Beruflich Dokumente

Kultur Dokumente

Welded Connection

Hochgeladen von

utsav_koshtiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welded Connection

Hochgeladen von

utsav_koshtiCopyright:

Verfügbare Formate

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

DESIGN OF STEEL ELEMENTS

1. Important Design Specifications for Fillet Welding as per IS 800:2007, IS 816:1969

and IS 9595:1996

Size of the weld, s 3mm

When a fillet weld is applied to a square edge of a part or section, s 1.5 mm less than

the edge thickness

When a fillet weld is applied to a rounded toe of a rolled section, s of the thickness

of the section at the toe

The minimum size of the fillet weld should be as given below to avoid cracking in the

absence of preheating

Thickness (t) of thicker part in mm

t 10

10 < t 20

20 < t 32

32 < t 50

t >50

S (mm)

3

5

6

10 (8 mm for first run)

Special precaution like

pre-heating to be taken

Effective throat thickness: 3 mm, 0.7 thickness of thinner part joined; For stress

calculations, effective throat thickness = Ks, where K depends on the angle between the

fusion faces. Usually, the angle is 90 for which K = 1/sqrt(2) = 0.7

Effective length of a fillet weld = (actual length 2s) 4s

Length of end returns should not be less than 2s

In lap connections, the minimum length of weld should not be less than 4 times the

thickness of the thinner part joined or 40mm whichever is more. If only side fillets are

used, the length of the weld on either edge should not be less than the transverse

spacing between the welds.

The throat thickness of the end fillet weld, normal to direction of force, should not be

less than 0.5t where t is thickness of the part

For intermittent fillet welds,

Effective length (wl) 4s or 40 mm, whichever is greater

Clear spacing (uwl) 12t (for compression)

16t (for tension)

200 mm

Where t is the thickness of thinner part joined

Design shear strength of a fillet weld, fwd = fwn/mw

where, fwn = nominal shear strength of fillet weld = fu/(sqrt3)

fu = ultimate strength of the weld or the parent metal

mw = partial safety factor = 1.25 for shop welding,

= 1.5 for site welding

The design procedure for the fillet weld is as follows:

Assume the size of the weld based on the thickness of the members to be joined

By equating the deign strength of the weld to the external factored load, the effective

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

length of the weld to be provided either as longitudinal fillet welds (parallel to load

axis) or as transverse fillet welds (perpendicular to load axis) along with longitudinal

fillet welds. It is a common practice to treat both the welds as if they are stressed

equally. If the length exceeds 150te, reduce design capacity by a factor lw as per

clause 10.5.7.3 of the code

If only the longitudinal fillet weld is provided, a check is made to see if the length of

each longitudinal fillet weld is more than the perpendicular distance between them

End returns of length equal to twice the size of the weld are provided at each end of

the longitudinal fillet weld

When subjected to combined tensile and shear stress, the equivalent stress, fe, should

satisfy,

fe = sqrt(fa2 + 3q2) fu/(sqrt3 mw) .............................................................(1)

where fa is normal stress due to axial force or bending moment, and q is shear stress

due to shear force or tension

2. Important Design Specifications for Bolted Connection as per IS 800:2007

Shear Capacity of a Bolt

The design strength of a bolt in shear Vdsb is given by Vdsb = Vnsb/ mb .....................(2)

Where Vnsb is the nominal shear capacity of a bolt = (fub/sqrt3) (nnAnb + nsAsb).....(3)

Bearing Capacity of a Bolt

The design strength of a bolt in bearing Vdpb is given by Vdpb = Vnpb/ mb .....................(4)

Where Vnpb is the nominal bearing strength of a bolt = 2.5kb dtfu .................................(5)

kb is the smallest of e/3d0, [(p/3d0) 0.25], fub/fu, 1

Tension Capacity of a Plate

The design strength of a plate in tension due to rupture at the net section

Tdn = 0.9 An fu/ m1.....................................................................................................(6)

Design Strength due to Block Shear

The block shear strength Tdb of the bolted connection is the least of

Tdb = (Avg fy/mo sqrt3) + 0.9Atnfu/m1 .................................................................(7)

OR

Tdb = (0.9 Avn fu/m1 sqrt3) + Atg fy/m0 .......................................................................(8)

Tension Capacity of a Bolt

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

The design strength of a bolt in tension Tdb is the least of

(i) the design strength of the bolt due to the yielding of the gross section (i.e. the shank)

