Beruflich Dokumente

Kultur Dokumente

Design of Steel Beams Using Allowable Stress Design (ASD

Hochgeladen von

Anonymous DJrec2Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of Steel Beams Using Allowable Stress Design (ASD

Hochgeladen von

Anonymous DJrec2Copyright:

Verfügbare Formate

S-Beam-ASD

1 of 5

http://www.ce-ref.com/s-beam-asd.htm

CE-Ref.COM

Web

www.ce-ref.com

ASCE Online Library Free search 600,000 pages All areas of civil engineering www.ascelibrary.org

SSBeam lightweight beams Heavy-duty lightweight steel beams Save up on weight and cost www.ssbeam.com

Space Frame Structures Glulam or steel Any size, any shape www.nedtruss.com

Design of steel beam (ASD, Allowable Stress design)

Design code: AISC Allowable Stress Design 9th edition, 1989.

Design requirements

1. Maximum bending stress, fb must not exceed allowable stress, Fb.

2. Deflection should not exceed allowable limit.

3. Maximum shear stress, fv shall not exceed allowable shear stress.

Design procedure:

1. Calculate design load.

2. Calculate design moment, M and bending stress, fb.

3. Select a trial beam size and calculate allowable bending stress, Fb (see below)

4. Calculate deflection and check with allowable deflection ratio.

5. Calculate design shear and shear stress, fv.

6. Calculate allowable shear stress, Fv.

Determine bending stress and shear stress

Bending stress shall be determined as

fb= M/S

where M is design moment, S is section modulus.

Design of steel beam with W, I shape or Channel

Determine allowable bending stress F b (ASD)

W, I shape and channel hot-roll section bending about its major axis or shear center

1. Compact section: allowable bending stress,

Fb = 0.66 Fy

if

Lb Lc

where

Fy is yield strength of steel members.

Lb is laterally unsupported length of the compression flanges,

Lc is the smaller of 76 bf/Fy or Lc = 20,000/[(d/Af)Fy]

bf is the width of the flange, Af is area of the flange.

2. Non-compact section: allowable bending stress

Fb = 0.60 Fy

if

Lb 76 bf/Fy

3. Compact or non-compact section, Fb is the larger of the following

When

[ASD F1-6]

When

[ASD F1-7]

For any value of l/rT.

6/11/2010 11:28 AM

S-Beam-ASD

2 of 5

http://www.ce-ref.com/s-beam-asd.htm

[ASD F1-8]

Note: for channels bent, allowable stress is determined from [F1-8].

Where

rT (inch) is radius of gyration of a section comprising the compression flange plus 1/3 of the compression web area, taken about an axis in

(note: rT is available in AISC steel table for most W and I section)

Af is area of flange,

Cb = 1.75+1.05(M1/M2)+0.3(M1/M2) but not more than 2.3.

M1 and M2 are the smaller and the larger applied moments

M1/M2 is positive if M1 and M2 have the same sign.

W and I shape hot-roll section bending about its minor axis,

1. Compact section: allowable bending stress,

Fb = 0.75 Fy

2. Non-compact section: allowable bending stress

Fb = 0.60 Fy

Maximum width-thickness for compression flange for W, I and Channel section

a. Compact section: bf/t 65/Fy.

b. Non-compact secton: bf/t 95/Fy.

Determine unsupported length

Simply supported beams

1. For simply supported beam, the top flange is in compression. If the beam is directly attached to roof deck or floor slab, the compression

supported. The unsupported length Lb is 0.

2. When the beam supporting joists or other beams, and its flange is directly attached to the supported joists or other beams, the unsuppor

spacing of the joists or other beams.

Cantilever beams:

1. For cantilever beam, the compression flange is at the bottom of the beam. If the bottom flange is unbraced, the unsupported length is th

cantilever beam.

