Beruflich Dokumente

Kultur Dokumente

Itp Non Asme

Hochgeladen von

Akhilesh KumarCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Itp Non Asme

Hochgeladen von

Akhilesh KumarCopyright:

Verfügbare Formate

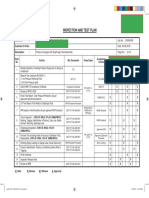

GULF SKY CRANES & CONT. COM.

LTD

ROAD No.118, SUPPORT INDUSTRIAL AREA, AL

JUBAIL INDUSTRIAL CITY - 31691

SAUDI ARABIA.

DOCUMENT NO:

JOB NO: GSCC-MD-2014-356

ITEM DESCRIPTION

PRESSURE VESSELS

ITEM NO / DRAWING NO:

PED-0246 & 0242 REV.1

PROJECT

RABIGH II REFINIG & PETROCHEMICALS

(CP3 & CP4)

INSPECTION TEST PLAN (ITP)

QA/QC

29/10/2014

Revised to incorporate client and PIM

comments

QA/QCENGG

GSCC

5/10/2014

For Approval

QA/QCENGG

GSCC

GSCC

QA/QC

MANAGER

GSCC

REV:

DATE:

ISSUENCE

PREPARED By

REVIEWED

By

DOC.NO. OPR08-01

REV.No: 02

MANAGER

ZS

GSCE

SA

ZS

GSCE

SA

ACCEPTE

D

APPROVED BY CLIENT

By

PAGE 1

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

Pre-Inspection Meeting

DOCUMENTS

1.1

Weld Map, WPS, PQR,

Weld Repair

Procedure,Welding

Control & Consumable

Procedure

1.2

Welder Qualification

Record Review

1.3

NDE Personnel

Qualification and Procedure

Review

CHARECTERISTIC

TO BE CHECKED

Review of Weld Map,WPS, Fabrication

Drawings, & Applicable Codes &

Specifications

Review of Welder Qualification Recoreds

Review of NDE (PT)

Procedures & Codes &

Spec.

EQUIPMENT NAME : CWR SAMPLING BOX

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION STAGES

INSPECTION

FORM &

RECORD

GSCC

Res

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

-

Approved Fabrication

Drawings,

ASME Sec. IX,

ASME Sec. VIII. Div 1

Approved GSCC

WPS & PQR and

& Approved

Procedures

As per ASME Sec. IX

Approved 3rd Party

WQT Records

AMES Sec. V

Approved 3rd Party

Procedures

Receiving Inspection

Visual Inspection, Dimension Checking

As Per Specification

Plates, Forgings, Pipes

Fittings & Nozzles

2.1

VESEEL TAG No: P 210-Z-1350

Identification Marking Heat Number

against MTC / Material

Specification

Review of MTC/ Material Specification

ASME Sec. II Part A

MTC & Material

Specification

Incoming Material

Inspection Report,

Doc.No:

OPR08-40

Mill Test

Certificates

As per Drawings

ASME Sec. VIII

Div.1

DOC.NO. OPR08-01

REV.No: 02

PAGE 2

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

2.2

Welding Consumables

Material Traceability

of Pressure Parts,

Attachment to

Pressure Parts

4.1

CHARECTERISTIC

TO BE CHECKED

VESEEL TAG No: P 210-Z-1350

EQUIPMENT NAME : CWR SAMPLING BOX

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

Verification against the Requirement

of the Consumable MTC

As per ASME Sec. II

Part C

INSPECTION STAGES

INSPECTION

FORM &

RECORD

GSCC

Res

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

Raw Material

Inspection

Report.Doc. OPR08-04

Traceability Verification As per MTC

and approved Fabrication Drawings.

Drawings, marking

on Plates & Pipes

ASME Sec. VIII

Div.1

Approved

Fabrication

Drawings,

Incoming Materail

Inspection Repors

Doc.OPR08-40

Fit-Up Alignment check, Tack Welds,

Surveillance of welding parameters

against the applicable WPS

Fabrication Drawings,

applicable WPS and

Weld Map

Inspection Report, DOC.

