Beruflich Dokumente

Kultur Dokumente

Intro, Adv. Disadv

Hochgeladen von

tusharaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Intro, Adv. Disadv

Hochgeladen von

tusharaCopyright:

Verfügbare Formate

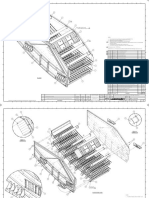

PRECAST CONCRETE :

What is Precast Concrete :

Precast concrete is a product that is produced by casting concrete in a reusable mould.

It is cured in a controlled environment, transported to site and lifted into place.

Precast concrete is a highly versatile product available in vast range of different sizes,

functions and finishes.

Types of Precast Concrete Systems:

1.Large Panel system

2.Frame system.

3.Slab -Column system with walls.

4. Mixed system.

ADVANTAGES OF PRECAST CONCRETE

The concrete of superior quality is produced as it is possible to have better technical

control on the production of concrete in factory.

It is not necessary to provide joints in the precast construction.

The labour required in the manufacturing process of the precast units can easily be

trained.

The moulds employed for preparing the precast units are of steel with exact

dimension in all directions. These moulds are more durable and they can be used

several times.

The precast articles may be given the desired shape and finish with accuracy.

The precast structures can be dismantled, when required and they can then be

suitably used elsewhere.

The transport and storage of various components of concrete for cast in situ work are

eliminated when precast members are adopted.

The work can be completed in a short time, when precast units are adopted.

When precast structures are to be installed, it is evident that the amount of

scaffolding and formwork is considerably reduced.

DISADVANTAGES OF PRECAST CONCRETE

Following are the disadvantages of precast concrete:

If not properly handled, the precast units may be damaged during transport.

It becomes difficult to produce satisfactory connections between the precast

members.

It is necessary to arrange for special equipment for lifting and moving of the precast

units.

The economy achieved in precast construction is partially balanced by the amount to

be spent in transport and handling of precast members. It becomes therefore

necessary to locate the precast factory at such a place that transport and handling

charges are brought down to the minimum possible extent.

PRE STRESSED CONCRETE :

What is Prestressed Concrete:

Concrete in which reinforcing steel bars are stretched and anchored to compress it

and thus increase its resistance to stress is prestressed concrete.

Pre-stressed concrete is a form of reinforced concrete that builds in compressive

stresses during construction to oppose those found when in use.

In other words it is a combination of steel and concrete that takes advantages of the

strengths of each material.

Prestressing is a technique of introducing stresses into a structural member during

fabrication and/or construction to improve its strength and performance. This

technique is often employed in concrete beams, columns, spandrels, single and

double tees, wall panels, segmental bridge units, bulb-tee girders, I-beam girders,

and others. "Prestressed member are crack-free under working loads and, as a

result, look better and more watertight, providing better corrosion protection for the

steel." Many projects find that prestressed concrete provides the lowest overall cost,

considering production and lifetime maintenance.

Why Pre stressed concrete:

Concrete remains un-cracked.

Reduction of steel corrosion.

Increases durability.

High span to depth ratio (ex: 45:1 vs. 28:1).

Less dead load.

More economical.

Types of Pre stressed Concrete Systems:

Pre-Tension Concrete: Pre-stressing steel is tension stressed prior to the placement

of the concrete and unloaded after concrete has harden to required strength.

Bonded post-tensioned concrete: Unstressed pre-stressing steel is placed with in the

concrete and then tension stressed after concrete has harden to required strength

Un-bonded post-tensioned concrete: Differs from bonded post-tensioning by

providing the pre-stressing steel permanent freedom of movement relative to the

concrete.

POST-TENSIONED CONCRETE

Post-tensioned concrete looks & acts just like other reinforced concrete. Post-tensioning is

simply a way to reinforce in a more active way.

What is Post-Tensioning

Post-tensioning is a form of prestressing. Prestressing simply means that the steel is

stressed (pulled or tensioned) before the concrete has to support the service loads. Most

precast, prestressed concrete is actually pre-tensioned-the steel is pulled before the

concrete is poured. Post-tensioned concrete means that the concrete is poured and then the

tension is applied-but it is still stressed before the loads are applied so it is still prestressed.

Post tensioning is a technique for reinforcing concrete. Post-tensioning tendons, which are

prestressing steel cables inside plastic ducts or sleeves, are positioned in the forms before

the concrete is placed. Afterwards, once the concrete has gained strength but before the

service loads are applied, the cables are pulled tight, or tensioned, and anchored against the

outer edges of the concrete.

Uses of Post stressed Concrete

The applications for post-tensioning are almost endless, but what holds it back is the

lack of experience among designers and builders. Some of the more common

applications are:

Slabs on ground: Today, PT is used extensively for slabs on grade where soils are

likely to move (expansive soils)-

Another good application for PT slabs is producing crack-free tennis courts.

