Beruflich Dokumente

Kultur Dokumente

Solved

Hochgeladen von

Jatin hemwani0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

80 Ansichten4 Seitentransformer topic 1

Copyright

© © All Rights Reserved

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

80 Ansichten4 SeitenSolved

Hochgeladen von

Jatin hemwaniSie sind auf Seite 1von 4

TRANSFORMER

INTRODUCTION & INFORMATION

SOLVED

Q.) State the working principle of transformer.

Ans. A transformer (xmer) consists of two electrically insulated

inductive coils where electrical energy is fed to the primary

winding while electrical energy is drawn out of secondary winding.

Due to an alternating voltage V1 applied to primary coil of

transformer an alternating current I1 flows through it producing

alternating flux in the core. This flux links with the primary winding

and according to Faradays Law of electromagnetic induction, emf

e1 is induced in the primary coil given by

e1 N1

d

dt

(1)

volt

where, N1 = No. of turns in primary coil.

The induced emf in primary coil is nearly equal and opposite

to applied voltage V1. Assuming negligible leakage flux and

mutual induction to be prevalent an emf e2 is produced in the

secondary coil given by

e2 N2

d

dt

(2)

volt

where, N2 is number of twins of secondary coil.

We conclude with the following that (i) e1 is the self induced

emf (ii) e2 is mutually induced emf (iii) a current I2 will flow if

secondary coil is closed through load.

TRANSFORMER

INTRODUCTION & INFORMATION

SOLVED

Q.) Explain in brief about the construction of a transformer.

Ans. The construction of a simple two-winding transformer

consists of each winding being wound on a separate limb or core

of the soft iron form which provides the necessary magnetic

circuit. This magnetic circuit, know more commonly as the

transformer core is designed to provide a path for the magnetic

field to flow around, which is necessary for induction of the

voltage between the two windings.

However, this type of transformer construction were the two

windings are wound on separate limbs is not very efficient since

the primary and secondary windings are well separated from each

other. This results in a low magnetic coupling between the two

windings as well as large amounts of magnetic flux leakage from

the transformer itself. But as well as this O shapes construction,

there are different types of transformer construction and designs

available which are used to overcome these inefficiencies

producing a smaller more compact transformer.

The efficiency of a simple Transformer Construction can be

improved by bringing the two windings within close contact with

each other thereby improving the magnetic coupling. Increasing

and concentrating the magnetic circuit around the coils may

improve the magnetic coupling between the two windings, but it

also has the effect of increasing the magnetic losses of the

transformer core.

As well as providing a low reluctance path for the magnetic field,

the core is designed to prevent circulating electric currents within

the iron core itself. Circulating currents, called eddy currents,

cause heating and energy losses within the core decreasing the

transformers efficiency.

These losses are due mainly to voltages induced in the iron

circuit, which is constantly being subjected to the alternating

2

TRANSFORMER

INTRODUCTION & INFORMATION

SOLVED

magnetic fields setup by the external sinusoidal supply voltage.

One way to reduce these unwanted power losses is to construct

the transformer core from thin steel laminations.

In all types of transformer construction, the central iron core is

constructed from of a highly permeable material made from thin

silicon steel laminations assembled together to provide the

required magnetic path with the minimum of losses. The resistivity

of the steel sheet itself is high reducing the eddy current losses by

making the laminations very thin.

These steel transformer laminations vary in thicknesss from

between 0.25mm to 0.5mm and as steel is a conductor, the

laminations are electrically insulated from each other by a very

thin coating of insulating varnish or by the use of an oxide layer

on the surface.

Q.) Write a note on core of transformer.

Ans. The steel used for the manufacturing of core is high grade

silicon steel on soft steel to reduce hysteris loss. Also due to

alternating flux certain currents called eddy currents are produced

which caused eddy current loss. To minimize this the core is

manufactured as a stack of laminations, where successive

laminations are insulated by thin layer of varnish. The above two

lasses i.e. hysterics and eddy current loss are called iron lass.

Q.) Differentiate between core type and shell type transformer.

Ans.

Core-type transformer

1. The windings enclose the

Shell-type transformer

1. The core encloses the

3

TRANSFORMER

INTRODUCTION & INFORMATION

whole core.

2. Average length of the core is

more.

3. Magnetic flux has only one

continuous path.

4. It is more suitable for high

voltage transformers.

5. It is easy to repair.

SOLVED

windings.

2. Average length of the core is

less.

3. Magnetic flux is distributed

into two parts.

4. It is more economical for low

voltage transformers.

5. It is difficult to repair.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- SolvedDokument17 SeitenSolvedJatin hemwani72% (39)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- SolvedDokument6 SeitenSolvedJatin hemwani100% (3)

- Bearden On Maxwell's EquationsDokument10 SeitenBearden On Maxwell's Equationspaulsub63Noch keine Bewertungen

- Bee AssignmentDokument17 SeitenBee AssignmentJatin hemwani43% (7)

- Maintenance of SubstationDokument129 SeitenMaintenance of Substationrama mohan100% (1)

- Advisor Webcast Exadata Disk Management and Troubleshotting Tips FinalDokument84 SeitenAdvisor Webcast Exadata Disk Management and Troubleshotting Tips FinalethenhuntNoch keine Bewertungen

- SolvedDokument10 SeitenSolvedJatin hemwani100% (6)

- CmeDokument41 SeitenCmekhalis@hotmail.com100% (1)

- Transformer Transformer Tests UnsolvedDokument2 SeitenTransformer Transformer Tests UnsolvedJatin hemwaniNoch keine Bewertungen

- TheoryDokument7 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- Transformer Efficiency & Its Condition UnsolvedDokument2 SeitenTransformer Efficiency & Its Condition UnsolvedJatin hemwaniNoch keine Bewertungen

