Beruflich Dokumente

Kultur Dokumente

Design Calculations For Slurry Agitators in Alumina Refinery

Hochgeladen von

Christopher LloydOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Calculations For Slurry Agitators in Alumina Refinery

Hochgeladen von

Christopher LloydCopyright:

Verfügbare Formate

Design Calculations for Slurry Agitators in Alumina Refinery

Rajendra Kunwar, India

Today I am presenting the gist of my technical paper on "Motor rating calculations

for slurry mixing agitators in Alumina refinery" which has been published recently in

aluminium issue of the magazine "Minerals & Metals Review" (page 30 and 31 in

MMR, August 2011 issue).

In various technical forums, process experts as well as equipment manufacturers

have opined that the design of agitators for mixing bauxite, residue and hydrate in

Alumina refinery is complicated and tricky issue. In this paper, we will discuss the

subject with brief description of involved terminology, associated design parameters

and methodology with sample motor rating calculations for the slurry mixing agitator

of a Pre-desilication tank of Alumina refinery.

Method to arrive at motor rating:

Impeller power for slurry mixing agitator is calculated using following mathematical

relations

Impeller Power,

P = Np * *N3 * Di5/(16*104) h.p.

Where

Di = Diameter of impeller in meters,

N = Revolution per minute for impeller,

Np = Power number for impeller and

= Specific gravity of slurry.

Sample calculations:

Simplified calculations to arrive at the motor rating for the agitator of Pre-desilication

tank of around 3000 m3 gross capacity with realistic assumptions have been

presented belowFluid Height in Tank , H = 16 m

Diameter of tank, Dt = 14 m

Slurry volume in tank = *Dt2*H/4 = * (14)2*16 /4 = 2463 m3

Solid consistency in Slurry = 50 % (w/w),

Specific gravity of slurry, = 1.602,

Viscosity of slurry, = 550 cp

Agitator Impeller Diameter, Di= 33 % of tank diameter = 14 * 33% m = 4.62 m

Tip speed of Impeller = 290 m/minute,

Drive motor RPM = 1500 rpm.

Gear Box Reduction Ratio = 75

Agitator RPM, N = Drive Motor RPM/Gear Box Reduction Ratio = 1500/75 = 20 rpm

Flow Number: Nq = 0.56

And

Power Number,

Np = 0.51 (assumed figures)

Pumping Capacity = Nq * N * Di3 m3/minute =

= 0.56 * 20 * (4.62) 3

= 1104.44 m 3/min.

= 18.41 m 3/sec.

Area of Tank = * Dt2 = *(14)2 / 4 = 153.94 m2

Bulk fluid Velocity

= pumping capacity/area of tank

= 1104.44 / 153.94= 7.18 m/min.= 23.55 ft./min.

Degree of Agitation = bulk fluid velocity / 6

(For 6 ft/min., degree of agitation =1 and Degree of agitation varies from 0 to 10)

= 23.55 / 6 = 3.93 ~ 4

Annular Area = * (Dt2- Di2 ) /4

Where

Dt = Diameter of tank

Di = Diameter of impeller in meters.

Annular Area = 3.14 * (142 (4.622) / 4 = 137.18 m2

Rising velocity of particles = pumping capacity / annular area

= 1104.44 / 137.18 = 8.051 m/min. = 0.1342 m/sec.

Tank Turnover rate = Pumping capacity / tank capacity

= 1104.44 / 2463 = 0.45 times / min.

Power Number Np

= 0.51

Shaft Power,

= Np* *(Di)5 * N3 /(16 *104)

Where

Np = Impeller power no.,

Di = Diameter of impeller in meters,

Shaft RPM, N = revolutions per minute

Shaft Power, P = 0.51 * 1.602 * (4.402)5 * 203 / (16 *104) = 85.98 h.p.

Taking Gear Box Efficiency = 80% and Drive Motor Efficiency = 95%,

Design margin

= 1.15

Drive Motor Rating = 1.15 * 85.98/(0.80 * 0.95) =130 h.p. = 97.0 kW.

Thus the drive motor of about 100 kW shall be adequate for successful

operation of agitator of 3000 m3 Pre-desilication tank in Alumina refinery.

Conclusions

The developed methodology clearly reveals that motor rating calculations for any

slurry mixing agitator can be carried out easily by simply replacing the associated

input process conditions, operating parameters, dimensions of tanks / vessel and

appropriate power number for impeller in above simplified derivation.