OPR08-64

IW

IW

Visual Inspection of welds 100%

ASME Sec. VIII

Div. 1

Inspection Report, DCO.OPR0807

Carry out PT (100%)

ASME Sec.V & ASME

Sec VIII,Div.1

3rd PARTY,

AIS QP-7.5.1C

In-Process Inspection

Fit up of Butt Welds in

Plates, Corner welds

between walls

DOC.No: OPR08-01

REV.NO: 02

PAGE 3

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

Nozzle Fabrication

VESEEL TAG No: P 210-Z-1350

EQUIPMENT NAME : CWR SAMPLING BOX

INSPECTION STAGES

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION

FORM &

RECORD

Fit-up alignment check, Tack Welds,

Surveillance of welding parameters

against the applicable WPS.

fabrication Drawings,

applicable WPS & ASME

Sec VIII. Div.1

Inspexction Reports,

DOC. OPR08-64

PT on the back gouged surfaces

& 100% Visual Inspection & 100 % PT

ASME Sec.V

3rd Party Procedure

AIS QP-7.5.1A AIS-QP 7.5 1C

As Per Fabrication

Drawings.

Inspexction Reports,

DOC. OPR08-67

CHARECTERISTIC

TO BE CHECKED

GSCC

Res

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

4.2

Nozzle Neck

4.3

Nozzle layout

Marking on shell and head

Nozzle Orientation conformity and

verifiaction of weld edge

ppreparation

DOC.No: OPR08-01

REV.NO: 02

PAGE 4

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

CHARECTERISTIC

TO BE CHECKED

Fit-Up Tack weld visual check,

Surveillance of

welding parameters

against applicable

WPS, weld Visual 100%

4.4

EQUIPMENT NAME : CWR SAMPLING BOX

INSPECTION STAGES

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION

FORM &

RECORD

Applicable WPS/ Weld

Map,

Reports

Inspection Report

OPR08-64 OPR08-07

& PT

Nozzle Neck to shell &

head fit-up & welding

ASME Sec.V

GSCC

Res

Joints of pipe to pipe, pipe

to elbow , pipe to flange ,

pipe to Tee etc.. (If

applicable)

Verify fit-up tolerance,100 % Weld visual

4.5

VESEEL TAG No: P 210-Z-1350

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

3rd Party Procedure

AIS QP-7.5.1A AIS-QP 7.5 1D

Fit-Up Tack weld visual check,

Surveillance of welding parameters

against applicable WPS, weld

Visual

100% .

Applicable WPS/ Weld

Map,

Drawings .

ASME

Sec.V

Insepection Reports Doc.

OPR08-64

IW /S

IW

PT on Nozzle to shell head weld

ASME Sev. V

3rd PARTY,

AIS QP-7.5.1D

DOC.No: OPR08-01

REV.NO: 02

PAGE 5

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

CHARECTERISTIC

TO BE CHECKED

Welding parametes, surveillance against

applicable WPS, Verification of location

Inspection of weld

4.6

External attachment

Fit-Up & Welding on

the vessels including

leg support and Lifting lugs

PT on Leg supports to Shell Attachment

wels

PT on all External

attachment welds & temporary support

removed area & Arc strikes removed area.

4.7

All the Internal

Fit-UP and Welding

on the Vessel

Fit-Up Tack weld visual check,

Surveillance of welding parameters

against applicable WPS,Verify Fit-Up

tolerance & weld Visual 100%

Visual Inspection of of Internal surface

4.8

Internal Inspection of

Vessel (Before

closing seam)

and verification of nozzle internal sharp

corners rouding off.

PT on Internal attachment welds

DOC.No: OPR08-01

VESEEL TAG No: P 210-Z-1350

EQUIPMENT NAME : CWR SAMPLING BOX

INSPECTION STAGES

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION

FORM &

RECORD

Fabrication Drawings,

Applicable WPS.

Inspection Report

DOC. OPR08-07

AMES Sec. V

3rd PARTY,

AIS QP-7.5.1C

AMES Sec. V

Applicable WPS/

Approved Drawings.

Inspection Reports.

ASME Sec.VIII. Div.1

Approved Drawings,

ASME Sec .V

GSCC

Res

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

IW/S

3rd PARTY,

AIS QP-7.5.1C

Inspection Report

WPS, DOC.

