Beruflich Dokumente

Kultur Dokumente

Multiple Foam Deluge System

Hochgeladen von

Trần VânCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Multiple Foam Deluge System

Hochgeladen von

Trần VânCopyright:

Verfügbare Formate

Foam 21a

June 1, 2008

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

1. Description

Multiple deluge foam risers can be supplied from a single foam concentrate source. Where a bladder tank is used as the foam concentrate storage container and foam concentrate source, a manifold foam concentrate supply from the bladder tank to the individual

risers is a cost effective method of installing many foam risers without duplicating the foam concentrate supply for each different riser.

The foam concentrate bladder tank will be sized by the most demanding system. It is important to remember that the most demanding

system will also mean taking in account that the duration requirement per system may differ as well.

Multiple deluge foam risers can be supplied by a single bladder tank when a concentrate manifold from the discharge head of the

bladder tank is installed to each individual riser. The foam concentrate manifold will be sized for the most severe volume requirement

and metered pressure drop requirement. At each riser location, a supply outlet will be provided from the concentrate manifold supply.

The supply outlet will have a concentrate shut-off valve, a Halar coated concentrate control valve, concentrate piping, a concentrate

swing check valve, and a concentrate controller with integral metering orifice.

The individual deluge riser will have a water supply control valve, Viking deluge valve with deluge trim, riser piping, concentrate

controller, solution test valve and system isolation valve.

A manifold supply from a bladder tank to multiple deluge risers allows for individual proportioning at each riser, allowing for different

size risers. A manifold supply from a bladder tank to multiple deluge risers also allows for individual system repair without completely

losing foam protection for other areas.

2. LISTINGS AND APPROVALS

No formal approval as a system. Main component approvals listed below.

Deluge Valve and Trim

UL Listed - Guide VLFT

FM - Automatic Water Control Valves

Concentrate Controller (Proportioner)

UL Listed - Guide GFGV

FM Approved - Low Expansion Foam Systems

Halar Coated Concentrate Control Valve (CCV)

UL Listed - Guide VLFT

FM Approved - Automatic Water Control Valve as standard deluge valve. No formal approval available for coating.

Foam Concentrate

UL Listed - Guide GFGV

FM Approved - Low Expansion Foam Systems

Viking Bladder Tank ASME Sect. VIII Certified

UL Listed - Guide GHXV

FM Approved - Low Expansion Foam Systems

3. technical data

Specifications:

Refer to individual component technical data page

Material Standards:

Refer to individual component technical data page

Ordering Information:

Viking Technical Data may be found on

The Viking Corporations Web site at

http://www.vikinggroupinc.com.

The Web site may include a more recent

edition of this Technical Data Page.

Refer to Tables 1 through 3

4. installation

A. Discharge Devices

Standard Spray Sprinklers (Open type)

Foam chambers

Foam makers

Fixed monitors

Form No. F_011601

Revised page replaces page Foam 22a-k dated July 5, 2006

(Updated part numbers to Chemguard Products)

June 1, 2008

Foam 21b

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Oscillating monitors

Spray Nozzles (Open type)

Listed discharge devices are tested with specific concentrates and may have different listed densities that what is listed in

various NFPA standards. AR-AFFF foam concentrates are listed with specific discharge devices and the fuels they are to

protect.

B. General Instructions and Warnings

1. Refer to the Warnings and General Notes on pages 2 a-d in the Design Notes section of the Viking Foam Data Book.

2. Refer to specific technical data sheets, acceptable installation standards, codes and Authority Having Jurisdiction for additional installation, operation and maintenance instructions.

3. Inspections It is imperative that the system be inspected and tested on a regular basis. See Section 6 - Inspections, Tests

and Maintenance.

4. Warning Any system maintenance or testing which involves placing a control valve or detection system out of service may

eliminate the fire protection of that system. Prior to proceeding, notify all Authorities Having Jurisdiction. Consideration should

be given to employment of a fire patrol in the effected area.

5. The valve, trim and assembly must be installed in an area not subject to freezing temperatures or physical damage.

C. Design and Installation

Warning: Locate all portions of the foam/water system subject to freezing in a heated area.

1. Refer to the Special Notes on page 21d and the Warnings and General Notes on pages 2 a-d in the Design Notes section of

the Viking Foam Data Book.

2. Install the deluge valve and trim (A) in accordance with Viking Engineering and Design Data Book.

3. Install the proportioning device, concentrate controller (B), in the riser at least 5 pipe diameters past the deluge valve. (The

concentrate controller must be installed 5 pipe diameters of straight piping past a valve or change of direction. The same 5

pipe diameters of straight pipe is required on the discharge side of the concentrate controller as well to ensure proper proportioning)

4. Install foam solution test valve (5) and system isolation valve (6). These valves are required to facilitate annual foam proportioning tests. The system isolation valve (6) is in the normally open position when the system is in operation. The solution

test valve (5) is in the normally closed position when the system is in operation. When the system is to be tested annually for

proportioning, the system isolation valve (6) is closed to eliminate foam water solution from entering the system piping. The

solution test valve (5) is opened once a flow rate is established in the riser. The solution test valve is normally sized the same

size as the riser piping to accept the design flow of the system. The discharge of the solution test valve is normally piped to

a test header with 2 angle valves to aid in controlling the discharge of foam solution.

5. Install the hydraulically actuated Halar coated concentrate control valve (C) and associated trim as indicated on trim charts

or technical data pages.

6. A concentrate shut-off valve (1) located upstream of the Halar coated concentrate control valve (C) is required to isolate

the Halar coated concentrate control valve when setting up the system or when repairs are to be made to the deluge foam

system.