Tdbg = fyb Asb/ m0 .............................................................................................(9)

(ii) the design strength of the bolt due to the rupture at the net section (i.e. at the root of

the threads)

Tdbn = 0.9 fub Anb/ mb ....................................................................................(10)

Bolt subjected to Combined Shear and Torsion

A bolt subjected to shear and torsion simultaneously should satisfy the condition

(Vsb/Vdb)2 + (Tb/Tdb)2 1 ..............................................................................(11)

Other Specifications

The diameter of the hole should be the nominal diameter of the bolt plus the

clearance as given below:

Nominal diameter of bolt (mm)

Standard Clearance

12-14

1.0

16-24

2.0

24

3.0

Minimum pitch: the distance between the centres of the bolts in the direction of

stress should not be less than 2.5 times the nominal diameter of the bolt

Maximum pitch:

(i) 32t or 300 mm, whichever is less for the bolts in members including the tacking

bolts,

(ii) 16t or 200 mm, whichever is less for the bolts in tension members

(iii)12t or 200 mm, whichever is less for the bolts in compression members

Where t is the thickness of thinner plate

Edge and End distance

(i) Minimum edge and end distances from the centre of any hole to the nearest edge

of a plate should not be less than 1.7 times the hole diameter for sheared or handflame cut edges; and 1.5 times the hole diameter for rolled, machine-flame cut,

sawn and planned edges

(ii) The maximum edge distance from the centre of hole to the nearest edge should not

exceed 12t, where = sqrt(250/fy) and t is the thickness of the thinner outer plate.

Tacking Bolts

These are the additional bolts provided other than strength consideration. The

maximum pitch of these bolts should be 32t or 300 mm, whichever is less, where t is

the thickness of the thinner plate. If the members are exposed to weather, the pitch

should not exceed 16 times the thickness of the outside plate or 200 mm, whichever is

less.

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

3. Tension Members

The designer has to arrive at the type and size of member, based on tensile force acting on

the member. The type of member is chosen based on the type of the structure and location

of the member. The design is iterative, involving a choice of a trial section and an

analysis of its capacity. The various steps are as follows:

Step-I The net area required An to carry the designed load T is obtained by the equation,

An = Tu/(fu/m1) ...............................................................................................(12)

Step-II From the required net area, the gross area may be computed by increasing the net area

by about 25% to 40%. The required gross area may also be checked against that

required from the yield strength of the gross section as follows:

Ag = Tu/(fu/m0) ..............................................................................................(13)

A suitable trial section may be chosen from steel tables to meet the required gross

area.

Step-III The number of bolts or welding required for the connections is calculated. They are

arranged in a suitable pattern and the net area of the chosen section is calculated. The

design strength of the trial section is evaluated using equations (12) to (15) for plates

and threaded bars and additionally equations (16) to (18) in case of angles.

Tdg = 0.909 fyAg ............................................................................................(14)

where Ag is the gross area of cross-section in mm2, fy is the yield strength of the

material (MPa)

Tdn = 0.72 fuAn ...............................................................................................(15)

where An is the net effective area of cross-section in mm2, fu is the ultimate strength of

the material (MPa)

Plates: The block shear strength Tdb of the connection is taken as the smaller of

Tdb1 = 0.525 Avgfy + 0.72 fuAtn ....................................................................(16)

Tdb2 = 0.416 fuAvn +0.909 fyAtg ....................................................................(17)

where Avg and Avn are the minimum gross and net area in shear along a line of

transmitted force, respectively. Atg and Atn are the minimum gross and net area in

tension from the hole to the toe of the angle or next last row of bolt in plates,

perpendicular to the line of force, respectively and fu and fy are the ultimate and yield

stress of the material (MPa), respectively.

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

Angles: Strength as governed by block shear failure in angle end connection is

calculated using equations (5) and (6). The design strength is governed by

the tearing of the net section is given in cl. 6.3.3 of the code. Substituting the

values of m1 = 1.25 and m0 = 1.1, we get

Tdn = 0.72fuAnc + 0.909 fy Ago .................................................................(18)

and

= 1.4 0.076[(bs/Lc)(w/t)(fy/fu)] 0.88 fy/fu 0.7..................................(19)

where, w and t are the size and thickness of the outstanding leg, respectively, bs is the

shear distance from the edge of the outstanding leg to the nearest line of fasteners,

measured along the centre line of the legs in the cross-section, Lc is the length of the

end connection measured from the centre of the first bolt hole to the centre of the last

bolt hole in the end connection or length of the weld along load direction and, Anc is

the net area of connected leg at the critical cross-section, computed after deducting the

diameter of hole (the diameter of the holes should be taken as 2-mm larger than the

nominal size in case of punched holes), and Ago is the gross area of the outstanding

leg. Alternatively, the equation suggested by code, for preliminary design, with the

partial safety factor for material m1 = 1.25, we get

Tdn = 0.8A fu................................... ............................................................(20)

with = 0.6 for one or two bolts, 0.7 for three bolts, and 0.8 for four or more bolts in

end connections or equivalent weld length.