2. If bracing is provided at the bottom flange, the unsupported length is the spacing between bracings.

Continuous beams:

1. For the positive moment portion of the beam, the compression flange is at the top of the beam. The unsupported length is determined a

supported beam.

2. For the negative moment portion of the beam, the compression flange is at the bottom of the beam. The unsupported length is determin

cantilever beam.

Check shear stress

Shear stress, fv =V/(twd) Allowable shear stress, Fv = 0.4 Fy

Where V is applied shear force, d is the depth of beam, tw is thickness of web.

Acceptable deflection in most building codes

Deflection limits listed in International Building Code 2003 Table 1604.3are

Construction

L

S or W

D+L

6/11/2010 11:28 AM

S-Beam-ASD

3 of 5

http://www.ce-ref.com/s-beam-asd.htm

Roof members

Supporting plaster ceiling

Supporting non-plaster ceiling

Not supporting ceiling

Floor members

Exterior walls and interior partitions

With brittle finishes

With flexible finishes

L/360

L/240

L/180

L/360

L/360

L/240

L/180

-

L/240

L/180

L/120

L/240

L/240

L/120

For cantilever beam, L is 2 time the length of cantilever.

Example 1:

Situation: A structural steel beam is supporting a roof as shown in the figure. The beam is simply supported at each end.

Design Code: AISC ASD 9th edition

Roof live load: WL = 12 psf

Roof dead load: WD = 20 psf

Length of beam: L = 35 ft

Unsupported length (Joist spacing): Lb = 5 ft

Tributary width: TriB = 35 ft

Material: ASTM A36, yield strength, Fy = 36 ksi

Requirements: Select a W24 beam

Solution:

Total load on beam: W = (WL+WD) TriB = 1120 lb/ft.

Maximum moment: M = W L2/8 = 171.5 kip-ft

Maximum unsupported length, Lb = 5 ft

Try W24x55, From AISC steel Table, d = 23.57 in, bf = 7 in, tf =0.5 in, Af = bf tf=3.5 in2, tw = 5/16 in

3

Section modulus, S = 114 in .

4

Moment of inertia, I = 1350 in .

Calculate compact length Lc = 76 bf/Fy = 76 (7) / 36 = 7.4 ft or

Lc =20000/[(d/Af)Fy] = 20000 /[23.75/ 3.5) 36 ] = 6.9 ft > Lb = 5 ft

Allowable stress: Fb = 0.66 Fy = 24 ksi

Bending stress: fb = M/S = 18.1 ksi

< Fb = 24 ksi O.K.

Check deflection: Elastic modulus, E = 29000 ksi

Total deflection, D = 5 W L4/(388 E I ) = 0.97 in

Deflection ratio, L/D = 1/435 < 1/ 240 O.K

Live load deflection, DL = D (12/32) = 0.36 in,

Live load deflection ratio, DL /L = 1/1160 < 1/360 O.K.

Check shear stress,

Shear force, V = WL/2 = 19.6 kips

Shear stress, fv = V/(twd) = 2.7 ksi

Allowable shear stress, Fv = 0.4 Fy = 14.4 ksi

Example 2:

6/11/2010 11:28 AM

S-Beam-ASD

4 of 5

http://www.ce-ref.com/s-beam-asd.htm

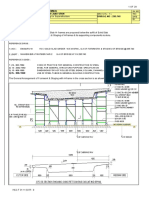

Situation: A structural steel beam with is supporting a roof as shown in the figure. The beam is simply supported at each end.

Design Code: AISC ASD 9th edition

Roof live load: WL = 12 psf

Roof dead load: WD = 20 psf

Length of beam: L = 36 ft

Length of cantilever: a = 12 ft

Tributary width: TriB = 24 ft

Material: ASTM A992, yield strength, Fy = 50 ksi

Requirements: Select a W18 beam

Solution:

Total load on beam: W = (WL+WD) TriB = 768 lb/ft.

