Beruflich Dokumente

Kultur Dokumente

PP RCT The Innovative Solution For Higher Competitiveness and Performance

Hochgeladen von

محمود أبو الحسنOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PP RCT The Innovative Solution For Higher Competitiveness and Performance

Hochgeladen von

محمود أبو الحسنCopyright:

Verfügbare Formate

Borealis and Borouge are leading providers of innovative

plastics solutions that create value for society. Building

on the unique Borstar and Borlink technologies and 50

years of experience in polyolefins, Borealis and Borouge

support key industries including infrastructure, automotive and advanced packaging. Their manufacturing

capacity reaches over 5.4 million tonnes of polyethylene

and polypropylene per year.

TM

Borealis is headquartered in Vienna, Austria, and operates in over 120 countries with around 6,200 employees

worldwide. Borouge, its joint venture with the Abu Dhabi

National Oil Company (ADNOC), employs approximately

1,700 people, has customers in more than 50 countries

and its headquarters are in Abu Dhabi in the UAE and

Singapore. Together, both companies provide services

and products to customers around the world.

Borealis offers a wide range of base chemicals, including

melamine, phenol, acetone, ethylene and propylene servicing a wide range of industries. Together with Borouge

the two companies will produce approximately 6 million

tonnes of Base Chemicals in 2014.

Borealis also creates real value for the agricultural

industry with a large portfolio of fertilizers. The company

distributes approximately 2.1 million tonnes per year. This

volume will increase to around 5 million tonnes by the end

of 2014.

Borealis and Borouge proactively benefit society by taking on todays challenges and are working to drive ideas

forward. Both companies are committed to the principles

of Responsible Care , driving improved safety performance within the chemical industry and contributing to

addressing the worlds water and sanitation challenges

through product innovation and their Water for the World

programme.

TM

For more information visit:

www.borealisgroup.com

www.borouge.com

www.waterfortheworld.net

2013 Borealis AG . 2013 Borouge Pte Ltd

PF BROCH 029 GB 2013 08 BB

Disclaimer The information contained herein is to our knowledge accurate and reliable as of the date of publication. Borealis and Borouge extend no warranties and make no representations as to the accuracy or completeness

of the information contained herein, and assume no responsibility regarding the consequences of its use or for any printing errors. It is the customers responsibility to inspect and test our products in order to satisfy himself

as to the suitability of the products for the customers particular purpose. The customer is also responsible for the appropriate, safe and legal use, processing and handling of our products. Nothing herein shall constitute

any warranty (express or implied, of merchantability, fitness for a particular purpose, compliance with performance indicators, conformity to samples or models, non-infringement or otherwise), nor is protection from any law or

patent to be inferred. Insofar as products supplied by Borealis and Borouge are used in conjunction with third party materials, it is the responsibility of the customer to obtain all necessary information relating to the third-party

materials and ensure that Borealis and Borouge products, when used together with these materials, are suitable for the customers particular purpose. No liability can be accepted in respect of the use of Borealis and Borouge

products in conjunction with other materials. The information contained herein relates exclusively to our products when not used in conjunction with any third party materials.

Borstar is a registered trademarks of the Borealis Group. Borlink and Water for the World are trademarks of the Borealis Group.

For more information :

visit www.borealisgroup.com and www.borouge.com

Borealis AG IZD Tower

Wagramer Strasse 17-19 A-1220 Vienna Austria

Tel +43 1 22 400 000 Fax +43 1 22 400 333

Borouge Pte Ltd Sales and Marketing Head Office

1 George Street 18-01 Singapore 049145

PP-RCT: The innovative

solution for higher

competitiveness and

performance

Close to 10 years' track record with PP-RCT; over 30

years experience with beta-nucleation

Plastic pipes made from Polypropylene Random

Copolymer (PP-R) were introduced more than 30 years

ago. Since then, they have been used mainly for hot and

cold water pipe systems and have significantly contributed

to the growth and acceptance of plastic pipes for plumbing and heating systems. While system components have

been gradually improved over time, no resin improvement

of particular significance has happened in the last 20

years.