Step-IV If the design strength is either small or too large compared to the design force, a new

trial section is chosen and step-III.

Step-V The slenderness ratio of the member is checked as per Table 3 of code.

4. Compression Members

The strength of a compression member is based on its gross area Ag (for slender crosssection, Aeff should be used). The strength is always a function of the effective slenderness

ratio KL/r, and for short columns the yield stress fy of the steel. Since the radius of

gyration r depends on the section selected, the design of compression members is an

iterative process. The design procedure involves the following steps.

Step-I: The axial force in the member is determined by a rationale frame analysis, or by

statics for statically determinate structures. The factored load Pu is determined by

summing up the specified loads multiplied by the appropriate partial load factors f.

Step-II: Select a trial section. Note that the width/thickness limitations as given in Table 2 of

code to prevent local buckling must be satisfied (most of the rolled section satisfy the

width-to-thickness ratios specified in Table 2). If it is not satisfied and a slender section is

chosen, the reduced effective area Aeff should be used in the calculation. The trial section

may be chosen by making initial guesses for Aeff/A, and fcd (between 0.4-0.6fy) and

calculating the target area A. Following member sizes may be used as a trial section:

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

(a) Single angle size 1/30 of the length of compression member

(b) Double angle size 1/35 of the length of compression member

(c) Circular hollow section diameter = 1/40 of length

The slenderness ratios as given in the Table 1 will help the designer to choose the trial

sections.

Table 1 Slenderness ratios to be assumed while selecting the trial sections

Type of Member

Single angles

CHS, SHS, RHS

Single channels

Double angles

Double channels

Single I-section

Double I-section

Slenderness ratio(L/r)

100-150

90-110

90-150

80-120

40-80

80-150

30-60

Step-III: Compute KL/r for the section selected. The computed value of KL/r should be

within the maximum limiting value given in Table 2. Using Fig 8 and Tables 9 and 10 of

code, compute fcd and the design strength Pd = Afcd.

Table 2 Maximum Slenderness ratio of compression members

Type of Member

KL/r

Carrying loads resulting from dead loads and superimposed loads

180

Carrying loads resulting from wind and seismic loads only, provided 250

the deformation of such a member does not adversely affect the stress

in any part of the structure

Normally acting as a tie in a roof truss or a bracing system but subject 350

to possible reversal of stress resulting from the action of wind or

seismic forces

Lacing bars in columns

145

Elements (components) in built-up sections

50

Step-IV: Compare Pd with Pu. When the strength provided does not exceed the strength

required by more than a few percentages, the design would be acceptable: otherwise

repeat steps 2 through 4.

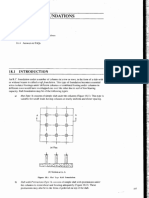

5. Beams

5.1 Laterally Supported Beams

The design of laterally supported beams consists of selecting a section on the basis of the

modulus of section and checking it for shear, deflection, and web crippling. The steps to

be followed are a follows:

Step-I: The loads that may be acting on the beam are ascertained. The design loads are

obtained by summing up the loads multiplied by the appropriate partial load factors as

given in Table 4 of the code.

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

Step-II: A trial beam section is assumed and the distribution of the bending moment along the

length of the beam is determined by an elastic analysis (if the beam is statically

indeterminate) or by statics (if the beam is statically determinate). The maximum

bending moment and shear force are calculated.

Step-III: The required section modulus may be determined by

Md = 0.909bZpfy 1.09Zefy 1.36 Zefy (for cantilever), when V < Vd .... (21)

Md is design bending strength, V is design shear force, Vd is the design shear strength,

b is 1 for plastic and semi-compact sections and b is Ze/Zp, for semi-compact

sections

Md = 0.909Zefy for class 3 semi-compact sections .......................................(22)

Md = Zefy for class 4 slender sections ..........................................................(23)

Zp and Ze are the plastic and elastic section moduli of the cross-section, respectively.,

and fy is the yield stress of the material.

