Beruflich Dokumente

Kultur Dokumente

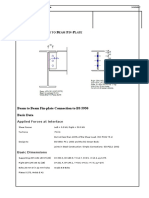

Report For 250x150x8 Base Plate

Hochgeladen von

ihpeterOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Report For 250x150x8 Base Plate

Hochgeladen von

ihpeterCopyright:

Verfügbare Formate

Profis Anchor 2.5.

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

3/24/2015

Specifier's comments:

1 Input data

Anchor type and diameter:

HIT-HY 200-A + HIT-Z M16

Effective embedment depth:

hef,act = 190 mm (hef,limit = - mm)

Material:

DIN EN ISO 4042

Evaluation Service Report:

ETA 12/0006

Issued I Valid:

3/15/2013 | 2/10/2017

Proof:

Design method ETAG BOND (EOTA TR 029)

Stand-off installation:

eb = 0 mm (no stand-off); t = 16 mm

Anchor plate:

lx x ly x t = 410 mm x 310 mm x 16 mm; (Recommended plate thickness: not calculated)

Profile:

Rectangular hollow; (L x W x T) = 250 mm x 150 mm x 16 mm

Base material:

cracked concrete, C40/50, fcc = 50.00 N/mm2; h = 10000 mm, Temp. short/long: 0/0 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

reinforcement spacing < 150 mm (any ) or < 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12 + close mesh (stirrups, hangers) s <=

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

3/24/2015

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Tension force

Shear force

Shear force x

Anchor

1

25.614

0.000

0.000

2

0.000

0.000

0.000

3

62.440

0.000

0.000

4

26.264

0.000

0.000

max. concrete compressive strain:

0.68 []

max. concrete compressive stress:

20.40 [N/mm2]

resulting tension force in (x/y)=(-89/63):

114.317 [kN]

resulting compression force in (x/y)=(156/-122): 88.317 [kN]

4

Tension

Shear force y

0.000

0.000

0.000

0.000

2

Compression

3 Tension load (EOTA TR 029, Section 5.2.2)

Load [kN]

62.440

Capacity [kN]

64.000

Utilization bN [%]

98

Status

OK

Combined pullout-concrete cone failure**

114.317

136.900

84

OK

Concrete Breakout Strength**

114.317

144.597

80

OK

N/A

N/A

N/A

N/A

Steel Strength*

Splitting failure**

* anchor having the highest loading

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

96.000

gM,s

1.500

NRd,s [kN]

64.000

NSd [kN]

62.440

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

232128

A0p,N [mm2]

82944

2

tRk,ucr,25 [N/mm ]

24.00

scr,Np [mm]

288

ccr,Np [mm]

144

yc

1.000

2

tRk,cr [N/mm ]

22.00

k

2.300

yg,Np

1.000

yg,Np

1.000

ec1,N [mm]

34

yec1,Np

0.828

ec2,N [mm]

25

yec2,Np

0.851

ys,Np

1.000

N0Rk,p [kN]

106.161

NRk,p [kN]

205.350

gM,p

1.500

NRd,p [kN]

136.900

NSd [kN]

114.317

cmin [mm]

hef,Helix [mm]

96

yre,Np

0.980

3.3 Concrete Breakout Strength

Ac,N [mm2]

644100

A0c,N [mm2]

324900

ccr,N [mm]

285

scr,N [mm]

570

ec1,N [mm]

34

yec1,N

0.893

ec2,N [mm]

25

yec2,N

0.919

N0Rk,c [kN]

133.336

gM,c

1.500

NRd,c [kN]

144.597

NSd [kN]

114.317

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

ys,N

1.000

yre,N

1.000

k1

7.200

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

3/24/2015

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

N/A

Capacity [kN]

N/A

Utilization bV [%]

N/A

Status

N/A

Steel failure (with lever arm)*

N/A

N/A

N/A

N/A

Pryout Strength*

N/A

N/A

N/A

N/A

Concrete edge failure in direction **

N/A

N/A

N/A

N/A

Steel Strength (without lever arm)*

* anchor having the highest loading

**anchor group (relevant anchors)

5 Displacements (highest loaded anchor)

Short term loading:

NSk

46.251 [kN]

VSk

0.000 [kN]

dN

0.436 [mm]

dV

0.000 [mm]

dNV

0.436 [mm]

dN

1.017 [mm]

dV

0.000 [mm]

dNV

1.017 [mm]

Long term loading:

NSk

46.251 [kN]

VSk

0.000 [kN]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

6 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Characteristic bond resistances depend on short- and long-term temperatures.