PP-RCT is a fully established pipe class on the market

PP-RCT (PolyPropylene-Random Crystallinity Temperature) is a material classification used to describe the

second-generation class of PP-R materials. Introduced

by Borealis in 2004 through its RA7050 range materials,

it sets a milestone in the advancement of PP pressure

piping systems. The pipe class has recently been included

in EN ISO 15874, the global standard for plastics piping

systems for hot and cold water pipe installations.

Picture courtesy of Bnninger

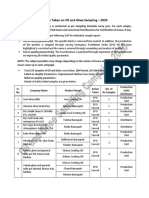

Comparison of reference curves PP-R and PPR-CT in accordance with ISO15874;ISO3213

100

Reference Curves for PP-R Material Class

Borealis RA7050-range is the well-established choice of

PP-RCT solutions on the market:

Increased pressure class with the same dimensioning

Close to 10-year track record on the market

Weight reduction (from 14% up to 25%) in pipe

production versus regular PP-R

Fully PP-RCT classified materials with CRS at

70C/50 years of above 5 MPa

Produced using a special multiple-reactor technology

Contain a high level of beta-nucleated crystals

enabling excellent slow crack growth properties

(no brittle failures with ISO9080 at any temperature)

The beta-nucleation technology is well-proven with

some 30 years, successful track record in demanding

industrial and chemical applications

State-of-the-art stabilisation package for excellent

thermal and chemical resistance

Ready compounded for maximum quality control

PP-RCT is a polypropylene-random-copolymer with a

special crystallinity which provides an improved pressure

resistance, especially at elevated temperatures. Pressure

tests according to ISO 9080 on pipes manufactured from

PP-RCT materials demonstrate 50 years service life at

70C of 5 MPa, compared to the 3.2 MPa for standard

PP-R materials. These very capabilities allow PP-RCT

to increase performance and competitiveness for PP-R

producers, and offer advantages for building designers

and end-users alike.

Using PP-RCT in your pipe design will allow for increased performance vs. standard PP-R such as:

Available in distinctive green (RA7050-GN) and

steel grey (RA7050) color shades

Established in a wide range of applications, including

large diameters for skyrise airconditioning systems

and re-enforced multi-layer heating pipes

Higher hydraulic capacity with same outer diameter

Higher percentage of smaller pipes in actual

installations (percentage depends upon specific design)

Reference Curves for PP-RCT Material Class

Hoop Stress (MPa)

The industry is calling for innovation

10

10

0,1

10

100

1000

10000

100000

Time to Failure (h)

Cost efficient system due to beneficial dimensioning

Easier installation

Borealis

RA7050-GN

Borealis

RA7050

Colour

Green

Steel grey

Optimised pipe dimensioning allow higher extrusion

speed lower production costs

Ral colour code

6024

7042

CRS at 70C/50 years

5.0 MPa

5.0 MPa

MFR (230/2.16)

0.3g/10 min

0.3 g/10 min

Greater possibilities to tailor your heating PP-R pipe

design

Modulus of Elasticity

900 MPa

900 MPa

Existing extrusion and injection moulding equipment

can be utilised without major changes

Opening up for special applications such as larger

diameter mains for skyrise airconditioning systems

Weldable with known PP welding procedures

Fully established in domestic- as well as global

standards incl. ISO and DIN

50 years

Table 1: Borealis RA7050-range of materials

1000000

Das könnte Ihnen auch gefallen

- Bottles, Preforms and Closures: A Design Guide for PET PackagingVon EverandBottles, Preforms and Closures: A Design Guide for PET PackagingBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Polyolefins For Pipe and FittingsDokument2 SeitenPolyolefins For Pipe and FittingsMd Minhaj100% (1)

- Circular Economy: Assessment and Case StudiesVon EverandCircular Economy: Assessment and Case StudiesNoch keine Bewertungen

- Drip Irrigation Borealis PDFDokument2 SeitenDrip Irrigation Borealis PDFchinmoyd1100% (1)

- Miscellaneous Plastics Products World Summary: Market Values & Financials by CountryVon EverandMiscellaneous Plastics Products World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- PP For Generations - BorougeDokument30 SeitenPP For Generations - BorougemujeebscribdNoch keine Bewertungen