Step-IV: Select a suitable section from steel table, which has a section modulus equal to or

more than the calculated section modulus.

Step-V: Evaluate whether the selected section falls in the category of compact, semi-compact

or plastic section. Check the adequacy of the selected section including self weight of the

beam to satisfy for required plastic section modulus

Step-VI: The selected beam is to be checked for shear. Calculate the factored design shear

force V. The V in a beam due to external actions should satisfy,

V Vd .........................................................................................................(24)

Where Vd, the design strength is given by

Vd = 0.909 Vn ...............................................................................................(25)

Vn is nominal shear strength of a cross-section and may be governed by plastic shear

resistance or the strength of the web governed by shear buckling.

Step-VII: The design capacity of the member is to be evaluated and should be more than the

maximum bending moment calculated.

Step-VIII: The beam is checked for deflection, as per Table 6 of the code. Actual deflection

should be less than allowable maximum deflection.

Step-IX: The beam is checked for web buckling. Strength of the section against web buckling

Fwb should be more than the calculated shear force.

Prof Urmil V Dave

Institute of Technology, Nirma University

2CL405 Design of StructuresIII

B. Tech. Civil Semester VII

Fwb = (b1 + n1) tfc ..........................................................................................(26)

Where, b1 is the stiff bearing length, n1 is the dispersion of 45 line at the mid depth of

the section, t is the web thickness and fc is the allowable compressive stress

corresponding to the assumed web strut. The effective length of the strut is taken as LE

as 0.7d, where d is the depth of the strut in between the flanges. The slenderness ratio

of the idealized strut is 2.5d/t.

Step-X: The beam is checked for web crippling/ web bearing. Strength of the section against

web buckling Fcrip should be more than the calculated shear force. The crippling strength

of the web (also called as the web bearing capacity) at supports is calculated as

Fcrip = (b1 + n2) tfyw ......................................................................................(27)

Where, n2 is the length obtained by dispersion through the flange, to the flange to web

connection (web toes of fillets), at a slope of 1:2.5 to the plane of flange (i.e. n2 = 2.5d1).

fyw is the design yield strength of the web. At an interior panel where concentrated load is

acting, the crippling strength is given by,

Fcrip = (b1 + 2n1) tfyw.......................................................................................(28)

If the above bearing capacity or crippling strength of the beam web is exceeded,

stiffeners must be provided to carry the load.

5.2 Laterally Unsupported Beams

When the compression flange of the beam is laterally unsupported, lateral torsional

buckling may take place, leading to failure at or below the elastic critical moment. The

design of laterally unsupported beams with equal flanges (e.g., I-sections and channel

sections) or mono symmetric beams is essentially a trial and error process, since the

section dimensions are not initially known. Hence, we have to assume a section in order

to compute the strength of that section. The design procedure is essentially the same as

described for a laterally supported section, except that in Step-III, the design strength Md

is computed based on provisions given in section 8.2.2 as well as E1.2 of the code for

mono symmetric section and compared with the factored design moment M. If it is not

equal to or greater than the factored design moment, next higher section is chosen and

the process is repeated till a section which satisfies the condition M Md is found.

Prof Urmil V Dave

Institute of Technology, Nirma University

Das könnte Ihnen auch gefallen

- Discrete Element Method to Model 3D Continuous MaterialsVon EverandDiscrete Element Method to Model 3D Continuous MaterialsNoch keine Bewertungen

- Axle Design For Trolley CartDokument2 SeitenAxle Design For Trolley CartHailemariam WeldegebralNoch keine Bewertungen

- Isolated Footing UniaxialDokument8 SeitenIsolated Footing Uniaxialrvshankar143Noch keine Bewertungen

- Project by Location: Girting Design ADokument10 SeitenProject by Location: Girting Design AJurie_sk3608Noch keine Bewertungen

- 498 Plate Girder CombinedDokument1 Seite498 Plate Girder CombinedYash DhabaliaNoch keine Bewertungen

- Zee Purlin Design Sheet AnalysisDokument4 SeitenZee Purlin Design Sheet AnalysisShawkat Ali KhanNoch keine Bewertungen

- Design Gusset Plate JointsDokument59 SeitenDesign Gusset Plate JointsVaibhav SharmaNoch keine Bewertungen