2

Maximum negative moment at cantilever end: Mneg = W a /2 = 55.3 kip-ft

Maximum unsupported length at cantilever, Lb = 12 ft

Try W18x35, From AISC Table, d = 17.7 in, bf = 6 in, tf =7/16 in, Af = bf tf=2.62 in2,

tw = 0.3 in, rT = 1.49 in

Section modulus, S = 57.6 in3.

Moment of inertia, I = 510 in4.

Check cantilever end:

Calculate compact length Lc = 76 bf/Fy = 76 (6) / 50 = 5.3 ft or

Lc =20000/[(d/Af)Fy] = 20000 /[17.7/ 2.62) 50 ] = 4.9 ft < Lb = 12 ft

Calculate a/rT = 96

Calculate Cb, M1 = 0, M2 = 69.1 kip-ft, Cb = 1.75

Allowable stress from Eq. F1-6:

Allowable stress from Eq. F1-8:

Maximum bending stress:

Bending stress: fb = M/S = 11.5 ksi

< Fb = 24.6 ksi O.K.

Maximum deflection at cantilever end, E = 29000 ksi

From structural analysis,

D = (Wa/24EI)(4a2L-L3+3a3) = -0.93 in

D/2a = 1/248 O.K.

Live load deflection, DL=D(12/32) = 0.35 in

D/2a = 1/825 O.K.

Check interior span:

Maximum negative moment is the same as cantilever end.

Unsupported length is less. O.K. by inspection.

Maximum positive moment:

Mpos = (W/8L2)(L+a)2(L-a)2 = 122.8 ft-kip

Bending stress: fb = Mpos/S = 25.6 ksi

The span is fully supported. Allowable stress: Fb=0.66Fy=33 ksi O.K.

Check deflection:

Maximum deflection at x = (L/2)[1-(a/L)2] = 16 ft

Deflection D = (Wx/24E I L)(L4-2L2x2+Lx3-2a2L2+2a2x2)=1.8 in

D/L = 1/310 O.K.

Live load deflection DL = (12/32)D = 0.54 in

DL/L= 1/802

O.K.

Check shear stress:

Shear force at cantilever end, V1=W a = 9.3 kip

2

Shear force at simply supported end, V2 = W (L+a) /2L =24.6 kips

Shear stress fv = V2/twd = 4.6 ksi

Allowable shear stress, Fv = 0.4 Fy = 20 ksi

O.K.

6/11/2010 11:28 AM

S-Beam-ASD

5 of 5

http://www.ce-ref.com/s-beam-asd.htm

Disclaimer: The content of this website was obtained and edited from various resources. The editor made reasonable effort of

editing. Nevertheless, the editor does not warrant, and assume no liability for accuracy and completeness of its content. The viewer

shall use his/her professional knowledge and judgment in use of the web content.

Webmaster: www.ce-ref.com

6/11/2010 11:28 AM

Das könnte Ihnen auch gefallen

- Design of Steel Beam 89edDokument5 SeitenDesign of Steel Beam 89edAdi SatriaNoch keine Bewertungen

- Design of Steel Beam (LRFD, Load and Resistance Factor Design)Dokument5 SeitenDesign of Steel Beam (LRFD, Load and Resistance Factor Design)surajoffshoreNoch keine Bewertungen

- Short column design with lateral tiesDokument25 SeitenShort column design with lateral tiesDharanidharan JNoch keine Bewertungen

- Design of ConcreteDokument36 SeitenDesign of ConcreteDenden Dermawan100% (3)

- ONE-WAY SLABS DESIGNDokument26 SeitenONE-WAY SLABS DESIGNJohn Mejia50% (4)

- Design of Steel BeamsDokument48 SeitenDesign of Steel BeamssirfmeinNoch keine Bewertungen

- 107 ConcreteDokument44 Seiten107 Concretenoadspls2029Noch keine Bewertungen

- Joist SlabDokument13 SeitenJoist SlabAhmed Nabil80% (5)