- Brochure Resins Polyols and Aspartics Polyols For Reaction With Polyisocyanates 14-06-2011 EDokument28 SeitenBrochure Resins Polyols and Aspartics Polyols For Reaction With Polyisocyanates 14-06-2011 EΣταύρος Βουγιουκλίδης100% (2)

- Automotive Interior Solutions Optimised Performance and Surface AestheticsDokument16 SeitenAutomotive Interior Solutions Optimised Performance and Surface AestheticsAmolPagdal100% (1)

- PPH Catalog PipingDokument16 SeitenPPH Catalog PipingBubai111Noch keine Bewertungen

- Clamp Seals and DIN 11864 O Rings GB enDokument16 SeitenClamp Seals and DIN 11864 O Rings GB enIvancho GrNoch keine Bewertungen

- RA130E-6015 Green DatasheetDokument3 SeitenRA130E-6015 Green Datasheetmabj68Noch keine Bewertungen

- PE Technical ManualDokument68 SeitenPE Technical ManualMuhammad SalmanNoch keine Bewertungen

- Automotive Exterior Solutions Optimised Performance and Surface AestheticsDokument9 SeitenAutomotive Exterior Solutions Optimised Performance and Surface Aestheticsshrisharang4367Noch keine Bewertungen

- Pressure Piping SystemDokument27 SeitenPressure Piping SystemAbemar GegantoniNoch keine Bewertungen

- Plant Capacity: - Plant & Machinery: - Working Capital: - T.C.I: - Return: 0.01% Break Even: N/ADokument2 SeitenPlant Capacity: - Plant & Machinery: - Working Capital: - T.C.I: - Return: 0.01% Break Even: N/AMahmud RezaNoch keine Bewertungen

- Technical Catalogue PP v1Dokument84 SeitenTechnical Catalogue PP v1Fluidra Group0% (1)

- PP Pipe and Fitting Complete Data.Dokument250 SeitenPP Pipe and Fitting Complete Data.kapilNoch keine Bewertungen

- Borsafe TM Pe Pipe Materials Made For GenerationsDokument38 SeitenBorsafe TM Pe Pipe Materials Made For GenerationsHung HaNoch keine Bewertungen

- Chilled Water Fittings - CoDokument209 SeitenChilled Water Fittings - CoHarish MenonNoch keine Bewertungen

- GFDokument86 SeitenGFchowhkNoch keine Bewertungen

- PP RCT The High Performance Material of Choice For Pipe SystemsDokument4 SeitenPP RCT The High Performance Material of Choice For Pipe SystemsTrevor J. HutleyNoch keine Bewertungen

- HDP Pipe and Fittings CatalougeDokument64 SeitenHDP Pipe and Fittings CatalougeThiruvengadamNoch keine Bewertungen

- Pigging Product & Service AssociationDokument8 SeitenPigging Product & Service AssociationIrha IiyrHhaNoch keine Bewertungen

- Products Summary Guide PDFDokument16 SeitenProducts Summary Guide PDFSushil Dhungana100% (1)

- 1a Aquaflow HDPE Pipe CatalogueDokument12 Seiten1a Aquaflow HDPE Pipe CatalogueNick BesterNoch keine Bewertungen

- EPD - Environ - Parquet MadeiraDokument15 SeitenEPD - Environ - Parquet Madeiraanakarolinasantos96jobNoch keine Bewertungen

- Hepworth ProfileDokument19 SeitenHepworth Profilediljamchris100% (1)

- Seal-Jet Norge As - Sealing SolutionsDokument73 SeitenSeal-Jet Norge As - Sealing SolutionsdanilovoaNoch keine Bewertungen

- DEKADokument20 SeitenDEKAneels06274Noch keine Bewertungen

- Crosslinking Elastomers and Thermoplastics: Organic Peroxides and AuxiliariesDokument15 SeitenCrosslinking Elastomers and Thermoplastics: Organic Peroxides and AuxiliariesGrzegorz WierzbaNoch keine Bewertungen

- Interim Financial Report 2012 EnglishDokument32 SeitenInterim Financial Report 2012 EnglishChristopher Adrian Cruz CorredorNoch keine Bewertungen

