Beruflich Dokumente

Kultur Dokumente

Reservoirs Function: by Downloading This Document You Acknowledge Acceptance of Our Terms and Conditions of Use

Hochgeladen von

retrospect1000Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reservoirs Function: by Downloading This Document You Acknowledge Acceptance of Our Terms and Conditions of Use

Hochgeladen von

retrospect1000Copyright:

Verfügbare Formate

___________________________________________________________________________

RESERVOIRS

Function

The reservoir or tank performs a number of functions in the hydraulic system:

fluid storage

separation of air

dissipation of heat

settling of contaminants

Sizing

Recommended reservoir fluid volume is 3 to 5 times the pump(s) output flow per minute with a 10% air cushion,

expressed by the following formula:

=

3 Q 1.1

reservoir volume in gallons or litres

flow rate of pump(s) in gallons per minute or litres per minute

Where

The volume chosen for a particular application will be influenced by available space and weight considerations,

which are typically more critical in mobile applications than in industrial applications. The unequal displacement of

cylinders must be also be considered, so that the minimum oil level with all cylinders extended is sufficient to

prevent a vortex at the pump suction outlet and reservoir volume can accommodate returning oil with all cylinders

retracted.

Construction

Where possible, the profile of the reservoir should be deep and narrow rather than shallow and broad. This reduces

the possibility of vortex effects and improves heat dissipation.

Suction and return lines should be separated by a baffle plate inside the tank. This assists in cooling, settling and deaerating return oil prior to recirculation through the system. The baffle plate should extend to 75% of the maximum

oil level and have the bottom corners cut diagonally, giving a sufficient opening to allow the oil level to equalise on

both sides of the baffle.

HydraulicSupermarket.com 2000 - 2002

By downloading this document you acknowledge acceptance of our Terms and Conditions of Use

___________________________________________________________________________

The pump suction penetration should be located above the bottom of the tank to prevent settled contaminants

entering the pump. Return and case drain penetrations should be located near the top of the tank and fitted with drop

pipes inside the tank that extend below the minimum oil level, to prevent aeration of return oil as it passes through

the air space inside the tank. Return oil should be filtered to 25 micron absolute or better before the reservoir. Refer

to our Technical Library document titled Filters for more information.

Inspection covers should be incorporated to facilitate periodic servicing and cleaning. A sight gauge, oil filler and air

breather (on vented reservoirs) are essential accessories. The air breather should include a filter of 5 micron or better

and be of sufficient airflow capability to prevent either a negative or positive pressure in the reservoir, as the working

oil volume changes.

Installation

Ideally, the reservoir should be located above the pump so that the pump inlet is always flooded. This improves

pump suction conditions, reducing the possibility of vortex flows and cavitation. Locating the tank in a wellventilated area will improve heat dissipation, although in practice the heat load dissipated from the tank is relatively

small. For more information refer our Technical Library document titled Cooling and Heating.

Email this article to a friend or colleague!

For more articles like this one, sign-up for our FREE newsletter.

2

HydraulicSupermarket.com 2000 - 2002

By downloading this document you acknowledge acceptance of our Terms and Conditions of Use

Das könnte Ihnen auch gefallen

- Marvel-Schebler Carburetor Repair ManualDokument21 SeitenMarvel-Schebler Carburetor Repair Manualbedford24100% (14)

- Carrier Refrigerant Piping SystemsDokument57 SeitenCarrier Refrigerant Piping Systemsrpiland2100% (5)

- D&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsDokument30 SeitenD&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsPitt Pacheco F100% (3)

- Surge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Dokument3 SeitenSurge Detection and Surge Control Systems For Centrifugal Compressors - Part 2Dewanjee AshrafNoch keine Bewertungen

- Instruction ManualDokument36 SeitenInstruction ManualJoséNoch keine Bewertungen

- Lear - Romec - Appl Book PDFDokument7 SeitenLear - Romec - Appl Book PDFMehdi Mansourian100% (1)

- Tecumseh Refrigerant PipingDokument24 SeitenTecumseh Refrigerant Pipingaries26marchNoch keine Bewertungen

- Basics of Hydralic SystemDokument101 SeitenBasics of Hydralic SystemNikhil MalhotraNoch keine Bewertungen

- Flowserve Mechanical Seal PlanDokument56 SeitenFlowserve Mechanical Seal PlanAnonymous 1XHScfCINoch keine Bewertungen