Das könnte Ihnen auch gefallen

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesVon EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNoch keine Bewertungen

- Agitator Power Requirement and Mixing Intensity CalculationDokument27 SeitenAgitator Power Requirement and Mixing Intensity CalculationElizabeth Allende CéspedesNoch keine Bewertungen

- Agitator SizingDokument2 SeitenAgitator Sizingsj_scribdNoch keine Bewertungen

- Agitator Design CalcDokument5 SeitenAgitator Design Calcranjit34380% (5)

- Agitator Power Requirement and Mixing Intensity CalculationDokument27 SeitenAgitator Power Requirement and Mixing Intensity Calculationmpshah29860% (5)

- Agitator Power Requirement and Mixing Intensity CalculationDokument27 SeitenAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- Agitator CalculationDokument4 SeitenAgitator CalculationAnkur Koul100% (4)

- Design Calculations For Slurry AgitatorsDokument19 SeitenDesign Calculations For Slurry Agitatorsmshah222100% (4)

- Design of AgitatorDokument3 SeitenDesign of Agitatorkaps12Noch keine Bewertungen

- Agitator DesignDokument2 SeitenAgitator Designnaruto256100% (1)

- Design of AgitatorDokument12 SeitenDesign of AgitatorPatil HemantNoch keine Bewertungen

- Agitator Guide for Mixing and Stirring Tank ProductsDokument10 SeitenAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591Noch keine Bewertungen

- Design Calculations of Pitch Blade TurbineDokument6 SeitenDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNoch keine Bewertungen

- Agitator Design 5 PDF FreeDokument36 SeitenAgitator Design 5 PDF FreeMeisam MomeniNoch keine Bewertungen

- Vertical Ribbon Mixer DesignDokument12 SeitenVertical Ribbon Mixer DesignHamza Al MahanaNoch keine Bewertungen

- Agitator Design 11 PDF FreeDokument9 SeitenAgitator Design 11 PDF FreeMeisam MomeniNoch keine Bewertungen

- Power Requirement (Agitator and High-Torque Stirrer)Dokument8 SeitenPower Requirement (Agitator and High-Torque Stirrer)DozdiNoch keine Bewertungen

- Design of Agitator 8 Batch Volume PDFDokument3 SeitenDesign of Agitator 8 Batch Volume PDFakash kumarNoch keine Bewertungen

- Project Date Equipment Appd RefDokument2 SeitenProject Date Equipment Appd RefWade ColemanNoch keine Bewertungen

- Tutorial TRK SolutionsDokument16 SeitenTutorial TRK SolutionsPanca WardhaniNoch keine Bewertungen

- Impeller Design For Mixing of SuspensionsDokument16 SeitenImpeller Design For Mixing of SuspensionsFaycel OuerdienNoch keine Bewertungen

- Calculation Double Helical Ribbon PDFDokument7 SeitenCalculation Double Helical Ribbon PDFcesamav100% (1)

- Reactor Geometry and Agitator SelectionDokument26 SeitenReactor Geometry and Agitator SelectionWael Abdel-MageedNoch keine Bewertungen

- Agitator Design CalculationDokument21 SeitenAgitator Design CalculationRupesh Ubale94% (36)

- Mixing CalculationDokument31 SeitenMixing CalculationTubagus100% (1)

- Agitator Power Calculation FormatDokument2 SeitenAgitator Power Calculation FormatSandeep GosaviNoch keine Bewertungen

- Sparger Design GuideDokument11 SeitenSparger Design GuideHarshavardhan D. GorakhNoch keine Bewertungen

- Weir Slurry Classification MethodDokument74 SeitenWeir Slurry Classification MethodJuan Pablo ApazaNoch keine Bewertungen

- 5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and CompressorsDokument3 Seiten5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and Compressorsamir885Noch keine Bewertungen

- Design of paddle type agitator for effluent agitationDokument4 SeitenDesign of paddle type agitator for effluent agitationuttam prabhuNoch keine Bewertungen

- Agitator Design and Speed CalculationsDokument6 SeitenAgitator Design and Speed CalculationsMuhammed Sulfeek0% (1)

- CHAPTER 5 AGITATATION and MIXING PDFDokument42 SeitenCHAPTER 5 AGITATATION and MIXING PDFProfessionalNoch keine Bewertungen

- Mixing With Helical Ribbon AgitatorsDokument9 SeitenMixing With Helical Ribbon AgitatorsWilson Agudelo CatañoNoch keine Bewertungen

- Flow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerDokument15 SeitenFlow Characteristics in Mixers Agitated by Helical Ribbon Blade Impellerkalyan555Noch keine Bewertungen

