Beruflich Dokumente

Kultur Dokumente

Sue Klassen

Hochgeladen von

suzie480 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

76 Ansichten3 SeitenResults-oriented professional with demonstrated achievements in quality assurance, management, and technical functions. Highly adaptable and able to work well under pressure in a fast-paced environment; capable of prioritizing workload and scheduling teams effectively. EDUCATION AND TRAINING Trios College London ON February 2010 Network Engineer Diploma Program Certifications MCITP: Enterprise Support Technician Microsoft Exchange Server 2007 Windows Server 2008 - Active Directory Configuration.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenResults-oriented professional with demonstrated achievements in quality assurance, management, and technical functions. Highly adaptable and able to work well under pressure in a fast-paced environment; capable of prioritizing workload and scheduling teams effectively. EDUCATION AND TRAINING Trios College London ON February 2010 Network Engineer Diploma Program Certifications MCITP: Enterprise Support Technician Microsoft Exchange Server 2007 Windows Server 2008 - Active Directory Configuration.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

76 Ansichten3 SeitenSue Klassen

Hochgeladen von

suzie48Results-oriented professional with demonstrated achievements in quality assurance, management, and technical functions. Highly adaptable and able to work well under pressure in a fast-paced environment; capable of prioritizing workload and scheduling teams effectively. EDUCATION AND TRAINING Trios College London ON February 2010 Network Engineer Diploma Program Certifications MCITP: Enterprise Support Technician Microsoft Exchange Server 2007 Windows Server 2008 - Active Directory Configuration.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Sue Klassen

515 8 Maison Parc Court 519-859-1880

Thornhill L4J 9K5

suzie48@live.ca

_____________________________________________________________________________________

PROFESSIONAL PROFILE

_____________________________________________________________________________

_

Results-oriented professional with demonstrated achievements in quality assurance, management, and

technical functions. Strong team leader with excellent communication and interpersonal skills who

motivates staff and encourages changes for improvement. Highly adaptable and able to work well under

pressure in a fast-paced environment; capable of prioritizing workload and scheduling teams effectively

to meet operational requirements. Demonstrated abilities:

Consistently supervises using a ‘lead by example’ style

Builds highly motivated teams who are dedicated to achieve company goals

Coordinated and managed the start up of two production lines including installation of production

equipment and hiring and training of required employees

EDUCATION AND TRAINING

Trios College London ON February 2010

Network Engineer Diploma Program

Certifications

MCITP: Enterprise Support Technician Microsoft Exchange Server 2007

Windows Server 2008 – Active Directory Configuration ComptIA Net+

Blackberry Certified System Administrator Linux+

BlackBerry Certified Support Specialist

Windows Server 2008 – Active Directory Configuration

Windows Server 2008 – Network Infrastructure Configuration

Windows Server 2008 – Administrator

Ministry Of Education, ON Canada

High School Equivalency Certificate

Manufacturing Leadership Certificate Program

Supervisory Skills for Business and Industry Coaching and developing people

Maintaining Effective Teams Computer Literacy/Applications

Continuous Improvement Processes QS9000

CAREER HISTORY

Therm-O-Disc Canada, St. Thomas, ON 2005 – 2008

Quality Supervisor

Maintains awareness of new manufacturing technology and equipment and Industrial measuring

equipment, investigates their potential application, and recommends incorporation of new technology

for Company applications where feasible and practical

Develops plans and work schedules for quality to achieve maximum effective utilization of all

available resources

Maintains an adequately skilled work force consistent with production goals and schedules

Anticipates problems and implements procedures to offset these problems

Provides training and guidance as required to personnel

Recommends and schedules overtime as production schedules warrant

Recommends and implements changes in methods and procedures and policies

Interfaces with other shifts and departments

Prepares regular Weekly and Monthly reports

Ensures that all TOD policies and procedures are encouraged and complied with by all employees,

including employee safety, equal opportunity and all other Company sponsored programs

Conducts employee performance reviews and corrective/disciplinary actions as needed

Provides input to management regarding cost reduction goals and capital expenditures

Assists in preparation of operational budgets

Ensures compliance with ISO quality procedures and policies and schedules and participates in ISO