Edge reinforcement is not required to avoid splitting failure

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

3/24/2015

7 Installation data

Anchor plate, steel: Profile: Rectangular hollow; 250 x 150 x 16 mm

Hole diameter in the fixture: df = 18 mm

Plate thickness (input): 16 mm

Recommended plate thickness: not calculated

Cleaning: No cleaning of the drilled hole is required

Anchor type and diameter: HIT-HY 200-A + HIT-Z M16

Installation torque: 0.080 kNm

Hole diameter in the base material: 18 mm

Hole depth in the base material: 245 mm

Minimum thickness of the base material: 290 mm

7.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

No accessory required

Setting

Dispenser including cassette and mixer

Torque wrench

y

205

40

205

230

155

155

2

40

40

330

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

-165

165

-165

165

y

-115

-115

115

115

c-x

-

c+x

-

c-y

-

c+y

-

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

40

Profis Anchor 2.5.0

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

3/24/2015

8 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Das könnte Ihnen auch gefallen

- Connections UB457 191x98xconnDokument3 SeitenConnections UB457 191x98xconnihpeterNoch keine Bewertungen

- 11Dokument3 Seiten11ihpeterNoch keine Bewertungen

- SBBDokument3 SeitenSBBihpeterNoch keine Bewertungen

- Anchor Bolt CheckDokument1 SeiteAnchor Bolt CheckihpeterNoch keine Bewertungen

- 20180923Dokument13 Seiten20180923ihpeterNoch keine Bewertungen

- Hilti Design Report PDFDokument6 SeitenHilti Design Report PDFihpeterNoch keine Bewertungen

- UB457 End PlateDokument4 SeitenUB457 End PlateihpeterNoch keine Bewertungen

- Portal Output 20180718 R2Dokument60 SeitenPortal Output 20180718 R2ihpeterNoch keine Bewertungen

- Connections UB457 191x98xconnDokument3 SeitenConnections UB457 191x98xconnihpeterNoch keine Bewertungen

- Expo Favoriteroom 5Dokument1 SeiteExpo Favoriteroom 5ihpeterNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.1Dokument6 Seiten1 Input Data: Profis Anchor 2.6.1ihpeterNoch keine Bewertungen

- ADokument7 SeitenAihpeterNoch keine Bewertungen

- Anchor Bolt CheckDokument1 SeiteAnchor Bolt CheckihpeterNoch keine Bewertungen

- 20170303Dokument4 Seiten20170303ihpeterNoch keine Bewertungen

- Conn ForcesDokument2 SeitenConn ForcesihpeterNoch keine Bewertungen

- Conn DetailDokument1 SeiteConn DetailihpeterNoch keine Bewertungen

- Circular Skylight Splice DetailDokument1 SeiteCircular Skylight Splice DetailihpeterNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.4Dokument6 Seiten1 Input Data: Profis Anchor 2.6.4ihpeterNoch keine Bewertungen

- 1 Input Data: Profis Anchor 2.6.4Dokument6 Seiten1 Input Data: Profis Anchor 2.6.4ihpeterNoch keine Bewertungen

- Reaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZDokument1 SeiteReaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZihpeterNoch keine Bewertungen

- SHS120 Post FixingDokument6 SeitenSHS120 Post FixingihpeterNoch keine Bewertungen

- SHS120 Post FixingDokument6 SeitenSHS120 Post FixingihpeterNoch keine Bewertungen

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateDokument6 SeitenUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterNoch keine Bewertungen

- RRDokument6 SeitenRRihpeterNoch keine Bewertungen

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateDokument6 SeitenUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterNoch keine Bewertungen

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDokument7 SeitenUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterNoch keine Bewertungen

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateDokument7 SeitenUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterNoch keine Bewertungen

- ADokument2 SeitenAihpeterNoch keine Bewertungen

- ADokument9 SeitenAihpeterNoch keine Bewertungen

- ADokument7 SeitenAihpeterNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- KDC MP148CR PDFDokument43 SeitenKDC MP148CR PDFMiguelNoch keine Bewertungen

- Latest Cisco EnsurePass ICND2 200 101 Dumps PDFDokument151 SeitenLatest Cisco EnsurePass ICND2 200 101 Dumps PDFkifayatktkNoch keine Bewertungen

