Beruflich Dokumente

Kultur Dokumente

Liquid Jet Breakup Mechanisms

Hochgeladen von

jideosCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Liquid Jet Breakup Mechanisms

Hochgeladen von

jideosCopyright:

Verfügbare Formate

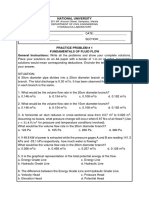

ILASS Europe 2013, 25th European Conference on Liquid Atomization and Spray Systems, Chania, Greece, 1-4 September

r 2013

Modelling of Unsteady Effects on Jet Breakup

E.O. Diemuodeke1 and I. Sher2

1: School of Engineering, Cranfield University, Cranfield, Bedfordshire, UK

Abstract

The theory of jet instabilities has been developed under several assumptions, which include the assumption that

the jets are steady. The common-rail diesel fuel injection systems utilizing pulsed injection have drastically

improved the ability to lower emissions, noise, and fuel consumption. However, with the application of the

injection techniques in modern engines, the unsteady effects introduced by the pulsed injection are yet to be fully

investigated. These unsteady effects may be attributed to some of the deviations observed in the literature

between theoretical predictions and experimental data. The present paper has been able to demonstrate through

analytical means that unsteady effects of liquid jet have significant impacts on the instability and breakup of

liquid fuel. The model was developed from the Navier-Stokes equation with linear perturbations, which

considers transient base flow parameters. Results obtained have good agreement with experimentally obtained

data for penetration length and spray angle.

Introduction

Fuel injector performance has a direct effect on the combustion efficiency, pollutant emissions and combustion

instability of combustion systems[1]. Government legislations regarding emissions are becoming stringent.

Therefore, there is a need for more effective design of fuel combustion systems. The effective design of

combustion systems is a function of good understanding of fuel breakup processes. The aim is to introduce the

liquid fuel in a high surface area to volume ratio for a stable combustion process. The process surrounding the

injection of liquid through a small aperture and the subsequent breakup of the bulk liquid has proven to be very

complex [2][3].

The atomization processes are mainly attributed to cavitation, turbulent and aerodynamic forces, but it is

generally acknowledged that the aerodynamic forces are the major controlling factor of the atomization

process[4][5]. The Kelvin-Helmholtz (KH) instability model for liquid breakup was suggested by Reitz and

Bracco [6] on the basis of surface waves formation as a result of hydrodynamic and aerodynamic forces

interactions. The model is constructed on the basis of a first order linear analysis of a KH instability growing on

the surface of a cylindrical liquid jet that is penetrating into a quiescent incompressible gas with a relative

velocity. Both the liquid and the gas are assumed to be incompressible, and the gas is assumed to be inviscid.

The dynamic of the liquid jet and gas interaction are described by the linearization of Navier-Stokes equations

for two-phase flow based on steady base flow parameters. The liquid phase is assumed as the disperse phase and

the gas phase as the continuous phase. The detailed analysis, which can be found in [6], yields a dispersion

equation relating the growth rate of a perturbation to its wavelength. The dispersion equation obtained is not

amenable to analytical solution; however, numerical curve fit was sorted, which shows that there exists a single

maximum in the wave growth rate curve and assumed that the maximum growth rate controls the liquid breakup.

The theory of jet instabilities has been developed under several assumptions, including an assumption that the

jets are steady. However, in most practical engineering applications these jets are highly unsteady, and the

transient effects are attributed to some of the inconsistencies between experimental data and theoretical data [4]

[5][7][8][9]. The acceleration of the liquid during start-up of the convectional injectors is in the order of 10 6

[m/s2] at the orifice exit for high Reynolds numbers. This transient effect on the liquid breakup mechanisms

would be more severe in the modern fuel injection techniques, e.g pulsed injection (illustrated in Figure. 1),

which are intended to mitigate exhaust emission and to improve fuel economy. Sazhin et al [4] have stressed the

importance of transient effects on jet instability and breakups by incorporating the jet acceleration into the

classical KH instability model. The solution method was further advanced in Turner et al. [5]. In this paper we

present results of a reconstructed K-H model [10, 11], predicting the characteristic breakup and penetration

lengths of an unsteady jet.

Injection velocity, uz[m/s]

25th ILASS Europe 2013

Modelling of Unsteady Effects on Jet Breakup

Pulsed

injection

Convectiona

l injection

Start-up

Shut-down

Time after start of injection t[s]

Figure 1. Velocity Evolution after Start of Iinjection

Mathematical modelling

It is assumed that the interaction between aerodynamic forces and the jet hydrodynamic forces induce surface

waves, as shear flow, because of relative velocity between the liquid and gas. Considering the assumptions made

by Reitz and Bracco [6] and Egger and Villermaux [12], one proceeds with the reconstruction of the classical

KH instability model for liquid breakups by modifying the linearization process of the Navier-Stokes equation.