- 220kv - NMC - Type Tower-CorrectedDokument19 Seiten220kv - NMC - Type Tower-Correctedpavan3961Noch keine Bewertungen

- Here: Mat Foundation Design Spreadsheet PDFDokument2 SeitenHere: Mat Foundation Design Spreadsheet PDFbiniamNoch keine Bewertungen

- Is800-2007 Appendix PDFDokument85 SeitenIs800-2007 Appendix PDFDebasish MondalNoch keine Bewertungen

- StruCad Evolution Getting Started TutorialDokument41 SeitenStruCad Evolution Getting Started Tutorialnifty25Noch keine Bewertungen

- Beam Column Web ConnectionsDokument9 SeitenBeam Column Web Connectionsmsiddiq1Noch keine Bewertungen

- JassimDokument29 SeitenJassimZain Communication0% (1)

- Duct Design With StiffenersDokument67 SeitenDuct Design With StiffenersRico CaraNoch keine Bewertungen

- Design of Face Mounted BracketDokument4 SeitenDesign of Face Mounted Bracketvishal tomarNoch keine Bewertungen

- 3 5mDokument8 Seiten3 5mSanjay sharmaNoch keine Bewertungen

- Shear Lug Verification Example 2Dokument1 SeiteShear Lug Verification Example 2Nasrul AdliNoch keine Bewertungen

- Metal Sheet Calculations for 44-195 ProfileDokument29 SeitenMetal Sheet Calculations for 44-195 ProfileAnonymous HkX2aE9FxNoch keine Bewertungen

- EC3 Steel Design ParametersDokument16 SeitenEC3 Steel Design ParametersBirendra2706Noch keine Bewertungen

- R.C.C DesignDokument14 SeitenR.C.C DesignVinayan PuthukadNoch keine Bewertungen

- Mechanical Columns Buckling FailureDokument19 SeitenMechanical Columns Buckling FailurePraful Patil100% (1)

- Fdocuments - in Insert Plate Design LugsDokument8 SeitenFdocuments - in Insert Plate Design Lugsarchetype designNoch keine Bewertungen

- Insert Plate DesignDokument8 SeitenInsert Plate DesignPiyushNoch keine Bewertungen

- 8224 Grating No HeaderDokument69 Seiten8224 Grating No HeadervishalnalwarNoch keine Bewertungen

- Dimensional Solutions Mat3DDokument69 SeitenDimensional Solutions Mat3DTimothy HancockNoch keine Bewertungen

- 11stiffened Seat ConnectionDokument5 Seiten11stiffened Seat ConnectionAjit SinghNoch keine Bewertungen

- Thrust 2 eDokument6 SeitenThrust 2 eWaheed AhmadNoch keine Bewertungen

- Design of Ring Girder SupportDokument3 SeitenDesign of Ring Girder Supportvishal guptaNoch keine Bewertungen

- Anchor Bolt Design for 26 kip Axial LoadDokument34 SeitenAnchor Bolt Design for 26 kip Axial LoadPioneer Design and Development LimitedNoch keine Bewertungen

- My 2 Way Slab ExcelDokument18 SeitenMy 2 Way Slab ExcelURVESHKUMAR PATELNoch keine Bewertungen

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Dokument49 SeitenSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgNoch keine Bewertungen

- Base Plate Design (Pin) Asd For CompressionDokument54 SeitenBase Plate Design (Pin) Asd For CompressionEmdadul HuqNoch keine Bewertungen

- Anchor Bolt Design Example As Per Indian Code - Google SearchDokument2 SeitenAnchor Bolt Design Example As Per Indian Code - Google Searchjebin_87Noch keine Bewertungen

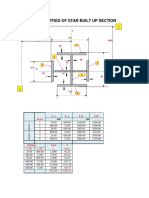

- Properties of Star Built Up Section: X-Dir y - Dir A KG/MDokument3 SeitenProperties of Star Built Up Section: X-Dir y - Dir A KG/Mdsananda100% (1)

- Column Properties:-: Due To UplitDokument2 SeitenColumn Properties:-: Due To UplitRohit SinghNoch keine Bewertungen

- Analysis & design of annular raft foundation under 1250 cum OHRDokument1 SeiteAnalysis & design of annular raft foundation under 1250 cum OHRanirban dasNoch keine Bewertungen

- CC RoadDokument3 SeitenCC RoadRupam ChoudhuriNoch keine Bewertungen

- Wind Load IS875Dokument30 SeitenWind Load IS875Pranjal Pareek100% (2)

