

and acidity [122]. Sulphoxides containing the S - 0 group, in contrast to the P - 0 group of organophosphorous compounds, are

simple compounds having a pyramidal molecular structure coordinating by donating of the electron pair on the oxygen. Their stability is

good and viscosity much lower than TBP. Uranium can be preferentially extracted from 5 M HCI with a neutral salting out agent at a low

temperature using a higher concentration of thorium than uranium.

The separation factor is 3690 and virtually all the uranium is extracted,

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

URANIUM AND THORIUM SOLVENT EXTRACTION

337

leaving thorium in the aqueous phase. Benzene is used as diluent and

the method is appropriate for laboratory work.

Comparative extraction by di(2-ethylhexyl)sulphoxide and T B P from

nitrate media has shown DEHSO is superior 11231. Use of binary

mixtures for simultaneous recovery of Th and rare earths in nitrate

medium has been recently patented [124]. The process comprises contacting a nitrate solution with an organic extractant compound containing two extractants, one from the group OP(OR1)(OR2)(OR3),

OP(OR1)(OR2)R3, O P ( O R ' ) R 2 ~ 3 , and OPR1R2R3 [R1-R3 =

hydrocarbon radical.]; and second from the group P(OR4)=(OR5)

0 , H [R4,RS = hydrocarbon radical]. The solvent mixture has a high

separation coefficient.

Use of dialkyl dithiophosphoric acids for thorium extraction has

been reported [125]. Studies on use of chelating extractants for uranium and thorium have been reported [126-130). LIX84 (2-hydroxy5-nonylacetophenone oxime) and its mixtures with other chelating

extractants or neutral donors showed very little extraction for thorium, although uranium was extracted. Extraction of uranium V1 from

nitrate solutions by 10% (v/v) LIX 622 in a benzene diluent was found

to increase with increasing equilibrium pH in the range 3-6. TBP acts

as a synergistic modifier upto 2%(v/v), beyond which antagonistic

effects are observed. Thorium-1V extraction by LIX 622 and its mixtures with Alamine 336 and Aliquat 336 was found to be poor in the

pH range 1-4. Separation of Mo-VI, which is undesirable in uranium

circuits, can be achieved at high acidity. The extraction corresponds to:

The dependence of distribution ratio D on the acidity is given as

log D

= log

+ log[NO;] + log[HL]

where K is the equilibrium constant.

In the process it was found that pH adjustment by addition of ammonia or caustic solution led to formation of turbidity and third phase,

and had to be carried out instead by the addition of pyridine. Extraction decreased with increasing concentration of CI and SO, ions.

338

H. S l N G H AND C. K. GUPTA

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Supercritical fluid extraction of uranium and thorium from nitric acid

solutions with organophosphorus reagents is an exciting new area

which can lead to newer separation processes [131]. An organophosphorus reagent is dissolved in supercritical CO, by passing the fluid

through a reagent vessel placed upstream of the extractor. Using TBPO

or T O P 0 in supercritical CO,, effective extraction of uranyl and thorium ions can be achieved even from dilute HNO, solutions.

Plant Flowsheets for Uranium and Thorium Separation

Uranium ores of the Elliot Lake, Canada contain thorium and rare

earths, and process flowsheets have been practiced for their recovery

[132]. Ore containing'0.l WOuranium, 0.028% thorium and 0.057%

rare earth oxides were processed by sulphuric leaching, clarification

and uranium extraction by ion-exchange. Barrens containing (g/l) 0.13

thorium, 0.10 rare earths, 0.005 uranium, 0.04 titanium, 18.9 sulphate

ion are processed in 3180 litres/min. solvent extraction plant. Organophosphorus extractant is used at aqueous/organic ratio of 9-11:l in

a mixer with contact time of 1-2 min and settler with a surface area of

149 m2. Phase separation is rapid and is complete in 30 sec. Solvent is

stripped with ION H,SO, at organic/aqueous phase ratio of 4:l Strip

settler has a capacity of 6813 litres. Mixed solvent loss is 333 ppm of

barren aqueous. Solvent regeneration is carried out partially using HF.

Thorium is recovered as a sulphate. Rare earths are co-precipitated.

In India monazite is the main source of rare earths and thorium,

besides producing by-product uranium. A new process for separation

of these elements by a solvent extraction route is shown in Figure 6.