- Existing:-Pitch Blade Turbine AgitatorDokument5 SeitenExisting:-Pitch Blade Turbine AgitatorPrathmesh Gujarati100% (1)

- Shaft diameter calculation for stainless steelDokument1 SeiteShaft diameter calculation for stainless steelAhmad Ashshiddieqy60% (5)

- Plant Eng Part 2 - ConveyorsDokument30 SeitenPlant Eng Part 2 - ConveyorsLehlohonoloNoch keine Bewertungen

- Slurry Handling Course Covers Pipeline DesignDokument4 SeitenSlurry Handling Course Covers Pipeline DesignarvapoNoch keine Bewertungen

- Mechanical Design of Shaft For Anchor AgitatorDokument11 SeitenMechanical Design of Shaft For Anchor AgitatorRafique AjmeriNoch keine Bewertungen

- Agitator Design Calculation for Blend TankDokument7 SeitenAgitator Design Calculation for Blend Tanknatarajan Ravisankar100% (3)

- Design of AgitatorDokument6 SeitenDesign of AgitatorVishalNoch keine Bewertungen

- The Hydrocyclone: International Series of Monographs in Chemical EngineeringVon EverandThe Hydrocyclone: International Series of Monographs in Chemical EngineeringBewertung: 5 von 5 Sternen5/5 (3)

- Method To Arrive at Motor RatingDokument5 SeitenMethod To Arrive at Motor RatingkiranNoch keine Bewertungen

- Design Calculations For Slurry Agitators: Method To Arrive at Motor RatingDokument21 SeitenDesign Calculations For Slurry Agitators: Method To Arrive at Motor RatingSachin5586Noch keine Bewertungen

- New Microsoft Word Document PDFDokument17 SeitenNew Microsoft Word Document PDFtusharNoch keine Bewertungen

- Pelton Wheel Quiz Solutions - SanjeetDokument8 SeitenPelton Wheel Quiz Solutions - SanjeetSanjeet Kumar100% (1)

- Machinery in Road ConstructionDokument20 SeitenMachinery in Road ConstructionErik Bonilla AlbertoNoch keine Bewertungen

- Exp 2 Performance Parameter of Diesel EngineDokument7 SeitenExp 2 Performance Parameter of Diesel EngineShashwat JainNoch keine Bewertungen

- Car crushing hydraulic circuit analysisDokument22 SeitenCar crushing hydraulic circuit analysisphankhoa83100% (1)

- PPD Week 5.1 LectureDokument28 SeitenPPD Week 5.1 LectureMaster CalculusNoch keine Bewertungen

- Combustion Air Consumption and Volumetric Efficiency: 1.1 ObjectiveDokument3 SeitenCombustion Air Consumption and Volumetric Efficiency: 1.1 ObjectiveHammam Abu ShoshehNoch keine Bewertungen

- Chemical Engineering Design of The Spray DryerDokument6 SeitenChemical Engineering Design of The Spray Dryervictor100% (1)

- Performance at Constant SpeedDokument6 SeitenPerformance at Constant Speedpurnachand raNoch keine Bewertungen

- Mar e Formula 1Dokument3 SeitenMar e Formula 1Raffy ZerimarNoch keine Bewertungen

- EXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable LoadDokument2 SeitenEXP 7 To Determine The Volumetric Efficiency of A Four Stroke Petrol Engine at Variable Load70130046Noch keine Bewertungen

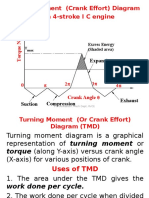

- Turning Moment Diagram & FlywheelDokument88 SeitenTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- Reciprocating Pump Experiment No: 6Dokument6 SeitenReciprocating Pump Experiment No: 6anil kumarNoch keine Bewertungen

- Engeineering Calculation Angels Demin MixbedDokument5 SeitenEngeineering Calculation Angels Demin MixbedropezNoch keine Bewertungen

- I.C. Engine Testing ParametersDokument1 SeiteI.C. Engine Testing ParametersAmit AmitNoch keine Bewertungen

- زندگی پنهان مادر ترزاDokument10 Seitenزندگی پنهان مادر ترزاChristopher LloydNoch keine Bewertungen

- Pressure Independent Control Valves (PICV) : Principle of OperationDokument2 SeitenPressure Independent Control Valves (PICV) : Principle of OperationChristopher LloydNoch keine Bewertungen

- WO2017037540A1Dokument29 SeitenWO2017037540A1Christopher LloydNoch keine Bewertungen

- Energy and Efficiency Characteristics of The Ejector Venturi ScrubberDokument5 SeitenEnergy and Efficiency Characteristics of The Ejector Venturi ScrubberChristopher LloydNoch keine Bewertungen