- Process Engineering: Facts, Fiction and FablesVon EverandProcess Engineering: Facts, Fiction and FablesBewertung: 3 von 5 Sternen3/5 (2)

- Fundamentals of HydraulicsDokument101 SeitenFundamentals of HydraulicsLuis Nunes100% (1)

- Evaluating Deaerator OperationDokument5 SeitenEvaluating Deaerator OperationYanuar KrisnahadiNoch keine Bewertungen

- 04 2429GDokument11 Seiten04 2429Gzanella159051Noch keine Bewertungen

- Reference Beach Russ Vacuum Pump Operation PDFDokument2 SeitenReference Beach Russ Vacuum Pump Operation PDFvasanth kumarNoch keine Bewertungen

- Gauge Gauge Tank Body:: FunctionsDokument9 SeitenGauge Gauge Tank Body:: FunctionsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Refrigeration PipingDokument43 SeitenRefrigeration PipingenigmazeeNoch keine Bewertungen

- Flushing & HidrotestDokument18 SeitenFlushing & HidrotestAbdul Hakam Mohamed Yusof100% (1)

- Hydraulic Resevoir Design Criteria PDFDokument10 SeitenHydraulic Resevoir Design Criteria PDF2345421Noch keine Bewertungen

- Overhauling Air Compressor On ShipsDokument12 SeitenOverhauling Air Compressor On ShipsTun Lin Naing100% (3)

- Control of CompressorDokument35 SeitenControl of CompressorAshik Jacob Oommen100% (1)

- Design and Application of FeedersDokument51 SeitenDesign and Application of Feedersretrospect1000Noch keine Bewertungen

- Recip-Compressor-Capacity Control Methods PDFDokument8 SeitenRecip-Compressor-Capacity Control Methods PDFChem.EnggNoch keine Bewertungen

- Bosch K Jetronic Fuel InjectionDokument10 SeitenBosch K Jetronic Fuel Injectionvictoson100% (5)

- Refrigeration Oil Cooling SystemsDokument4 SeitenRefrigeration Oil Cooling Systemsgoodspeed_ph100% (1)

- Flushing ProcedureDokument3 SeitenFlushing ProcedureRex ValenciaNoch keine Bewertungen

- CLB11003 - Exp 4Dokument6 SeitenCLB11003 - Exp 4Nur DiyanahNoch keine Bewertungen

- FRAMODokument128 SeitenFRAMOFanisKountouris100% (5)

- API Plans - FlowserveDokument66 SeitenAPI Plans - FlowserveJosé Alberto Herrera100% (2)

- Compressor Selection GuidelineDokument1 SeiteCompressor Selection Guidelinepradeep1987coolNoch keine Bewertungen

- Treaters SeparatorDokument6 SeitenTreaters SeparatorDayo IdowuNoch keine Bewertungen

- Lubricating Oil System For A Marine Diesel EngineDokument9 SeitenLubricating Oil System For A Marine Diesel EngineJohn FredyNoch keine Bewertungen

- Pressure Control For Vacuum SystemsDokument4 SeitenPressure Control For Vacuum SystemsnasirmuzaffarNoch keine Bewertungen

- Difference Between 53 A B CDokument3 SeitenDifference Between 53 A B CAmol PatkiNoch keine Bewertungen

- Steam Trap ScienceDokument5 SeitenSteam Trap ScienceSandi AslanNoch keine Bewertungen

- CMPAPPP Separator Vessel and Filter Design GuideDokument18 SeitenCMPAPPP Separator Vessel and Filter Design GuideJWilson73Noch keine Bewertungen

- Design of Falling-Film EvaporatorsDokument7 SeitenDesign of Falling-Film EvaporatorsHubert Dandie MarshalleckNoch keine Bewertungen

- Reference - Beach-Russ Vacuum Pump OperationDokument2 SeitenReference - Beach-Russ Vacuum Pump Operationtpplant100% (2)

- Recip Compressor Capacity Control MethodsDokument8 SeitenRecip Compressor Capacity Control MethodsAnonymous KpVxNXsNoch keine Bewertungen

- Aeration Calculation PDFDokument20 SeitenAeration Calculation PDFBrian Thomas100% (1)

- Excellent Thesis DesignDokument117 SeitenExcellent Thesis DesignHemanth Peddavenkatappa GariNoch keine Bewertungen

