Beruflich Dokumente

Kultur Dokumente

514design and Fabrication of Anti Roll Back System in Vehicles Using Ratchet and Pawl Mechanism PDF

Hochgeladen von

Jeevan Landge PatilCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

514design and Fabrication of Anti Roll Back System in Vehicles Using Ratchet and Pawl Mechanism PDF

Hochgeladen von

Jeevan Landge PatilCopyright:

Verfügbare Formate

International Journal of Emerging Technology in Computer Science & Electronics (IJETCSE)

ISSN: 0976-1353 Volume 12 Issue 3 JANUARY 2015.

DESIGN AND FABRICATION OF ANTI ROLL

BACK SYSTEM IN VEHICLES USING

RATCHET AND PAWL MECHANISM

A.Arunkumar 1, T. Muthumani 2, V. Balasubramani 3

1,2

B.E. Mechanical Engineering, Thiagarajar college of engineering

3

Assistant Professor, Department of Mechanical Engineering

Thiagarajar College of Engineering, Madurai 625015, INDIA

Abstract In this work the mechanism has been

developed to stop the vehicle from rolling backwards

when the vehicle is moving in the hill roads. Ratchet

and Pawl mechanism has been identified to arrest the

motion to the front axle. Anti-Roll Back mechanism has

been fabricated and tested on the front axle assembly.

The mechanism works well.

and the ratchet and pawl has to be designed for it. In

order to design for the worst case the road maximum

slope is considered- Zoji pass Road Kashmir which

has 21.80 o with gradient 2/5.

II. LITRATURE SURVEY

Index Terms-Ratchet, Pawl, Drive shaft, Hill Road

A. Anti-creep and hill holder brake system

I.

INTRODUCTION

Cook George suggested a hill holder mechanism

holds the vehicle in slope for 2 seconds by using the

brake pressure. A device operable in a transmission

of a vehicle for substantially preventing vehicular

rollback on an incline, comprising: a shaft rotatable

which is supported in a transmission housing; a gear

selectively connected for common rotation with the

shaft, wherein the gear is rotatable in a first rotary

direction and a second rotary direction.

Ratchet and pawl mechanism is used in many

applications effectively where the one side power

transmission is required for example in (i) Giant

wheel- It is the large wheel used in the amusement

parks to rotate along the horizontal axis to rotate in

one direction while carrying the number of

passengers. (ii)Clocks- where the hands rotate in

clockwise directions only.(iii) Baffle gates- in the

entrances of many buildings which rotates about

vertical axis in one direction.(iv) Shaping Machines

in the crank and slotted arm.

B. Improved release mechanism for a hill holder

device

In the hill station, the most common problem to the

drivers isto park their cars in the slope and to start up

the car. While waiting in the traffic , the cars have to

move on step by step very slowly, this situation is a

difficult one for the drivers to make their car not to

roll back in the slope. So the mechanism has to be

developed to stop the vehicle from rolling back and it

should not stop the vehicle in accelerating forwards.

This function can be achieved by using the ratchet

and pawl mechanism.

William kent utilized a load sensor connected with a

wheel brake to sense a change in wheel braking

torque and communicate responsively with a

mechanical brake control device. If a car is stopped

on an incline while the motor is still running, there's a

good chance that some kind of hill-start control will

be needed. A sensor that detects an incline of more

than a certain amount, three degrees or more, can

send a signal to the hill-start control indicating that

the vehicle has the potential to start rolling. The

disadvantage of incline detection is that sometimes a

car maybe on an incline without needing the hill-start

control - for instance, when a tire slips into a pothole.

The ratchet and pawl has to be designed and has to be

fit in the front drive shaft in case of the front drive

vehicles. The Maruti Swift Dzire car is considered

International Journal of Emerging Technology in Computer Science & Electronics (IJETCSE)

ISSN: 0976-1353 Volume 12 Issue 3 JANUARY 2015.

C. Improved release mechanism for a hill holder

device

Grzegorz Janiszewski stated that the use of piston

cylinder device, controlled by an electronic unit

which is coupled to a hydraulic pressure system and

acts on the brake pedal for two seconds.

