Beruflich Dokumente

Kultur Dokumente

Acast - PS 1870 - Rev - 2

Hochgeladen von

bhavin178Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Acast - PS 1870 - Rev - 2

Hochgeladen von

bhavin178Copyright:

Verfügbare Formate

1602 Wagner Avenue

Erie, PA 16510

Title

Scope:

Radiographic Inspection of Steel Castings

This process specification covers the inspection of steel castings

by outside vendors. This includes first piece sample qualification,

process qualification and inspection of castings of qualified parts

from suppliers.

Reference documents: Drawings attached.

The qualification process and inspection for process for castings to be produced at a

specified vendor will be as follows. No repair welding is permitted to meet acceptance

of the First Piece Inspection or the Process Qualification.

Map of Castings:

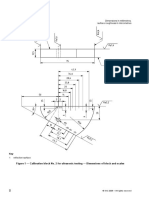

Large 1 Piece castings (10-16): The casting is divided into a grid defined

by three sections axially and the flange (Axial 1-3 and Flange) in Section A-A

on Page 4 and into ten 36 radial segments in the top view (Radial 1-10).

There are also areas labeled Boss, Bottom, Pad 1 and Pad 2. NOTE: on 16

castings pad 1 and 2 are centered on the nozzle opening and Pad 1 is above

the nozzle and Pad 2 is below the nozzle.

Large Ring Nozzle castings (8-16): The casting is divided into a grid

defined by three sections axially (Axial 1-3) in Section A-A on Page 5 and into

ten 36 radial segments in the top view (Radial 1-10). There are also areas

labeled Boss, Pad 1 and Pad 2. NOTE: on 16 castings pad 1 and 2 are

centered on the nozzle opening and Pad 1 is above the nozzle and Pad 2 is

below the nozzle.

Large Base Castings (8-16): The casting is divided into a grid defined by 1

section axially and the 4 and into ten 36 radial segments in the top view

(Radial 1-10). There are also areas labeled Boss, Bottom, Pad 1 and Pad 2.

Small 1 Piece castings (2-6): The casting is divided into a grid defined by

one or two sections axially (as appropriate for the size of film used) and the

flange (Axial 1-2 and Flange) in Section A-A on Page 6 and into 5 72 radial

segments in the top view (Radial 1-5). There are also areas labeled Boss,

Bottom, Pad 1 and Pad 2 (only 1 pad on 2 castings).

Misc. Pressure Castings: These castings include, but are not limited to RB

bodies, cast covers, nozzle sections, etc. The casting is divided into a grid

defined by three sections axially and the flange (Axial 1-3 and Flange) in

Section A-A on Page 4 and into ten 36 radial segments in the top view (Radial

1-10). There are also areas labeled Boss, Bottom, Pad 1 and Pad 2.

First Piece (Sample) Inspection: The first sample (no more than two pieces) are to

be inspected via 100% radiographic inspection (for the areas defined in the attached

drawing(s)) using the acceptance criteria specified below. Radiographic reports are to

Drawing Number: PS-1870

Drawn By: GHW, 9/8/06

Approved By: JL, 9/8/06

Drawing Revision: 2

Revision Reference No.:

2006E0267

Page 1 of 5

1602 Wagner Avenue

Erie, PA 16510

be submitted to FMC Engineering and Quality Control for approval prior of shipment of

the castings.

Process Qualification: Following approval of the first sample, the next 20 parts will

be for the process being qualified via a partial radiograph of each of the parts. Two

radiographs (180 apart, if applicable, must not be two adjacent sections) of each of

the areas of the axial segments defined by the axial and radial grid (for example Axial

1 and Radial 1 and Axial 1 and Radial 5 total of two radiographs) are to be

radiographed on each of the castings. No two axial segments shall be located in the

same radial segment on each casting. The boss, pad 1, pad 2, and the bottom shall

be radiographed on every 5th casting produced.

Areas radiographed shall not be repeated until each quadrant is inspected on castings

produced. This is regardless of the number of castings per PO.