7. Install the Viking foam bladder tank and associated trim in accordance with Viking foam bladder tank installation manual.

a. Install the foam concentrate piping from the discharge head of the foam bladder tank to the individual sprinkler risers. The

concentrate manifold supply line may be oversized from the concentrate controller inlet piping to make up for friction loss

from the bladder tank to the most remote sprinkler riser.

b. Allow access to the foam bladder tank for filling from barrels of foam concentrate and bladder replacement. When a bladder is replaced in a foam bladder tank, a vertical tank will be laid on its side and tank flanges removed, a horizontal bladder

tank has all tank flanges removed for bladder removal.

c. All valves and devices should be located for easy access for operation and maintenance.

8. Placing System in Service

a. Verify that the water supply control valve (2) is closed, then place deluge valve ( C) in service (See instructions on Viking

Technical Data Sheet) Open System isolation valve (6) if closed. Close solution test valve (5) if open.

b. Priming the deluge valve will prime the Halar coated concentrate control valve (C) . Priming pressure will be present

on the priming pressure gauge located as part of the concentrate control valve trim package. Bleed off any air pressure

trapped in the priming line (3) to the Viking Halar coated concentrate control (C) by opening the 3-way pressure gauge

valve (4).

c. Open the water supply control valve (2) to the deluge valve after the deluge valve and the concentrate control valve (C)

Foam 21c

June 1, 2008

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

has been primed.

d. Place foam bladder tank in service. The concentrate shut-off valve (1) will be in the closed position until foam bladder tank

is placed in service. After filling the bladder tank in accordance with the Viking Bladder tank installation manual, the bladder tank water supply control valve will be opened. The concentrate manifold drain valve (9) should be slightly opened to

vent any air from the concentrate line. Once concentrate is discharged from the concentrate manifold drain valve, close

the valve and allow concentrate manifold piping to pressurize. Foam concentrate pressure will be indicated on the foam

concentrate pressure gauge (10) located upstream of the of the concentrate shut-off valve (1). Once pressure is indicated

on concentrate pressure gauge (10), slowly open foam concentrate shut-off valve.

e. Once foam concentrate shut-off valve (1) is opened, verify that foam concentrate is not passing by the Halar coated

concentrate control valve (C) by opening the foam concentrate auxiliary drain valve (7). If foam concentrate appears,

close concentrate shut-off valve (1) immediately. If foam concentrate is passing by the Halar coated concentrate control

valve (C), the valve is not seating and is most likely fouled. Debris must be removed from seat of Halar coated concentrate control valve (C).

8. Removing the System From Service

a. Close water supply control valve (2).

b. Close concentrate shut-off valve (1).

c. Leave system isolation valve (6) open.

d. Leave solution test valve (5) closed.

e. Refer to instructions for removing deluge valve (A) from service in the Viking Engineering and Design Data Book.

f. Perform maintenance and service on system and riser piping.

g. If maintenance is required to be performed on concentrate piping, close the bladder tank water supply control valve (8),

open the shell vent valve on the bladder tank, this will relieve the pressure from the foam concentrate manifold piping.

Open the concentrate manifold drain valve (9) to drain concentrate from manifold piping. It is important to remember to

capture the foam concentrate drained from the concentrate piping. If disposal is required of the foam concentrate, check

with local authorities for the acceptable method in which to do so.

NOTE: If repairs or modifications are required on the foam concentrate supply piping, the deluge valve and deluge system may be

kept in service for protection, while repairs to the foam system concentrate piping are performed.

5. Operation

Once the deluge system release system operates, the deluge valve opens allowing water to enter the deluge system piping. The

Halar coated concentrate control valve (C) is primed from a common connection with the deluge valve, once the deluge valves

priming pressure is relieved, the Halar coated concentrate control valve (C) priming pressure is relieved as well. The concentrate

control valve (C) will open and foam concentrate will flow into the inlet of the concentrate controller. The foam concentrate is supplied by the foam bladder tank which is under the same water pressure as the deluge riser. Once water starts flowing into the deluge

riser(s), water is flowing into the bladder tank to displace the foam concentrate required at the concentrate controller. The water being

supplied into the tank is equal to the foam concentrate being metered into the water stream at the concentrate controller.

Once water passes through the concentrate controller, foam concentrate is discharged into the concentrate controller through an orifice listed and approved for the foam concentrate to be utilized. The foam and water mix and create a foam/water solution. Generally

the foam solution has a proportion of 1% or 3% of foam concentrate to water. A foam blanket is created once it has discharged

through the discharge device(s). A foam blanket is produced through one of two actions, agitation as what would happen when discharged through a standard sprinkler head, or aeration as what would happen when discharged through a foam chamber or foam

maker. The foam blanket that is created by the discharge device is part of the listing or approval obtained with the foam concentrate

testing.

6. INSPECTION, Tests AND MAINTENANCE

NOTICE: The owner is responsible for maintaining the fire protection system and devices in proper operating condition. For minimum maintenance and inspection requirements, refer to recognized standards such as those produced by NFPA, LPC and VdS

which describe care and maintenance of sprinkler systems. In addition, the Authority Having Jurisdiction may have additional

maintenance, testing and inspection requirements which must be followed.

WARNING - Any system maintenance or testing which involves placing a control valve or detection system out of service may eliminate the Fire Protection of that system. Prior to proceeding, notify all Authorities Having Jurisdiction. Consideration should be given

to employment of a Fire Patrol in the affected area.

Inspections - It is imperative that the system be inspected and tested on a regular basis. The following recommendations are

minimum requirements. The frequency of the inspections may vary due to contaminated or corrosive water supplies and corrosive

June 1, 2008

Foam 21d

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

atmospheres. In addition, the alarm devices or other connected equipment may require more frequent inspections. Refer to the

technical data, system description, applicable codes and Authority Having Jurisdiction for minimum requirements. Prior to testing

the equipment, notify appropriate personnel.