III. RESEARCH GAP

The greatest disadvantage of hill holder mechanism is

that it can hold the vehicle in the slope for just two to

three seconds. Though it avoids rolling back, the

driver has to be alert. Besides this, the system is

expensive. These shortcomings are identified in hill

holder mechanism and the following problems are

faced by the driver while the vehicle is driven in hill

roads

D. Release mechanism for a hill holder device

William K. Messersmith used the load cell with

electrical control for braking system. But it requires

continuous electric energy for the production and

display of signals. It also requires an amplification

circuit for the generation of output display because

the signals produced by the gauge itself are of very

much low voltage almost in milli-volts. In a vehicle

having a clutch pedal and a brake pedal, a hill holder

device is utilized to maintain the brake pedal in the

applied position so that the vehicle operator's foot is

free to operate the accelerator pedal. A mechanical

brake control device may be disposed between the

clutch and brake pedals, with the clutch pedal

connected by a linkage to the brake control device so

that release of the clutch pedal will cause

deactivation of the brake control device and result in

release of the brake pedal from the applied position.

The release mechanism should be usable with either a

mechanical brake control device or a braking

assistance servo-motor system.

(i)

Most of the drivers face difficulties

while operating the brake, clutch and

accelerator simultaneously while

driving the car in hill roads.(Fig.1)

Figure 1: Schematic representation of operating

the brake, clutch and accelerator simultaneously

E. Vehicle transmission hill holder

Alvin H. Berger used a one-way clutch when

engaged it prevents rolling of the vehicle. A device

operable in a transmission for substantially

preventing vehicular rollback on an incline includes a

shaft, a gear, a one-way clutch, and a pawl member.

The gear is selectively connected for common

rotation with the shaft. The gear is rotatable in a first

rotary direction and a second rotary direction. The

one-way clutch has an inner race and an outer race,

where the inner race is connected to the gear and the

outer race has an outer surface having a plurality of

engaging teeth. The pawl member has a first end and

a second end, where the first end is pivotal mounted

to a transmission housing. The second end of the

pawl has a first angled portion configured to release

and engage at least one of the plurality of engaging

teeth of the outer race as the outer race rotates in the

second rotary direction.

(ii)

It is not advisable to use the hand

brakes while the car is moving in

forward movement.

IV. WORKING

In this work, Ratchet and Pawl mechanism is

identified to arrest the backward motion to the car.

The ratchet is placed in the front drive shaft and the

Pawl is fitted with the frame. When the vehicle is

moved in the hill road, the lever has to make the pawl

to touch the ratchet. If the vehicle tends to move

backward direction, the pawl would stop the ratchet

to move Counter Clock-wise direction with respect to

front wheel.

As the vehicle is in neutral position, the pawl

engaged the ratchet and the vehicle did not move in

International Journal of Emerging Technology in Computer Science & Electronics (IJETCSE)

ISSN: 0976-1353 Volume 12 Issue 3 JANUARY 2015.

The fabricated Ratchet and Pawl mechanism is

shown in Figure3.

backward direction. So the hand brakes need not to

be applied.

When the vehicle is in moving condition, the

engagement between the ratchet and pawl is

detached.

V. DESIGN OF RATCHET AND PAWL

The mechanism is designed for the loading

conditions of MARUTI Swift DZIRE. The

circumference of the front drive shaft of this car is

measured and the diameter is determined as

23.89mm. The weight and Torque of the MARUTI

SWIFT DZIRE car are 1060 Kg and 190N-m,

respectively.

SLOPE OF THE ROAD: The steepest road in India

is ZOJI PASS in KASHMIR and the angle of

inclination of the road is found to be 21.80 degrees.

The percentage slope there is about 40 %.

Figure 3: Fabricated Ratchet and Pawl

Mechanism

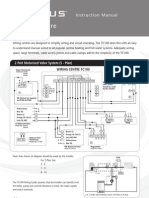

VI.ANTI ROLL BACK MECHANISM

The material considered for ratchet and pawl are

Figure 2. Three dimensional model of Ratchet &

Pawl Mechanism.

Figure 4: Anti Roll Back Mechanism

Grey cast iron and C45 respectively. Both surfaced

are considered to be hardened. The number of teeth

on ratchet wheel is assumed as 12. The following

parameters are considered for the design of the

mechanism. The three dimensional model of the

mechanism is shown in Figure 2.