- Experimental Evaluation of Ball Bar Standard ThermDokument12 SeitenExperimental Evaluation of Ball Bar Standard ThermChristopher LloydNoch keine Bewertungen

- Funk, Baker - Dust Cyclone Technology - A Literature Review PDFDokument12 SeitenFunk, Baker - Dust Cyclone Technology - A Literature Review PDFJorge VeraNoch keine Bewertungen

- CyclonesDokument11 SeitenCyclonesMisdi HabibiNoch keine Bewertungen

- Wet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubbersDokument11 SeitenWet Scrubber Application Guide: Impingement Plate Scrubbers Venturi Scrubbers Eductor Venturi ScrubberssilahganNoch keine Bewertungen

- All-Round Ceramic Protection: by Tim Connors, Blasch Precision Ceramics, USADokument3 SeitenAll-Round Ceramic Protection: by Tim Connors, Blasch Precision Ceramics, USAChristopher LloydNoch keine Bewertungen

- کنترل آشوبDokument41 Seitenکنترل آشوبmshahNoch keine Bewertungen

- EVE 402 Air Pollution Generation and Control: Wet CollectorsDokument8 SeitenEVE 402 Air Pollution Generation and Control: Wet CollectorsChristopher LloydNoch keine Bewertungen

- Comparison of Jet Aeration Systems vs. Diffused Aeration SystemsDokument8 SeitenComparison of Jet Aeration Systems vs. Diffused Aeration SystemsChristopher LloydNoch keine Bewertungen

- Venturi Scrubber Design Project for Air Pollution ControlDokument1 SeiteVenturi Scrubber Design Project for Air Pollution ControlChristopher LloydNoch keine Bewertungen

- Modelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsDokument10 SeitenModelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsChristopher LloydNoch keine Bewertungen

- Balancing of Industrial Ventilation SystemsDokument4 SeitenBalancing of Industrial Ventilation SystemsChristopher LloydNoch keine Bewertungen

- Fire Evacuation Analysis of an AuditoriumDokument8 SeitenFire Evacuation Analysis of an AuditoriumChristopher LloydNoch keine Bewertungen

- Description of Thermal Oxidizers PDFDokument5 SeitenDescription of Thermal Oxidizers PDFChristopher LloydNoch keine Bewertungen

- Fire Evacuation Analysis of an AuditoriumDokument8 SeitenFire Evacuation Analysis of an AuditoriumChristopher LloydNoch keine Bewertungen

- Fire Evacuation Analysis of an AuditoriumDokument8 SeitenFire Evacuation Analysis of an AuditoriumChristopher LloydNoch keine Bewertungen

- Description of Thermal Oxidizers PDFDokument5 SeitenDescription of Thermal Oxidizers PDFChristopher LloydNoch keine Bewertungen

- Description of Thermal Oxidizers PDFDokument5 SeitenDescription of Thermal Oxidizers PDFChristopher LloydNoch keine Bewertungen

- (1647) PDFDokument114 Seiten(1647) PDFChristopher LloydNoch keine Bewertungen

- Water Mist Systems in Tunnels: Some Unanswered QuestionsDokument10 SeitenWater Mist Systems in Tunnels: Some Unanswered QuestionsChristopher LloydNoch keine Bewertungen

- Thermodynamic Analysis of EAF Electrical Energy deDokument17 SeitenThermodynamic Analysis of EAF Electrical Energy demshahNoch keine Bewertungen

- Energy and Exergy of Electric Arc Furnace PDFDokument26 SeitenEnergy and Exergy of Electric Arc Furnace PDFChristopher LloydNoch keine Bewertungen

- Normal To Real Flow Rate and FAD Flow RateDokument25 SeitenNormal To Real Flow Rate and FAD Flow RateChristopher LloydNoch keine Bewertungen

- Notes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelDokument7 SeitenNotes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelChristopher LloydNoch keine Bewertungen

- Capture and Purify Gas Arc Steel-Smelting FurnacesDokument4 SeitenCapture and Purify Gas Arc Steel-Smelting FurnacesChristopher LloydNoch keine Bewertungen

- Modelling of Flows in A Ladle With Gas Stirred Liquid Wood's Metal PDFDokument6 SeitenModelling of Flows in A Ladle With Gas Stirred Liquid Wood's Metal PDFRasul BzNoch keine Bewertungen

- Typical Piping DeliverablesDokument4 SeitenTypical Piping DeliverablesShyam Prasad K S100% (1)