7. Availability

The Wet Pipe Foam/Water System is available through a network of domestic and international distributors. See the Viking Corp.

web site for closest distributor or contact The Viking Corporation.

8. guarantee

For details of warranty, refer to Vikings current list price schedule or contact Viking directly.

SPECIAL NOTES

A.

Provide a minimum of 5 pipe diameters of straight pipe on the inlet and outlet of the concentrate controller (B) to minimize turbulence inside the concentrate controller.

B.

The combined total equivalent length of pipe, fittings and valves in both the water supply inlet piping and the foam concentrate discharge piping, must not exceed 50 equivalent feet (15.2 meters). This will allow both pipes to be the same size as the foam liquid

inlet to the concentrate controller. Should the total equivalent length exceed 50 feet (15.2 meters), then refer to the Proportioning

Device Design Data located in the Design section of this Data book for the method of calculating these pipe sizes.

C.

The Halar coated concentrate control deluge valve (C) and swing check valve must be connected adjacent to the concentrate

controller using pipe nipples as short as possible.

D.

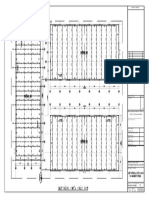

Figures 1-2 are general schematics of the required piping arrangement. Refer to the appropriate technical data page for specific

information regarding the valve, tank and related trim and devices.

E.

The technical information, statements and recommendations contained in this manual are based on information and tests which,

to the best of our knowledge, we believe to be dependable. It represents general guidelines only, and the accuracy or completeness thereof, are not guaranteed since conditions of handling and usage are outside our control. The purchaser should determine

the suitability of the product for its intended use and assumes all risks and liability whatsoever in connection therewith.

F.

The Halar coated concentrate control deluge valve (C) does not require any trim except for a priming line and water pressure

gauge and 3-way valve from the main deluge valve (A) to the priming chamber of valve (C). Plug all the remaining valve trim

outlets. Connect Halar coated concentrate control deluge valve (C) priming line to deluge valve (A) as shown on Figures 1 - 2.

Refer to the Valves section of this data book to find the correct trim kit part number for the corresponding size of Halar coated

foam concentrate control deluge valve (C) required.

G. A strainer is not required in the foam concentrate discharge piping of bladder tank systems per NFPA Standards.

Foam 21e

June 1, 2008

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 1

June 1, 2008

Foam 21f

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

Figure 2

Foam 21g

June 1, 2008

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

For complete Wet Pipe Low Flow Foam Water System, select alarm valve and trim, Retard Chamber and Circuit Closer Vent Trim, Pilot Operated

Pressure Control Valve, Foam Concentrate Control Valve and Trim, Foam Concentrate, Controller, Bladder Tank and accessories.

DESCRIPTION

Threaded

Flange/

Flange

Flange/

Groove

Deluge Valves - Angle Style

Model & Pipe O.D.

Model E-3 48mm

1 / DN40

Model E-1 60mm

2 / DN50

Model & Pipe O.D.

Model E-4 48mm

1 / DN40

Model E-2 60mm

2 / DN50

Flange Drilling

Model E-1

ANSI

3

ANSI

4

ANSI

6

ANSI/Japan

6

PN10/16

DN80

PN10/16

DN100

PN10/16

DN150

Flange Drilling

Model E-2

ANSI

3

ANSI

4

ANSI

6

PN10/16

DN80

PN10/16

DN100

PN10/16

DN150

Flange Drilling / Pipe O.D.

Model E-1

ANSI / 89mm

3

ANSI / 114mm

4

ANSI / 168mm

6

PN10/16 / 89mm

DN80

PN10/16 / 114mm

DN100

PN10/16 / 168mm

DN150

Flange Drilling / Pipe O.D.

Model E-2

ANSI / 89mm

3

ANSI / 114mm

4

ANSI / 168mm

6

PN10/16 / 168mm

DN150

PART

NUMBER

DATA PAGE

Painted Red

09889

209 a-h

05852C

210 a-h

Halar Coated

09890Q/B

212 a-j

08361Q/B

213 a-j

Painted Red

05912C

05909C

05906C

07136

211 a-h

08626

08629

08631

Halar Coated

08362Q/B

08363Q/B

08364Q/B

213 a-j

08862Q/B

08863Q/B

08864Q/B

Painted Red

05835C

05839C

05456C

211 a-h

09539

09540

05456C

Halar Coated

11064Q/B

11065Q/B

213 a-j

11001Q/B

11001Q/B

PART

DATA PAGE

NUMBER

Deluge Valves - Straight Through

Pipe O.D.

Model F-1

Painted Red

NPT 48mm

1

12126

214 a-f

NPT 60mm

2

12059

NPT 65mm

2

12401

218 a-j

BSP 48mm

DN40

12682

BSP 60mm

DN50

12686

Pipe O.D.

Model F-2

Halar Coated

NPT 65mm

2

12402Q/B

219 a-k

DESCRIPTION

Threaded

NOMINAL SIZE

Flange/

Flange

Flange/

Groove

NOMINAL SIZE

Table 1

NOMINAL

PART

DATA

SIZE

NUMBER

PAGE

Deluge Valves - Straight Through

Flange Drilling

Model F-1

Painted Red

ANSI

3

12014

ANSI

4

11953

ANSI

6

11955

ANSI

8

11991

ANSI/Japan

6

11964

218 a-j

PN10/16

DN80

12026

PN10/16

DN100

11965

PN10/16

DN150

11956

PN10

DN200

11995

PN16

DN200

11999

Flange Drilling

Model F-2

Halar Coated

ANSI

3

12015Q/B

ANSI

4

11960Q/B

ANSI

6

11962Q/B

ANSI

8

11992Q/B

PN10/16

DN80

12027Q/B

219 a-k

PN10/16

DN100

11966Q/B

PN10/16

DN150

11963Q/B

PN10

DN200

11996Q/B

PN16

DN200

12000Q/B

Flange Drilling / Pipe O.D.