- Fujitsu Siemens Scenicview B17-2ci SMDokument55 SeitenFujitsu Siemens Scenicview B17-2ci SMVergil OlteanuNoch keine Bewertungen

- GP 14-01 Noise ControlDokument12 SeitenGP 14-01 Noise Controlzepol051Noch keine Bewertungen

- 05 - Transmission Fuller MGES1-WE-1111 - 1st PDFDokument174 Seiten05 - Transmission Fuller MGES1-WE-1111 - 1st PDFPengecoransemester6Noch keine Bewertungen

- ISO2409 16669-PART3 - 563502 Cross Cut AdhesionDokument12 SeitenISO2409 16669-PART3 - 563502 Cross Cut AdhesionUday SharmaNoch keine Bewertungen

- Ug Awus036achDokument19 SeitenUg Awus036achEd PMNoch keine Bewertungen

- 7Q 1 (1) .C ToolsDokument74 Seiten7Q 1 (1) .C ToolssrinivasancptNoch keine Bewertungen

- BS 476-3 - 2004Dokument16 SeitenBS 476-3 - 2004Vijayakumar GNoch keine Bewertungen

- Normal Consistency ASTM C 187Dokument3 SeitenNormal Consistency ASTM C 187Guido GarateNoch keine Bewertungen

- 23xrv 4ssDokument154 Seiten23xrv 4ssLouie DupayaNoch keine Bewertungen

- Tolerances NotesDokument14 SeitenTolerances NotesAshween Royos DoutalNoch keine Bewertungen

- Indoor Cable Floor Heating Systems: Application ManualDokument52 SeitenIndoor Cable Floor Heating Systems: Application ManualLucian CiudinNoch keine Bewertungen

- LEED-NC MV Plan Template 7-9-08Dokument26 SeitenLEED-NC MV Plan Template 7-9-08rasheedillikkal0% (1)

- Load Fastening, Lashing, SupportingDokument16 SeitenLoad Fastening, Lashing, Supportingdsn_sarma100% (1)

- D07be8 Com It Msys3Dokument1 SeiteD07be8 Com It Msys3Harsh MehtaNoch keine Bewertungen

- ZC201UPDokument11 SeitenZC201UPChengalrayulu Mudiraj100% (1)

- Differences Related To Computer MaintenanceDokument5 SeitenDifferences Related To Computer MaintenanceAlpesh ThesiyaNoch keine Bewertungen

- AS9102 FormsDokument4 SeitenAS9102 Formstongai100% (1)

- Samaveda Svara SupportDokument3 SeitenSamaveda Svara SupportMadhu ChanNoch keine Bewertungen

- PLC Anupam Samanta 2010JE0976Dokument64 SeitenPLC Anupam Samanta 2010JE0976Anupam SamantaNoch keine Bewertungen

- 20113e W Ci Ie2 PDFDokument30 Seiten20113e W Ci Ie2 PDFElio DiazNoch keine Bewertungen

- Medical Electrical Equipment - Part 2-19: Particular Requirements For The Basic Safety and Essential Performance of Infant IncubatorsDokument46 SeitenMedical Electrical Equipment - Part 2-19: Particular Requirements For The Basic Safety and Essential Performance of Infant IncubatorsEver Daniel Castro RodriguezNoch keine Bewertungen

- Zentyal As A GatewayDokument14 SeitenZentyal As A Gatewayartur_martinezNoch keine Bewertungen

- 07-IsY10221 Meetings Agendas & MinutesDokument4 Seiten07-IsY10221 Meetings Agendas & Minutesjohn paroNoch keine Bewertungen

- Logs 23-03-30 194409Dokument2 SeitenLogs 23-03-30 194409Sven TlyerNoch keine Bewertungen

- ConnectorsDokument20 SeitenConnectorsAnayanziGuadalupeVargasValdezNoch keine Bewertungen

- (Sephirotic) Kizumonogatari I Tekketsu-Hen (BD 1280x544 PHi444 DTS MA 5.1) (4929D3E2)Dokument3 Seiten(Sephirotic) Kizumonogatari I Tekketsu-Hen (BD 1280x544 PHi444 DTS MA 5.1) (4929D3E2)Anonymous 4q1mOk3lNoch keine Bewertungen

- XML API Developer GuideDokument159 SeitenXML API Developer GuidegirishpoojariNoch keine Bewertungen

- DBR CalculatorDokument69 SeitenDBR CalculatorSURJIT SINGHNoch keine Bewertungen