A recently developed application of PT is external post-tensioning for strengthening

of existing structures, especially as an upgrade to resist seismic forces.

PT allows longer spans and keeps cracks tight.

Concrete water tanks are often post-tensioned to reduce crack width and leakage.

Advantages of Post stressed concrete:

Post-tensioning, which is a form of pre stressing, has several advantages over standard

reinforcing steel :

It reduces or eliminates shrinkage cracking-therefore no joints, or fewer joints, are

needed

Cracks that do form are held tightly together

It allows slabs and other structural members to be thinner

It allows us to build slabs on expansive or soft soils

It lets us design longer spans in elevated members, like floors or beams

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- K-Tron Premier Rep Catalog Dec 2010 PDFDokument429 SeitenK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)

- Spent Caustic Treatment Options-Saudi AramcoDokument20 SeitenSpent Caustic Treatment Options-Saudi Aramcoonizuka-t22630% (1)

- Abb PDFDokument24 SeitenAbb PDFFreddy Mauricio LucayNoch keine Bewertungen

- Cathelco ICCP Hull Protection SystemsDokument8 SeitenCathelco ICCP Hull Protection SystemsdalianbouriNoch keine Bewertungen

- Permanent Metal - Data - Sheet - AFP 1 209B NewDokument1 SeitePermanent Metal - Data - Sheet - AFP 1 209B NewSunnyNoch keine Bewertungen

- Impact TestDokument5 SeitenImpact TestGolden ChanNoch keine Bewertungen

- Megadoor S1500 Brochure - HB 290Dokument28 SeitenMegadoor S1500 Brochure - HB 290Shamsul Bahrin SulaimanNoch keine Bewertungen

- Lux Meter ReportDokument2 SeitenLux Meter ReportKaran MalhiNoch keine Bewertungen

- Ansi C84.1Dokument24 SeitenAnsi C84.1jojagucaNoch keine Bewertungen

- NBK TA Brochure 2016-EmailDokument11 SeitenNBK TA Brochure 2016-EmailPietrus NimbusNoch keine Bewertungen

- 000 SP Pi02 0221Dokument10 Seiten000 SP Pi02 0221Samuel ValbuenaNoch keine Bewertungen

- Experiment 1Dokument4 SeitenExperiment 1Kathrine E. BautistaNoch keine Bewertungen

- Engine Control System: SectionDokument1.924 SeitenEngine Control System: SectionMihai IavorschiNoch keine Bewertungen

- 1805P ReguladoresDokument8 Seiten1805P ReguladoresALBERTONoch keine Bewertungen

- Delayed CokingDokument7 SeitenDelayed CokingMatheus RodriguesNoch keine Bewertungen

- Sustainablesupplierselection Paper PublishedDokument9 SeitenSustainablesupplierselection Paper PublishedShivasanggari RamasamyNoch keine Bewertungen

- Dokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bDokument5 SeitenDokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bjuane27Noch keine Bewertungen

- Nanobiochar and Biochar Based NanocompositesDokument12 SeitenNanobiochar and Biochar Based NanocompositesJaini FakhrudinNoch keine Bewertungen

- Quick Process DesignDokument35 SeitenQuick Process DesignAkshat JainNoch keine Bewertungen

- Isolated Phase Busduct Ipb EnerbusDokument2 SeitenIsolated Phase Busduct Ipb EnerbuszulryNoch keine Bewertungen

- Bemco BrochureDokument19 SeitenBemco BrochurelightsonsNoch keine Bewertungen

- Product Life Cycle and LifeDokument3 SeitenProduct Life Cycle and LifejoelNoch keine Bewertungen

- Cryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDokument2 SeitenCryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDr. Awanish MishraNoch keine Bewertungen

- Acc Gearbox ManualDokument47 SeitenAcc Gearbox ManualShivakumar100% (1)

- Strength of Materials StressDokument5 SeitenStrength of Materials StressMarianne Lou PalomarNoch keine Bewertungen

- 1301A01422 Zaranda 3500Dokument2 Seiten1301A01422 Zaranda 3500Edgar FloresNoch keine Bewertungen

- Plastiment VZ PDFDokument2 SeitenPlastiment VZ PDFDarwin SyahputraNoch keine Bewertungen

- Design of Solar Panel Deployment Mechanism For A 1U CubeSatDokument7 SeitenDesign of Solar Panel Deployment Mechanism For A 1U CubeSatAliMurtazaKothawalaNoch keine Bewertungen

- 0620 s13 Ms 32 PDFDokument6 Seiten0620 s13 Ms 32 PDFShad muhammad KhanNoch keine Bewertungen

- Suction Cups/grippers: Duraflex® BagDokument2 SeitenSuction Cups/grippers: Duraflex® BagBe HappyNoch keine Bewertungen