Model F-1

Painted Red

ANSI / 89mm

3

12018

ANSI / 114mm

4

11952

ANSI / 168mm

6

11954

PN10/16 / 89mm

DN80

12030

218 a-j

PN10/16 / 114mm

DN100

11958

PN10/16 / 165mm

DN150

12640

PN10/16 / 168mm

DN150

11954

Flange Drilling / Pipe O.D.

Model F-2

Halar Coated

ANSI / 89mm

3

12019Q/B

ANSI / 114mm

4

11959Q/B

ANSI / 168mm

6

11961Q/B

PN10/16 / 89mm

DN80

12644Q/B

219 a-k

PN10/16 / 114mm

DN100

12645Q/B

PN10/16 / 165mm

DN150

12641Q/B

PN10/16 / 168mm

DN150

11961Q/B

Pipe O.D.

Model F-1

Painted Red

48mm 1 / DN40

12125

214 a-f

60mm

2 / DN50

12057

73mm 2 / DN65

12403

76mm

DN80

12729

89mm

3 / DN80

12022

114mm

4 / DN100

11513

218 a-j

165mm

DN150

11910

168mm

6 / DN150

11524

219mm

8 / DN200

11018

Pipe O.D.

Model F-2

Halar Coated

48mm 1 / DN40

12127Q/B

60mm

2 / DN50

12058Q/B

73mm 2 / DN65

12404Q/B

76mm

DN80

12730Q/B

89mm

3 / DN80

12023Q/B

219 a-k

114mm

4 / DN100

11514Q/B

165mm

DN150

11911Q/B

168mm

6 / DN150

11525Q/B

219mm

8 / DN200

11118Q/B

DESCRIPTION

Groove/

Groove

June 1, 2008

Foam 21h

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

DESCRIPTION

NOMINAL SIZE

PART NUMBER

DESCRIPTION

MATERIAL PART NUMBER DATA PAGE

RELEASE TRIM PACKAGES

Pneumatic Release

Galvanized

09069

267 b

Brass

09717

Use with Angle

Style Valves

Electric Release

Galvanized

09070

267 a

Brass

09698

Pneumatic Release

Galvanized

10809

265 b

Brass

10811

Use with Straight

Through Valves

Electric Release

Galvanized

10830

265 a

Brass

10832

DATA PAGE

Deluge Valve Trim

Use with Angle

Style Valves

Galvanized

Brass

1 / DN40

14629-1

14629-2

225 a-c

2 / DN50

14630-1

14630-2

226 a-c

3 / DN80

14631-1

14631-2

4 / DN100

14632-1

14632-2

6 / DN150

14633-1

14633-2

14635-1

14635-2

235 a-c

14637-1

14637-2

239 e-g

4 / DN100

14638-1

14638-2

240 a-c

6 / DN150

14640-1

14640-2

241 a-c

8 / DN200

14643-1

14643-2

242 a-c

14634-1

14634-2

235 e-g

1 / DN40

2 / DN50

2 / DN65

3 / DN80

Horizontal

Use with

Straight

Through

Valves

1 / DN40

2 / DN50

2 / DN65

Vertical

227 a-c

14636-1

14636-2

239 e-g

4 / DN100

14639-1

14639-2

240 e-g

6 / DN150

14641-1

14641-2

241 a-c

8 / DN200

14643-1

14643-2

242 e-g

3 / DN80

DESCRIPTION

NOMINAL SIZE

Includes Conventional Trim,

Release Trim, and Flexible

Hose Kit

Electric Release

12228B-1

244 a-s

Pneumatic Release

12229B-2

245 a-t

Trimpac

Drain Package

Use with TrimPac (above)

NOMINAL

SIZE

DESCRIPTION

PART

NUMBER

DATA PAGE

Model E-4 48mm

1 / DN40

09890Q/B

Model E-2 60mm

2 / DN50

08361Q/B

Use with Angle Style Valve

Groove/

Groove

11894-3

3 / DN80

11894-3

4 / DN100

11894-4

6 / DN150

11894-4

8 / DN200

11894-4

PART

NUMBER

Refer to

Trimpac

Data Page

DATA PAGE

Model F-2

2

61a-f

12402Q/B

Pipe O.D.

Model F-2

48mm

1 / DN40

60mm

2 / DN50

73mm

2 / DN65

12404Q/B

1 / DN40

08098

2 / DN50

08099

Brass

Straight Through

NPT 65mm

11894-2

2 / DN65

Galvanized

Model & Pipe O.D.

Pipe O.D.