- Lecture 5 Year 2-1Dokument28 SeitenLecture 5 Year 2-1Saurabh ChauhanNoch keine Bewertungen

- CONTINUOUS BEAMDokument57 SeitenCONTINUOUS BEAMZulhilmi MohanapNoch keine Bewertungen

- Design of Beams LRFDDokument18 SeitenDesign of Beams LRFDabdul latifNoch keine Bewertungen

- One Way Solid SlabDokument26 SeitenOne Way Solid SlabalaajabbarNoch keine Bewertungen

- Reinforced Concrete Beam DesignDokument8 SeitenReinforced Concrete Beam DesignEngr Alam Shah FarooqiNoch keine Bewertungen

- Notation:: Steel DesignDokument16 SeitenNotation:: Steel Designpbharadwaj545Noch keine Bewertungen

- Reinforced Concrete Beam DesignDokument8 SeitenReinforced Concrete Beam DesignLindy Kho100% (1)

- Semi-Integral-Abutment Design Example (USA Unit)Dokument20 SeitenSemi-Integral-Abutment Design Example (USA Unit)Ya YangNoch keine Bewertungen

- Design Calculation of Louvers-1Dokument7 SeitenDesign Calculation of Louvers-1vj8584Noch keine Bewertungen

- API 650 Design TanksDokument34 SeitenAPI 650 Design TanksSyedZainAli100% (13)

- Prepared by Jishnu V Engineer Bhel-IsgDokument38 SeitenPrepared by Jishnu V Engineer Bhel-IsgmSNDjvnsnNoch keine Bewertungen

- 425-Chp7-Bond Development Length SplicesDokument41 Seiten425-Chp7-Bond Development Length SplicesAhsan BuriroNoch keine Bewertungen

- RC Beam Design Procedure SummaryDokument4 SeitenRC Beam Design Procedure SummaryRohana Illukkumbura100% (1)

- Problem Statment DARSHANDokument10 SeitenProblem Statment DARSHANMayuresh NalawadeNoch keine Bewertungen

- LT Buckling Beam Design - Simple Method - 2upDokument5 SeitenLT Buckling Beam Design - Simple Method - 2upberto2008Noch keine Bewertungen

- Load Rating Training Session 4ADokument45 SeitenLoad Rating Training Session 4Atofa01Noch keine Bewertungen

- API 650 Design TanksDokument39 SeitenAPI 650 Design TanksAhmedAli25% (4)

- Method of Design - SLAB & BEAMDokument19 SeitenMethod of Design - SLAB & BEAMসামিউলইসলামNoch keine Bewertungen

- Pipe Stress Analysis Work-1Dokument28 SeitenPipe Stress Analysis Work-1nguyentrungsonctm7Noch keine Bewertungen

- Davit CalcDokument6 SeitenDavit Calcrustamriyadi100% (1)

- One way joist slab analysis designDokument12 SeitenOne way joist slab analysis designسجى وليدNoch keine Bewertungen

- Lesson 5Dokument12 SeitenLesson 5MIKE ARTHUR DAVID100% (1)

- Shear Strength CalculationDokument4 SeitenShear Strength CalculationAnil kumar RNoch keine Bewertungen

- Corbel DesignDokument3 SeitenCorbel DesignManoj JaiswalNoch keine Bewertungen

- Slabs: Serviceability and Shear: WWW - Eurocode2.infoDokument56 SeitenSlabs: Serviceability and Shear: WWW - Eurocode2.infoKai Lin TayNoch keine Bewertungen

- Reinforced Concrete Beam Design and AnalysisDokument17 SeitenReinforced Concrete Beam Design and AnalysisRAHUL DasNoch keine Bewertungen

- Reinforced Concrete Beam Design Procedure - : StateDokument4 SeitenReinforced Concrete Beam Design Procedure - : Statensureshbabu100% (1)