OPR08-07

Inspection Report

DOC. OPR08-07,

3rd PARTY

AIS QP-7.5.1C

REV.NO: 02

PAGE 6

Sign

GULF SKY CRANES & CONT. CO. LTD

INSPECTION TEST PLAN ( ITP) No:

GSCC-ZS-PV-ITP-005-2014

CLIENT : ZAMIL STEEL CO.LTD.

REV. NO: 1

DATE: 29/10/2014

DRAWING No: PED-0242-37-001

P.O No: 101652 REV.0

PROJECT TITLE : RABIGH II REFINING AND PETROCHEMICAL PROJECT

DESCRIPTION : PRESSURE VESSEL FABRICATION

ITE

WORK PROCESESS

M

ACTIVITY

No:

CHARECTERISTIC

TO BE CHECKED

VESEEL TAG No: P 210-Z-1350

EQUIPMENT NAME : CWR SAMPLING BOX

INSPECTION STAGES

REFERENCE

DOCUMENTS/

ACCEPTANCE

CRETERIA.

INSPECTION

FORM &

RECORD

Fabrication Drawings,

Inspection Reports.

Fabrication Tolerence

APPROVED DWG,

Inspection Reports. DOC.

OPR08-08

GSCC

Res

ZS

CLIENT

GS E&C

Sign Res Sign Res

SA

Sign Res

4.9

Final Dimension &

Visual checking of Vessel

Verification of dimension (Over all

dimensions,Nozzles and attachments)

and Final Visual Inspection

4.10

RF Pads leak Test

(If applicable)

Pneumatic Test of Pads at 5 PSIG

Approved Procedures

QP PPT-08 Rev.0

Inspection Report OPR08-12

4.11

Documents Review and

Equipment Release

Dossier Review (IRB)

ASME Sec.VIII , Div.1

Approved Formates

LEGEND:

IW- Initial Witness , H- Hold Points , W- Witness Points , S- Surveillance , R- Review of Records

DOC.No: OPR08-01

REV.NO: 02

PAGE 7

Sign

Das könnte Ihnen auch gefallen

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Dokument7 SeitenInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNoch keine Bewertungen

- Fabrication of Steel Structure and Steel Equipment (Itp)Dokument4 SeitenFabrication of Steel Structure and Steel Equipment (Itp)Javed MANoch keine Bewertungen

- Content List MDR Storange TankDokument72 SeitenContent List MDR Storange Tankunto gunungNoch keine Bewertungen

- Welding Inspection ReportDokument1 SeiteWelding Inspection ReportabdiNoch keine Bewertungen

- LPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewDokument13 SeitenLPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewabdiNoch keine Bewertungen

- Procedure Fabrikasi TankiDokument10 SeitenProcedure Fabrikasi TankiMuhammad Yunus NurdinNoch keine Bewertungen

- Client: Job No.: Job Title: Client's Job No.:: Company NameDokument13 SeitenClient: Job No.: Job Title: Client's Job No.:: Company NamejorgekarlosprNoch keine Bewertungen

- Steel TankDokument4 SeitenSteel TankRanu JanuarNoch keine Bewertungen

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDokument1 SeiteNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Procedure: Technical Bid Evaluation For Catodic ProtectionDokument6 SeitenProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus Handoko100% (1)

- Roundness Check Record of 1St Shell CourseDokument1 SeiteRoundness Check Record of 1St Shell CourseRhannie GarciaNoch keine Bewertungen

- Method Statement For Tank Erection by Hydraulic JackDokument4 SeitenMethod Statement For Tank Erection by Hydraulic Jackmanish pathrabeNoch keine Bewertungen

- GSB-Form-246 Dimension Inspection Report (Circum)Dokument1 SeiteGSB-Form-246 Dimension Inspection Report (Circum)Made GileeNoch keine Bewertungen

- Prosedur Penetran TestingDokument11 SeitenProsedur Penetran TestingIkhsan DalimuntheNoch keine Bewertungen

- Incoming Material Inspection Report: Date of ReceiptDokument1 SeiteIncoming Material Inspection Report: Date of ReceiptRaj MNoch keine Bewertungen

- Tool Fab - WorkshopDokument347 SeitenTool Fab - Workshophrdsby100% (1)

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDokument16 SeitenHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamNoch keine Bewertungen

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDokument11 Seiten0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusNoch keine Bewertungen