11894-1

2 / DN50

FOAM CONCENTRATE CONTROL VALVE TRIM

Angle Style

Threaded

NPT

1 / DN40

NOMINAL

SIZE

DESCRIPTION

FOAM CONCENTRATE CONTROL VALVE HALAR COATED

Threaded

NPT

PART NUMBER DATA PAGE

1 / DN40

09694

2 / DN50

09695

Galvanized

1 / DN40

12848-1

12127Q/B

2 / DN50

12848-1

12058Q/B

2 / DN65

12929-1

Use with Straight Through Valves

TANK

SIZE

PART

NUMBER

HORIZONTAL BLADDER TANK

50 - 4500 Gallon

CHBT2-xxxx *

VERTICAL BLADDER TANK

25 - 4500 Gallon

CVBT2-xxxx *

DESCRIPTION

* Where xxxx is the tank size

Table 2

Brass

1 / DN40

12848-2

2 / DN50

12848-2

2 / DN65

12929-2

DATA PAGE

240 a-h

61a-f

Foam 21i

June 1, 2008

TECHNICAL DATA

Multiple foam/water

deluge systems

supplied by a bladder tank

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

For complete Wet Pipe Low Flow Foam Water System, select alarm valve and trim, Retard Chamber and Circuit Closer Vent Trim, Pilot Operated

Pressure Control Valve, Foam Concentrate Control Valve and Trim, Foam Concentrate, Controller, Bladder Tank and accessories.

DESCRIPTION

NOMINAL

SIZE

PART

NUMBER

DATA

PAGE

Foam Concentrate Swing Check Valve

1 / DN40

99S-0150

2 / DN50

99S-0200

2 / DN65

05497C

803 a-d

Foam Solution Test Valve

Grooved Butterfly Valve

Description

PART

NUMBER

DATA

PAGE

PART

NUMBER

2-1/2 (65 mm) Threaded 1 NPT

F15001/A

3 (80 mm) Wafer 1-1/4 NPT

F15007/A

4 (100 mm) Wafer 1-1/2 NPT

F15013/A

6 (150 mm) Wafer 2 NPT

F15019/A

01G-0250

3 / DN80

01G-0300

4 / DN100

01G-0400

6 / DN150

01G-0600

8 (200 mm) Wafer 2-1/2 NPT

F15026/A

8 / DN200

01G-0800

2-1/2 (65 mm) Threaded 1 NPT

F15001/B

2 / DN65

01G-0250

3 / DN80

01G-0300

4 / DN100

01G-0400

6 / DN150

01G-0600

8 / DN200

01G-0800

1% AFFF

C103

3% AFFF

C303

F14969

F14970

100 a-b

101 a-b

3% AFFF MS

C301 MS

F14971

102 a-b

Water Supply Control Valve

OS & Y

RATIO FLOW CONTROLLER

SIZE

2 / DN65

System Isolation Valve

Grooved Butterfly Valve

Foam CONCENTRATES AND RATIO FLOW CONTROLLERS

Foam CONCENTRATE

2 / DN65

8068A-0250

3 / DN80

8068A-0300

F15007/B

F15013/B

6 (150 mm) Wafer 2 NPT

F15019/B

8 (200 mm) Wafer 2-1/2 NPT

F15026/B

2-1/2 (65 mm) Threaded 1 NPT

F15001/C

3 (80 mm) Wafer 1-1/4 NPT

F15007/C

4 (100 mm) Wafer 1-1/2 NPT

F15013/C

6 (150 mm) Wafer 2 NPT

F15019/C

8 (200 mm) Wafer 2-1/2 NPT

F15026/C

2-1/2 (65 mm) Threaded 1 NPT

F15001/J

3 (80 mm) Wafer 1-1/4 NPT

F15007/J

4 (100 mm) Wafer 1-1/2 NPT

F15013/J

6 (150 mm) Wafer 2 NPT

F15019/J

4 / DN100

8068A-0400

6 / DN150

8068A-0600

8 / DN200

8068A-0800

8 (200 mm) Wafer 2-1/2 NPT

F15026/J

Foam Concentrate Shut-Off Valve

2-1/2 (65 mm) Threaded 1 NPT

F15001/D

3 (80 mm) Wafer 1-1/4 NPT

F15007/D

4 (100 mm) Wafer 1-1/2 NPT

F15013/D

Ball Valve

1 / DN40

T595Y66-0150

2 / DN50

T595Y66-0200

3% AR-AFFF

CUG

3 (80 mm) Wafer 1-1/4 NPT

4 (100 mm) Wafer 1-1/2 NPT

3% / 6% ARAFFF @ 3%

C363

F14972

F14973

104 a-b

103 a-b

ACCESSORIES FOR FOAM/WATER SPRINKLER SYSTEMS

Model D-1 PORV

/ DN15

13598

287 a-b

1/8 / 3mm Restricted

Orifice

/ DN15

06555A

Soft Seat Check

Valve

/ DN15

03945A

Y Strainer

/ DN15

Ball Valve

/ DN15

01054A

10355

3% / 6% ARAFFF @ 6%

C363

2% High Ex

C2

F14973

F14974

Concentrate Control Valve Priming Connection

Pkg.

Required to connect priming chamber

10985

Bladder Tank Water Supply Control Valve

Ball Valve

1 / DN40

Ball Valve

2 / DN50

WBV-0150

WBV-0200

OS & Y

2 / DN65

8068A-0250

OS & Y

3 / DN80

8068A-0300

Table 3

103 a-b

105 a-b

6 (150 mm) Wafer 2 NPT

F15022

2-1/2 (65 mm) Threaded 1 NPT

F15001/E

3 (80 mm) Wafer 1-1/4 NPT

F15007/E

4 (100 mm) Wafer 1-1/2 NPT

F15013/E

6 (150 mm) Wafer 2 NPT

F15019/D

2-1/2 (65 mm) Threaded 1 NPT

F15001/H

3 (80 mm) Wafer 1-1/4 NPT

F15007/H

4 (100 mm) Wafer 1-1/2 NPT

F15013/H

6 (150 mm) Wafer 2 NPT

F15019/H

DATA

PAGE

170 a-d

This page left

intentionally

left blank

Form No. F_011601

Revised page replaces page Foam 22a-k dated July 5, 2006

(Updated part numbers to Chemguard Products)