Compliance audits

Ensure compliance to CSA and UL regulations

H&G Powder Painting, London, ON 2003 – 2005

Quality Manager

Prepared production part approval, part packages and presented to customers

Prepared, implemented, and maintained the ISO9001quality systems

Wrote method sheets and trained employees; Trained internal ISO auditors

Tested and adjusted chemicals in the wash system

Performed daily quality audits and customer satisfaction surveys

Johnson Controls, Tillsonburg, ON 1983 – 2003

Plant Superintendent

Developed and submitted production budget to top management

Ensured employee evaluations were performed in a timely manner

Member of the joint health and safety committee, ergonomics improvement team, and member of the

grievance committee

Responsible for all aspects of QS9000 implementation and follow-up audits

Tracked cost savings through six sigma, kaizan, and continuous improvement activities

Developed plans and work schedules to achieve maximum effective utilization of all available

resources

Developed tracking procedures and reported Company goals and objectives

Participated in contract negotiations

Responsible for 100 hourly and 3 salary employees

Developed and maintained manning spreadsheets for current and forecasted manning

Experience with all aspects of shipping and receiving departments

Johnson Controls, Tillsonburg, ON 1994 – 1999

Production Supervisor

Supervise and oversee employees on the production floor

Coach and mentor staff to develop performance to company standards

Ensure maximum use of available capacity and effective use of labor

Proactively manage production costs and minimize waste

Ensure that on a daily basis all company standards and customer commitments are

followed within the plant

Monitor all production control procedures, coordinate & communicate changes in

schedules to meet unforeseen conditions

Build effective relationships with all internal departments to produce a superior product

Implement and maintain plant safety regulations and housekeeping practices and

encourage employees to become safety conscious

Maintain effective departmental quality procedures

Supervise employees to accomplish productivity, safety, quality and efficiency goals

Prepare and submit reports as required

Process Technician 1991 – 1994

Production Technician 1983 – 1991

References Available Upon Request

Das könnte Ihnen auch gefallen

- Mohammad ShukriDokument5 SeitenMohammad ShukriMohammed Shukri Al QudraNoch keine Bewertungen

- HVAC TechnicianDokument2 SeitenHVAC Technicianapi-121313522Noch keine Bewertungen

- Factory JDDokument16 SeitenFactory JDSatyam DixitNoch keine Bewertungen

- Operations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsDokument2 SeitenOperations Continuous Improvement Manager in Phoenix AZ Resume Paul RobertsPaulRoberts2Noch keine Bewertungen

- Quality Engineering Operations Director in Toledo OH Resume Kelly OkdieDokument2 SeitenQuality Engineering Operations Director in Toledo OH Resume Kelly OkdieKellyOkdieNoch keine Bewertungen

- Sample Quality Assurance ResumeDokument2 SeitenSample Quality Assurance ResumeProbal SilNoch keine Bewertungen

- Manufacturing Engineer Production Manager in New York City Resume Ivan DominguezDokument2 SeitenManufacturing Engineer Production Manager in New York City Resume Ivan DominguezIvanDominguezNoch keine Bewertungen

- Dreamzone Varanasi Visualcv ResumeDokument4 SeitenDreamzone Varanasi Visualcv Resumeyiloy64051Noch keine Bewertungen

- Plant HeadDokument25 SeitenPlant Headpankajmpawar1986Noch keine Bewertungen

- Resume Ajaykoul.Dokument3 SeitenResume Ajaykoul.Monica KanganNoch keine Bewertungen

- Quality Manager or Quality EngineerDokument3 SeitenQuality Manager or Quality Engineerapi-77217896Noch keine Bewertungen

- KhalidDokument3 SeitenKhalidMuhammad FarooqNoch keine Bewertungen

- Manufacturing Team Leader Generic JDDokument4 SeitenManufacturing Team Leader Generic JDTaufiq KimasNoch keine Bewertungen

- Naukri ShrishailBChougula (23y 0m)Dokument4 SeitenNaukri ShrishailBChougula (23y 0m)Amit SinhaNoch keine Bewertungen