- Lish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFDokument1 SeiteLish No Certificate Po 4008 0111 00 Imn 8000 2019 PDFliving goodNoch keine Bewertungen

- ITPDokument1 SeiteITPVenkatesh PethurajNoch keine Bewertungen

- Daily Welding Report PLD LogoDokument1 SeiteDaily Welding Report PLD Logonike_y2kNoch keine Bewertungen

- Belt Conveyor Draw FinishDokument1 SeiteBelt Conveyor Draw FinishRizki FauziNoch keine Bewertungen

- QAP Format - QA 01 F 01Dokument1 SeiteQAP Format - QA 01 F 01Murukan PadmanabhanNoch keine Bewertungen

- Mfjo694 MRB 0001 IndexDokument2 SeitenMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Hydrostatic Test Quality Control and Inspection Report FormMHT allamNoch keine Bewertungen

- Ug PipingDokument1 SeiteUg PipingVinoth KumarNoch keine Bewertungen

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Dokument1 SeiteIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarNoch keine Bewertungen

- APV STD Insp & Test Plan API6D ValvesDokument4 SeitenAPV STD Insp & Test Plan API6D ValvesdbmingoNoch keine Bewertungen

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDokument1 SeiteStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFRadhakrishna VachaNoch keine Bewertungen

- 2018-01-15 Kasuari WTP Erection & Installation ProcedureDokument6 Seiten2018-01-15 Kasuari WTP Erection & Installation ProcedureavriamandaNoch keine Bewertungen

- WPS - Smaw - 2Dokument6 SeitenWPS - Smaw - 2Harkesh RajputNoch keine Bewertungen

- Method Statement For Installation of Fire Protection SystemDokument34 SeitenMethod Statement For Installation of Fire Protection SystemRM ENTERPRISESNoch keine Bewertungen

- Occpl: Hydro & Pneumatic Test ProcedureDokument3 SeitenOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNoch keine Bewertungen

- Fabrication Method For HSM 2 ProjectDokument14 SeitenFabrication Method For HSM 2 ProjectMikiRoniWijayaNoch keine Bewertungen

- Inspection Test and Plan For Storage Tank For Material Carbon SteelDokument5 SeitenInspection Test and Plan For Storage Tank For Material Carbon SteelPLTU SULUT QC PASTINoch keine Bewertungen

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Dokument1 SeiteIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNoch keine Bewertungen

- Ferro FabDokument20 SeitenFerro Fabsd.ehtesham100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDokument3 SeitenWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNoch keine Bewertungen

- Sample WPS 1Dokument13 SeitenSample WPS 1waqas pirachaNoch keine Bewertungen

- Job Methodology For DRT Tank Procedure - 0618-R1Dokument15 SeitenJob Methodology For DRT Tank Procedure - 0618-R1purshottam GHNoch keine Bewertungen

- Body of Requisition - ROW Work Package PDFDokument60 SeitenBody of Requisition - ROW Work Package PDFmahandhieNoch keine Bewertungen

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDokument15 SeitenPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- B2020-TDC-VF-009 Vessel Fabrication R0Dokument5 SeitenB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNoch keine Bewertungen

- Hydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkDokument8 SeitenHydrotest Procedure For HVAC PKG#2 (Incl. Fire Fighting) WorkCipta Adikarya100% (1)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDokument1 SeiteStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNoch keine Bewertungen

- S-3000-3130-001 - 0-General Specification For Steel Structure and Miscellenous MaterialsDokument15 SeitenS-3000-3130-001 - 0-General Specification For Steel Structure and Miscellenous MaterialsMessaoud Goutas100% (1)

- List Welder PT - InstrucomDokument4 SeitenList Welder PT - InstrucomHerlan HutabaratNoch keine Bewertungen

- Original: Mill Test CertificateDokument3 SeitenOriginal: Mill Test CertificateAhmad NafilulhudaNoch keine Bewertungen

- Condensate Tank WELDING LOGDokument6 SeitenCondensate Tank WELDING LOGhasan shahriarNoch keine Bewertungen

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- 3 Steel Structure Installation CLDokument2 Seiten3 Steel Structure Installation CLwhah11Noch keine Bewertungen

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDokument1 SeiteMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNoch keine Bewertungen