Module

Width of ratchet

Diameter of pawl

Length of pawl

(m) =

(b) =

(Dp) =

(L) =

The fabricated mechanism is fitted in drive shaft for

testing experimentally to check whether the

functionality has been achieved (Figure 5). The hand

driven lever is turned in forward direction, similar to

forward motion of the car, the pawl does not stop the

ratchet to rotate. The hand lever is turned in opposite

direction similar to the reverse motion of the car in

the hill road, and the pawl stops the rotation of the

ratchet. So, the drive shaft and the wheels did not

rotate. Therefore the reverse motion of the wheels is

5mm

12.5 mm

14.47mm

31.4mm

International Journal of Emerging Technology in Computer Science & Electronics (IJETCSE)

ISSN: 0976-1353 Volume 12 Issue 3 JANUARY 2015.

arrested. The same can be achieved if this model is

fitted in the car. This will be the case while fitting

this mechanism in the drive shaft of the car. When it

has been done the car cannot move in reverse

direction in the slope as the pawl locks the ratchet.

A.Arunkumar is pursuing his

bachelors degree in mechanical

engineering in Thiagarajar college

of engineering, Madurai, India.

His areas of interest are Strength

of Materials and Geometric

modeling.

VII. CONCLUSION

T. Muthumani is pursuing his

bachelors degree in mechanical

engineering in Thiagarajar college

of Engineering, Madurai, India.

His area of interest is Design of

Machine elements and Strength of

Materials.

Thus the mechanism can stop the vehicle from rolling

back in hill roads. This would be more helpful for the

drivers to drive their cars comfortably in hilly roads

and he can take off the car in the uphill without

rolling back the car.

REFERNCES:

[1] T.J. Prabu-Design ofTransmission system,

[2] Transport Research Wing, Road Accidents

in India, Ministry of Road Transport and

Highways, India, 2011.

[3] The New In-Depth, At-the-Scene, Accident

Investigation Database in India by

N.Rameshkrishnan, A. Sathyakumar, S.

Balakumar, A. M. Hassan, R. Rajaraman, J.

Padmanaban.

[4] Mahesh shahapuri-Anti-roll back system for

manual

transmission

vehicles

(WO

2013024491 A2)

[5] Cook George -Anti creep and hill holder

brake system (US 2938611 A)

[6] William kent-Improved release mechanism

for a hill holder device.

[7] Grzegorz Janiszewski-Improved release

mechanism for a hill holder device.

[8] William

K.

Messersmith-Release

mechanism for a hill holder device.

[9] Alvin H. Berger-Vehicle transmission hill

holder.

Das könnte Ihnen auch gefallen

- Steering Mechanism With Zero Turning RadiusDokument19 SeitenSteering Mechanism With Zero Turning RadiusAbhay RanjanNoch keine Bewertungen

- Mechanical Four Wheels SteeringDokument74 SeitenMechanical Four Wheels Steeringvijayan m g91% (22)

- Study of Steering Mechanism MechanicalDokument9 SeitenStudy of Steering Mechanism MechanicalSANURASAGARNoch keine Bewertungen

- Motor Controls Troubleshooting of Electric MotorsDokument34 SeitenMotor Controls Troubleshooting of Electric MotorsAdil RezoukNoch keine Bewertungen

- 4.abrasive Belt GrinderDokument63 Seiten4.abrasive Belt GrinderIyappan Alagappan67% (15)

- 4.abrasive Belt GrinderDokument63 Seiten4.abrasive Belt GrinderIyappan Alagappan67% (15)

- Traction-Control-Oriented State Estimation For MotorcyclesDokument8 SeitenTraction-Control-Oriented State Estimation For Motorcyclespremkumarreddy_n4922Noch keine Bewertungen

- ISO 9001 General AwarenessDokument24 SeitenISO 9001 General AwarenesspvendaraNoch keine Bewertungen

- QP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00Dokument13 SeitenQP-ENG-PRC-008 - QP Procedure For Site Acceptance Test - Rev 00salem elhajNoch keine Bewertungen

- 90 Degree Turning Motorized Steering MechanismDokument62 Seiten90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- 6881009Y05-O Vol 1 Understanding Your Astro 25Dokument615 Seiten6881009Y05-O Vol 1 Understanding Your Astro 25zargon2012100% (1)

- Hydraulic Car Parking PDFDokument5 SeitenHydraulic Car Parking PDFSamik Mukherjee100% (2)

- MA4001 15 16sem1Dokument14 SeitenMA4001 15 16sem1Pearlyn Tiko Teo0% (2)

- Model of Anti Roll Back System On Hilling Situation in Car-29317Dokument4 SeitenModel of Anti Roll Back System On Hilling Situation in Car-29317kanchan boneNoch keine Bewertungen