Das könnte Ihnen auch gefallen

- Documentation AnsulDokument40 SeitenDocumentation AnsulkdsessionsNoch keine Bewertungen

- Water Spray SystemDokument5 SeitenWater Spray SystemNguyenThanhdungNoch keine Bewertungen

- Naffco Foam SystemDokument40 SeitenNaffco Foam SystemMd. Asrafujjaman (Livon)Noch keine Bewertungen

- Sprinklers PDFDokument43 SeitenSprinklers PDFpil7194Noch keine Bewertungen

- Foam System - V.0 - WS PDFDokument82 SeitenFoam System - V.0 - WS PDFSajjadNoch keine Bewertungen

- Level 1Dokument121 SeitenLevel 1Jerry RdzNoch keine Bewertungen

- Contractor'S Material and Test Certificate Fire Sprinkler SystemsDokument4 SeitenContractor'S Material and Test Certificate Fire Sprinkler SystemsToufik MedjNoch keine Bewertungen

- Fire Fighting - QatarDokument21 SeitenFire Fighting - QatarrajeshjamesNoch keine Bewertungen

- Sprinkler System ComponentsDokument68 SeitenSprinkler System Componentsjosediaz141Noch keine Bewertungen

- Product Manual DCP Trolley Mounted 25-50-75 KGDokument6 SeitenProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNoch keine Bewertungen

- Ansul R-102Dokument4 SeitenAnsul R-102heliopintoNoch keine Bewertungen

- Maintenance ManualDokument17 SeitenMaintenance ManualSean ChanNoch keine Bewertungen

- Tyco - Window Sprinklers As An Alternative To Fire PDFDokument19 SeitenTyco - Window Sprinklers As An Alternative To Fire PDFingenierosunidosNoch keine Bewertungen

- ANSUL Aircraft HangarsDokument8 SeitenANSUL Aircraft Hangarsاحمد الجزار2007100% (1)

- Hi-Fog For Buildings: Technical IntroductionDokument16 SeitenHi-Fog For Buildings: Technical IntroductionEsther TapiaNoch keine Bewertungen

- Nfpa 13 Chapter 1Dokument34 SeitenNfpa 13 Chapter 1hmayordomo100% (1)

- Royal Oman Police (English)Dokument191 SeitenRoyal Oman Police (English)Khizer ArifNoch keine Bewertungen

- A Comparison of The Fire Suppression Performance o PDFDokument34 SeitenA Comparison of The Fire Suppression Performance o PDFDayanne MartinsNoch keine Bewertungen

- Waterspray MistextinguishingsystemDokument10 SeitenWaterspray MistextinguishingsystemSalley BukhariNoch keine Bewertungen

- HVAC Ductwork SpecificationDokument4 SeitenHVAC Ductwork SpecificationhvacwallyNoch keine Bewertungen

- Guideline For TSP Sapphire SystemsDokument15 SeitenGuideline For TSP Sapphire SystemsCK ChioNoch keine Bewertungen

- Training ManualDokument15 SeitenTraining Manualrajeshrahul321Noch keine Bewertungen

- Sprinkler System DesignDokument19 SeitenSprinkler System DesignRajahi Moahmed100% (1)

- Tyco Water SprayDokument6 SeitenTyco Water SprayFadlul Akbar HerfiantoNoch keine Bewertungen

- PotterSprinkler CatalogDokument36 SeitenPotterSprinkler CatalogSaleh Mohamed100% (1)

- Fire Suppression SystemDokument26 SeitenFire Suppression SystemLawrence Ting0% (3)

- How Does A FPE Calculate The Fire Water Demand For A BuildingDokument12 SeitenHow Does A FPE Calculate The Fire Water Demand For A BuildingArt James100% (1)

- Section 15310 Fire Protection PipingDokument8 SeitenSection 15310 Fire Protection PipingkdpmansiNoch keine Bewertungen

- DIOM Tyco Hygood IG541Dokument103 SeitenDIOM Tyco Hygood IG541appril26Noch keine Bewertungen

- Break TanksDokument3 SeitenBreak TanksReza Khaje100% (1)

- Sidewall SprinklerDokument6 SeitenSidewall SprinklerAhrian BenaNoch keine Bewertungen

- 6special Protection SystemDokument59 Seiten6special Protection SystemGurusumiNoch keine Bewertungen

- Water Spray SystemDokument2 SeitenWater Spray SystemFIRE KNOCKNoch keine Bewertungen

- HydraulicDokument8 SeitenHydraulicOsama OmayerNoch keine Bewertungen

- Clean Agent System Test Report-1Dokument96 SeitenClean Agent System Test Report-1bayrammtnNoch keine Bewertungen

- Fire Suppression Systems UL 300: Length of HoodDokument3 SeitenFire Suppression Systems UL 300: Length of Hoodkdsessions100% (2)

- Fire Hose Reel SystemDokument7 SeitenFire Hose Reel SystemRedford DonguyaNoch keine Bewertungen

- PN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingDokument5 SeitenPN 38 2014 Fire Hydrants System Design, Installation, Commissioning and TestingKadiri OlanrewajuNoch keine Bewertungen

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDokument18 SeitenIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNoch keine Bewertungen

- Fire Protection Design GuidelinesDokument11 SeitenFire Protection Design GuidelinesMarck Gheson InacayNoch keine Bewertungen

- Supplementary Specification To NFPA 750 Water Mist Fire Protection SystemsDokument25 SeitenSupplementary Specification To NFPA 750 Water Mist Fire Protection SystemsMohamed MansourNoch keine Bewertungen