Inspection of Qualified Castings: For line items with a quantity greater then 10,

th

every 10 casting must be radiographed (I.E. qty 40, 4 X-rays - qty 55, 5 X-rays). For

line items with a quantity less than 10, 1 casting is to be radiographed.

Inspection procedure consists of two radiographs (180 apart, if applicable, must not

be two adjacent sections) of each of the areas of the axial segments defined by the

axial and radial grid (for example Axial 1 and Radial 1 and Axial 1 and Radial 5 total

of two radiographs) are to be radiographed on each of the castings. No two axial

segments shall be located in the same radial segment on each casting. The boss,

pad 1, pad 2, and the bottom shall be radiographed.

Areas radiographed shall not be repeated until each quadrant is inspected on castings

produced. This is regardless of the number of castings per PO. Any weld repair of

castings shall be in accordance with PS-1875

Radiographic Inspection for Materials acc. to ASTM Standards: The castings

shall be radiographed per Appendix 7-2 (c) of ASME Section VIII Division 1. All

reports are to be certified by ASNT SNT-TC-1A Level 2 qualified individuals.

Certification of individuals qualifications to ASNT SNT-TC-1A Level 2 are to be

supplied upon request of FMC.

Radiographic Inspection for Materials acc. to European DIN EN Standards: The

scope of testing for steel castings is dependent of the Quality Level and stipulated in

technical Bulletin W5 Table 2 of AD2000 Regulation. The Quality Level is defined in

Table1 of AD2000-W5.

Drawing Number: PS-1870

Drawn By: GHW, 9/8/06

Approved By: JL, 9/8/06

Drawing Revision: 2

Revision Reference No.:

2006E0267

Page 2 of 5

1602 Wagner Avenue

Erie, PA 16510

Excerpt-Table1 of AD2000-W5

Quality Level

Allowable max.

Allowable max.

RT(4)

Working

Working Pressure

bar

Temperature

C

1(1)

Welding Ends

1

2

> 450

> 80

2

3

up to 450

up to 80

3

(1)

Linear or alighned indications, when detected by surface testing are not permitted

(4)

Radiographic examination RT in accordance with DIN EN 12680/acceptance criteria

in accordance with Appendix 1 AD 2000-Merkblatt

All reports are to be certified by PED/ EN473 Level 2 qualified individuals.

Certification of individuals qualifications to PED/ EN 473 Level 2 are to be supplied

upon request of FMC.

Acceptance Criteria are defined in technical Bulletin W5 Addendum 1 Table A1 of

AD2000 Regulation.

For castings having radiographed thickness up to 2 inches (51 mm), the radiographs

shall be compared to those in ASTM E446, Standard Reference Radiographs for

Steel Castings Up to 2 in. (51 mm) in Thickness. For castings having radiographed

thickness 2 inches (51 mm) to 4 in. (114 mm), the radiographs shall be compared

to those in ASTM E186, Standard Reference Radiographs for Heavy Walled [2 to 4

1/2 in. (51 mm to 114 mm)] Steel Castings. The maximum acceptable severity levels

for imperfections shall be as follows:

Imperfection Category

A Gas porosity

B Sand and Slag

C Shrinkage (all types)

D Cracks

E Hot Tears

F - Inserts

Maximum Severity Level

3

3

3

0

0

0

Deliverables:

Certificate of conformance to this specification must be supplied with each shipment

referencing the affected heat numbers, how many castings were inspected, and a

signature of the 3d party inspector certifying conformance. Third party inspector can

work for the same foundry, however, they must not report to/through production.

Inspection results are to be kept by the supplier for a minimum of 7 years and be

available for review by FMC personnel or their designate during an audit.

Drawing Number: PS-1870

Drawn By: GHW, 9/8/06

Approved By: JL, 9/8/06

Drawing Revision: 2

Revision Reference No.:

2006E0267

Page 3 of 5

1602 Wagner Avenue

Erie, PA 16510

Heat number of the casting being x-rayed must be visible on the x-ray (lead letters or

equivalent). Each casting that is x-rayed will be marked as such (indelible ink, etc.) so

FMC can verify x-ray results.