- Hill Station Breaking SystemDokument48 SeitenHill Station Breaking Systemkanchan bone80% (5)

- Mini Report-Hill Station Breaking SystemDokument24 SeitenMini Report-Hill Station Breaking SystemNikhil PimpareNoch keine Bewertungen

- Full ReportDokument32 SeitenFull ReportANAND KRISHNANNoch keine Bewertungen

- Automatic Braking SystemDokument32 SeitenAutomatic Braking SystemRamkumarNoch keine Bewertungen

- Wheel Steering SystemDokument28 SeitenWheel Steering SystemKshitij SharmaNoch keine Bewertungen

- Anti Roll BackDokument4 SeitenAnti Roll BackMaharaja Placement100% (1)

- 1 Front Page (13 Files Merged)Dokument27 Seiten1 Front Page (13 Files Merged)SreekanthKottavilayilNoch keine Bewertungen

- Automatic Side Stand Retrival SystemDokument4 SeitenAutomatic Side Stand Retrival SystemsankaramarayananNoch keine Bewertungen

- Three Mode Steering System For Light Weight Automobile VehiclesDokument4 SeitenThree Mode Steering System For Light Weight Automobile VehiclesijsretNoch keine Bewertungen

- Downloads Papers N5a66e02a2e2c7 PDFDokument7 SeitenDownloads Papers N5a66e02a2e2c7 PDFpramodh kumarNoch keine Bewertungen

- Four-Wheel Steering Mechanism - ReviewDokument4 SeitenFour-Wheel Steering Mechanism - ReviewRajatNoch keine Bewertungen

- Introduction To Automobile: Four Wheel DriveDokument20 SeitenIntroduction To Automobile: Four Wheel DriveRavi AnuNoch keine Bewertungen

- Modelling and Simulation of Automatic TransmissionDokument7 SeitenModelling and Simulation of Automatic TransmissionIJRASETPublicationsNoch keine Bewertungen

- A Seminar Report-1Dokument21 SeitenA Seminar Report-1Rameez BedekarNoch keine Bewertungen

- Synopsis On Martian VehicleDokument7 SeitenSynopsis On Martian Vehicleniel7288Noch keine Bewertungen

- Four Wheels SteeringDokument18 SeitenFour Wheels SteeringArpith KumarNoch keine Bewertungen

- Combined Pedal Mechanism For Braking & Acceleration: Adit Khakhar, Karthik Rao, Siddhant Satam, Farheen BobereDokument2 SeitenCombined Pedal Mechanism For Braking & Acceleration: Adit Khakhar, Karthik Rao, Siddhant Satam, Farheen BobereSamyak JainNoch keine Bewertungen

- Project SynapsisDokument6 SeitenProject Synapsisnayan RNoch keine Bewertungen

- Ijmet 11 02 009Dokument7 SeitenIjmet 11 02 009sivamadesh0409Noch keine Bewertungen

- Steering SystemDokument12 SeitenSteering Systemmayur_lanjewarNoch keine Bewertungen

- Seminar Report On Fuel Cell Powered CarsDokument28 SeitenSeminar Report On Fuel Cell Powered CarsANAND POZHATHNoch keine Bewertungen

- Towing The Machine (SEBU8751)Dokument4 SeitenTowing The Machine (SEBU8751)Anderson Oliveira SilvaNoch keine Bewertungen

- Automatic Brake in Hill StationDokument15 SeitenAutomatic Brake in Hill StationNikhil PimpareNoch keine Bewertungen

- Anti Roll System: S. B. Pawar, S. P. Lawhate, M. D. Bhujbal, A. B. Mane, G. T. LagadDokument5 SeitenAnti Roll System: S. B. Pawar, S. P. Lawhate, M. D. Bhujbal, A. B. Mane, G. T. Lagadsuyash pingaleNoch keine Bewertungen

- Design of 360 Degree Rotating Car Ijariie3105Dokument5 SeitenDesign of 360 Degree Rotating Car Ijariie3105abiNoch keine Bewertungen

- Mechatronic System Based Manual Transmission: International Journal of Mechanical Engineering and Technology (Ijmet)Dokument6 SeitenMechatronic System Based Manual Transmission: International Journal of Mechanical Engineering and Technology (Ijmet)jonjonnyNoch keine Bewertungen