- Solutions For Extrusion Coating ApplicationsDokument2 SeitenSolutions For Extrusion Coating ApplicationscesamavNoch keine Bewertungen

- HDPEDokument16 SeitenHDPEfirengineerNoch keine Bewertungen

- INSTAFLEX Technical Manual 2006Dokument190 SeitenINSTAFLEX Technical Manual 2006CristianDumitruNoch keine Bewertungen

- DownloadDokument20 SeitenDownloadkeyur1109Noch keine Bewertungen

- (VESBO) Catalog en 100317Dokument55 Seiten(VESBO) Catalog en 100317AnhNguyen100% (1)

- Bep Brochure PDFDokument12 SeitenBep Brochure PDFandrewvermaakNoch keine Bewertungen

- PVC U 01Dokument664 SeitenPVC U 01Antonio CarlosNoch keine Bewertungen

- Kriti IndustriesDokument12 SeitenKriti IndustriesHemant ChaudharyNoch keine Bewertungen

- Polymer Modifier Solutions GuideDokument12 SeitenPolymer Modifier Solutions GuideFJNovaes45450% (2)

- PP-R and PP-RCT Pipe Systems: Hot and Cold Water Systems and Heating ApplicationsDokument24 SeitenPP-R and PP-RCT Pipe Systems: Hot and Cold Water Systems and Heating ApplicationsKwadwo Siaw-MarfoNoch keine Bewertungen

- PCF Series Product ProfileDokument2 SeitenPCF Series Product ProfileDelphi CrackerNoch keine Bewertungen

- ASTM F-894 High-Density Spirolite Polyethylene Pipe Product Data SpiroliteDokument19 SeitenASTM F-894 High-Density Spirolite Polyethylene Pipe Product Data SpiroliteS KarthikeyanNoch keine Bewertungen

- Industry Profiles 2014/15Dokument6 SeitenIndustry Profiles 2014/15Milling and Grain magazineNoch keine Bewertungen

- Spray Foam KnowledgeDokument23 SeitenSpray Foam KnowledgeRaheel AsgharNoch keine Bewertungen

- PPR Pipes Fittings Complete Submittal Rev.1Dokument153 SeitenPPR Pipes Fittings Complete Submittal Rev.1anon_31671419480% (5)

- 5-MS00063645 Polyisocyanates Prepolymers SF05 0313 MADokument40 Seiten5-MS00063645 Polyisocyanates Prepolymers SF05 0313 MAHugo Wizenberg100% (1)

- Company Profile 4 April - CompressedDokument10 SeitenCompany Profile 4 April - CompressedPhilip PhilipsNoch keine Bewertungen

- Broshura Gas Pipes enDokument32 SeitenBroshura Gas Pipes enJayeshNarangNoch keine Bewertungen

- COG Broschuere Industrie ENGDokument28 SeitenCOG Broschuere Industrie ENGa100acomNoch keine Bewertungen

- Borclear RB707CF: PolypropyleneDokument3 SeitenBorclear RB707CF: PolypropylenesamiviamNoch keine Bewertungen

- Questions To AskDokument18 SeitenQuestions To AskNatalie WyattNoch keine Bewertungen

- Driscoplex 6400Dokument12 SeitenDriscoplex 6400AlbertoNoch keine Bewertungen

- 0E10101 - Aquatherm Green Pipe PDFDokument164 Seiten0E10101 - Aquatherm Green Pipe PDFrashidNoch keine Bewertungen

- Price List: Sales and Enquiries Please Contact: 01622 795 225Dokument1 SeitePrice List: Sales and Enquiries Please Contact: 01622 795 225DissasekaraNoch keine Bewertungen

- BS&BDokument20 SeitenBS&BNUR AFIFAHNoch keine Bewertungen

- Hobas FTBDokument78 SeitenHobas FTBdarkroomzc100% (1)

- Molded Electrofusion Couplings: Available Size RangeDokument1 SeiteMolded Electrofusion Couplings: Available Size RangeAdam KnottNoch keine Bewertungen

- Pipe Specification-1 PDFDokument37 SeitenPipe Specification-1 PDFzamijakaNoch keine Bewertungen