The free-surface shear of a liquid jet indicating the linearization parameters is shown in Figure 2.

r

Free- surface velocity, uzg=0

Nozzle wall

(0,R0)

z

Shear layer

thickness

u(z,r,t)

Figure 2. Cylindrical material coordinate system model for a liquid jet

The Navier-Stokes equations for the 2D cylindrical material coordinate system shown in Figure 2 can be written,

as follows:

The continuity equation:

(1)

The momentum equation:

r-direction momentum

(2)

z-direction momentum

(3)

The transient effects of the fuel injection are incorporated in the linearization process by decomposing velocity

and pressure as follows:

and

(4)

It is postulated that the growth of perturbed parameters varies with time [10, 11], thus, the perturbed parameters

have the following forms:

;

;

(5a,b,c,d)

2

25th ILASS Europe 2013

Modelling of Unsteady Effects on Jet Breakup

The governing equations are subject to the following boundary conditions:

(1) The kinematic boundary condition

(6)

(2) The dynamic boundary condition at the interface of liquid and gas

With

follows thus

where

denotes the surface for which

(7)

has to be determined, it

(8)

(3) The axisymmetric assumption

(9)

Solving this system with its boundary conditions for the dispersion relation, for a case of a quiescent gas phase

gives ([11]):

(10)

It is assumed that the disturbance growth rate is approximately constant,

velocity rate change is the jet acceleration, hence,

considering the real part,

, and that the base

and

. With these assumptions and

, in the frame of temporal analysis, Eq.(11) is obtained:

(11)

The plot of Eq.(11), for constant axial velocity, shows that there exists a maximum (Figure 3). The dominant or

the liquid breakup controlling wave number,

, which corresponds to the maximum growth rate,

,

is expected to occur at

[6].

350

Uz=50

300

250

a=200

a=180

a=160

a=140

a=120

w[1/s]

200

a=100

150

a=80

a=60

100

a=40

a=20

50

a=0

0

500

1000

1500

2000

2500

k[1/m]

3000

3500

4000

4500

5000

Figure 3. Variation of growth rate,

, with wavenumber,

, and jet acceleration, a[m/s2] at constant velocity

The breakup controlling wavenumber and the corresponding growth rate are, therefore, respectively given as

([11]):

(12)

and

(13)

The unsteady jet breakup macro structure is obtained accordingly. The relation for the half spray angle,

Trinh and Chen (2006) as proposed by Reitz and Bracco (1982) [6] is used:

, in

(14)

where

is a constant that accounts for the nozzle entrance shape, which must be fitted experimentally [6], and

is the optimum wavelength.

3

25th ILASS Europe 2013

Modelling of Unsteady Effects on Jet Breakup

The spray angle can be obtained by geometrical considerations - approximating the half of the spray as an

isosceles triangle with the height being half the penetration length[13][14], as follows:

(15)

where is the upstream half image projected spray area and

The penetration length is obtained as:

is the spray penetration length.

(16)

where

Results and Discussion

Transient experimental injection velocity, , presented in [8][9] for a 3 hole 0.2 mm diameter valve covered

orifice (VCO) diesel injector at different injection pressures, were used for the validation of the developed

transient KH instability model.

Figure 4 shows the model predicted spray angle and experimental spray angle data [8] for transient fuel

injection. Figure 4 shows that there is a good agreement between model predicted results and the experimental

data. The spray angle is observed to be very high at the initial start of injection and later settled for a value

around 17o, which corresponds to the steady fuel injection region. It is observed that the 60 [MPa] injection

pressure has a wider spray angle compared to higher injection pressures, this may be attributed to initial low

penetration velocity into dense ambient and more time to adjust to the surrounding gases, which makes it less

constrained to expand. The significant difference in the spray angle in the accelerating region, 0-0.5 [ms] after

start of injection and the steady region shows that the unsteady effects have significant effects on the liquid fuel

breakups.

Figure 4. Spray Angle Variation with the Time after Start of Injection in an Ambient of

Density 47 [kg/m3] at various Injection Pressures.

Figure 5 shows the penetration length variation with injection time at various injection pressures in an ambient

density of 47 [kg/m3]. Figure 5 shows that there exists an agreement between unsteady KH instability model and

the experimental penetration length [8]. Careful observation of Figure 5 reveals that there exists a maximum in

the predicted penetration length by the KH instability model. This observation is in conformity with majority of

experimental data presented in the literature [15]. In terms of the injection pressure, it is observed that the liquid

penetration reached the maximum value faster with elevated injection pressure due to the higher jet velocity,

which induces instability and breakup more rapidly.