The composition of various streams is shown in Table VI.

BINARY EXTRACTANTS

Extraction of uranium by a binary mixture of Aliquat 336 and PC88A

from aqueous phosphoric acid has been studied recently [133]. In the

extraction studies using 5%(v/v) Aliquat 336 (trade name for tricapryl

methyl ammonium chloride:R,R'NH,PO,), 5% (v/v) PC88A (trade

name for 2-ethyl-hexyl phosphonic acid mono-2-ethyl hexyl ester:

(HA),) and their 1 : 1 binary mixtures in xylene, it was found that there

is a synergistic effect over the entire range of acid concentrations,

URANIUM AND THORIUM SOLVENT EXTRACTION

339

103'0 ALAMINE-336 INKEROSENE

I

Loaded Organic

.

,

U &Fe

STRIPPING

Ra&nate I

bJcous

O.lNHQ

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

Feed

1 M P C S A INKEROSENE

EXTRACTION

STRIPPING

5%

J-

Scmb

aEinate I1

RE. Th. Fc. Ti

FIGURE 6

Ti Strip

Th, Ti. F

RE,Th.Fe. Ti

Flowsheet for separation of U, Th and rare earths.

TABLE VI Typical composition of streams for separation of uranium, thorium and

rare earths by PC8BA/Alamine 336

Stream, gll- >

CeO,

RE0

Nd,O,

Tho,

U,O,

Fe,O,

TiO,

Aqueous Feed

Raffinate I

U-Strip

Raflinate I1

Scrub

Th-Strip

Alamine 336 Extract

PC 88A Extract

Stripped Alamine 336

Stripped PC 88A

Ti-Strip

Flouride concentration in strippcd PC88A can be in the range of 1-100 ppm and in the Ti strip

solution 5%. Streams correspond to the Figure 6 streams.

which was attributed to the formation of mixed adduct species,

UO,A,(R,R'N,)(H,PO,), in the extracted organic phase. The distribution ratio was found to decrease in the acidity range 0.4-1.4 M

H . SINGH AND C. K. GUPTA

Downloaded By: [ABM Utvikling STM / SSH packages] At: 06:19 4 January 2009

340

H,PO,. Effect of diluent showed that there was a decrease in extraction by a factor of 1.15 when diluent was changed from xylene to

kerosene.

In a similar study, involving uranium extraction from phosphoric

acid solutions [134], it was found that there was antagonism in using

mixtures involving tri-isodecylamine (Alamine 310), TBP, di-n-pentyl

sulfoxide (DPSO). Maximum extraction was found in the higher acidity

range. Extraction was less by bis(2,4,4-trimethyl penty1)phosphininc

acid (Cyanex 301) and its mixtures in the range 0.2-1.0 M H,PO,.

Uranyl extraction by mixtures of Cyanex301/Alamine 308

(triisooctylamine) with TBP/DDSO(didecyl sulfoxide) from chloride

solutions has been reported [135]. Mixtures of Cyanex301 (RH) with

TBP, DDSO and Alamine308 show significant synergism by the solvation mechanism. Extracted species is of the type UO,R,.L where

RH is Cyanex 301 and L is for the synergistic neutral ligand TBP,

DDSO o r Alamine 308.

UO:&,

+ 2RH(org)=UO,R,(orgj + 2H + (aqj

(23)

It is to be noted that Alamine 308 behaves like a neutral donor in the

range 0.2 to 1.0 M HCI mixtures of Alamine 308 with TBP or D D S O

is

result in a synergism where a species of the type (R,'NH),UO,Cl,L

extracted, with R,'N being the amine and L = T B P or DDSO.

Mixtures of Alamine 308 and Cyanex 301 used for extraction from

aqueous phase at acidities above 2 M HCI were found to show strong

antagonism.

Quarternary ammonium compounds (such as Aliquat 336) have

better extractive power than the tertiary amines [136-1381 and the

extraction of uranium with mixtures of Aliquat 336 and PC88A, in

xylene diluent, from nitric-sulphuric acid medium has been investigated [139]. Aliquat 336 is a quarternary ammonium compound of

the type tricapyryl methyl ammonium chloride. Extraction from

0.5-6 M HNO, solution showed maximum synergism at 3 M. The