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDokument16 SeitenSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- Quentin A. Baker Et Al - Update of "Guidelines To Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire Hazards"Dokument10 SeitenQuentin A. Baker Et Al - Update of "Guidelines To Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire Hazards"SodaMoussezNoch keine Bewertungen

- Tank Blanketing BasicsDokument4 SeitenTank Blanketing BasicsOmkar VazeNoch keine Bewertungen

- Reservatórios HidráulicosDokument2 SeitenReservatórios HidráulicosMateus EugênioNoch keine Bewertungen

- Hydraulic Reservoirs For Mobile Equipment 7-18-14Dokument9 SeitenHydraulic Reservoirs For Mobile Equipment 7-18-14mulle2002Noch keine Bewertungen

- PCVDokument20 SeitenPCVyared abebeNoch keine Bewertungen

- HydralulicsDokument12 SeitenHydralulicsCarlitos Lara RambalNoch keine Bewertungen

- Fundamentals of HydraulicsDokument101 SeitenFundamentals of HydraulicswissamhijaziNoch keine Bewertungen

- Best Practice Guide For Power Transformer Maintenance EEPDokument1 SeiteBest Practice Guide For Power Transformer Maintenance EEPashutosh ambeyNoch keine Bewertungen

- Zenith Service BulettinDokument5 SeitenZenith Service Bulettinmike hilliardNoch keine Bewertungen

- Mechanical Pumps For Vacuum ProcessingDokument10 SeitenMechanical Pumps For Vacuum Processinghwang2Noch keine Bewertungen

- Ijett V39P245Dokument6 SeitenIjett V39P245Mawada RashedNoch keine Bewertungen

- Yellowjacket 13-22Dokument10 SeitenYellowjacket 13-22remwel_Noch keine Bewertungen

- Oil ChargingDokument9 SeitenOil ChargingNang Vu ducNoch keine Bewertungen

- Flash Economizer: Installation, Operation and Maintenance InstructionsDokument2 SeitenFlash Economizer: Installation, Operation and Maintenance InstructionsMaximilianoRodrigoCabestreroNoch keine Bewertungen

- Minggu 11Dokument19 SeitenMinggu 11ryo asg5Noch keine Bewertungen

- Performance and Dimension RCS OLD MANUAL 8INCH2.PDF NewDokument16 SeitenPerformance and Dimension RCS OLD MANUAL 8INCH2.PDF NewJorge A VilalNoch keine Bewertungen

- Onboard Fuel Storage Treatment HandlingDokument2 SeitenOnboard Fuel Storage Treatment HandlingjosecarlosjerezNoch keine Bewertungen

- Bulk Separation of GasDokument7 SeitenBulk Separation of GasEnnecyr Pilling PintoNoch keine Bewertungen

- Installation, Commissioning and Maintenance Guidelines: For Electrohydraulic SystemsDokument0 SeitenInstallation, Commissioning and Maintenance Guidelines: For Electrohydraulic Systemsanta77100% (1)

- Solutions For Reservoir DesignDokument7 SeitenSolutions For Reservoir DesignSympatyagaNoch keine Bewertungen

- 3306 Cylinder Head To Block Joint Repair Procedure (1124, 1101, 1201)Dokument24 Seiten3306 Cylinder Head To Block Joint Repair Procedure (1124, 1101, 1201)Nick Ildefonso Fuenmayor AntunezNoch keine Bewertungen

- PPCO FlushingCentrifugalPumpDokument6 SeitenPPCO FlushingCentrifugalPumprizky efrinaldoNoch keine Bewertungen

- API Mechanical Seal Flushing Plan Part 1Dokument11 SeitenAPI Mechanical Seal Flushing Plan Part 1Dhanraj BaroleNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- Baked Spaghetti: IngredientsDokument1 SeiteBaked Spaghetti: Ingredientsretrospect1000Noch keine Bewertungen

- CrappieDokument6 SeitenCrappieretrospect1000Noch keine Bewertungen

- Shrimp Francesca: IngredientsDokument1 SeiteShrimp Francesca: Ingredientsretrospect1000Noch keine Bewertungen

- Brussels Sprouts PizzaDokument1 SeiteBrussels Sprouts Pizzaretrospect1000Noch keine Bewertungen

- Honey Roasted Red PotatoesDokument1 SeiteHoney Roasted Red Potatoesretrospect1000Noch keine Bewertungen