25th ILASS Europe 2013

Modelling of Unsteady Effects on Jet Breakup

Figure 5. Evolution of Penetration Length after time of injection at various Injection

Pressures in an ambient Density of 47 [kg/m3]

Conclusions

The theory of jet instabilities has been developed under several assumptions, which include the assumption that

the jets are steady. These assumptions may be attributed to some of the deviations observed in the literature

between theoretical predictions and experimental data. The present work has been able to demonstrate through

analytical means that unsteady effects of liquid jet have significant impacts on the instability and breakup of

liquid fuel. Results obtained have good agreement with experimentally obtained data for penetration length and

spray angle. Unsteady jets are particularly prevalent in modern fuel injection strategies, like pulsed injection.

Nomenclature

Symbol

A

A

I

K

L

p

R0

Re

t

u

Quantity

Area

Acceleration

Modified first-kind Bessel function

Modified second-kind Bessel function

Length

Pressure

Jet radius

Real part

Timescale

Velocity

wavenumber

Units

m2

m/s2

Function parameter

Full spray angle

Wavelength

Smooth function

Constant

Perturbed boundary

Density

Surface tension

Growth rate

m

N/m2

m

s

m/s

1/m

Greek letter

Subscript

0

1

g

l

max

m

m

kg/m3

N/m

1/s

Zero-order

First-order

Gas

Liquid

Maximum parameter

5

25th ILASS Europe 2013

opt

p

r

z

Superscript

Modelling of Unsteady Effects on Jet Breakup

Optimum parameter

Penetration

Radial direction

Axial direction

Perturbed parameter; derivative

References

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

Stiesch, G. Modelling Engine Spray and Combustion Processes: Heat and Mass Transfer. Berlin

Heidelberg: Springer Verlag, 2010.

Gorokhovski, M.; Herrmann, M. Modelling Primary Atomization, Annual Review of Fluid Mechanics,

vol. 40, pp. 343366, 2008.

Jiang, X.; Siamas, G.A.; Jagus, K.; Karayiannis, T. G. Physical Modelling and Advanced Simulation of

Gas-Liquid Two-phase Jet Flows in Atomization and Sprays, Progress in Energy and Combustion

Science, vol. 36, pp. 131167, 2010.

Sazhin, S.S.; Turner, M.R.; Healey, J.J.; Martynov, S. B. Transient Diesel Fuel Jets and Spray:

Mathematical Analysis and Application, in ILASS-Europe, 24th European Conference on Liquid

Atomization and Spray Systems, Sept. 2011, 2011.

Turner, M.R.; Healey, J.J.; Sazhin, S.S.; Piazzesi, R. Wave Packet Analysis and Breakup Length

Calculations for an Accelerating Plannar Liquid Jet, Fluid Dynamics Research, vol. 44, no. 1, p.

015503, 2012.

Reitz, R.D.; Bracco, F. V. Mechanism of Atomization of Liquid Jet, Physics of Fluids, vol. 25, no. 10,

pp. 17301742, 1982.

Bae, C.; Kang, J. The Structure of a Break-up Zone in the Transient Diesel Spray of a Valve-Covered

Orifice Nozzle, International Journal of Engine Research, vol. 7, no. 4, pp. 319334, 2006.

Karimi, K. Characterisation of Multiple-Injection Diesel Sprays at Elevated Pressures and

Temperatures, PhD Thesis, School of Engineering, University of Brighton, 2007.

Karimi, K.; Sazhina, E M.; Abdelghaffar, W A.; Crua, C.; Cowell, T.; Heikal, M R.; Gold, M. R.

Developments in Diesel Spray Characterisation and Modelling, in THIESEL 2006 Conference on

Thermo- and Fluid Dynamic Processes in Diesel Engines, 13-15 September,, 2006.

Sher, I. Stability and Breakup of Transient Jets, in ILASS-Europe, 6-8 September, 2010.

Sher, I., E.O. Diemuodeke, "Transient Jet Breakup Modelling", to be published, 2013.

Eggers and E. Villermaux, J. Physics of liquid jets, Reports on Progress in Physics, vol. 71, no. 3, p.

036601, 2008.

Naber, D.; Siebers, D. L. Effects of Gas Density and Vaporization on Penetration and Dispensation of

Diesel Spray, SAE Paper, p. 960034, 2006.

Payri, F.; Payri, R.; Salvador, F.J.; Bardi, M. Effect of Gas Properties on Diesel Spray Penetration and

Spreading Angle for the ECN Injectors, in ICLASS-Europe, 2-6 September, 2012.