- Rollover Stabilisation in Electric Vehicles: Richa Bansal, Tushar Sharma and Sudipto MukherjeeDokument15 SeitenRollover Stabilisation in Electric Vehicles: Richa Bansal, Tushar Sharma and Sudipto MukherjeeTushar_Sharma_6486Noch keine Bewertungen

- A Review of Automatic Gear Shifting Mechanism For Physically Challenged Persons Vehicle With Reverse MotionDokument3 SeitenA Review of Automatic Gear Shifting Mechanism For Physically Challenged Persons Vehicle With Reverse MotionIJRASETPublicationsNoch keine Bewertungen

- SELECTION AND MODIFICATION OF INDEPENDENT SUSPENSION MECHANISM FOR A TERRAIN VEHICLE WITH FOUR WHEELS DRIVE Ijariie1405 1 Volume 1 15 Page 61 66Dokument6 SeitenSELECTION AND MODIFICATION OF INDEPENDENT SUSPENSION MECHANISM FOR A TERRAIN VEHICLE WITH FOUR WHEELS DRIVE Ijariie1405 1 Volume 1 15 Page 61 66Sami Onur VuralNoch keine Bewertungen

- Advanced Four Wheel Steering SystemDokument5 SeitenAdvanced Four Wheel Steering SystemSyedAbuBakar'sAlkaffNoch keine Bewertungen

- Automatic Side StandDokument23 SeitenAutomatic Side StandShekhar Sawant0% (1)

- ESC&AWK Operation&Maintenance ManualDokument21 SeitenESC&AWK Operation&Maintenance ManualWander GomesNoch keine Bewertungen

- Design and Development of Intelligent Braking SystemDokument5 SeitenDesign and Development of Intelligent Braking SystemAnonymous izrFWiQNoch keine Bewertungen

- Introduction To The AutomobileDokument9 SeitenIntroduction To The AutomobileShivamDivyamNoch keine Bewertungen

- Technical Report - Steering (Fall 2007)Dokument26 SeitenTechnical Report - Steering (Fall 2007)Mahmoud El-MahdyNoch keine Bewertungen

- A Comparative Study On Automatic Gear Shift in Motor-CycleDokument7 SeitenA Comparative Study On Automatic Gear Shift in Motor-CycleIJRASETPublicationsNoch keine Bewertungen

- Adaptive Vehicle Skid Control: E. Faruk Kececi, Gang TaoDokument11 SeitenAdaptive Vehicle Skid Control: E. Faruk Kececi, Gang TaoManish KumarNoch keine Bewertungen

- Motion Evaluation of A Wheelchair Prototype For Disabled PeopleDokument7 SeitenMotion Evaluation of A Wheelchair Prototype For Disabled PeopleMofeed MahrousehNoch keine Bewertungen

- .Design of Automatic Motor Bike Stand SliderDokument5 Seiten.Design of Automatic Motor Bike Stand SliderAbhishek SharmaNoch keine Bewertungen

- Optimal Design of A Clutch Plate Using Ansys: V Mani Kiran Tipirineni, P. Punna RaoDokument5 SeitenOptimal Design of A Clutch Plate Using Ansys: V Mani Kiran Tipirineni, P. Punna RaoInternational Journal of computational Engineering research (IJCER)Noch keine Bewertungen

- Synopsis Cms Vehicle: (With Anti Collision and Chassis Free Steering System)Dokument5 SeitenSynopsis Cms Vehicle: (With Anti Collision and Chassis Free Steering System)Pushpendra KumarNoch keine Bewertungen

- Adaptive Headlight SystemDokument14 SeitenAdaptive Headlight SystemprincegirishNoch keine Bewertungen

- System Modelling of Rocker-Bogie Mechanism For Disaster ReliefDokument7 SeitenSystem Modelling of Rocker-Bogie Mechanism For Disaster ReliefGourdhan Singh ShekhawatNoch keine Bewertungen

- Automated Car Jack - PDFDokument3 SeitenAutomated Car Jack - PDFleena175Noch keine Bewertungen

- Four Wheels SteeringDokument19 SeitenFour Wheels SteeringBharathNaikPanjaNoch keine Bewertungen

- Front-and-Rear-Wheel-Independent-Drive-Type Electric Vehicle (FRID EV) With Compatible Driving Performance and SafetyDokument10 SeitenFront-and-Rear-Wheel-Independent-Drive-Type Electric Vehicle (FRID EV) With Compatible Driving Performance and Safetykkumaran32Noch keine Bewertungen