- Bella's Rosemary Red PotatoesDokument1 SeiteBella's Rosemary Red Potatoesretrospect1000Noch keine Bewertungen

- Stress Concentration Produced by Holes and Notches: D, W, D/W - D/WDokument9 SeitenStress Concentration Produced by Holes and Notches: D, W, D/W - D/Wretrospect1000Noch keine Bewertungen

- AdhesivesDokument1 SeiteAdhesivesretrospect1000Noch keine Bewertungen

- Chocolate Chocolate Chip Cookies IIDokument1 SeiteChocolate Chocolate Chip Cookies IIretrospect1000Noch keine Bewertungen

- Cookie Pralines: IngredientsDokument1 SeiteCookie Pralines: Ingredientsretrospect1000Noch keine Bewertungen

- Freeze ProtectionDokument3 SeitenFreeze Protectionretrospect1000Noch keine Bewertungen

- 2013 Fenwick CatalogDokument22 Seiten2013 Fenwick Catalogretrospect1000Noch keine Bewertungen

- c954 Aluminum BronzeDokument2 Seitenc954 Aluminum Bronzeretrospect1000Noch keine Bewertungen

- Air Maintenance DeviceDokument4 SeitenAir Maintenance DeviceNgô Khoai SắnNoch keine Bewertungen

- Catalogue Oilfree Screw CompressorsDokument4 SeitenCatalogue Oilfree Screw Compressorsramachandran_chemNoch keine Bewertungen

- PFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingDokument4 SeitenPFI ES-4-1985 (R1997) Hydrostatic Testing of Fabricated PipingRodrigo Chambilla VernazaNoch keine Bewertungen

- Singer PRV ManualDokument3 SeitenSinger PRV ManualAdityaNoch keine Bewertungen

- Crowngas Detection System Profile - Doha, QatarDokument8 SeitenCrowngas Detection System Profile - Doha, QatarCrowngas Detection System - Doha, QatarNoch keine Bewertungen

- Mass-Transfer Operations - Robert E. Treybal - 3rd EditionDokument229 SeitenMass-Transfer Operations - Robert E. Treybal - 3rd EditionluucabreraisquierdoNoch keine Bewertungen

- Revised Weld Map (23!07!2015)Dokument15 SeitenRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Topic 7 FF in Res 1Dokument18 SeitenTopic 7 FF in Res 1Aneesch PreethaNoch keine Bewertungen

- EireportbnichollseiDokument9 SeitenEireportbnichollseidalila_agueroNoch keine Bewertungen

- Seatwork No. 2Dokument3 SeitenSeatwork No. 2Allen DagsilNoch keine Bewertungen

- Booher Chem Sketch Activity 1Dokument13 SeitenBooher Chem Sketch Activity 1c_booher9561Noch keine Bewertungen

- Chapter 1Dokument14 SeitenChapter 1John Dave Andales BaguinbinNoch keine Bewertungen

- Alltech Pump ManualDokument1 SeiteAlltech Pump ManualGAUTHAMSANoch keine Bewertungen

- Minor Losses ReportDokument12 SeitenMinor Losses Reportميسرة100% (4)

- AA-RCC6S-dual: $2875/unit (220v50hz, 1ph) $3025/unit (110v50hz, 1ph)Dokument1 SeiteAA-RCC6S-dual: $2875/unit (220v50hz, 1ph) $3025/unit (110v50hz, 1ph)James BindNoch keine Bewertungen

- FM24 Complete ManualDokument35 SeitenFM24 Complete ManualShaffaf ThajudheenNoch keine Bewertungen

- Sample Question Paper:: Explain Two Applications of Check Valve With Suitable DiagramDokument4 SeitenSample Question Paper:: Explain Two Applications of Check Valve With Suitable DiagramD06 suraj kumarNoch keine Bewertungen

- 2020 Sept14 ME004ADokument11 Seiten2020 Sept14 ME004ADaniel ManivoughNoch keine Bewertungen

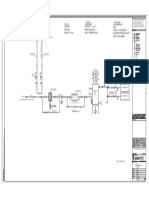

- 10815-PID-01 Sht. 1 of 2 - REV. 3Dokument1 Seite10815-PID-01 Sht. 1 of 2 - REV. 3R.P.PATELNoch keine Bewertungen

- Manual Caldero 750-184 Model Cble-125-200bhpDokument200 SeitenManual Caldero 750-184 Model Cble-125-200bhpvicvargNoch keine Bewertungen