- Manufacturing Skill Standards Council OverviewDokument22 SeitenManufacturing Skill Standards Council OverviewMatthewNoch keine Bewertungen

- VP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerDokument2 SeitenVP Quality Lean Sigma Development in TX OK MO KS Resume Mark FellerMark FellerNoch keine Bewertungen

- Mark Knofler: Career OverviewDokument2 SeitenMark Knofler: Career OverviewknoflerNoch keine Bewertungen

- Job OverviewDokument4 SeitenJob OverviewSrinivasarao YadlapalliNoch keine Bewertungen

- Job Description: Roles and ResponsibilitiesDokument3 SeitenJob Description: Roles and ResponsibilitiesbhushanNoch keine Bewertungen

- Mark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunaDokument2 SeitenMark Daniel Atienza. Bañarez: Barangay Real Calamba City, LagunamarkNoch keine Bewertungen

- Thomas Clark: - Director of ManufacturingDokument2 SeitenThomas Clark: - Director of ManufacturingHitendra Nath BarmmaNoch keine Bewertungen

- Functional Area:: ManufacturingDokument4 SeitenFunctional Area:: ManufacturingHuman ResorceNoch keine Bewertungen

- Production PPC Leader Production SupervisorDokument3 SeitenProduction PPC Leader Production SupervisornorlieNoch keine Bewertungen

- Vaibhav CVDokument3 SeitenVaibhav CVSoham MalpathakNoch keine Bewertungen

- Naveen Tejpal ResumeDokument3 SeitenNaveen Tejpal ResumeNaveen TejpalNoch keine Bewertungen

- Production Manager or Production SupervisorDokument3 SeitenProduction Manager or Production Supervisorapi-121382640Noch keine Bewertungen

- Quality EngineerDokument3 SeitenQuality Engineerapi-777738350% (1)

- Quality Manager in Chicago IL Resume Kevin McMahonDokument2 SeitenQuality Manager in Chicago IL Resume Kevin McMahonKevinMcMahon100% (2)

- WAHID HUSSAIN - CV - Doc-1Dokument2 SeitenWAHID HUSSAIN - CV - Doc-1Mubi MalikNoch keine Bewertungen

- Maintenance Manager Generic JDDokument5 SeitenMaintenance Manager Generic JDabderrahmane messaounNoch keine Bewertungen

- Operations Manager Medical Device in Minneapolis ST Paul MN Resume Kevin RileyDokument2 SeitenOperations Manager Medical Device in Minneapolis ST Paul MN Resume Kevin RileyKevin RileyNoch keine Bewertungen

- Abhijtt-Resume: Profile SummaryDokument5 SeitenAbhijtt-Resume: Profile SummaryDrSyed ShujauddinNoch keine Bewertungen

- Job Description - GM IndiaDokument2 SeitenJob Description - GM Indiasuresh sivadasanNoch keine Bewertungen

- Program Manager Electronic Manufacturing in Melbourne FL Resume Joseph SmithDokument2 SeitenProgram Manager Electronic Manufacturing in Melbourne FL Resume Joseph SmithJosephSmith2100% (1)

- Bill Hill ResumeDokument5 SeitenBill Hill ResumeenderjosNoch keine Bewertungen

- Pradeep Kumar Updated CVDokument4 SeitenPradeep Kumar Updated CVMallesh QCNoch keine Bewertungen

- Quality Manager & Production Manager CompetencyDokument6 SeitenQuality Manager & Production Manager CompetencyManoj MehraNoch keine Bewertungen

- Operations Logistics Manager in Newport News Hampton Norfolk VA Resume Tracy WatkinsDokument2 SeitenOperations Logistics Manager in Newport News Hampton Norfolk VA Resume Tracy WatkinsTracyWatkinsNoch keine Bewertungen

- Quality Improvement Manager Engineer in Lincoln NE Resume Monte BainterDokument2 SeitenQuality Improvement Manager Engineer in Lincoln NE Resume Monte BainterMonteBainterNoch keine Bewertungen

- Production Manager Operations Supervisor in New York City Resume Ariel GatewoodDokument3 SeitenProduction Manager Operations Supervisor in New York City Resume Ariel GatewoodArielGatewoodNoch keine Bewertungen