- Guideline For FM200 Systems Rev18Dokument17 SeitenGuideline For FM200 Systems Rev18Salman YahyaNoch keine Bewertungen

- Inergen SpecDokument19 SeitenInergen SpecMargaret DaughertyNoch keine Bewertungen

- Basic Framework For Submission of Performance-Based SolutionsDokument83 SeitenBasic Framework For Submission of Performance-Based Solutionsahmed abdohNoch keine Bewertungen

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Dokument46 SeitenSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- Fire Pump SpecificationDokument5 SeitenFire Pump SpecificationThiru AnanthNoch keine Bewertungen

- R-FIR-DIOMM INEREX-GB-2015 02 UL 2015 05 17 KomprimiertDokument128 SeitenR-FIR-DIOMM INEREX-GB-2015 02 UL 2015 05 17 Komprimiertthuan100% (1)

- Deluge Valve HD FireDokument14 SeitenDeluge Valve HD FireKeshodbana KeshodNoch keine Bewertungen

- Cen TS 14816Dokument29 SeitenCen TS 14816Miguel MarinNoch keine Bewertungen

- List of NFPA Codes & StandardsDokument1 SeiteList of NFPA Codes & StandardsSahil PalNoch keine Bewertungen

- Jci 2017072Dokument15 SeitenJci 2017072Toretta AdrianNoch keine Bewertungen

- Reliable Storage Sprinklers BrochureDokument26 SeitenReliable Storage Sprinklers Brochureari78100% (2)

- TEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1Dokument8 SeitenTEC-212200 - MET-DoR-005 (Method Statement For Installation and Inspection of Clean Agent system-FM 200 - 1swamyNoch keine Bewertungen

- 6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFDokument1 Seite6.4 - Sprinklers For Concealed Spaces and Raised Floors PDFHaitham MohammadNoch keine Bewertungen

- Installation of Sprinkler Piping SystemDokument6 SeitenInstallation of Sprinkler Piping SystemJosef MadronaNoch keine Bewertungen

- Taco Expansion TankDokument20 SeitenTaco Expansion TankDhirendra Singh RathoreNoch keine Bewertungen

- What Is A Deluge Fire System PDFDokument1 SeiteWhat Is A Deluge Fire System PDFmister_no34Noch keine Bewertungen

- HygoodDokument1 SeiteHygoodSachin Darne100% (1)

- Foam System ManualDokument66 SeitenFoam System Manualriyasudeen786Noch keine Bewertungen

- Foam System ManualDokument66 SeitenFoam System Manualchaker0550% (2)

- Foam SL-FHA-20-3BarDokument9 SeitenFoam SL-FHA-20-3BarTrần VânNoch keine Bewertungen

- Foam SL-FHA-20-3BarDokument9 SeitenFoam SL-FHA-20-3BarTrần VânNoch keine Bewertungen

- Combine 2F T1CDokument1 SeiteCombine 2F T1CTrần VânNoch keine Bewertungen

- CÁC CÔNG VIỆC CẦN THỰC HIỆN ĐỂ BÀN GIAO SÀN-CHỮA CHÁY B1-MU4Dokument1 SeiteCÁC CÔNG VIỆC CẦN THỰC HIỆN ĐỂ BÀN GIAO SÀN-CHỮA CHÁY B1-MU4Trần VânNoch keine Bewertungen

- Bom Grundfos-17122019154351Dokument3 SeitenBom Grundfos-17122019154351Trần VânNoch keine Bewertungen

- Foam SL-FHA-20-3BarDokument9 SeitenFoam SL-FHA-20-3BarTrần VânNoch keine Bewertungen

- Alarm Vale Armas-1 - 1555493257Dokument10 SeitenAlarm Vale Armas-1 - 1555493257Trọng Trương NgọcNoch keine Bewertungen

- LookUp TablesDokument3 SeitenLookUp TablesMaxwell_HammerNoch keine Bewertungen

- Amerex SampleDokument4 SeitenAmerex SampleTrần VânNoch keine Bewertungen

- Analysis of Water Distribution Systems Using A PDFDokument8 SeitenAnalysis of Water Distribution Systems Using A PDFTrần VânNoch keine Bewertungen

- 2014cepaperst48 PDFDokument66 Seiten2014cepaperst48 PDFTrần VânNoch keine Bewertungen

- BH-6 BH-7 PDFDokument1 SeiteBH-6 BH-7 PDFTrần VânNoch keine Bewertungen

- Ansul SampleDokument3 SeitenAnsul SampleTrần VânNoch keine Bewertungen

- Tender Permit Design For Approval Construction Revised As-BuiltDokument1 SeiteTender Permit Design For Approval Construction Revised As-BuiltTrần VânNoch keine Bewertungen

- Revolving Nozzle: HD Fire Protect Pvt. Ltd. Technical DataDokument2 SeitenRevolving Nozzle: HD Fire Protect Pvt. Ltd. Technical DataTrần VânNoch keine Bewertungen

- Tender Permit Design For Approval Construction Revised As-BuiltDokument1 SeiteTender Permit Design For Approval Construction Revised As-BuiltTrần VânNoch keine Bewertungen

- HEC-RAS 5.0 Reference ManualDokument547 SeitenHEC-RAS 5.0 Reference ManualTrần Vân100% (4)

- Revolving Nozzle: HD Fire Protect Pvt. Ltd. Technical DataDokument2 SeitenRevolving Nozzle: HD Fire Protect Pvt. Ltd. Technical DataTrần VânNoch keine Bewertungen

- E110Dokument8 SeitenE110munazarNoch keine Bewertungen

- Fire Fighting SystemDokument20 SeitenFire Fighting Systemanuavi93Noch keine Bewertungen