In the event of a major change to the patterns, the first part will be subjected to 100%

x-ray. Assuming the part passes, you can resume the in-process inspection interval.

Drawing Number: PS-1870

Drawn By: GHW, 9/8/06

Approved By: JL, 9/8/06

Drawing Revision: 2

Revision Reference No.:

2006E0267

Page 4 of 5

Drawn By: GHW, 9/8/06

Approved By: JL, 9/8/06

Drawing Number: PS-1870

Revision Reference No.:

2006E0267

Page 5 of 5

Drawing Revision: 2

1602 Wagner Avenue

Erie, PA 16510

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- NORSOK Standard D-010 Rev 4Dokument224 SeitenNORSOK Standard D-010 Rev 4Ørjan Bustnes100% (7)

- ISO 2400-Calibration Block No.1Dokument1 SeiteISO 2400-Calibration Block No.1bhavin178Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Feeding Systems FosecoDokument12 SeitenFeeding Systems Fosecobhavin178Noch keine Bewertungen

- Quality Management System (QMS) ManualDokument28 SeitenQuality Management System (QMS) Manualbhavin178100% (8)

- BS en 12681-1:2017Dokument2 SeitenBS en 12681-1:2017bhavin178Noch keine Bewertungen

- BS en Iso 16826-2014 PDFDokument26 SeitenBS en Iso 16826-2014 PDFbhavin178Noch keine Bewertungen

- Special Alloy Steel MaterialsDokument8 SeitenSpecial Alloy Steel Materialsbhavin178Noch keine Bewertungen

- Steel Grades HandbookDokument6 SeitenSteel Grades Handbookbhavin178Noch keine Bewertungen

- DIN EN 1369-Acceptance TableDokument2 SeitenDIN EN 1369-Acceptance Tablebhavin178Noch keine Bewertungen

- BS EN ISO 9934-1 Current CalculationDokument3 SeitenBS EN ISO 9934-1 Current Calculationbhavin178Noch keine Bewertungen

- EN 1369:2012 (E) DIN EN 1369:2013-01: 5.2.1 GeneralDokument1 SeiteEN 1369:2012 (E) DIN EN 1369:2013-01: 5.2.1 Generalbhavin178100% (1)

- EN 12681-1-IQI - ClassADokument1 SeiteEN 12681-1-IQI - ClassAbhavin178Noch keine Bewertungen

- BS EN ISO 9934-1-Type of MagnetizationDokument3 SeitenBS EN ISO 9934-1-Type of Magnetizationbhavin178Noch keine Bewertungen

- BS EN ISO 9934-1 Current RectificationDokument1 SeiteBS EN ISO 9934-1 Current Rectificationbhavin178Noch keine Bewertungen

- Annex D Severity Levels For Aluminium Alloy and Magnesium Alloy CastingsDokument2 SeitenAnnex D Severity Levels For Aluminium Alloy and Magnesium Alloy Castingsbhavin178Noch keine Bewertungen

- Annex E Severity Levels For Copper Alloy Castings: (Normative)Dokument2 SeitenAnnex E Severity Levels For Copper Alloy Castings: (Normative)bhavin178Noch keine Bewertungen

- Table A.2 - Image Quality Requirements For Testing Class B: BS EN 12681-1:2017Dokument1 SeiteTable A.2 - Image Quality Requirements For Testing Class B: BS EN 12681-1:2017bhavin178Noch keine Bewertungen

- EN ISO 7963 - Calibration Block No.2 PDFDokument1 SeiteEN ISO 7963 - Calibration Block No.2 PDFbhavin178Noch keine Bewertungen

- Complete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface FinishDokument15 SeitenComplete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface Finishbhavin178Noch keine Bewertungen

- Materials and Melt: Batching SmeltingDokument4 SeitenMaterials and Melt: Batching Smeltingbhavin178Noch keine Bewertungen

- FANUC at IMTEX FORMING - 2016 21 26 January, 2016Dokument1 SeiteFANUC at IMTEX FORMING - 2016 21 26 January, 2016bhavin178Noch keine Bewertungen