- Cold Formed BendingDokument8 SeitenCold Formed BendinggeorgeispasoiuNoch keine Bewertungen

- Design of Pressure VesselDokument27 SeitenDesign of Pressure VesselJose BijoyNoch keine Bewertungen

- TOS 5 Unit 2c T Beams and L BeamsDokument8 SeitenTOS 5 Unit 2c T Beams and L BeamsKshitija100% (1)

- Development Length - Part 1Dokument39 SeitenDevelopment Length - Part 1Tawfeeq AbusaifNoch keine Bewertungen

- MonorailDokument13 SeitenMonorailleodegarioporralNoch keine Bewertungen

- Design For RC Flat SlabsDokument70 SeitenDesign For RC Flat SlabsAil Aafaaq100% (3)

- CIVN 3011 Course Design StepsDokument43 SeitenCIVN 3011 Course Design StepsKatleho RampineNoch keine Bewertungen

- Chegg: Taobao 切回中⽂Dokument11 SeitenChegg: Taobao 切回中⽂pei chanNoch keine Bewertungen

- FLANGED BEAMS DESIGNDokument43 SeitenFLANGED BEAMS DESIGNMansa ArthurNoch keine Bewertungen

- FLANGED BEAMS DESIGNDokument43 SeitenFLANGED BEAMS DESIGNMansa ArthurNoch keine Bewertungen

- Design of Steel Beams To AISC - LRFDDokument52 SeitenDesign of Steel Beams To AISC - LRFDsony setyawan100% (1)

- Shutter DesignDokument28 SeitenShutter DesignRajendra Prasad GubbalaNoch keine Bewertungen

- Chapter - 3: Design of Rectangular Beams and One-Way SlabsDokument9 SeitenChapter - 3: Design of Rectangular Beams and One-Way SlabsMudasir HussainNoch keine Bewertungen

- STEEL BEAM DESIGN AND BENDING STRESSDokument10 SeitenSTEEL BEAM DESIGN AND BENDING STRESSHomer Batalao75% (4)

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Steel and Its Heat Treatment: Bofors HandbookVon EverandSteel and Its Heat Treatment: Bofors HandbookBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Solution Manual for 100 Genesys Design Examples: Second EditionVon EverandSolution Manual for 100 Genesys Design Examples: Second EditionNoch keine Bewertungen

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Pressure Vessel and Stacks Field Repair ManualVon EverandPressure Vessel and Stacks Field Repair ManualBewertung: 4 von 5 Sternen4/5 (4)

- O level Physics Questions And Answer Practice Papers 2Von EverandO level Physics Questions And Answer Practice Papers 2Bewertung: 5 von 5 Sternen5/5 (1)

- Factor of Safety On The Geotechnical Information WebsiteDokument2 SeitenFactor of Safety On The Geotechnical Information WebsiteAnonymous DJrec2Noch keine Bewertungen

- The Business Model CanvasDokument1 SeiteThe Business Model CanvasAnonymous DJrec2Noch keine Bewertungen

- 117 Excerpts 2004Dokument7 Seiten117 Excerpts 2004Anonymous DJrec2Noch keine Bewertungen

- Foundation Code 2004Dokument64 SeitenFoundation Code 2004Patie Zheng100% (2)

- External Friction Angle On The Geotechnical Information WebsiteDokument2 SeitenExternal Friction Angle On The Geotechnical Information WebsiteAnonymous DJrec2100% (1)

- Cohesion On The Geotechnical Information WebsiteDokument2 SeitenCohesion On The Geotechnical Information WebsiteAnonymous DJrec2Noch keine Bewertungen

- Bearing Capacity Factors On The Geotechnical Information WebsiteDokument2 SeitenBearing Capacity Factors On The Geotechnical Information WebsiteAnonymous DJrec2Noch keine Bewertungen

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDokument48 Seiten4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNoch keine Bewertungen