- Case StudiesDokument104 SeitenCase StudiesIshanNoch keine Bewertungen

- 3 Thick CylindersDokument21 Seiten3 Thick CylindersMalay ShahNoch keine Bewertungen

- BS 4504-Part 3.2Dokument31 SeitenBS 4504-Part 3.2Simon LawNoch keine Bewertungen

- The Linea - Heavy Duty Cafe Espresso MachineDokument112 SeitenThe Linea - Heavy Duty Cafe Espresso Machinevicky wicaksanaNoch keine Bewertungen

- Installation AND Maintenance Manual: Always A Step Ahead in TechnologyDokument8 SeitenInstallation AND Maintenance Manual: Always A Step Ahead in TechnologyyoyoNoch keine Bewertungen

- Cp16 Road Crossing AnalysisDokument3 SeitenCp16 Road Crossing Analysisboonico Nicco0% (1)

- Varco BushingsDokument1 SeiteVarco BushingsVision100% (1)

- Ultimate Bearing Capacity of Foundation On Clays - MeyerhofDokument3 SeitenUltimate Bearing Capacity of Foundation On Clays - Meyerhofsreekx0073916100% (1)

- Welding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)Dokument266 SeitenWelding Stainless Steel - Questions and Answers A Guide For Troubleshooting Stainless Steel Welding-Related Problems - AWS (2013)arnoldbatista55100% (1)

- NEW - I Can Offer FRF / SGO 2 BIN Conversion and BIN 2 SGO / FRF For Almost ALL VAG DSG Gearboxes !! PRICES Between 50 and 100 EurDokument1 SeiteNEW - I Can Offer FRF / SGO 2 BIN Conversion and BIN 2 SGO / FRF For Almost ALL VAG DSG Gearboxes !! PRICES Between 50 and 100 Euralmia tronicsNoch keine Bewertungen

- Feejoy BrochureDokument6 SeitenFeejoy BrochureOswaldo HernandezNoch keine Bewertungen

- Simulation and Test Correlation of Wheel Impact TestDokument8 SeitenSimulation and Test Correlation of Wheel Impact Testesmaeel ghafariNoch keine Bewertungen

- 1618 TP-Sales Kit AMW 1618Dokument23 Seiten1618 TP-Sales Kit AMW 1618niharjyotilahonNoch keine Bewertungen

- BOQ Pengumuman 1065.RKSDokument2 SeitenBOQ Pengumuman 1065.RKSDangolNoch keine Bewertungen

- RAPT - PT Slab and Beam Design Procedure Rev01Dokument17 SeitenRAPT - PT Slab and Beam Design Procedure Rev01AlirezaNoch keine Bewertungen

- Schapery RA 1962 (PHD Dissertation)Dokument182 SeitenSchapery RA 1962 (PHD Dissertation)Marcelo MedeirosNoch keine Bewertungen

- Denison Hydraulics Stack Valves Cetop 03 GuideDokument13 SeitenDenison Hydraulics Stack Valves Cetop 03 Guideabuzer1981100% (1)

- Cypecad Vs Etabs - En1Dokument37 SeitenCypecad Vs Etabs - En1dskumar49Noch keine Bewertungen

- Maintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesDokument12 SeitenMaintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesjohnNoch keine Bewertungen

- BWT 7000 SCDokument1 SeiteBWT 7000 SCMehdi AcilNoch keine Bewertungen

- Key information on motor dataDokument8 SeitenKey information on motor dataRadj90Noch keine Bewertungen

- Soldier Pile and Lagging Caltan 1990 Tedds CalcDokument2 SeitenSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQNoch keine Bewertungen

- พอฤทัย วิริยะภาค26 3.5Dokument2 Seitenพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคNoch keine Bewertungen

- Process Design of Distillation ColumnDokument6 SeitenProcess Design of Distillation ColumncristianoNoch keine Bewertungen

- Inst Headers Install TitianDokument3 SeitenInst Headers Install TitianhuntersgreenNoch keine Bewertungen

- Baja Design Report PDFDokument9 SeitenBaja Design Report PDFZubair HussainNoch keine Bewertungen

- 2.CH890.02 - IMA - S 223.1422-02.enDokument63 Seiten2.CH890.02 - IMA - S 223.1422-02.enJoe Vargas JulcaNoch keine Bewertungen

- Paper On GravitationDokument8 SeitenPaper On GravitationShama tanveerNoch keine Bewertungen

- NR24R Imo InformmationDokument12 SeitenNR24R Imo Informmationronny ArdiansyahNoch keine Bewertungen