- Shubailat - Omar - Quality and MBA Leadership Resume (June 09)Dokument3 SeitenShubailat - Omar - Quality and MBA Leadership Resume (June 09)Omar ShubailatNoch keine Bewertungen

- Manuel Felipe Solís Serra Rojas IDMA07-B 6385: The ChallengeDokument6 SeitenManuel Felipe Solís Serra Rojas IDMA07-B 6385: The ChallengeManuel SolisNoch keine Bewertungen

- Samip C Gaikwad: Currently Associated Artheon Battery Company PVT - Ltd. As A Quality Deputy Manager.Dokument2 SeitenSamip C Gaikwad: Currently Associated Artheon Battery Company PVT - Ltd. As A Quality Deputy Manager.Samip GaikwadNoch keine Bewertungen

- Naveen Tejpal ResumeDokument3 SeitenNaveen Tejpal ResumeNaveen TejpalNoch keine Bewertungen

- The Production Manager 'S Job Summary:: General and AdministrativeDokument2 SeitenThe Production Manager 'S Job Summary:: General and AdministrativeDe Silva ShmapkNoch keine Bewertungen

- Manufacturing Plant Manager Resume SampleDokument0 SeitenManufacturing Plant Manager Resume SamplePrem Singh LaishangbamNoch keine Bewertungen

- P.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludeDokument2 SeitenP.O. Box 12672 Albany, NY 12212-2672: Professional Strengths IncludesdvikkiNoch keine Bewertungen

- VP Quality Operations Executive in Kansas City MO Resume Saul PachecoDokument3 SeitenVP Quality Operations Executive in Kansas City MO Resume Saul PachecoSaulPacheco100% (2)

- Olaigbe-Cv Rev 2.0Dokument3 SeitenOlaigbe-Cv Rev 2.0Idehen KelvinNoch keine Bewertungen

- Revised JD Process Engineers - Press ShopDokument2 SeitenRevised JD Process Engineers - Press ShopAmiya KumarNoch keine Bewertungen

- VP Director Operations Manufacturing in Chicago IL Resume Erik PetersonDokument2 SeitenVP Director Operations Manufacturing in Chicago IL Resume Erik PetersonErikPeterson1Noch keine Bewertungen

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDokument3 SeitenDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2Noch keine Bewertungen

- Industrial Engineer in DMV DE PA NJ Resume Olukayode Ademola AlabiDokument6 SeitenIndustrial Engineer in DMV DE PA NJ Resume Olukayode Ademola AlabiOlukayodeAdemolaAlabiNoch keine Bewertungen

- William Hemming 2023Dokument3 SeitenWilliam Hemming 2023fin0522Noch keine Bewertungen

- Unmesh CV PDFDokument5 SeitenUnmesh CV PDFUnmesh UnnikrishnanNoch keine Bewertungen

- Career Objective: Nagarajan PalanysamyDokument4 SeitenCareer Objective: Nagarajan PalanysamySarvean TharanNoch keine Bewertungen

- Resume of Swallace901Dokument3 SeitenResume of Swallace901api-28494294Noch keine Bewertungen

- QA QC Job DescriptionDokument10 SeitenQA QC Job DescriptionVaibhav PatilNoch keine Bewertungen

- SK Kamaluddin (Resume)Dokument4 SeitenSK Kamaluddin (Resume)VIVEK SHAKYANoch keine Bewertungen

- Laboratory Cold ChainDokument22 SeitenLaboratory Cold ChainEmiNoch keine Bewertungen

- SPA - MichaelDokument1 SeiteSPA - Michaelgilberthufana446877Noch keine Bewertungen

- Mushrooms and Religion: Amanita MuscariaDokument8 SeitenMushrooms and Religion: Amanita MuscariaGummyCola50% (2)

- Answers To Your Questions About Circumcision and HIV/AIDSDokument2 SeitenAnswers To Your Questions About Circumcision and HIV/AIDSAlex BrownNoch keine Bewertungen

- Assignment - Lab Accidents and PrecautionsDokument6 SeitenAssignment - Lab Accidents and PrecautionsAnchu AvinashNoch keine Bewertungen