- Al Bilad Company Profile PDFDokument53 SeitenAl Bilad Company Profile PDFQuerubin R Yolando Jr.Noch keine Bewertungen

- Atlasul Biblic PDFDokument199 SeitenAtlasul Biblic PDFDoru Moruz100% (3)

- Astm F 1290Dokument3 SeitenAstm F 1290محمود أبو الحسنNoch keine Bewertungen

- ASTM D 4101-04 Standard Specification For Polypropylene Injection and Extrusion MaterialsDokument16 SeitenASTM D 4101-04 Standard Specification For Polypropylene Injection and Extrusion MaterialsbimatheNoch keine Bewertungen

- Jubail HDPE Pipes CatalogueDokument4 SeitenJubail HDPE Pipes Catalogueمحمود أبو الحسن67% (3)

- Din en 1519-1 - e - 2000Dokument31 SeitenDin en 1519-1 - e - 2000محمود أبو الحسنNoch keine Bewertungen

- DP SubmittalDokument9 SeitenDP Submittalمحمود أبو الحسنNoch keine Bewertungen

- Chapter 5: The Human Thermal System: Juan G. FloresDokument9 SeitenChapter 5: The Human Thermal System: Juan G. Floresمحمود أبو الحسنNoch keine Bewertungen

- TM - 1 1520 237 10 - CHG 10Dokument841 SeitenTM - 1 1520 237 10 - CHG 10johnharmuNoch keine Bewertungen

- Cyber Safety PP Presentation For Class 11Dokument16 SeitenCyber Safety PP Presentation For Class 11WAZ CHANNEL100% (1)

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDokument10 SeitenVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorNoch keine Bewertungen

- Challenger 350 Recommended Operating Procedures and TechniquesDokument104 SeitenChallenger 350 Recommended Operating Procedures and Techniquessebatsea100% (1)

- Payroll Solution in Single SheetDokument818 SeitenPayroll Solution in Single SheetTarique KhanNoch keine Bewertungen

- Onuaguluchi1996 1Dokument10 SeitenOnuaguluchi1996 1IkaSugihartatikNoch keine Bewertungen

- 7 Fuel Failure in Water Reactors - Causes and MitigationDokument165 Seiten7 Fuel Failure in Water Reactors - Causes and MitigationLauri RubertiNoch keine Bewertungen

- Endothermic Gas Production Overview: Tmosphere Ngineering OmpanyDokument6 SeitenEndothermic Gas Production Overview: Tmosphere Ngineering OmpanyJhon ChitNoch keine Bewertungen

- Action Taken On Oil and Ghee Sampling - 2020Dokument2 SeitenAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNoch keine Bewertungen

- As Level Chemistry Practical Paper 3 - GCE GuideDokument1 SeiteAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliNoch keine Bewertungen

- Tractor Price and Speci Cations: Tractors in IndiaDokument4 SeitenTractor Price and Speci Cations: Tractors in Indiatrupti kadamNoch keine Bewertungen

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Dokument1 SeiteUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajNoch keine Bewertungen

- Assignment On Inservice Education Sub: Community Health NursingDokument17 SeitenAssignment On Inservice Education Sub: Community Health NursingPrity DeviNoch keine Bewertungen

- Safety Tips in Playing ArnisDokument2 SeitenSafety Tips in Playing ArnisDensyo De MensyoNoch keine Bewertungen

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDokument34 SeitenFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)

- Nodular Goiter Concept MapDokument5 SeitenNodular Goiter Concept MapAllene PaderangaNoch keine Bewertungen

- A Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthDokument13 SeitenA Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthWinda KhosasiNoch keine Bewertungen

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDokument14 SeitenMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47Noch keine Bewertungen

- Atlas of Feline Anatomy For VeterinariansDokument275 SeitenAtlas of Feline Anatomy For VeterinariansДибензол Ксазепин100% (4)

- Microsoft Security Intelligence Report Volume 21 EnglishDokument180 SeitenMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoNoch keine Bewertungen

- NTJN, Full Conference Program - FINALDokument60 SeitenNTJN, Full Conference Program - FINALtjprogramsNoch keine Bewertungen