- Sir - 11 - 21 Rate List 2022Dokument10 SeitenSir - 11 - 21 Rate List 2022akshayNoch keine Bewertungen

- Thermodynamics Nozzle 1Dokument19 SeitenThermodynamics Nozzle 1waseemjuttNoch keine Bewertungen

- GSM RF Interview QuestionsDokument26 SeitenGSM RF Interview QuestionsmohammedelrabeiNoch keine Bewertungen

- The Voice: and The Musical InstrumentsDokument12 SeitenThe Voice: and The Musical InstrumentsnireadaetaNoch keine Bewertungen

- STP Tender Document For 08.05.2018Dokument32 SeitenSTP Tender Document For 08.05.2018Arunprasad DurairajNoch keine Bewertungen

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDokument1 SeiteConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNoch keine Bewertungen

- Tracer-AN Series: MPPT Solar Charge ControllerDokument4 SeitenTracer-AN Series: MPPT Solar Charge ControllerNkosilozwelo SibandaNoch keine Bewertungen

- Template Extended-AbstractDokument3 SeitenTemplate Extended-AbstractGraita PurwitasariNoch keine Bewertungen

- YAMAHA Blaster (Parts) PDFDokument65 SeitenYAMAHA Blaster (Parts) PDFAlberto VegaNoch keine Bewertungen

- Waste To Wealth Green Potential From Palm Biomass in MalaysiaDokument9 SeitenWaste To Wealth Green Potential From Palm Biomass in MalaysiaLai Mei EeNoch keine Bewertungen

- 6CS6.2 Unit 5 LearningDokument41 Seiten6CS6.2 Unit 5 LearningAayush AgarwalNoch keine Bewertungen

- Dana Trailer Suspension: SpicerDokument14 SeitenDana Trailer Suspension: SpicerCarlos Manuel Vazquez SanchezNoch keine Bewertungen

- COP24SummaryReport 2018Dokument14 SeitenCOP24SummaryReport 2018AlfiahaleNoch keine Bewertungen

- Capilares Diferentes GasesDokument14 SeitenCapilares Diferentes GasesWalter RuedaNoch keine Bewertungen

- Topic 10 - Advanced Approvals in Salesforce CPQDokument18 SeitenTopic 10 - Advanced Approvals in Salesforce CPQRamkumar Poovalai100% (1)

- XDokument20 SeitenXAlberto BarrosNoch keine Bewertungen

- Item 3 Ips C441u c441r Ieb Main ListDokument488 SeitenItem 3 Ips C441u c441r Ieb Main Listcristian De la OssaNoch keine Bewertungen

- Em - 1110 1 1005Dokument498 SeitenEm - 1110 1 1005Sajid arNoch keine Bewertungen

- Firearms in America 1600 - 1899Dokument310 SeitenFirearms in America 1600 - 1899Mike100% (3)

- Oct 15 Action Research PLT AgendaDokument2 SeitenOct 15 Action Research PLT Agendaapi-231962429Noch keine Bewertungen

- Antony Kungu - Final Project AssignmentDokument11 SeitenAntony Kungu - Final Project Assignmentapi-420816837Noch keine Bewertungen

- Example Quality PlanDokument11 SeitenExample Quality PlanzafeerNoch keine Bewertungen

- Buku Panduan P2K2 FINALDokument44 SeitenBuku Panduan P2K2 FINALHandayani lestariNoch keine Bewertungen

- Sony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Dokument94 SeitenSony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Mauro Mendez100% (1)

- List of The Registered UAE CompaniesDokument3 SeitenList of The Registered UAE Companiesirfan aminNoch keine Bewertungen

- Fax 283Dokument3 SeitenFax 283gary476Noch keine Bewertungen

- Tiger SharkDokument2 SeitenTiger Sharkstefanpl94Noch keine Bewertungen

- Filtration 2Dokument5 SeitenFiltration 2Ramon Dela CruzNoch keine Bewertungen

- RSC 406 (English)Dokument11 SeitenRSC 406 (English)Tuấn DũngNoch keine Bewertungen