- SolvedDokument5 SeitenSolvedJatin hemwaniNoch keine Bewertungen

- TheoryDokument6 SeitenTheoryJatin hemwani100% (1)

- Transformer No-Load & On-Load Transformer UnsolvedDokument1 SeiteTransformer No-Load & On-Load Transformer UnsolvedJatin hemwaniNoch keine Bewertungen

- TheoryDokument7 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- Transformer Equivalent Circuit & Voltage Regulation UnsolvedDokument1 SeiteTransformer Equivalent Circuit & Voltage Regulation UnsolvedJatin hemwani100% (1)

- TheoryDokument8 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- TheoryDokument5 SeitenTheoryJatin hemwani100% (1)

- Solved ProbsDokument5 SeitenSolved ProbsJatin hemwani67% (3)

- Q.) Give Information About The Working of The TransformerDokument1 SeiteQ.) Give Information About The Working of The TransformerJatin hemwaniNoch keine Bewertungen

- A.C Circuits Phasor Representation UnsolvedDokument2 SeitenA.C Circuits Phasor Representation UnsolvedJatin hemwaniNoch keine Bewertungen

- TheoryDokument11 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- TheoryDokument12 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- SolvedDokument2 SeitenSolvedJatin hemwani100% (1)

- TheoryDokument3 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- A.C Circuits Resonance in A.C UnsolvedDokument1 SeiteA.C Circuits Resonance in A.C UnsolvedJatin hemwaniNoch keine Bewertungen

- TheoryDokument20 SeitenTheoryJatin hemwaniNoch keine Bewertungen

- A.C Circuits Resistor, Inductor & Capacitor in A.C UnsolvedDokument1 SeiteA.C Circuits Resistor, Inductor & Capacitor in A.C UnsolvedJatin hemwaniNoch keine Bewertungen

- UnsolvedDokument1 SeiteUnsolvedJatin hemwaniNoch keine Bewertungen

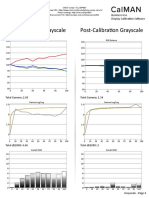

- TCL 55P607 CNET Review Calibration ResultsDokument3 SeitenTCL 55P607 CNET Review Calibration ResultsDavid KatzmaierNoch keine Bewertungen

- Lesson Plan 18 (Final)Dokument3 SeitenLesson Plan 18 (Final)ryan agustianNoch keine Bewertungen

- Integumentary SystemDokument8 SeitenIntegumentary SystemAshley Brithanie RamosNoch keine Bewertungen

- Manual ApolloDokument263 SeitenManual ApolloJose Luis CristanchoNoch keine Bewertungen

- KTG Week 1Dokument22 SeitenKTG Week 1Rebecca Soriano SantosNoch keine Bewertungen

- Schottky DiodeDokument5 SeitenSchottky Diodeilg1Noch keine Bewertungen

- Armando Anaya Guenter y Zender - Sak Tz'iDokument14 SeitenArmando Anaya Guenter y Zender - Sak Tz'iAngel Sanchez GamboaNoch keine Bewertungen

- FFA Furfural Fire and Health HazardsDokument2 SeitenFFA Furfural Fire and Health HazardsYuga Pria PungkasanNoch keine Bewertungen

- Manual F700GS 2013Dokument164 SeitenManual F700GS 2013j gfatggNoch keine Bewertungen

- in 01 en KATALOGDokument50 Seitenin 01 en KATALOGSigma Ragam ManunggalNoch keine Bewertungen

- Brown Stock WashingDokument22 SeitenBrown Stock Washingtreese2Noch keine Bewertungen

- Spread of Virus ModelledDokument2 SeitenSpread of Virus ModelledDouglas TanNoch keine Bewertungen

- ES Q2 Mod8Dokument26 SeitenES Q2 Mod8maacovsNoch keine Bewertungen

- Lab 2 Centrifugal PumpsDokument29 SeitenLab 2 Centrifugal PumpslalelaNoch keine Bewertungen

- DBA Roles and ResponsibilitiesDokument2 SeitenDBA Roles and ResponsibilitiesMahesh Babu Sri100% (2)

- AS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingDokument3 SeitenAS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingThylaneNoch keine Bewertungen

- Fluid Mechanics Chapter on Mechanical Energy and EfficiencyDokument43 SeitenFluid Mechanics Chapter on Mechanical Energy and EfficiencyShazrel IzlanNoch keine Bewertungen

- 8 - Chitapon - TR Winding Buckling - Paper PDFDokument5 Seiten8 - Chitapon - TR Winding Buckling - Paper PDFbcqbaoNoch keine Bewertungen

- Messenger No69Dokument72 SeitenMessenger No69European Southern ObservatoryNoch keine Bewertungen

- Project PBLDokument19 SeitenProject PBLAdam LuqmanNoch keine Bewertungen

- ALGEBRA 1B Solving Quadratic EquationsDokument2 SeitenALGEBRA 1B Solving Quadratic EquationsMaurizio FanniNoch keine Bewertungen

- Carbon 06 00052Dokument17 SeitenCarbon 06 00052Elbahi DjaalabNoch keine Bewertungen

- Refining of MaterialsDokument38 SeitenRefining of MaterialsJAWAD AHMAD BURTNoch keine Bewertungen

- Coreldraw 12 Hotkeys - Keyboard ShortcutsDokument6 SeitenCoreldraw 12 Hotkeys - Keyboard ShortcutsRais AhmadNoch keine Bewertungen

- Problem Set Ee8205 PDFDokument4 SeitenProblem Set Ee8205 PDFksajjNoch keine Bewertungen

- Digital Electronics Basics - Flip-FlopsDokument6 SeitenDigital Electronics Basics - Flip-FlopsPaolopiniNoch keine Bewertungen