- The Nature and Purpose of Accounting ExplainedDokument16 SeitenThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиNoch keine Bewertungen

- 0217 PresentationDokument73 Seiten0217 PresentationHector RodriguezNoch keine Bewertungen

- Development and Future of Circulating Fluidized Bed Boilers in ChinaDokument4 SeitenDevelopment and Future of Circulating Fluidized Bed Boilers in ChinaAnonymous DJrec2Noch keine Bewertungen

- Evolution of Management ThoughtDokument17 SeitenEvolution of Management ThoughtAnonymous DJrec2Noch keine Bewertungen

- CFD Simulation On CFBC BoilerDokument6 SeitenCFD Simulation On CFBC BoilerAnonymous DJrec2Noch keine Bewertungen

- Foundation Code 2004Dokument64 SeitenFoundation Code 2004Patie Zheng100% (2)

- Managing A Safe Work PlaceDokument3 SeitenManaging A Safe Work PlaceAnonymous DJrec2Noch keine Bewertungen

- Understanding MarketingDokument5 SeitenUnderstanding MarketingAnonymous DJrec2Noch keine Bewertungen

- Third Quarter 2016 Investment Outlook: Asset Class SectorDokument6 SeitenThird Quarter 2016 Investment Outlook: Asset Class SectorAnonymous DJrec2Noch keine Bewertungen

- Engineers in Construction Industry - Ir. Choo Kok BengDokument22 SeitenEngineers in Construction Industry - Ir. Choo Kok BengAnonymous DJrec2Noch keine Bewertungen

- BEM Code of Ethics - Ir. Yim Hon WaDokument53 SeitenBEM Code of Ethics - Ir. Yim Hon WaAnonymous DJrec2Noch keine Bewertungen

- CiMB Research Report On REITDokument6 SeitenCiMB Research Report On REITAnonymous DJrec2Noch keine Bewertungen

- Industrial LowbayDokument8 SeitenIndustrial LowbayAnonymous DJrec2Noch keine Bewertungen

- Dry-Type Transformers: Codes and Standards Enhancement (CASE) StudyDokument22 SeitenDry-Type Transformers: Codes and Standards Enhancement (CASE) StudyAnonymous DJrec2Noch keine Bewertungen

- The Nature and Purpose of Accounting ExplainedDokument16 SeitenThe Nature and Purpose of Accounting ExplainedSubashiиy PяabakaяaиNoch keine Bewertungen

- BEM Code of EthicsDokument11 SeitenBEM Code of EthicsAbdul Hakim AbdullahNoch keine Bewertungen

- Power Amps Efficiency PFDokument5 SeitenPower Amps Efficiency PFAnonymous DJrec2Noch keine Bewertungen

- HarmonicsDokument7 SeitenHarmonicsAnonymous DJrec2Noch keine Bewertungen

- Basics of Power CableDokument7 SeitenBasics of Power CableAnonymous DJrec2Noch keine Bewertungen

- Motor Load and Efficiency PDFDokument16 SeitenMotor Load and Efficiency PDFwfjerrNoch keine Bewertungen

- Malaysia Kia Sportage Price List 2012Dokument1 SeiteMalaysia Kia Sportage Price List 2012Anonymous DJrec2Noch keine Bewertungen

- Airflex C Highbay 18 DelviroDokument3 SeitenAirflex C Highbay 18 DelviroDanielNoch keine Bewertungen

- AIR SAFETY PROCEDURES MANUAL - IndiaDokument141 SeitenAIR SAFETY PROCEDURES MANUAL - IndiaRichard R M Thodé100% (1)

- Inventory Items DestinyDokument11 SeitenInventory Items DestinyManish NautiyalNoch keine Bewertungen