- Irjet V5i3171Dokument3 SeitenIrjet V5i3171Tejzas ParabNoch keine Bewertungen

- Side Stand Retrieving System For Two WheelersDokument31 SeitenSide Stand Retrieving System For Two WheelersAakash DindigulNoch keine Bewertungen

- Modelling and Development of Antilock Braking SystemDokument43 SeitenModelling and Development of Antilock Braking SystemNithin ThriveniNoch keine Bewertungen

- Motorcycle, Solo (Harley-Davidson Model WLA)Von EverandMotorcycle, Solo (Harley-Davidson Model WLA)Noch keine Bewertungen

- PaverDokument29 SeitenPaverJeevan Landge PatilNoch keine Bewertungen

- Reuse of Plastic Waste in Paver BlocksDokument3 SeitenReuse of Plastic Waste in Paver BlocksMehran Amin BattNoch keine Bewertungen

- Speed of Cutting Wheel (N)Dokument3 SeitenSpeed of Cutting Wheel (N)Jeevan Landge PatilNoch keine Bewertungen

- Literature Review On Different Plastic Waste Materials Use in ConcreteDokument4 SeitenLiterature Review On Different Plastic Waste Materials Use in ConcreteAkshay NivaleNoch keine Bewertungen

- Maximum Weight of Single Man 100 KGDokument4 SeitenMaximum Weight of Single Man 100 KGJeevan Landge PatilNoch keine Bewertungen

- E BicycleDokument44 SeitenE BicycleJeevan Landge PatilNoch keine Bewertungen

- ShaftDokument3 SeitenShaftJeevan Landge PatilNoch keine Bewertungen

- ShaftDokument48 SeitenShaftJeevan Landge PatilNoch keine Bewertungen

- Design Calculations:: 5.1 Selection of Material For FrameDokument7 SeitenDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNoch keine Bewertungen

- Box Transport MDokument59 SeitenBox Transport MJeevan Landge PatilNoch keine Bewertungen

- Design Calculations:: 5.1 Selection of Material For FrameDokument7 SeitenDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNoch keine Bewertungen

- (FC) Required. The Study Used A Rotary Shaft Encoder To Measure The Speed of The BladesDokument7 Seiten(FC) Required. The Study Used A Rotary Shaft Encoder To Measure The Speed of The BladesJeevan Landge PatilNoch keine Bewertungen

- Drawing1 PDFDokument1 SeiteDrawing1 PDFJeevan Landge PatilNoch keine Bewertungen

- Drawing 1Dokument7 SeitenDrawing 1Jeevan Landge PatilNoch keine Bewertungen

- Design Calculations:: 5.1 Selection of Material For FrameDokument2 SeitenDesign Calculations:: 5.1 Selection of Material For FrameJeevan Landge PatilNoch keine Bewertungen

- ShaftDokument3 SeitenShaftJeevan Landge PatilNoch keine Bewertungen

- 3 Wheel TractorDokument14 Seiten3 Wheel TractorJeevan Landge Patil100% (1)

- AngleDokument3 SeitenAngleJeevan Landge PatilNoch keine Bewertungen

- ShaftDokument48 SeitenShaftJeevan Landge PatilNoch keine Bewertungen

- Mechatronics Project Consultancy: Payment TermsDokument1 SeiteMechatronics Project Consultancy: Payment TermsJeevan Landge PatilNoch keine Bewertungen

- ShaftDokument3 SeitenShaftJeevan Landge PatilNoch keine Bewertungen

- Rectangular Tapered Hopper VolumeDokument1 SeiteRectangular Tapered Hopper VolumeJeevan Landge PatilNoch keine Bewertungen

- Determining of Your System Specifi Cations and ConditionsDokument1 SeiteDetermining of Your System Specifi Cations and ConditionsJeevan Landge PatilNoch keine Bewertungen

- MouldingDokument5 SeitenMouldingJeevan Landge PatilNoch keine Bewertungen

- Automatic Pneumatic Braking and Bumper SystemDokument46 SeitenAutomatic Pneumatic Braking and Bumper SystemJeevan Landge PatilNoch keine Bewertungen

- Design of Mini Compressorless Solar Powered Refrigerator: Project Report ONDokument36 SeitenDesign of Mini Compressorless Solar Powered Refrigerator: Project Report ONJeevan Landge PatilNoch keine Bewertungen

