Beruflich Dokumente

Kultur Dokumente

Large-Area Organic Light-Emitting Diode Technology

Hochgeladen von

acedude16Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Large-Area Organic Light-Emitting Diode Technology

Hochgeladen von

acedude16Copyright:

Verfügbare Formate

10.1117/2.1200804.

1104

Large-area organic

light-emitting diode technology

Joerg Amelung

The technology of solid-state lighting and flat panel displays can benefit

from advances in organic layer deposition and homogeneous light

output.

Displays based on organic light-emitting diodes (OLEDs ) have

benefited from significant advances that have now made them

commercially available. Due to the high efficiency of the technology, OLED-based lighting is expected to capture a promising market share. OLEDs are flat light sources that emit diffuse

light from a potentially large active area. They do not need light

distribution elements, which translates into significant cost benefits in the production of lighting panels. In contrast, inorganic

light-emitting diodes are point sources that do require light distribution components for flat panel lighting. Another advantage

of OLEDs is that, because they produce light via relatively low

peak brightness over a large area, they do not build up heat in

one spot, so do not need cooling elements.

A typical OLED consists of stacks of organic layers of

100nm thickness inserted between a cathode and an anode.

Usually, the substrate is glass, coated with a transparent conductive oxide as anode, followed by the organic stack and the

inorganic cathode (see Figure 1).

OLED technology uses materials from two different groups.

The first includes materials with low molecular weight

called small-molecule (SM) OLEDs, originally developed by

the Ching Tang group at the Kodak Laboratories in 1987.

The deposition of SM-OLEDs is based on vacuum thermal evaporation. The other group of materials includes

polymer-based OLEDs consisting of long polymer organic

chains deposited by spin-cast or ink-jet methods. SM-OLEDs

achieve higher efficiencies and currently dominate OLED

applications.

One of the key advantages of OLED technology is the chemical variability of the organic luminescence, allowing production of virtually any color, including white, by two or three red,

green, and blue layers. Other advantages include the use of thinfilm technology, allowing large area and low-cost deposition,

Figure 1. Schematic drawing of an organic light-emitting diode. Al:

Aluminium. ITO: Indium tin oxide.

and the possibility of using thin and even flexible substrates to

realize a novel class of lighting and display solutions not achievable with other technologies.

The fabrication of large-emission-area OLEDs for lighting at a

reasonable cost is essential for the successful penetration of large

markets. Achieving this goal however, requires OLED fabrication improvements. The electrical doping of the charge transport

layers of these devices represents an important step in this direction. The organic materials used in OLEDs commonly have very

low conductivities resulting in high device voltages. The problem has been addressed by the simultaneous evaporation of two

materials with higher conductivities as organic layers, shown

to significantly decrease the operating voltage.1, 2 Devices with

very high power efficiency have also been realized by combining electrical doping with highly efficient emitter systems.36 A

typical architecture for such devices is p-i-n stacking, a proprietary technology of Novaled AG.

Besides producing highly-efficient white OLED devices, fabrication technology improvements are also essential to realize functional OLED lighting tiles. One important requirement

is the achievement of an homogenous light output. Based on

the limiting conductivity of indium tin oxide (ITO), typically

10ohm/square, voltage drops can be related to lighting inhomogeneities. Improved current distributions therefore require

Continued on next page

10.1117/2.1200804.1104 Page 2/2

Author Information

Joerg Amelung

Fraunhofer Institute for Photonic Microsystems

Dresden, Germany

Figure 2. Metal support line integration reduces overall resistance and

improves evenness of the light output.

Joerg Amelung is responsible for the business unit of organic

materials and systems at the Fraunhofer Institute for Photonic

Microsystems. He is also one of the founders of spin-off Novaled

AG, Dresden.

References

1. M. Pfeiffer, K. Leo, X. Zhou, J. S. Huang, M. Hofmann, A. Werner, and J.

Blochwitz-Nimoth, Doped organic semiconductors: physics and application in light emitting diodes, Org. Electron. 4 (2-3), pp. 89103, 2003.

2. J. Kido and T. Matsumoto, Bright organic electroluminescent devices having a metaldoped electron-injecting layer, Appl. Phys. Lett. 73 (20), pp. 28662868, 1998.

3. M. Pfeiffer, S. Forrest, K. Leo, and M. E. Thompson, Electrophosphorescent p-i-n Organic Light-Emitting Devices for Very-High-Efficiency Flat-Panel Displays, Adv. Mater.

14 (22), pp. 16331636, 2002.

4. C. Adachi, M. A. Baldo, S. R. Forrest, and M. E. Thompson, High-efficiency organic

electrophosphorescent devices with tris(2-phenylpyridine)iridium doped into electrontransporting materials, Appl. Phys. Lett. 77 (6), pp. 904906, 2000.

5. J. Birnstock, M. Hofmann, S. Murano, M. Vehse, J. Blochwitz-Nimoth, Q. Huang,

G. F. He, M. Pfeiffer, and K. Leo, Novel OLEDs for full color displays with highest power

efficiencies and long lifetime, SID Symp. Digest Tech. Papers 36 (1), pp. 4043, 2005.

6. P. Wellmann, M. Hofmann, O. Zeika, A. Werner, J. Birnstock, R. Meerheim, G.

He, K. Walzer, M. Pfeiffer, and K. Leo, High-efficiency p-i-n organic light-emitting

diodes with long lifetime, J. Soc. Inf. Disp. 13 (5), pp. 393397, 2005.

