Beruflich Dokumente

Kultur Dokumente

Casco HM2-PT (Ansi Z89 1) PDF

Hochgeladen von

Andres Antonio Moreno CastroOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Casco HM2-PT (Ansi Z89 1) PDF

Hochgeladen von

Andres Antonio Moreno CastroCopyright:

Verfügbare Formate

ruS

lllGt"momronrns

Test Report T4441-02-02lssue 2

riann Lih

tffi

it-tft:,: ?,lo3"DN BHD.

HM2.PT

23 June 2009

Approved by:

Prepared by:

elley Brddl-Capota

Head Protection

Lab Manager

Head Protection - Administrator

a) Reports are issued pursuant to the ICS standard Terms and Conditions agreemenl

b) The contents of this test report are confidential, Reproduction of the report

unless approved inwriting by ICS Laboratories, Inc.

is

prohibited except infull,

c) Unless otherwise indicated, the test results contained in this report apply only to the samples tested and not to

lots or batches from which they were taken.

ICS Laboratoriesr lnc. o1072 Industrial Parkway North o Brunswick, Ohio 44212 USA

Phone:330.220.0515 Fax:330.220.0516

AF3.3-la (04-June-04)

G-r

ruS

lilGil"momronrns

Issued

to:

lAccREprTEpl

-L'

Date:

Jiann Lih Safety Products (M) SDN. BHD.

Lot I32, Jalan Empat, Kompleks Perabut Olak

Lempit, Jalan Dengk1l,42700 Banting Selangor Darul

Ehsan, Malaysia

Report:

23 June 2009

74441-02-02

Issue: 2

Page: I of3

Objective:

Contract testing to ANSI Z,89.1-2003 "American National Standard for Industrial Head Protection".

Type

l,

Class C, G

&E

Sample(s):

HM2-PT Industrial Safew

etv Helmets:

Hel

Description

Qtv

Yellow Shell w/ Pinlock Suspension

Yellow Shell w/ Ratchet Suspension

Date Code

32

I

Material

sl09

Received

Mav 2009

22 June 2009

2l

PE

ICS ID

lA-2xx

N/A

Procedures:

Testing protocols in accord with good laboratory practice were employed unless otherwise specified, for all

tests.

Testing procedures as specified within Section 9 of ANSI 2,89.1-2003 were followed.

Testing was perforrned at room temperature 23"C + 2"C (73.4oF + 3.6"F) per ANSI Z,89.1 -2003.

Variant with ratchet suspension not assessed. Client claims that the pinlock and ratchet varia4ts are of the

same material and design. Theoretically the performance of the HM2-PT hard hat with ratchet suspension

should not be different from performance of the HM2-PT hard hat with pinlock suspension which was fully

assessed to the test procedures defined in

ANSI

Z,89.1

-2003.

Assessment Summary:

Date tested: 27 May 2009

Non Compliant

Not assessed

Requirements

6

7

Compliant

Instruction and Marking

Performance Requirements

7.1 Requirements for Trnre I and Tyre

II

.1.1 Flammability

7 .1.2 Force Transmission

7

7

7

.1.3 Apex Penetration

.1.4 Flectrical Insulation Requirement

7 .1.4.1 Electrical Insulation Requirement - Class G

7.1.4.2 Electrical Insulation Requirement - Class E

X

X

X

X

X

Sample as assessed do meetthe requirements of ANSI 289.1 2009 for Tlpe I, Class C, G

&

E as assessed.

ru$

IIIGlranonaronrns

Issued

to:

Certificate 1722"01

Date:

Jiann Lih Safety Products (M) SDN. BHD.

Lot 132, Jalan Empat, Kompleks Perabut Olak

Lempit, Jalan Dengkil,42700 Banting Selangor Darul

Ehsan, Malaysia

Report:

Issue:

Page:

23 June 2009

T4441-02-02

2

2 of3

Results:

7.1.1

Flammabi

Sample

Afterflame (sec)

ID

tA-212

0.0

Fail

<5

Specification:

7.1.2

Pass

Force Transmission

Sample

ID

Conditioning

Velocity

Force

Specified Value

(m/s)

cN)

(N)

5.49

5.47

2303

2239

1A-201

tA-202

rA-243

5.5 r

tA-204

5.49

2t96

2t3t

14-205

5.51

2004

tA-206

5.51

2r78

2139

tA-ztt

5.55

5.52

5.52

5.52

5.47

tA-212

s.52

tA-207

49" + 2"C

l4-208

rA-209

1A-210

Average

tA-213

tA-214

tA-215

5.50

5.54

lA-216

5.50

lA-217

lA-218

5.50

5.5

tA-220

tA-22r

5.5 r

267 s

rA-222

rA-223

5.52

5.50

2801

lA-224

5.51

2559

2552

Average

Specification:

Note:

Drop Height: 60.7 inches

5.50

0.05 m/s

< 3780

2707

2688

2867

2473

2737

-18 + 2"C

< 4450

2067

5.49

5.52

5.49

tA-2t9

X

X

X

X

X

2t90

2t98

2178

2217

2003

2739

27 55

Pass

< 4450

3458

27 t7

s 3780

x

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Fail

G-a

ruS

lllGlranonaronrns

Issued

7.1.3

lAccREptTEpl

-\_ts

Products (M) SDN. BHD.

Lot 132, Jalan Empat, Kompleks Perabut Olak

Date:

Lempit, Jalan Dengkll,42700 Banting Selangor Darul

Ehsan, Malaysia

Issue:

Page:

to: Jiann Lih Safety

x en etrati on

Sample

Velocity

tA-230

6.99

6.98

6.93

6.94

6.99

7.00

Electrical Contact

(Yes/ No)

No

No

No

No

No

No

Specification:

7.0+ 0.1 m/s

No Electrical Contact Allowed

ID

tA-225

tA-226

tA-227

Conditioning

(m/s)

49" + 2"C

tA-228

tA-229

Note:

7.1.4

Report:

-18 + 2"C

of3

Pass

Fail

X

X

X

X

X

X

Drop Height: 98.3 inches

EI ectricalIIlnsulation Reo uirements

Sample

ID

Leakage (mA)

assG&E

G

Burn Through

(Yes/ No)

Pass

No

No

X

X

tA-20t

0.3

tA-213

Specification:

0.3

ClassG: <3mA

tA-202

3.2

tA-2t4

3.3

No

No

Specification:

ClassE:<9mA

No Burn Through Allowed

Note:

23 June 2009

T4441-02-02

No Burn Through Allowed

Class G - 2200 volts, 60 Hz, lminute

Class E - 20,000 volts, 60H2,3 minutes, 30,000 volts no burn through.

Sample Photographs:

X

X

Fail

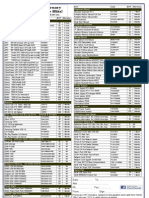

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Ansi S2-42 PDFDokument40 SeitenAnsi S2-42 PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Ansiz359 4-2007 PDFDokument4 SeitenAnsiz359 4-2007 PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Astm D 4603-2003 PDFDokument4 SeitenAstm D 4603-2003 PDFb_afrinaldiNoch keine Bewertungen

- Roles and Responsibilities TemplateDokument5 SeitenRoles and Responsibilities Templatebrajeshsinghfdd100% (2)

- Ansi C80-5Dokument11 SeitenAnsi C80-5Andres Antonio Moreno CastroNoch keine Bewertungen

- Ansi B31.8 PDFDokument185 SeitenAnsi B31.8 PDFAndres Antonio Moreno Castro100% (1)

- Ansi B31.8 PDFDokument185 SeitenAnsi B31.8 PDFAndres Antonio Moreno Castro100% (1)

- Ansi B31.4Dokument121 SeitenAnsi B31.4Andres Antonio Moreno Castro100% (1)

- Ansi B16.28 InterDokument2 SeitenAnsi B16.28 InterAndres Antonio Moreno CastroNoch keine Bewertungen

- ASME B16.20b-1997 Addenda: Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedDokument34 SeitenASME B16.20b-1997 Addenda: Asme Metallic Gaskets For Pipe Flanges Ring-Joint, Spiral-Wound, and JacketedAndres Antonio Moreno CastroNoch keine Bewertungen

- Ansi ABMADokument56 SeitenAnsi ABMAAndres Antonio Moreno Castro100% (2)

- Sav4747 PDFDokument49 SeitenSav4747 PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Ansi ABMA11Dokument23 SeitenAnsi ABMA11Andres Antonio Moreno CastroNoch keine Bewertungen

- Ansi ABMA7Dokument19 SeitenAnsi ABMA7Andres Antonio Moreno CastroNoch keine Bewertungen