- MouldingDokument5 SeitenMouldingJeevan Landge PatilNoch keine Bewertungen

- AdsdsasdDokument2 SeitenAdsdsasdJeevan Landge PatilNoch keine Bewertungen

- Quiz - 2 Solution-DP 2019Dokument2 SeitenQuiz - 2 Solution-DP 2019dash spiderNoch keine Bewertungen

- 2016 EIBN Sector Report Gaming IndustryDokument23 Seiten2016 EIBN Sector Report Gaming IndustryUlen IndonesiaNoch keine Bewertungen

- Introduction To CaeDokument44 SeitenIntroduction To Caewadlan0% (1)

- Electrical Equipment Check ListDokument3 SeitenElectrical Equipment Check ListPuran Singh LabanaNoch keine Bewertungen

- Case Study Analysis of Rubco Huat PVT LTDDokument16 SeitenCase Study Analysis of Rubco Huat PVT LTDUma MaheswariNoch keine Bewertungen

- 00040900Dokument30 Seiten00040900asperfudNoch keine Bewertungen

- The 5S's: Five Keys To A Total Quality Environment: by Takashi OsadaDokument5 SeitenThe 5S's: Five Keys To A Total Quality Environment: by Takashi OsadaAvdhut GopewadNoch keine Bewertungen

- HOPE 3 Module 6 Dance EtiquetteDokument18 SeitenHOPE 3 Module 6 Dance EtiquetteFrancine FlorandaNoch keine Bewertungen

- WSN SyllabusDokument2 SeitenWSN SyllabusAnil V. WalkeNoch keine Bewertungen

- Department of Chemical Engineering: Welcomes The New Inductees OF 2021-22 BATCH Under CVM UniversityDokument40 SeitenDepartment of Chemical Engineering: Welcomes The New Inductees OF 2021-22 BATCH Under CVM UniversityYash PatelNoch keine Bewertungen

- Form# Adm Ims FRM 13 009 Rev.00Dokument2 SeitenForm# Adm Ims FRM 13 009 Rev.00yash89799Noch keine Bewertungen

- Chapter 2. Database ConceptsDokument29 SeitenChapter 2. Database ConceptsMikaellacalubayan DelmoNoch keine Bewertungen

- Birring NDE Center FlyerDokument1 SeiteBirring NDE Center FlyerMg MgNoch keine Bewertungen

- Amidon#AMI PDFDokument19 SeitenAmidon#AMI PDFSyaiful AmriNoch keine Bewertungen

- Eye Tracking Literature AnalysisDokument11 SeitenEye Tracking Literature AnalysisSudhanshu DNoch keine Bewertungen

- CH Wiring DiagramDokument2 SeitenCH Wiring DiagramflyingpeteNoch keine Bewertungen

- How To Migrate VMware VMs To Hyper-V in 3 Ways - Vinchin BackupDokument4 SeitenHow To Migrate VMware VMs To Hyper-V in 3 Ways - Vinchin Backupamit_post2000Noch keine Bewertungen

- Third - Year - Information Technology - 2019 - Course - 09.07.2021Dokument114 SeitenThird - Year - Information Technology - 2019 - Course - 09.07.2021Dhiraj GawhaneNoch keine Bewertungen

- Workflow TrainingDokument61 SeitenWorkflow TrainingAmman MajidNoch keine Bewertungen

- Development of A Vision-Based Sorting Laboratoryv2Dokument19 SeitenDevelopment of A Vision-Based Sorting Laboratoryv2Mihail AvramovNoch keine Bewertungen

- BDLO Labsii Fandii Daandii 224 Bara 2012Dokument10 SeitenBDLO Labsii Fandii Daandii 224 Bara 2012Freesun AbbasNoch keine Bewertungen

- Packing List: # Mark Poste Gis 63/15Kv Fidjrosse BeninDokument20 SeitenPacking List: # Mark Poste Gis 63/15Kv Fidjrosse BeninImam TLNoch keine Bewertungen

- At Commands Interface Guide For at X41bDokument461 SeitenAt Commands Interface Guide For at X41bEuuE2008Noch keine Bewertungen

- Auto PIADokument2 SeitenAuto PIATold Told LeungNoch keine Bewertungen

- Quote Generator DocumentDokument47 SeitenQuote Generator DocumentPrajwal KumbarNoch keine Bewertungen

- ITIL Interview QuestionsDokument6 SeitenITIL Interview QuestionsasimNoch keine Bewertungen