- Beam Columns Example - Is 800Dokument7 SeitenBeam Columns Example - Is 800anil97232Noch keine Bewertungen

- Embedded PlateDokument2 SeitenEmbedded PlateAlma M. LaraNoch keine Bewertungen

- Skylight StructureDokument16 SeitenSkylight Structuremsiddiq1Noch keine Bewertungen

- Design of Rectangular Footing Col Edge 3Dokument28 SeitenDesign of Rectangular Footing Col Edge 3Shaikh Muhammad AteeqNoch keine Bewertungen

- Eccentric FootingDokument13 SeitenEccentric FootingMegatech Engineering Consultants100% (1)

- Moment ConnectionDokument5 SeitenMoment ConnectionjanethNoch keine Bewertungen

- Roof purlin design and stress analysisDokument1 SeiteRoof purlin design and stress analysis_jessecaNoch keine Bewertungen

- Pile Cap DimensionsDokument13 SeitenPile Cap DimensionsEr Navneet JassiNoch keine Bewertungen

- Base Plate DesignDokument4 SeitenBase Plate DesignPradeep Kumar RajNoch keine Bewertungen

- Staircase Design: 8.28kN/m 15.57kN/mDokument3 SeitenStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNoch keine Bewertungen

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDokument6 SeitenStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNoch keine Bewertungen

- IS 800-2007 Provisions SummaryDokument30 SeitenIS 800-2007 Provisions SummarySachin MeenaNoch keine Bewertungen

- Equal angle steel profiles data sheetDokument2 SeitenEqual angle steel profiles data sheetGalih PutraNoch keine Bewertungen

- AISC LRFD Column DesignDokument4 SeitenAISC LRFD Column Designwinlugue3059Noch keine Bewertungen

- RC Raft Foundation DesignDokument19 SeitenRC Raft Foundation Designvijaycool889Noch keine Bewertungen

- Beam AnalDokument7 SeitenBeam Analgercho23Noch keine Bewertungen

- Ce (PC) 604Dokument14 SeitenCe (PC) 604jyotirmaynath4444Noch keine Bewertungen

- Design OfSteel Structures-IDokument50 SeitenDesign OfSteel Structures-IBhagyshri SiddheNoch keine Bewertungen

- Eccentric ConnecctionsDokument41 SeitenEccentric ConnecctionsShyam Suryawanshi100% (1)

- (Products Data) Calculation of Punch Strength - Misumi, The Catalog Press Die ComponentsDokument5 Seiten(Products Data) Calculation of Punch Strength - Misumi, The Catalog Press Die Componentsmonu991Noch keine Bewertungen

- Comparision Between WPB 160x30.44kg (300 Mpa) and SC 152x37Dokument1 SeiteComparision Between WPB 160x30.44kg (300 Mpa) and SC 152x37renu.messagesNoch keine Bewertungen

- Slide Share Design of Tension MembersDokument19 SeitenSlide Share Design of Tension MembersMina W. SayedNoch keine Bewertungen

- Gou 2016-Robust Hybrid Simulation With PDFDokument326 SeitenGou 2016-Robust Hybrid Simulation With PDFutsav_koshtiNoch keine Bewertungen

- 10.1007@978 94 024 0867 6 PDFDokument735 Seiten10.1007@978 94 024 0867 6 PDFutsav_koshtiNoch keine Bewertungen

- Research ArticleDokument6 SeitenResearch Articleutsav_koshtiNoch keine Bewertungen

- Modal Analysis For Random Vibration of Hysteretic FramesDokument19 SeitenModal Analysis For Random Vibration of Hysteretic Framesutsav_koshtiNoch keine Bewertungen

- Research Article: Seismic Performance Evaluation of Building-Damper System Under Near-Fault EarthquakeDokument21 SeitenResearch Article: Seismic Performance Evaluation of Building-Damper System Under Near-Fault Earthquakeutsav_koshtiNoch keine Bewertungen

- Chapter 05 - Least Squares PDFDokument27 SeitenChapter 05 - Least Squares PDFadlantama prihadiNoch keine Bewertungen

- A New Approach in Fatigue Testing and Evaluation of Hot Mix Asphalt Using A Dynamic Shear RheometerDokument10 SeitenA New Approach in Fatigue Testing and Evaluation of Hot Mix Asphalt Using A Dynamic Shear Rheometerutsav_koshtiNoch keine Bewertungen