- RMP ContractDokument181 SeitenRMP ContractHillary AmistosoNoch keine Bewertungen

- TherabandDokument1 SeiteTherabandsuviacesoNoch keine Bewertungen

- Fundamental Molecular Biology: GenomesDokument45 SeitenFundamental Molecular Biology: GenomesMoonHoLeeNoch keine Bewertungen

- Havehas Affirm Neg Interrogwith Aliens - 19229Dokument3 SeitenHavehas Affirm Neg Interrogwith Aliens - 19229Ana Victoria Cuevas BeltránNoch keine Bewertungen

- Operator'S Manual Controller R-30iBDokument25 SeitenOperator'S Manual Controller R-30iBZied RaouakNoch keine Bewertungen

- Geology Harn v1 2Dokument17 SeitenGeology Harn v1 2vze100% (1)

- Library PDFDokument74 SeitenLibrary PDFfumiNoch keine Bewertungen

- DeMeo HERETIC'S NOTEBOOK: Emotions, Protocells, Ether-Drift and Cosmic Life Energy: With New Research Supporting Wilhelm ReichDokument6 SeitenDeMeo HERETIC'S NOTEBOOK: Emotions, Protocells, Ether-Drift and Cosmic Life Energy: With New Research Supporting Wilhelm ReichOrgone Biophysical Research Lab50% (2)

- Maya Mendez ResumeDokument2 SeitenMaya Mendez Resumeapi-520985654Noch keine Bewertungen

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (5)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- Monkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeVon EverandMonkeys, Myths, and Molecules: Separating Fact from Fiction, and the Science of Everyday LifeBewertung: 4 von 5 Sternen4/5 (1)

- AP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeVon EverandAP® Chemistry Crash Course, For the 2020 Exam, Book + Online: Get a Higher Score in Less TimeBewertung: 5 von 5 Sternen5/5 (1)

- It's Elemental: The Hidden Chemistry in EverythingVon EverandIt's Elemental: The Hidden Chemistry in EverythingBewertung: 4 von 5 Sternen4/5 (10)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (90)

- Taste: Surprising Stories and Science About Why Food Tastes GoodVon EverandTaste: Surprising Stories and Science About Why Food Tastes GoodBewertung: 3 von 5 Sternen3/5 (20)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeVon EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeBewertung: 5 von 5 Sternen5/5 (4)

- Guidelines for Defining Process Safety Competency RequirementsVon EverandGuidelines for Defining Process Safety Competency RequirementsBewertung: 3 von 5 Sternen3/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeVon EverandChemistry for Breakfast: The Amazing Science of Everyday LifeBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Formulating, Packaging, and Marketing of Natural Cosmetic ProductsVon EverandFormulating, Packaging, and Marketing of Natural Cosmetic ProductsNoch keine Bewertungen

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolVon EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNoch keine Bewertungen

- Handbook of Formulating Dermal Applications: A Definitive Practical GuideVon EverandHandbook of Formulating Dermal Applications: A Definitive Practical GuideNoch keine Bewertungen

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsVon EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsBewertung: 5 von 5 Sternen5/5 (3)

- The Periodic Table: A Very Short IntroductionVon EverandThe Periodic Table: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Tribology: Friction and Wear of Engineering MaterialsVon EverandTribology: Friction and Wear of Engineering MaterialsBewertung: 5 von 5 Sternen5/5 (1)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsVon EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsBewertung: 4 von 5 Sternen4/5 (146)

- AP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeVon EverandAP Chemistry Flashcards, Fourth Edition: Up-to-Date Review and PracticeNoch keine Bewertungen

- The Billion-Dollar Molecule: The Quest for the Perfect DrugVon EverandThe Billion-Dollar Molecule: The Quest for the Perfect DrugBewertung: 5 von 5 Sternen5/5 (2)

- Fundamentals of Chemistry: A Modern IntroductionVon EverandFundamentals of Chemistry: A Modern IntroductionBewertung: 5 von 5 Sternen5/5 (1)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactVon EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Integrating Process Safety into Engineering ProjectsVon EverandGuidelines for Integrating Process Safety into Engineering ProjectsNoch keine Bewertungen