- Casco HM2-PT (Ansi Z89 1) PDFDokument4 SeitenCasco HM2-PT (Ansi Z89 1) PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Ascendedores PDFDokument1 SeiteAscendedores PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Bro - 010507 - Ansi - Carabiners MOSQUETON PERA PDFDokument2 SeitenBro - 010507 - Ansi - Carabiners MOSQUETON PERA PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- Bro - 010507 - Ansi - Carabiners MOSQUETON PERA PDFDokument2 SeitenBro - 010507 - Ansi - Carabiners MOSQUETON PERA PDFAndres Antonio Moreno CastroNoch keine Bewertungen

- 6852 BemDokument370 Seiten6852 Bemrudolf_laszlokNoch keine Bewertungen

- ID-PRC 21 - Anti-Corrosion Wrapping UG Steel PipingDokument10 SeitenID-PRC 21 - Anti-Corrosion Wrapping UG Steel Pipingcloud23Noch keine Bewertungen

- Mc100e131fn (D Flip Flop) ICDokument8 SeitenMc100e131fn (D Flip Flop) ICDwp BhaskaranNoch keine Bewertungen

- ESRS Policy Server Installation Guide-2.08-Windows-ADIntegrationDokument14 SeitenESRS Policy Server Installation Guide-2.08-Windows-ADIntegrationSumanta MaitiNoch keine Bewertungen

- V23 Training ManualDokument76 SeitenV23 Training ManualVaworker100% (3)

- Scripting With SiebelDokument69 SeitenScripting With Siebelanishkrai100% (1)

- BEST PRACTICES Hydrostatic Pressure Testing Rev01.1webDokument15 SeitenBEST PRACTICES Hydrostatic Pressure Testing Rev01.1webehsan.sadeghi1545Noch keine Bewertungen

- Flexwave Universal Radio HeadDokument6 SeitenFlexwave Universal Radio HeadforwirelessNoch keine Bewertungen

- Edm Aq410 2 S.1GB02.12 40-75Dokument52 SeitenEdm Aq410 2 S.1GB02.12 40-75Advokat HadziTonicNoch keine Bewertungen

- Bondwell Specials Combo SpecDokument1 SeiteBondwell Specials Combo SpecMaxFijiNoch keine Bewertungen

- Corrosion TestsDokument3 SeitenCorrosion TestsbalakaleesNoch keine Bewertungen

- Tutorials Frame 2D DesignDokument59 SeitenTutorials Frame 2D DesignMahmud RochyNoch keine Bewertungen

- Teomasino: Thomasian Theology Quiz: Committee On The Religious and Academic Formation of Thomasians (Craft)Dokument3 SeitenTeomasino: Thomasian Theology Quiz: Committee On The Religious and Academic Formation of Thomasians (Craft)Josephine Lyn ValbarezNoch keine Bewertungen

- BR010 High Level Gap AnalysisDokument12 SeitenBR010 High Level Gap AnalysisMohan RajendranNoch keine Bewertungen

- Duties and Responsibilities of A Quality EngineerDokument1 SeiteDuties and Responsibilities of A Quality EngineerRichard Periyanayagam100% (1)

- Cummins Ism, QSMDokument11 SeitenCummins Ism, QSMibnu67% (6)

- Rele de Nivel SIEMENSDokument5 SeitenRele de Nivel SIEMENSdabalejoNoch keine Bewertungen

- Pavement Distresses and Roughness Modeling - A Case Study: I J I R S E TDokument9 SeitenPavement Distresses and Roughness Modeling - A Case Study: I J I R S E Tdivyadeenu9390Noch keine Bewertungen

- Trough CompassDokument8 SeitenTrough CompassShrey ManishNoch keine Bewertungen

- C535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineDokument3 SeitenC535 - 16 - Standard Test Method For Resistance To Degradatio of Large-Size Coarse Aggregate ByAbrasion Impact in The Los Angeles MachineTomás Venegas Pardo100% (1)

- 03 Deploying Mpls l3vpnDokument47 Seiten03 Deploying Mpls l3vpnkmadNoch keine Bewertungen

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFDokument556 SeitenPCS-902 - X - Instruction Manual - EN - Overseas General - X - R2.01 PDFAyub HasersNoch keine Bewertungen

- Manual Olimpus PDFDokument64 SeitenManual Olimpus PDFmachine_toolsNoch keine Bewertungen

- Information Security ChallengesDokument8 SeitenInformation Security ChallengesDheeraj KumarNoch keine Bewertungen

- Broca Canhão CatalogoDokument48 SeitenBroca Canhão CatalogodkfaNoch keine Bewertungen

- Lab 6 ManualDokument4 SeitenLab 6 Manualsonti11Noch keine Bewertungen

- Simatic Logon enDokument13 SeitenSimatic Logon entosukNoch keine Bewertungen