- List Certificates of Werder QualificationDokument2 SeitenList Certificates of Werder QualificationMuhammad FajarNoch keine Bewertungen

- Protocol Column AlignmentDokument9 SeitenProtocol Column AlignmentManikandan elumalaiNoch keine Bewertungen

- Daily Welding Record LPDokument27 SeitenDaily Welding Record LProbby moneNoch keine Bewertungen

- Standard Inspection & Test Plan (ITP) FOR Tank PadDokument5 SeitenStandard Inspection & Test Plan (ITP) FOR Tank PaddendyNoch keine Bewertungen

- JK Pipeline Welding & Installation Traceability Procedure CoDokument1 SeiteJK Pipeline Welding & Installation Traceability Procedure Cogst ajahNoch keine Bewertungen

- (Painting Works) : Inspection and Test PlanDokument2 Seiten(Painting Works) : Inspection and Test Planrize1159Noch keine Bewertungen

- Repair Procedure ANNEXUREDokument16 SeitenRepair Procedure ANNEXUREShaikh AdilNoch keine Bewertungen

- (732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06Dokument10 Seiten(732-Itp-40 (V-6905) 42000-SNG-69-42000P-MS-5733-504-0000-06sathi11189Noch keine Bewertungen

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDokument16 SeitenProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNoch keine Bewertungen

- Project:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDDokument14 SeitenProject:Panipat-Jallandhar LPG Pipeline Project. Owner:I.O.C.L. Conntractor: M/s Indcon Projects & Equipment LTDAkhilesh KumarNoch keine Bewertungen

- PaintingDokument6 SeitenPaintingAkhilesh KumarNoch keine Bewertungen

- 12 Form WorkDokument7 Seiten12 Form WorkAkhilesh KumarNoch keine Bewertungen

- 15 ConcretingDokument22 Seiten15 ConcretingAkhilesh KumarNoch keine Bewertungen

- Anti TermiteDokument30 SeitenAnti TermiteAkhilesh KumarNoch keine Bewertungen

- WaterproofingDokument5 SeitenWaterproofingAkhilesh KumarNoch keine Bewertungen

- Procedure For Flooring WorksDokument4 SeitenProcedure For Flooring WorksAkhilesh Kumar0% (1)

- 11-Backfiling at Station NoDokument7 Seiten11-Backfiling at Station NoAkhilesh KumarNoch keine Bewertungen

- Procedure For Horticulture WorksDokument4 SeitenProcedure For Horticulture WorksAkhilesh KumarNoch keine Bewertungen

- Procedure For Fencing WorksDokument3 SeitenProcedure For Fencing WorksAkhilesh KumarNoch keine Bewertungen

- Procedure For Plumbing Sanitary WorkDokument5 SeitenProcedure For Plumbing Sanitary WorkAkhilesh Kumar100% (1)

- 06-Earthwork in ExcavationDokument7 Seiten06-Earthwork in ExcavationAkhilesh KumarNoch keine Bewertungen

- Procedure For Area Grading and Development WorksDokument3 SeitenProcedure For Area Grading and Development WorksAkhilesh KumarNoch keine Bewertungen

- Procedure For Surveying and Levels FixingDokument3 SeitenProcedure For Surveying and Levels FixingAkhilesh KumarNoch keine Bewertungen

- Procedure For Steel Door Windows and VentilatorsDokument3 SeitenProcedure For Steel Door Windows and VentilatorsAkhilesh KumarNoch keine Bewertungen

- Procedure For ScafoldingDokument4 SeitenProcedure For ScafoldingAkhilesh KumarNoch keine Bewertungen

- Procedure For Roof Water ProofingDokument4 SeitenProcedure For Roof Water ProofingAkhilesh KumarNoch keine Bewertungen

- Roof Treatment Proc.Dokument4 SeitenRoof Treatment Proc.Akhilesh KumarNoch keine Bewertungen

- Proedure For PlasteringDokument4 SeitenProedure For PlasteringAkhilesh KumarNoch keine Bewertungen

- WBM For Road Work Proc.Dokument3 SeitenWBM For Road Work Proc.Akhilesh KumarNoch keine Bewertungen

- Reinforcement Work Proc.Dokument5 SeitenReinforcement Work Proc.Akhilesh Kumar0% (1)