- Conv Gaetanomiraglia Xxxi Assembled PHD Thesis v2 PDFDokument214 SeitenConv Gaetanomiraglia Xxxi Assembled PHD Thesis v2 PDFutsav_koshtiNoch keine Bewertungen

- Experimental and Numerical Analysis of MR Dampers: Manuel T. Braz-César, Rui C. BarrosDokument19 SeitenExperimental and Numerical Analysis of MR Dampers: Manuel T. Braz-César, Rui C. Barrosutsav_koshtiNoch keine Bewertungen

- Parameter Estimation of Bouc-Wen Hysteretic Systems by Sawtooth Genetic AlgorithmDokument18 SeitenParameter Estimation of Bouc-Wen Hysteretic Systems by Sawtooth Genetic Algorithmutsav_koshtiNoch keine Bewertungen

- Modeling and Random Vibration Analysis of Sdof Systems With Asymmetric HysteresisDokument12 SeitenModeling and Random Vibration Analysis of Sdof Systems With Asymmetric Hysteresisutsav_koshtiNoch keine Bewertungen

- V. Nonlinear Regression by Modified Gauss-Newton Method: TheoryDokument39 SeitenV. Nonlinear Regression by Modified Gauss-Newton Method: Theoryutsav_koshtiNoch keine Bewertungen

- Method Nonlinear Least-SquaresDokument30 SeitenMethod Nonlinear Least-SquaresIzul MkNoch keine Bewertungen

- Master Class Solving Optimization Problems With MatlabDokument110 SeitenMaster Class Solving Optimization Problems With Matlabutsav_koshtiNoch keine Bewertungen

- SeismoStruct 2021 User Manual - ENG PDFDokument562 SeitenSeismoStruct 2021 User Manual - ENG PDFutsav_koshtiNoch keine Bewertungen

- Numerical Study of A Hybrid Damping System Composed of A Buckling Restrained Brace With A Magneto Rheological DamperDokument8 SeitenNumerical Study of A Hybrid Damping System Composed of A Buckling Restrained Brace With A Magneto Rheological Damperutsav_koshtiNoch keine Bewertungen

- Numerical Study of A Hybrid Damping System Composed of A Buckling Restrained Brace With A Magneto Rheological DamperDokument8 SeitenNumerical Study of A Hybrid Damping System Composed of A Buckling Restrained Brace With A Magneto Rheological Damperutsav_koshtiNoch keine Bewertungen

- SeismoStruct 2021 User Manual - ENG PDFDokument562 SeitenSeismoStruct 2021 User Manual - ENG PDFutsav_koshtiNoch keine Bewertungen

- DssDokument98 SeitenDssnaveenpnaidu1100% (1)

- Enhancing An Upper Division Structural Dynamics Course Using KneDokument16 SeitenEnhancing An Upper Division Structural Dynamics Course Using Kneutsav_koshtiNoch keine Bewertungen

- RCC - Civil Engineering Objective QuestionsDokument9 SeitenRCC - Civil Engineering Objective Questionsutsav_koshtiNoch keine Bewertungen

- Development of Small Scale Models For K 12 and Undergraduate Students To Demonstrate Earthquake Effects On Building Structures and Aseismic Design ProceduresDokument23 SeitenDevelopment of Small Scale Models For K 12 and Undergraduate Students To Demonstrate Earthquake Effects On Building Structures and Aseismic Design Proceduresutsav_koshtiNoch keine Bewertungen

- 1 Matlab IntroDokument21 Seiten1 Matlab IntroankursonicivilNoch keine Bewertungen

- Deep Foundations Definitions and TypesDokument51 SeitenDeep Foundations Definitions and TypesMohammed HazemNoch keine Bewertungen

- Bili Near HysteresisDokument5 SeitenBili Near HysteresisMauricio_Vera_5259Noch keine Bewertungen

- Appendix D PDFDokument16 SeitenAppendix D PDFFloren Ardila AlvaradoNoch keine Bewertungen

- Objective Civil EngineeringDokument59 SeitenObjective Civil Engineeringutsav_koshtiNoch keine Bewertungen

- Master Thesis MAS500 MR Damper Hysteresis Characterization For The Semi-Active Suspension SystemDokument65 SeitenMaster Thesis MAS500 MR Damper Hysteresis Characterization For The Semi-Active Suspension Systemutsav_koshtiNoch keine Bewertungen