- Brochure CPR ENDokument8 SeitenBrochure CPR ENMakiberNoch keine Bewertungen

- Chem 31.1 Midterms Reviewer Experiment 1: Solubility of Organic CompoundsDokument6 SeitenChem 31.1 Midterms Reviewer Experiment 1: Solubility of Organic CompoundsSteffi GatdulaNoch keine Bewertungen

- En 818-6 PDFDokument5 SeitenEn 818-6 PDFlub007Noch keine Bewertungen

- ABB 4 Pole Contactor, 230V, 40ADokument1 SeiteABB 4 Pole Contactor, 230V, 40ASEERALANNoch keine Bewertungen

- Installation Manual: Automatic TWIN Greasing SystemDokument62 SeitenInstallation Manual: Automatic TWIN Greasing SystemWill FrontNoch keine Bewertungen

- An Experimental Comparative Review - PK NanavatiDokument9 SeitenAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiNoch keine Bewertungen

- History Spring08Dokument7 SeitenHistory Spring08Anonymous 9VcxlFErfNoch keine Bewertungen

- Two-Way Floor SystemDokument11 SeitenTwo-Way Floor SystemJason TanNoch keine Bewertungen

- Et200s Im151 1 Standard Manual en-US en-USDokument66 SeitenEt200s Im151 1 Standard Manual en-US en-USJesús Zacarías ZapataNoch keine Bewertungen

- Ship Stability 5Dokument31 SeitenShip Stability 5jeaneva guiaoNoch keine Bewertungen

- Contact Inform 2002 PDFDokument24 SeitenContact Inform 2002 PDFFrank AlmeidaNoch keine Bewertungen

- Soil Analysis Bitupan LastDokument25 SeitenSoil Analysis Bitupan Lastbitupon boraNoch keine Bewertungen

- Anna University International Admissions GuideDokument4 SeitenAnna University International Admissions GuideAmir AzeezNoch keine Bewertungen

- Adaptive Cruise Control: Current Flow DiagramDokument5 SeitenAdaptive Cruise Control: Current Flow DiagramHany ElsehrawyNoch keine Bewertungen

- Quantifying Life Safety Part II - Quantification of Fire Protection SystemsDokument6 SeitenQuantifying Life Safety Part II - Quantification of Fire Protection SystemskusumawardatiNoch keine Bewertungen

- Caterpillar Cat 320d 320dl Excavator Parts ManualDokument34 SeitenCaterpillar Cat 320d 320dl Excavator Parts ManualSara Sarmiento Echeverry100% (1)

- Atlassian Certificate-IsO 27001Dokument2 SeitenAtlassian Certificate-IsO 27001David BriggsNoch keine Bewertungen

- Article 5 - How To Purge Husqvarna Hydrostatic TransmissionDokument3 SeitenArticle 5 - How To Purge Husqvarna Hydrostatic TransmissionSofia AlyaNoch keine Bewertungen

- IJCSEIERDFEB20174Dokument10 SeitenIJCSEIERDFEB20174TJPRC PublicationsNoch keine Bewertungen

- IC EngineDokument2 SeitenIC EnginePrince SethiNoch keine Bewertungen

- Anchor Bolt BiAxialDokument10 SeitenAnchor Bolt BiAxialALPHYL BALASABASNoch keine Bewertungen

- Ec7 WallapDokument20 SeitenEc7 WallapJack DoverNoch keine Bewertungen

- Section 3Dokument56 SeitenSection 3Fernanda Medeiros CarvalhoNoch keine Bewertungen

- Jsa-Wif-9 Pulling CableDokument12 SeitenJsa-Wif-9 Pulling CableY a n i. A h m e dNoch keine Bewertungen

- 2755 22 (G78A) Milwaukee PBDokument2 Seiten2755 22 (G78A) Milwaukee PBZeckNoch keine Bewertungen

- Stability Data BookletDokument18 SeitenStability Data BookletPaul Ashton25% (4)

- Count rows in all tablesDokument25 SeitenCount rows in all tablessatya1401Noch keine Bewertungen