Ming, H.; Shenlun, L.; Haifeng, L.; Chia-fon, F. L. Investigation on Spray Characteristics of Water

Emulsified Diesel with Different Injection Pressure and Ambient Temperature, in Proc. of ICLASSEurope, 2-6 September, 2012.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Moody LF Paper 1944Dokument14 SeitenMoody LF Paper 1944Nguyen Thanh BinhNoch keine Bewertungen

- Aerothermodynamics and Propulsion Integration For Hypersonic Vehicles PDFDokument445 SeitenAerothermodynamics and Propulsion Integration For Hypersonic Vehicles PDFNevenGrguricNoch keine Bewertungen

- Flowrate & Pipe Size PDFDokument10 SeitenFlowrate & Pipe Size PDFSamuel JohnsonNoch keine Bewertungen

- The LIFT FormulaDokument4 SeitenThe LIFT FormulaJoséMendesNoch keine Bewertungen

- Osborne Reynold ExperimentDokument6 SeitenOsborne Reynold ExperimentUthpala WanninayakeNoch keine Bewertungen

- Pump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDokument20 SeitenPump Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignAlexanderNoch keine Bewertungen

- Microfiche Reference Library: A Project of Volunteers in AsiaDokument57 SeitenMicrofiche Reference Library: A Project of Volunteers in Asiameku44Noch keine Bewertungen

- Practice Unit Test Part 1 - Dynamics (May 2011)Dokument4 SeitenPractice Unit Test Part 1 - Dynamics (May 2011)Shakib FirouziNoch keine Bewertungen

- CFD Application Library Manual-COMSOL Multiphysics 5.3Dokument434 SeitenCFD Application Library Manual-COMSOL Multiphysics 5.3meysam NaaNoch keine Bewertungen

- Moment of Inertia of Diferent ShapesDokument4 SeitenMoment of Inertia of Diferent Shapesresurrection786Noch keine Bewertungen

- Physics 101 Chapter 8 RotationDokument52 SeitenPhysics 101 Chapter 8 RotationAndrew GoolsbyNoch keine Bewertungen

- Hidrolika Saluran TerbukaDokument58 SeitenHidrolika Saluran TerbukaArif Husain SidikNoch keine Bewertungen

- Development of 1D Turbomachinery Meanline Solver With Physics-Based Detailed Loss ModelsDokument4 SeitenDevelopment of 1D Turbomachinery Meanline Solver With Physics-Based Detailed Loss ModelsBrahimABDNoch keine Bewertungen

- Chanson, 2 BUKU ReportDokument136 SeitenChanson, 2 BUKU ReportKuswandi Andi100% (1)

- The Influence of Compressibility On The Aerodynamics of An Inverted Wing in Ground EffectDokument12 SeitenThe Influence of Compressibility On The Aerodynamics of An Inverted Wing in Ground EffectSamson Paul PintoNoch keine Bewertungen

- Preliminary Design of A Vortex Pool For Electrical GenerationDokument6 SeitenPreliminary Design of A Vortex Pool For Electrical GenerationJohnny TestNoch keine Bewertungen

- OLD Q Paper+Solution 10CV35Dokument106 SeitenOLD Q Paper+Solution 10CV35Abhijeeth Nagaraj100% (1)

- ME6604 Gas Dynamics and Jet Propulsion 2 MarksDokument14 SeitenME6604 Gas Dynamics and Jet Propulsion 2 MarksMALANoch keine Bewertungen

- Rating CurveDokument7 SeitenRating CurvePRAVEEN CHAUDHARYNoch keine Bewertungen

- Numerical of MVDokument14 SeitenNumerical of MVshivam raiNoch keine Bewertungen

- Aerodynamic DragDokument23 SeitenAerodynamic DragSunil JogdandNoch keine Bewertungen

- Forensicballistic Final-ExamDokument7 SeitenForensicballistic Final-ExamJonel BallesterosNoch keine Bewertungen

- Hydraulic Engineering PDFDokument36 SeitenHydraulic Engineering PDFZaid Hadi100% (2)

- Practice Problem No. 1 Hydraulics Fundamentals of Fluid FlowDokument2 SeitenPractice Problem No. 1 Hydraulics Fundamentals of Fluid FlowCharlamagne MirandaNoch keine Bewertungen

- Learning Objectives: Core SupplementDokument19 SeitenLearning Objectives: Core SupplementNilar LwinNoch keine Bewertungen

- Cve 372 Hydromechanics - 2 Flow in Closed Conduits 2Dokument54 SeitenCve 372 Hydromechanics - 2 Flow in Closed Conduits 2ashoku2Noch keine Bewertungen

- HPC Unit. 1x PDFDokument21 SeitenHPC Unit. 1x PDFSaix CreationsNoch keine Bewertungen

- Coriolis AccelerationDokument6 SeitenCoriolis AccelerationlauravbleedioteNoch keine Bewertungen

- Physics Ticker Tape Tomatoes LabDokument6 SeitenPhysics Ticker Tape Tomatoes Labapi-329194114Noch keine Bewertungen

- XFLR5 and Stability AnalysisDokument41 SeitenXFLR5 and Stability AnalysisAhmed HassanNoch keine Bewertungen