- MATLAB Programming For Numerical ComputationsDokument12 SeitenMATLAB Programming For Numerical Computationstsram90Noch keine Bewertungen

- Nlls SlidesDokument22 SeitenNlls Slidesutsav_koshtiNoch keine Bewertungen

- Biomechanics of Advanced Tennis: January 2003Dokument7 SeitenBiomechanics of Advanced Tennis: January 2003Katrien BalNoch keine Bewertungen

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Dokument28 SeitenMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palNoch keine Bewertungen

- CHEM206 Answers 1Dokument3 SeitenCHEM206 Answers 1Shiro UchihaNoch keine Bewertungen

- HU675FE ManualDokument44 SeitenHU675FE ManualMar VeroNoch keine Bewertungen

- My16-Td My16-AtDokument6 SeitenMy16-Td My16-AtRodrigo ChavesNoch keine Bewertungen

- Mechanical Questions & AnswersDokument161 SeitenMechanical Questions & AnswersTobaNoch keine Bewertungen

- Brooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFDokument36 SeitenBrooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFlois.guzman538100% (12)

- DAT MAPEH 6 Final PDFDokument4 SeitenDAT MAPEH 6 Final PDFMARLYN GAY EPANNoch keine Bewertungen

- Basic Calculus: Performance TaskDokument6 SeitenBasic Calculus: Performance TasksammyNoch keine Bewertungen

- Digital Citizenship Initiative To Better Support The 21 Century Needs of StudentsDokument3 SeitenDigital Citizenship Initiative To Better Support The 21 Century Needs of StudentsElewanya UnoguNoch keine Bewertungen

- The Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsDokument10 SeitenThe Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsLanta KhairunisaNoch keine Bewertungen

- Summer Internship Project-NishantDokument80 SeitenSummer Internship Project-Nishantnishant singhNoch keine Bewertungen

- Pfrs 16 LeasesDokument4 SeitenPfrs 16 LeasesR.A.Noch keine Bewertungen

- Reaction rate determination and simulation of hydrogenation processDokument3 SeitenReaction rate determination and simulation of hydrogenation processToMemNoch keine Bewertungen

- Write 10 Lines On My Favourite Subject EnglishDokument1 SeiteWrite 10 Lines On My Favourite Subject EnglishIrene ThebestNoch keine Bewertungen

- Eudragit ReviewDokument16 SeitenEudragit ReviewlichenresearchNoch keine Bewertungen

- EMECH 2 MarksDokument18 SeitenEMECH 2 MarkspavanraneNoch keine Bewertungen

- Compare and Contrast High School and College EssayDokument6 SeitenCompare and Contrast High School and College Essayafibkyielxfbab100% (1)

- Jesus - The Creator Unleashes Our Creative PotentialDokument1 SeiteJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongNoch keine Bewertungen

- AJK Newslet-1Dokument28 SeitenAJK Newslet-1Syed Raza Ali RazaNoch keine Bewertungen

- Mama Leone's Profitability AnalysisDokument6 SeitenMama Leone's Profitability AnalysisLuc TranNoch keine Bewertungen

- Legal Research MethodsDokument10 SeitenLegal Research MethodsCol Amit KumarNoch keine Bewertungen

- Ilham Bahasa InggrisDokument12 SeitenIlham Bahasa Inggrisilhamwicaksono835Noch keine Bewertungen

- EG-45-105 Material Information Sheet (Textura) V2Dokument4 SeitenEG-45-105 Material Information Sheet (Textura) V2GPRNoch keine Bewertungen

- HP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityDokument65 SeitenHP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityAlexandru BotnariNoch keine Bewertungen

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Dokument11 SeitenJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- JR Hydraulic Eng. Waterways Bed Protection Incomat BelfastDokument2 SeitenJR Hydraulic Eng. Waterways Bed Protection Incomat Belfastpablopadawan1Noch keine Bewertungen

- Hotel and Restaurant at Blue Nile FallsDokument26 SeitenHotel and Restaurant at Blue Nile Fallsbig johnNoch keine Bewertungen

- January 2013 Igcse Timetable 22-06-2012Dokument2 SeitenJanuary 2013 Igcse Timetable 22-06-2012Rizwanur RahmanNoch keine Bewertungen

- April 3rd - Asynchronous Class - Questions-4Dokument3 SeitenApril 3rd - Asynchronous Class - Questions-4alidrissiNoch keine Bewertungen