- Riber 6-s1 SP s17-097 336-344Dokument9 SeitenRiber 6-s1 SP s17-097 336-344ᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢNoch keine Bewertungen

- Valve Material SpecificationDokument397 SeitenValve Material Specificationkaruna34680% (5)

- Ventricular Septal DefectDokument8 SeitenVentricular Septal DefectWidelmark FarrelNoch keine Bewertungen

- Paper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Dokument11 SeitenPaper Specific Instructions:: GATE Chemical Engineering MSQ Paper - 1Mayank ShelarNoch keine Bewertungen

- Mycotoxin in Food Supply Chain (Peanuts)Dokument2 SeitenMycotoxin in Food Supply Chain (Peanuts)Ghanthimathi GvsNoch keine Bewertungen

- ATI Respiratory PowerpointDokument90 SeitenATI Respiratory PowerpointAnn KelseaNoch keine Bewertungen

- Biopolymers: Overview of Several Properties and Consequences On Their ApplicationsDokument10 SeitenBiopolymers: Overview of Several Properties and Consequences On Their ApplicationsrafacpereiraNoch keine Bewertungen

- 5SDD 71B0210Dokument4 Seiten5SDD 71B0210Merter TolunNoch keine Bewertungen

- Basics of Fire SprinklerDokument21 SeitenBasics of Fire SprinklerLeo_1982Noch keine Bewertungen

- Guideline On Smacna Through Penetration Fire StoppingDokument48 SeitenGuideline On Smacna Through Penetration Fire Stoppingwguindy70Noch keine Bewertungen

- Appendix B - Distance Tables - Metric Units PDFDokument15 SeitenAppendix B - Distance Tables - Metric Units PDFitisINoch keine Bewertungen

- University of Puerto Rico at PonceDokument16 SeitenUniversity of Puerto Rico at Ponceapi-583167359Noch keine Bewertungen

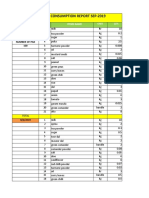

- Daily Staff Food Consumption Reports Sep-2019Dokument4 SeitenDaily Staff Food Consumption Reports Sep-2019Manjit RawatNoch keine Bewertungen

- Electri RelifDokument18 SeitenElectri Relifsuleman247Noch keine Bewertungen

- Current Concepts of Enzyme Histochemistry in Modern PathologyDokument11 SeitenCurrent Concepts of Enzyme Histochemistry in Modern PathologyRosa AquinoNoch keine Bewertungen

- Multi-Wing Engineering GuideDokument7 SeitenMulti-Wing Engineering Guidea_salehiNoch keine Bewertungen

- Health Promotion Officers - CPD Booklet Schedule PDFDokument5 SeitenHealth Promotion Officers - CPD Booklet Schedule PDFcharles KadzongaukamaNoch keine Bewertungen

- Cultivation Vaderstad Manual 2017Dokument128 SeitenCultivation Vaderstad Manual 2017deroryNoch keine Bewertungen

- Characteristics of Testable HypothesesDokument30 SeitenCharacteristics of Testable HypothesesMarivic Diano67% (3)

- Inlet Manifold Pressure - Test: Testing and AdjustingDokument2 SeitenInlet Manifold Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHENoch keine Bewertungen

- GrowNote Faba South 3 Pre PlantingDokument22 SeitenGrowNote Faba South 3 Pre PlantingDawitNoch keine Bewertungen

- Flame Retardant and Fire Resistant Cable - NexansDokument2 SeitenFlame Retardant and Fire Resistant Cable - NexansprseNoch keine Bewertungen

- SGT PDFDokument383 SeitenSGT PDFDushyanthkumar DasariNoch keine Bewertungen

- TraceGains Inspection Day FDA Audit ChecklistDokument2 SeitenTraceGains Inspection Day FDA Audit Checklistdrs_mdu48Noch keine Bewertungen

- DX340LC: Crawler ExcavatorDokument20 SeitenDX340LC: Crawler ExcavatorFeristha Meriani TabitaNoch keine Bewertungen