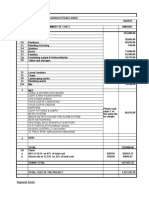

Figure 3. Large area OLED module. Dimensions: 8020cm2 . Light

output: 250lumen.

development to achieve homogeneous large area lighting. One

possibility is to use metal support lines, which can lower the effective ITO resistance to less than 1ohm/square (see Figure 2). Of

course, such metal lines also reduce the effective lighting area,

but they can fortunately be limited to a maximum of 1020% of

the lighting area.

The combination of highly efficient OLEDs and improved

lighting integration technology recently allowed the fabrication

of the largest SM-OLED lighting module ever reported, with dimensions of 8020cm2 , subdivided in four panels. The OLED

active area is 1100cm2 , and the light output of 250lumen could

be improved up to 500lumen in future modules (see Figure 3).

Other production aspects, such as fabrication yield and costs,

should also be addressed to achieve a large market penetration.

However, the advances summarized above represent important

solutions to achieve promising new lighting technology for the

future.

c 2008 SPIE

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Mandolite 550 DSDokument4 SeitenMandolite 550 DSnrd9771Noch keine Bewertungen

- Literature Case Study On Design CollegeDokument21 SeitenLiterature Case Study On Design CollegeSophia Chin100% (1)

- Abhijeet Adjustment Techoptions - BOQ - R3 - 25022014Dokument16 SeitenAbhijeet Adjustment Techoptions - BOQ - R3 - 250220147p InfomediaNoch keine Bewertungen

- Hot Tap ProcedureDokument6 SeitenHot Tap ProcedureNatarajan MurugesanNoch keine Bewertungen

- United States Patent: (45) Date of Patent: Aug - 21, 2018Dokument22 SeitenUnited States Patent: (45) Date of Patent: Aug - 21, 2018RiskaNoch keine Bewertungen

- MEMS-module 4-5Dokument34 SeitenMEMS-module 4-5johnnyNoch keine Bewertungen

- Struktol WB 212: Technical DataDokument1 SeiteStruktol WB 212: Technical DataSikander AleemNoch keine Bewertungen

- Chapter8 Vapor Cycles ProblemsDokument77 SeitenChapter8 Vapor Cycles ProblemsAldren ArnaizNoch keine Bewertungen

- Gajjar Industries ADokument15 SeitenGajjar Industries AMPNoch keine Bewertungen

- 2011 Trs SowDokument56 Seiten2011 Trs SowmaniNoch keine Bewertungen

- Liquid Recirculation System-2Dokument7 SeitenLiquid Recirculation System-2Behnam AshouriNoch keine Bewertungen

- Sika Concrete Hand BookDokument151 SeitenSika Concrete Hand BookIwan TirtaNoch keine Bewertungen

- Shedule Work: Proyek Jasa Konstruksi Revitalisasi Terminal LPG Arun (Rtla) Lhokseumawe, AcehDokument1 SeiteShedule Work: Proyek Jasa Konstruksi Revitalisasi Terminal LPG Arun (Rtla) Lhokseumawe, AcehEdy D'archee100% (1)

- Computational Contact Mechanics YastrebovDokument308 SeitenComputational Contact Mechanics YastrebovJoe SatchNoch keine Bewertungen

- Breaker Operator's and Services ManualDokument96 SeitenBreaker Operator's and Services Manuallinuskotte100% (1)

- Water Phase DiagramDokument9 SeitenWater Phase DiagramboddarambabuNoch keine Bewertungen

- Washing Machine: User ManualDokument112 SeitenWashing Machine: User ManualHadiNoch keine Bewertungen

- RDSO GuidelineDokument57 SeitenRDSO GuidelineSyed Nizam ElahiNoch keine Bewertungen

- Aerospace Applications of Shape Memory Alloys PDFDokument16 SeitenAerospace Applications of Shape Memory Alloys PDFjtpqNoch keine Bewertungen

- Api 6D 2016Dokument2 SeitenApi 6D 2016raulNoch keine Bewertungen

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDokument7 SeitenStandard Test Procedures Manual: 1. Scope 1.1. Description of TestMuhsin KhanNoch keine Bewertungen

- SP 1275Dokument191 SeitenSP 1275Ibrahim Naguib0% (1)

- Martini Absorb Installation Guide - 0421Dokument3 SeitenMartini Absorb Installation Guide - 0421lac ngoNoch keine Bewertungen

- Camaster HRC Fuse Holders: RANGE: 30, 30, 60, and 100 Amp at 600V A.CDokument3 SeitenCamaster HRC Fuse Holders: RANGE: 30, 30, 60, and 100 Amp at 600V A.CprekNoch keine Bewertungen

- HS POLYBAG - ADDITION INSTALL ELECTRICAL SYSTEM FACTORY 견적서 20191223Dokument6 SeitenHS POLYBAG - ADDITION INSTALL ELECTRICAL SYSTEM FACTORY 견적서 20191223Nhí LêNoch keine Bewertungen

- Manual Midea Ac MPN1 08CR.10CR EN Version1 PDFDokument24 SeitenManual Midea Ac MPN1 08CR.10CR EN Version1 PDFwayne dinhNoch keine Bewertungen

- Price-List Polycab Industrial Flexible CablesDokument3 SeitenPrice-List Polycab Industrial Flexible CablesVirendraDwivediNoch keine Bewertungen

- Eng TipsDokument5 SeitenEng TipsBenedictus MurdonoNoch keine Bewertungen

- A New K-E Eddy Viscosity Model For High Reynolds Number Turbulent Flows-Model Development and Validatio PDFDokument34 SeitenA New K-E Eddy Viscosity Model For High Reynolds Number Turbulent Flows-Model Development and Validatio PDFAHMAD DiabNoch keine Bewertungen

- Measuring and Cutting PipesDokument13 SeitenMeasuring and Cutting PipesKareen Jenn AmlosNoch keine Bewertungen