- Foam SprinklerDokument2 SeitenFoam SprinklerTrần VânNoch keine Bewertungen

- HD237Dokument4 SeitenHD237Trần VânNoch keine Bewertungen

- HD111Dokument4 SeitenHD111Trần VânNoch keine Bewertungen

- HD186 PDFDokument2 SeitenHD186 PDFTrần VânNoch keine Bewertungen

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

- 18-TCVN 4878 Phan Loai ChayDokument1 Seite18-TCVN 4878 Phan Loai Chaym0123456789Noch keine Bewertungen

- FM200 DatasheetDokument5 SeitenFM200 DatasheetSergio Diaz PereiraNoch keine Bewertungen

- TFP340 03 2007Dokument6 SeitenTFP340 03 2007Trần VânNoch keine Bewertungen

- Clean Agent Enclosure Design Per NFPA 2001Dokument9 SeitenClean Agent Enclosure Design Per NFPA 2001amechmar5935Noch keine Bewertungen

- Viking Foam Manual 001Dokument24 SeitenViking Foam Manual 001Trần VânNoch keine Bewertungen

- D Gluconic Acid D Glucano Delta LactoneDokument3 SeitenD Gluconic Acid D Glucano Delta LactoneI. Murali KrishnaNoch keine Bewertungen

- Mal 4Dokument5 SeitenMal 4Heri HidayatNoch keine Bewertungen

- KPCL - Steam Blowing ProcedureDokument7 SeitenKPCL - Steam Blowing ProcedureAtiqur RahmanNoch keine Bewertungen

- Recommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)Dokument35 SeitenRecommended Practices ON Static Electricity: OISD-110 OISD - 110 (Rev.1)manuppm100% (1)

- Want To Be A DoctorDokument17 SeitenWant To Be A DoctormadhavNoch keine Bewertungen

- Class 10 Chemistry Workbook PDFDokument118 SeitenClass 10 Chemistry Workbook PDFSayan Dutta100% (1)

- Antimicrobial Activity and Chemical Composition of Essential Oil FromDokument9 SeitenAntimicrobial Activity and Chemical Composition of Essential Oil FromTrần Thuý QuỳnhNoch keine Bewertungen

- Drilling and Blasting As A Tunnel Excavation MethodDokument26 SeitenDrilling and Blasting As A Tunnel Excavation MethodMIGUEL FERNANDO AGUIRRE QUISPE100% (1)

- Properties of Gelatins From Skins of Fish - Black Tilapia (Oreochromis Mossambicus) and Red Tilapia (Oreochromis Nilotica)Dokument4 SeitenProperties of Gelatins From Skins of Fish - Black Tilapia (Oreochromis Mossambicus) and Red Tilapia (Oreochromis Nilotica)Rizky Febrian SatrianiNoch keine Bewertungen

- Model Questions ElasticityDokument3 SeitenModel Questions Elasticityrameshbabu_1979Noch keine Bewertungen

- Pearson Science 8 SB Chapter 5 Unit 5.2Dokument11 SeitenPearson Science 8 SB Chapter 5 Unit 5.2teerapong onogk67% (3)

- Piercing Extrusion of Long Hollow Component With Subsidiary TensionDokument4 SeitenPiercing Extrusion of Long Hollow Component With Subsidiary TensionDhan CNoch keine Bewertungen

- 1-Internal Heat GainDokument15 Seiten1-Internal Heat GainWunNa100% (1)

- DR VipinDokument27 SeitenDR VipinSam SamayaNoch keine Bewertungen

- Viscosity of Fluids Lab Ball Drop MethodDokument4 SeitenViscosity of Fluids Lab Ball Drop MethodNOKIANoch keine Bewertungen

- 5 Mass TransferDokument85 Seiten5 Mass TransfergeorgiadisgNoch keine Bewertungen

- Colloidal Processing of CeramicsDokument18 SeitenColloidal Processing of CeramicsmlombardiTO100% (1)

- Astm 578Dokument5 SeitenAstm 578ASWANTH T S100% (1)

- Trunnion CalculationDokument8 SeitenTrunnion CalculationPrashant ChauhanNoch keine Bewertungen

- Matter Sphere For Mage The AscensionDokument2 SeitenMatter Sphere For Mage The AscensionBeth100% (3)

- Soil 2Dokument12 SeitenSoil 2LolNoch keine Bewertungen

- Laser Cooling and Trapping of Neutral AtomsDokument21 SeitenLaser Cooling and Trapping of Neutral Atomsdevendratiwari0Noch keine Bewertungen

- 2561 Rubber Based Adhesives For Automobile IndustryDokument14 Seiten2561 Rubber Based Adhesives For Automobile IndustryKaushik SenguptaNoch keine Bewertungen

- Design of Heads and Covers: Chapter SixDokument15 SeitenDesign of Heads and Covers: Chapter SixmatiasregistroNoch keine Bewertungen

- Elephant Toothpaste ExperimentDokument4 SeitenElephant Toothpaste ExperimentMakariuos TharwatNoch keine Bewertungen

- The Art of Candle and SoapDokument126 SeitenThe Art of Candle and SoapMallory GuestNoch keine Bewertungen

- Attock Petroleum Limited: Lubricant Product ListDokument1 SeiteAttock Petroleum Limited: Lubricant Product ListAbdul MajidNoch keine Bewertungen

- Combiglide Quick Start ManualDokument52 SeitenCombiglide Quick Start Manuala_singhal007Noch keine Bewertungen

- Shin 2016Dokument8 SeitenShin 2016pur bNoch keine Bewertungen

- Schultz 1987Dokument18 SeitenSchultz 1987Ruiz ManuelNoch keine Bewertungen